Efficient manufacturing starts with proper product configuration. In Odoo 18, setting up products for manufacturing ensures smooth production planning, material tracking, and workflow automation. Whether you're managing a small workshop or a large production unit, Odoo’s Manufacturing module simplifies the process.

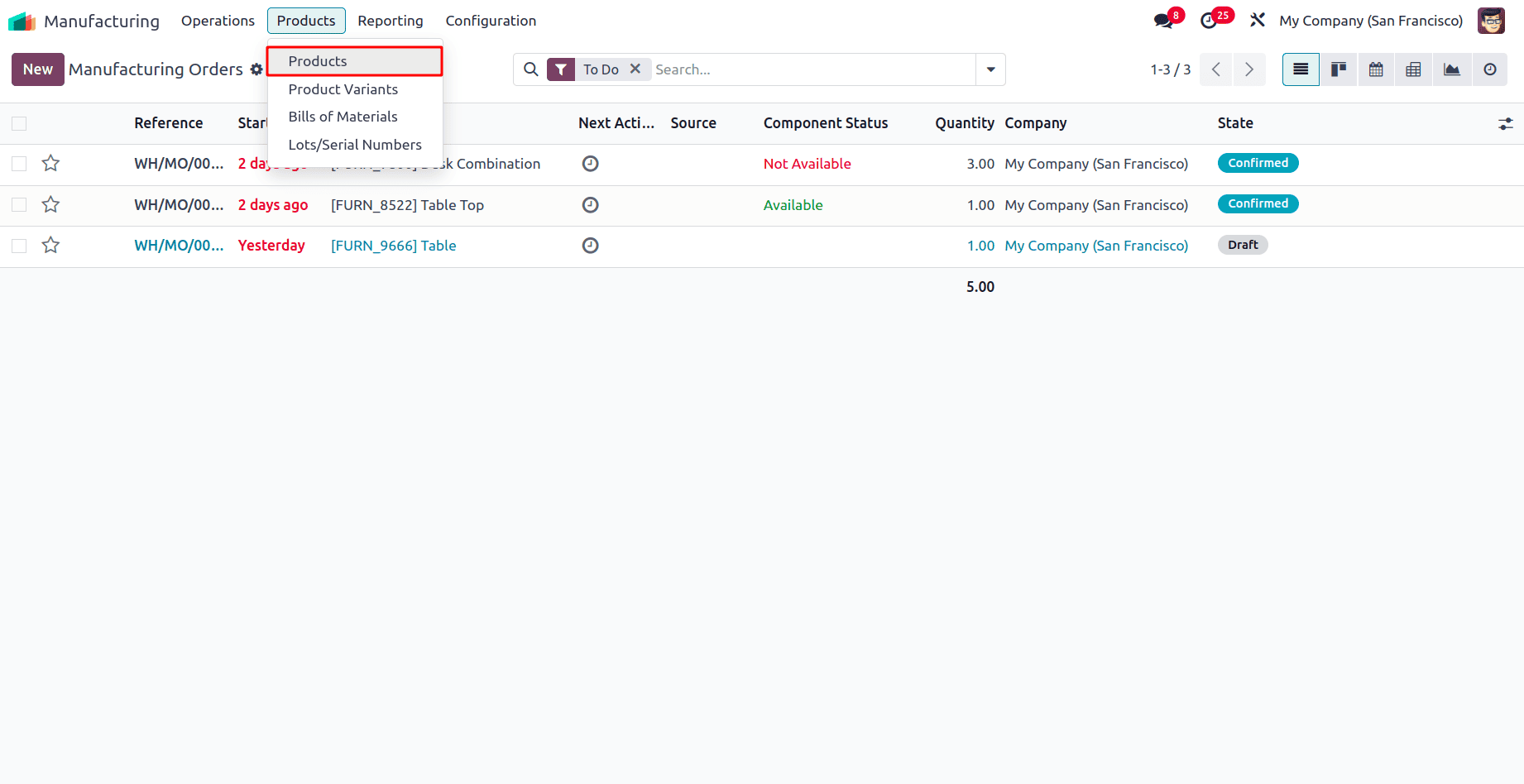

Before manufacturing a product, it must be created in the database first. For creating the product, navigate to Manufacturing > Products > Products.

