Quality control processes verify that manufactured products meet their intended specifications without requiring additional modifications. Strong quality management systems lead to improved customer satisfaction levels. By implementing quality checks at various stages during manufacturing, companies can pinpoint exactly where issues occur and implement appropriate corrective measures. The specific quality assurance methods employed vary based on the particular industry and its requirements.

In the manufacturing industry, maintaining product quality is essential. To guarantee that a product meets the required standards and is free from defects, it typically undergoes several quality checks. Odoo’s Quality module supports this process by enabling you to perform and manage quality inspections at various stages of production.

Odoo Quality can be used to monitor product quality at key stages, such as during picking, before adding items to inventory, and before shipping. Manufacturers can automate these checks by setting up quality control points that trigger inspections at defined steps in the production workflow.

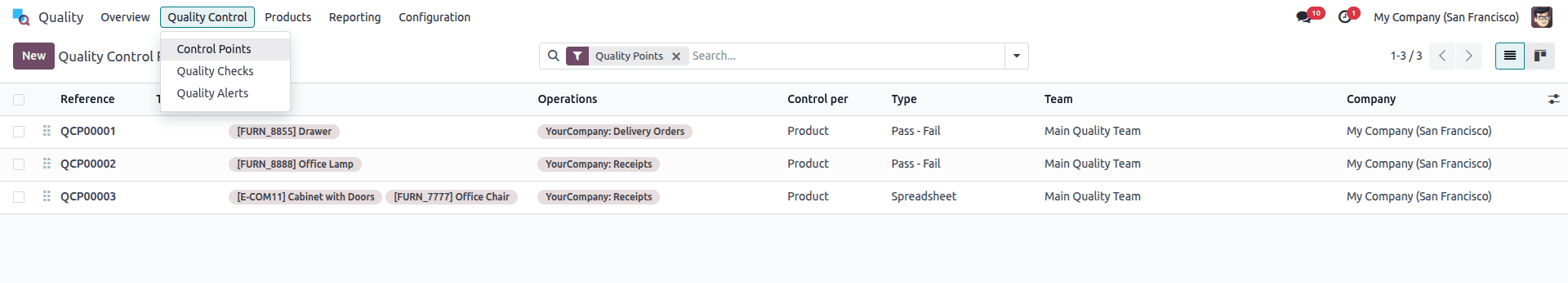

To carry out quality analysis in Odoo across different transfer operations, start by accessing the Quality module. From there, you can create a new quality control option, as shown in the steps below.

Open the Quality module and click on Quality Control. From there, create a new quality control point as shown in the example above.

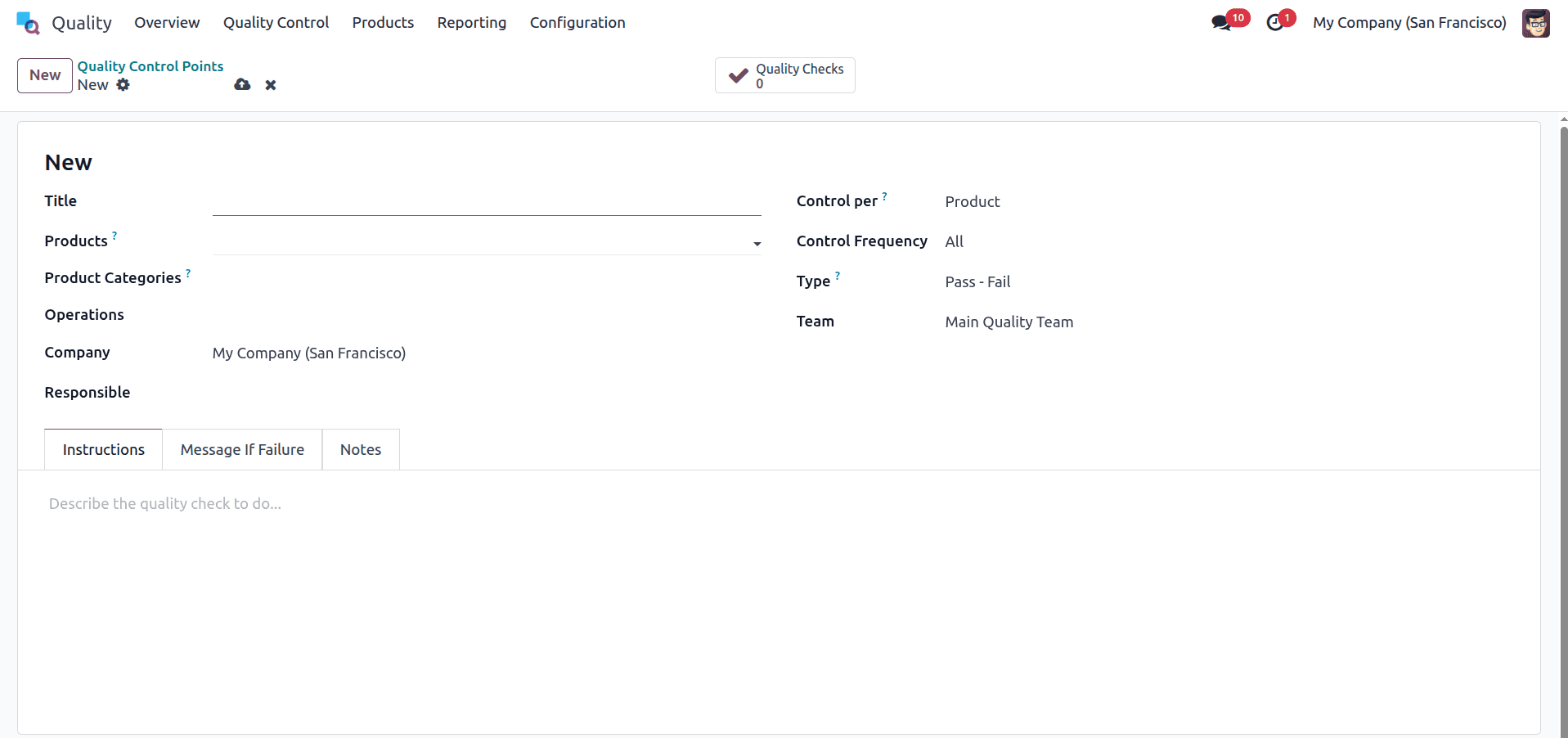

The quality control form includes fields that help users clearly define each control point. The Title allows for a descriptive name that is easily understood by production and quality assurance teams. In the Products field, users can specify the relevant product(s) or product category to which the control point applies. Additionally, users can assign the quality check to specific operations such as manufacturing, receipts, or delivery orders.

The Company field specifies which organization will carry out the quality control point, typically, this is the company that owns the Odoo database. The Control Type dropdown allows you to define the frequency of checks: it can be set to trigger during all operations, at random, or at regular intervals. Under the Type field, users can choose the nature of the check, such as providing instructions, taking a photo, or performing a pass/fail evaluation. You can also assign a responsible person to oversee the inspection and select the quality team in charge of reviewing the outcomes.

At the bottom of the form, you’ll find several tabs designed to provide additional guidance to the quality team. The Instructions tab outlines the steps required to perform the quality check. The If Failure tab details the actions to take if the item does not pass inspection. For any extra details or remarks, you can use the Notes section.

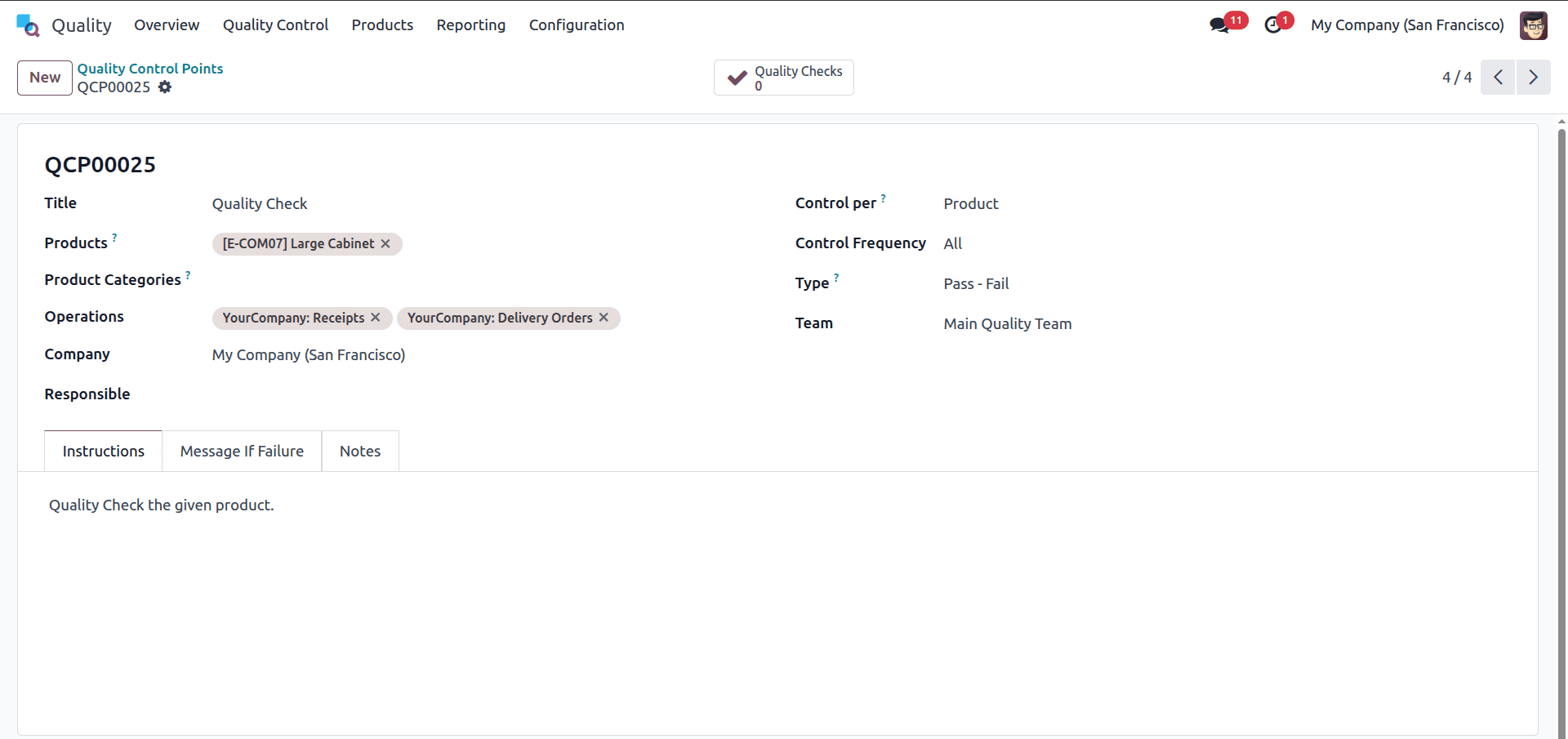

Once a quality control point is set up, a quality check is automatically triggered when the related operation or work order is completed. To demonstrate this, let’s create a new quality control point for the Large Cabinet product, assigning Delivery and Return as the operation types, as shown below.

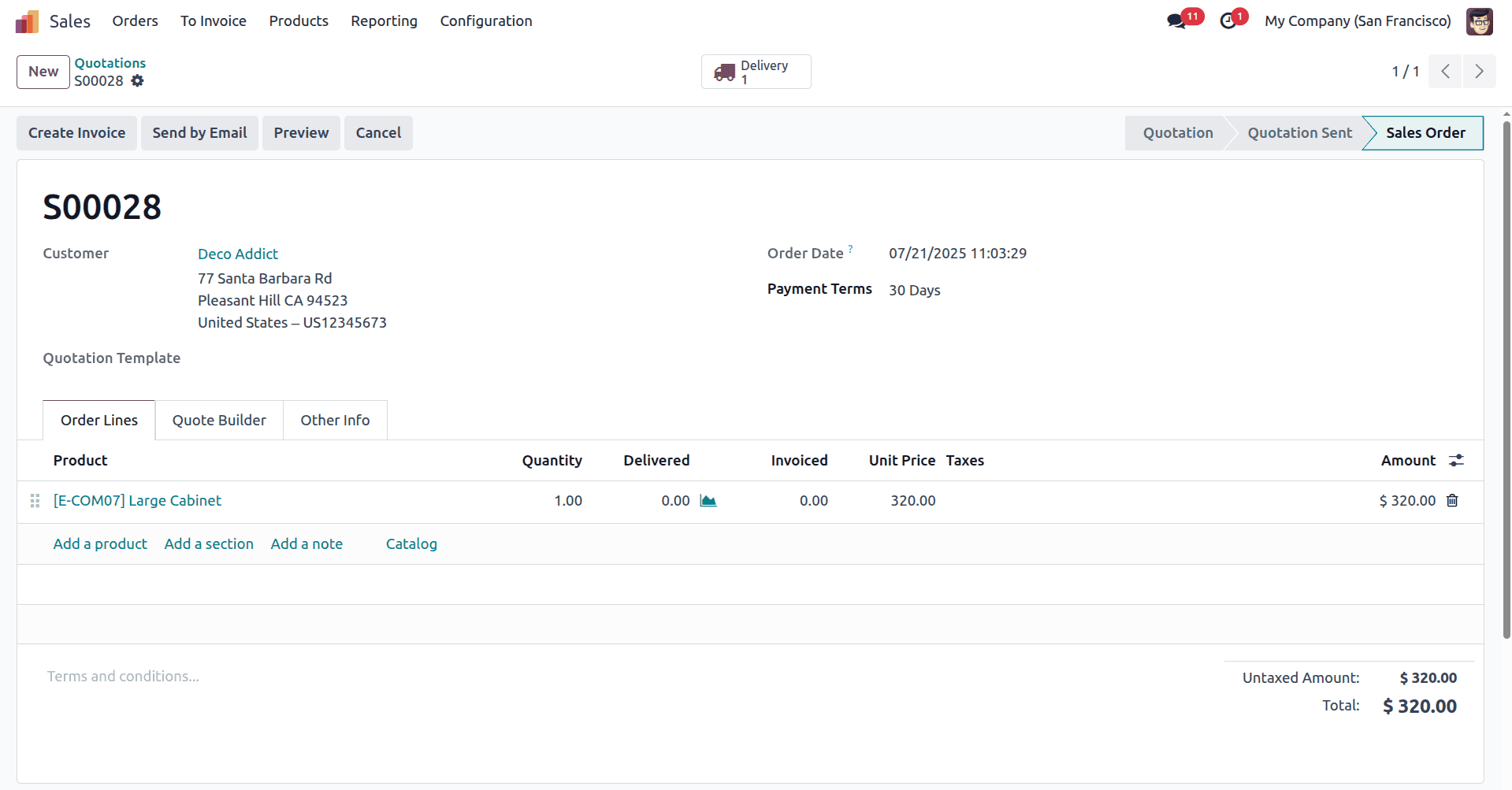

Next, let’s take a look at how quality analysis is performed during an operation. To begin, create a sales order for the Large Cabinet product and confirm it, as shown below.

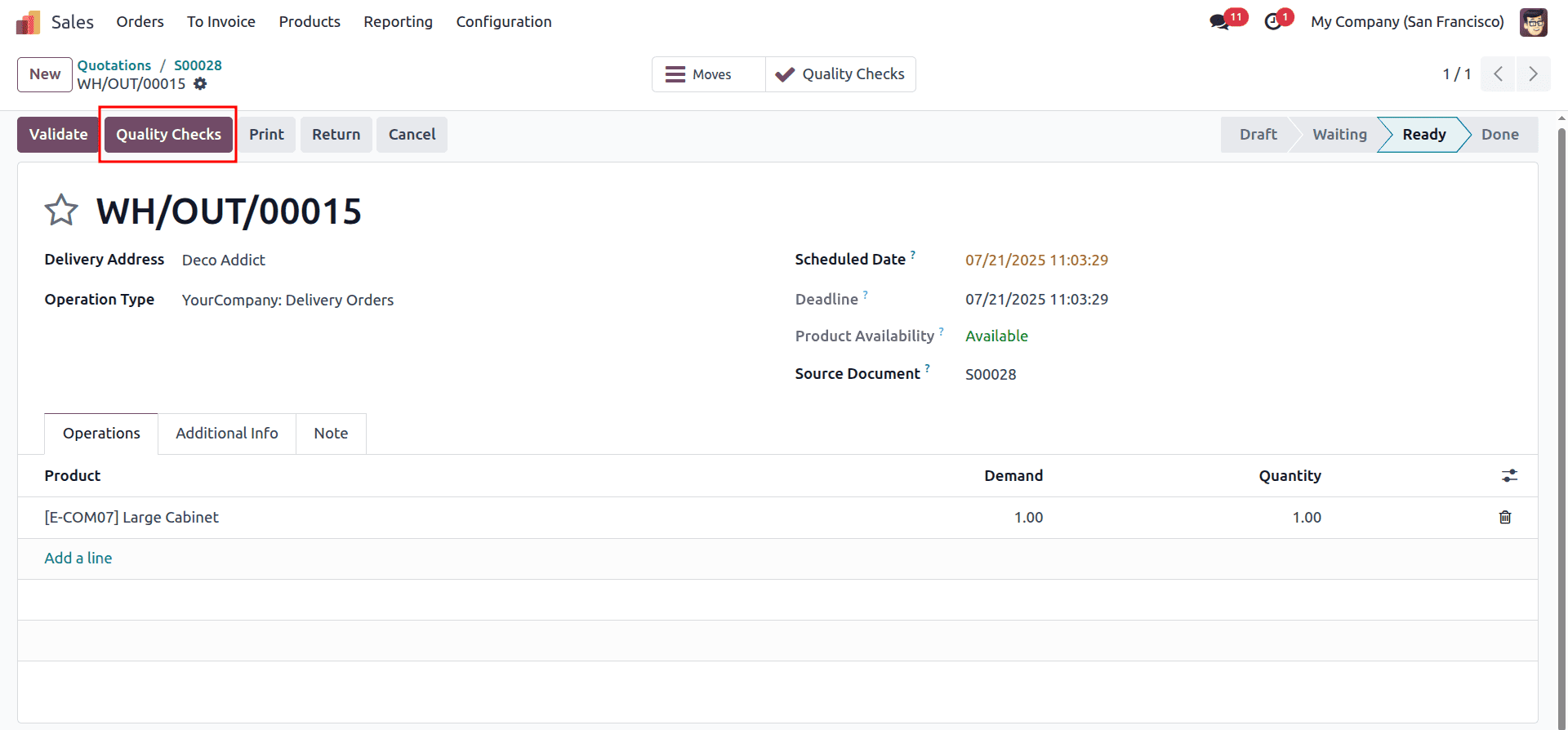

During the delivery validation process, a Quality Check button appears, as shown below. This option allows the user to perform a final inspection of the product before it is shipped to the customer.

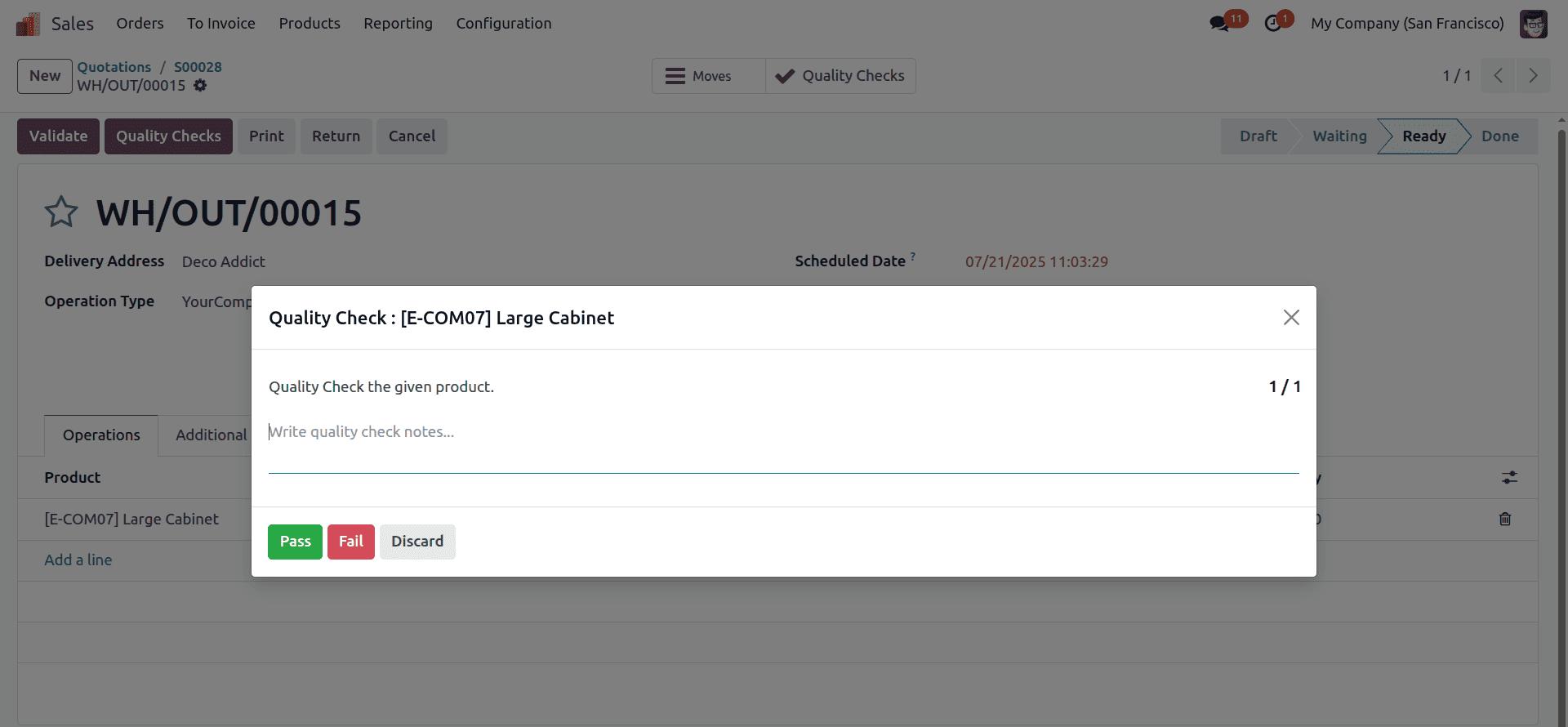

By clicking the Quality Check button, a pop-up window appears, allowing the user to carry out the inspection and add any relevant notes, as shown below.

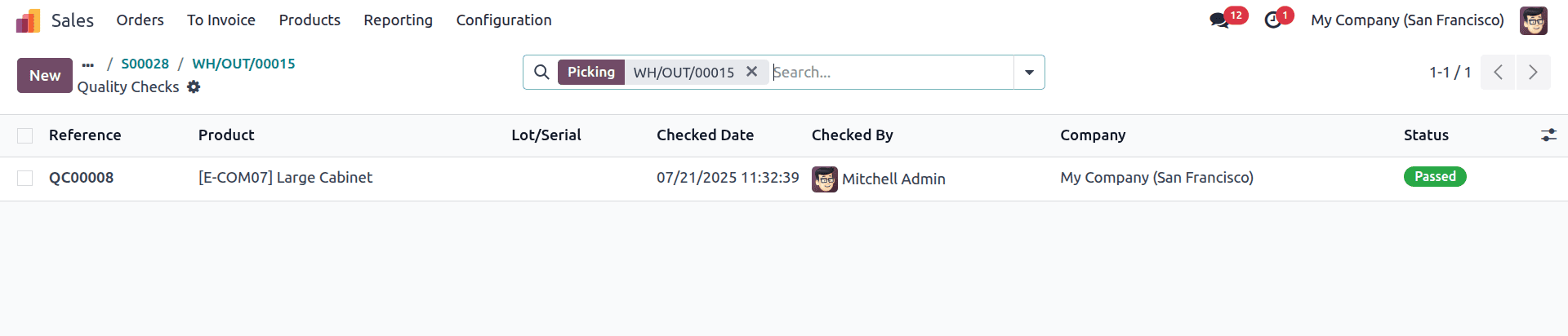

After performing the quality check and marking it as complete, the user can click the Quality Check button on the delivery form to review all related details, as shown below.

Similarly, to verify whether the quality check option is available during a return, let’s initiate a return for the same sales order, as shown below.

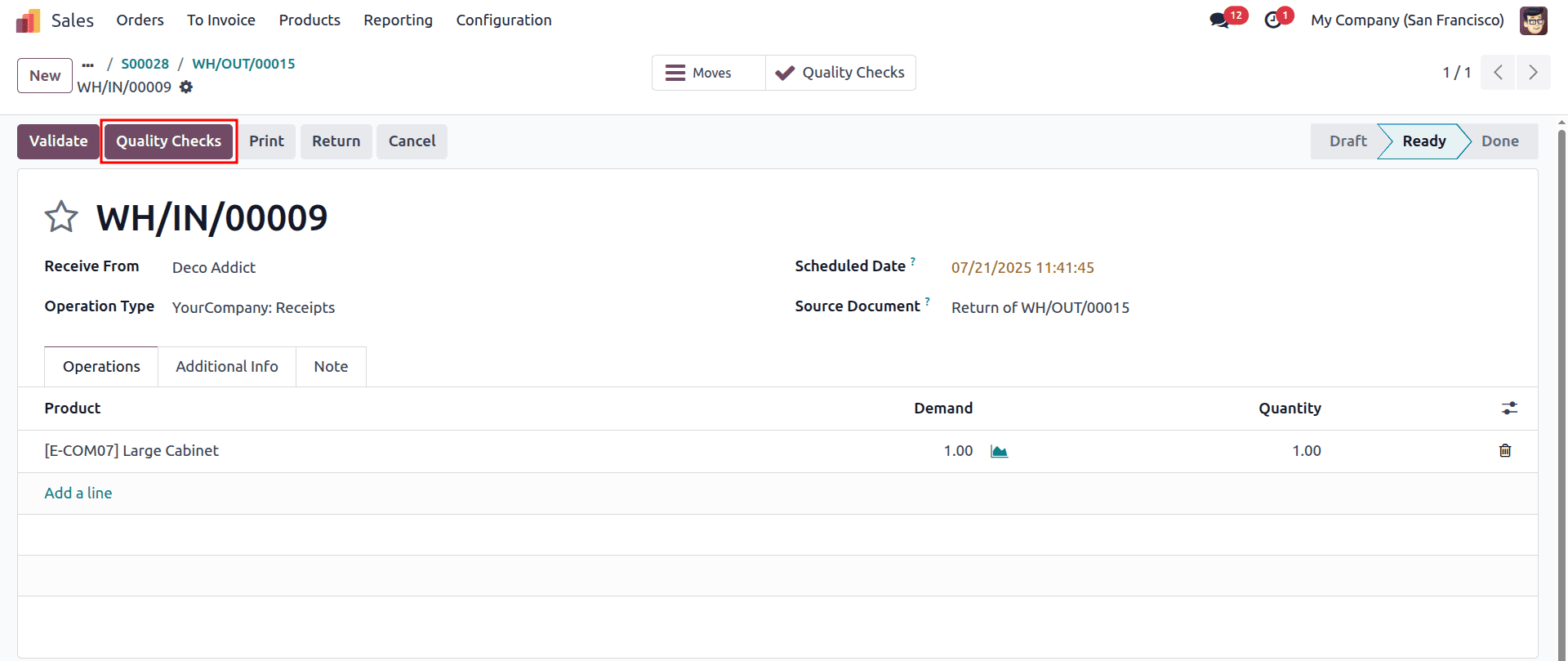

As shown below, once you click the Return button, a reverse transfer is created with the Quality Check button enabled.

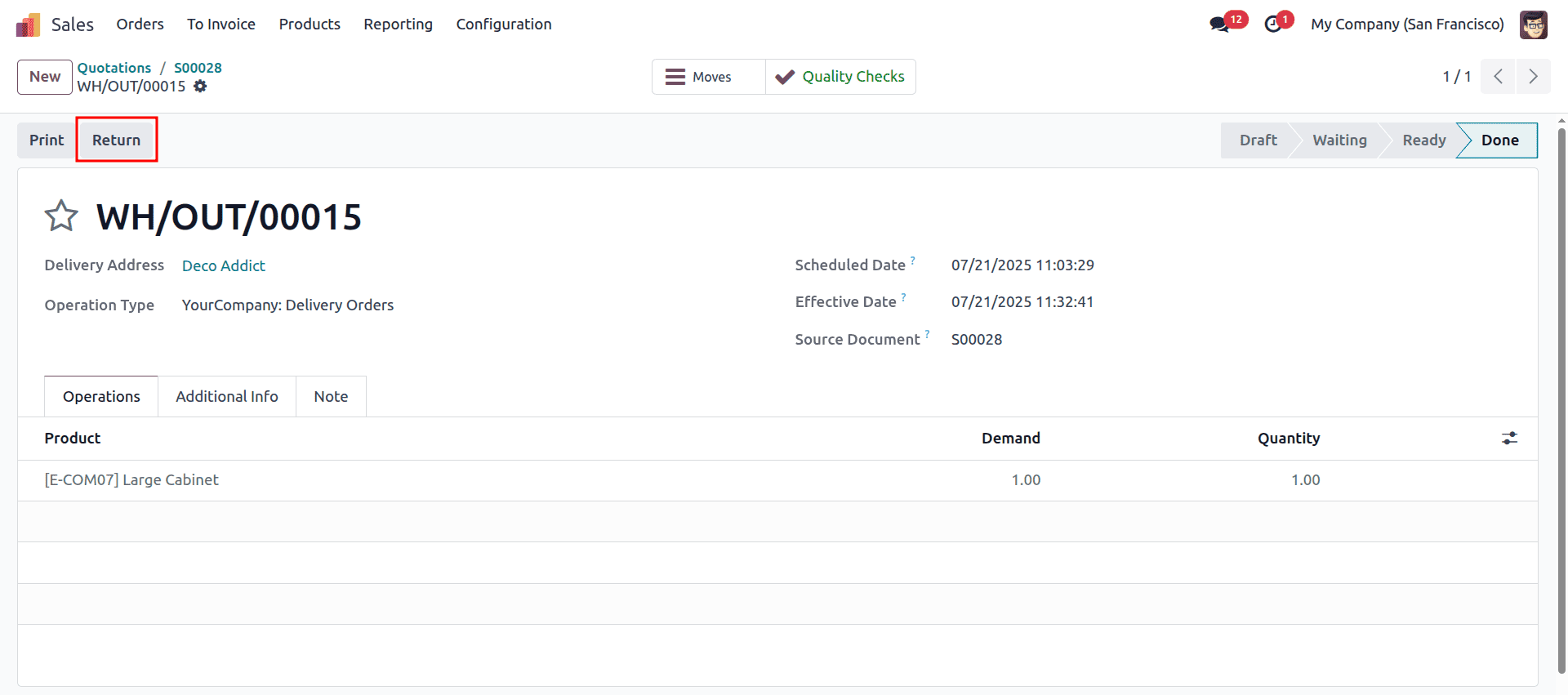

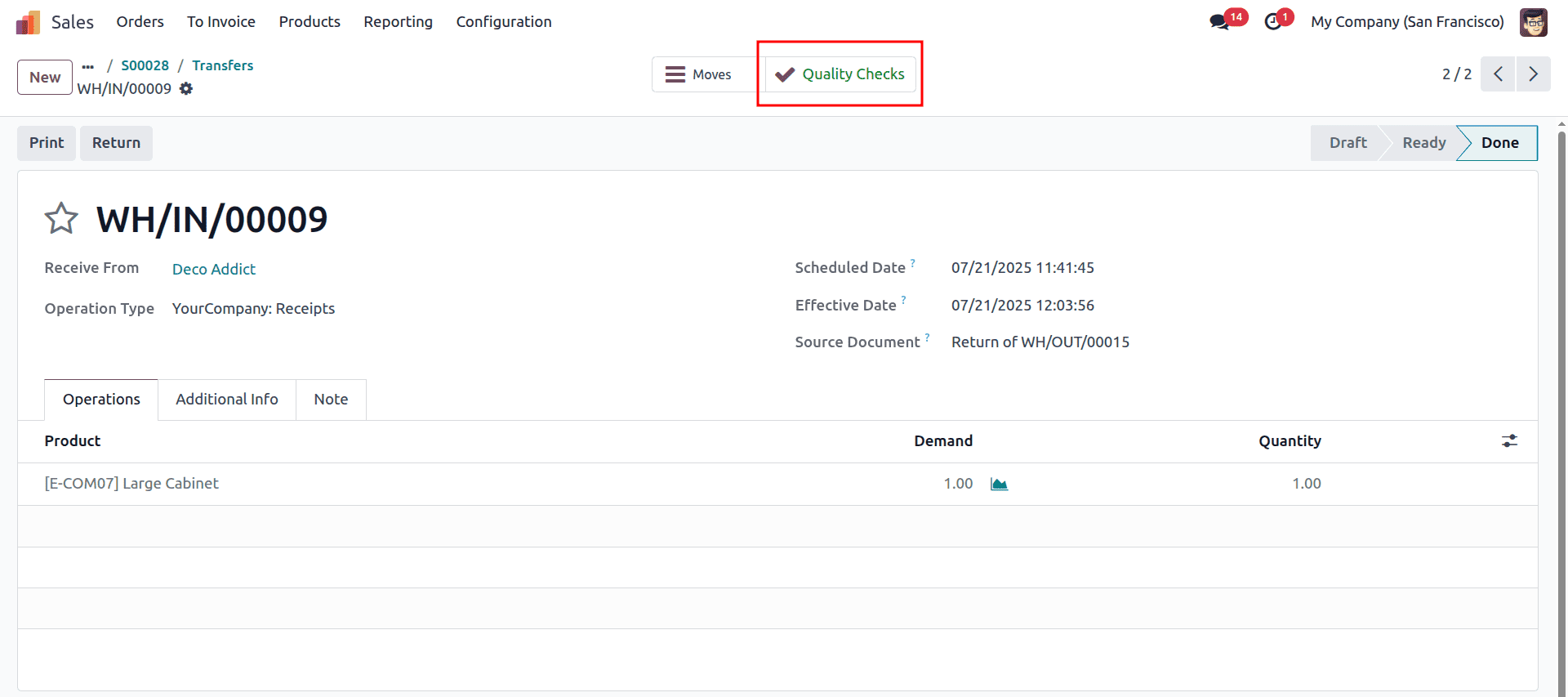

As shown below, once the quality check is completed and verified, the Quality Checks smart button displays a green checkmark.

The Quality module in Odoo enables manufacturers to maintain product standards by establishing quality control points and conducting inspections at various stages, including manufacturing, delivery, and returns, thereby ensuring that issues are identified early and products meet customer expectations.

To read more about How to Optimize Transfer Operations with Quality Control in Odoo 18, refer to our blog How to Optimize Transfer Operations with Quality Control in Odoo 18.