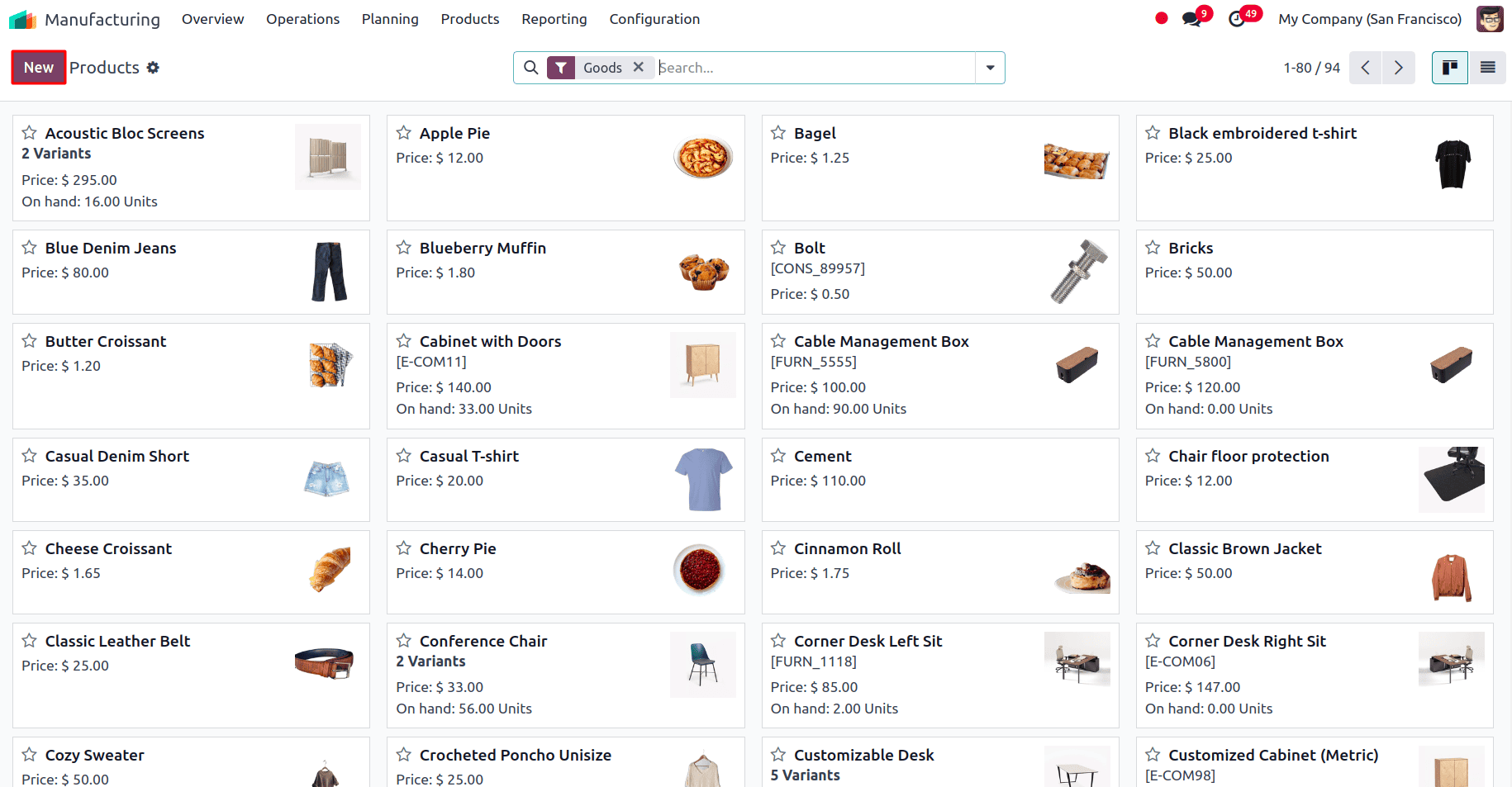

All the created products can be viewed from there, and to create a new product, click on the New button.

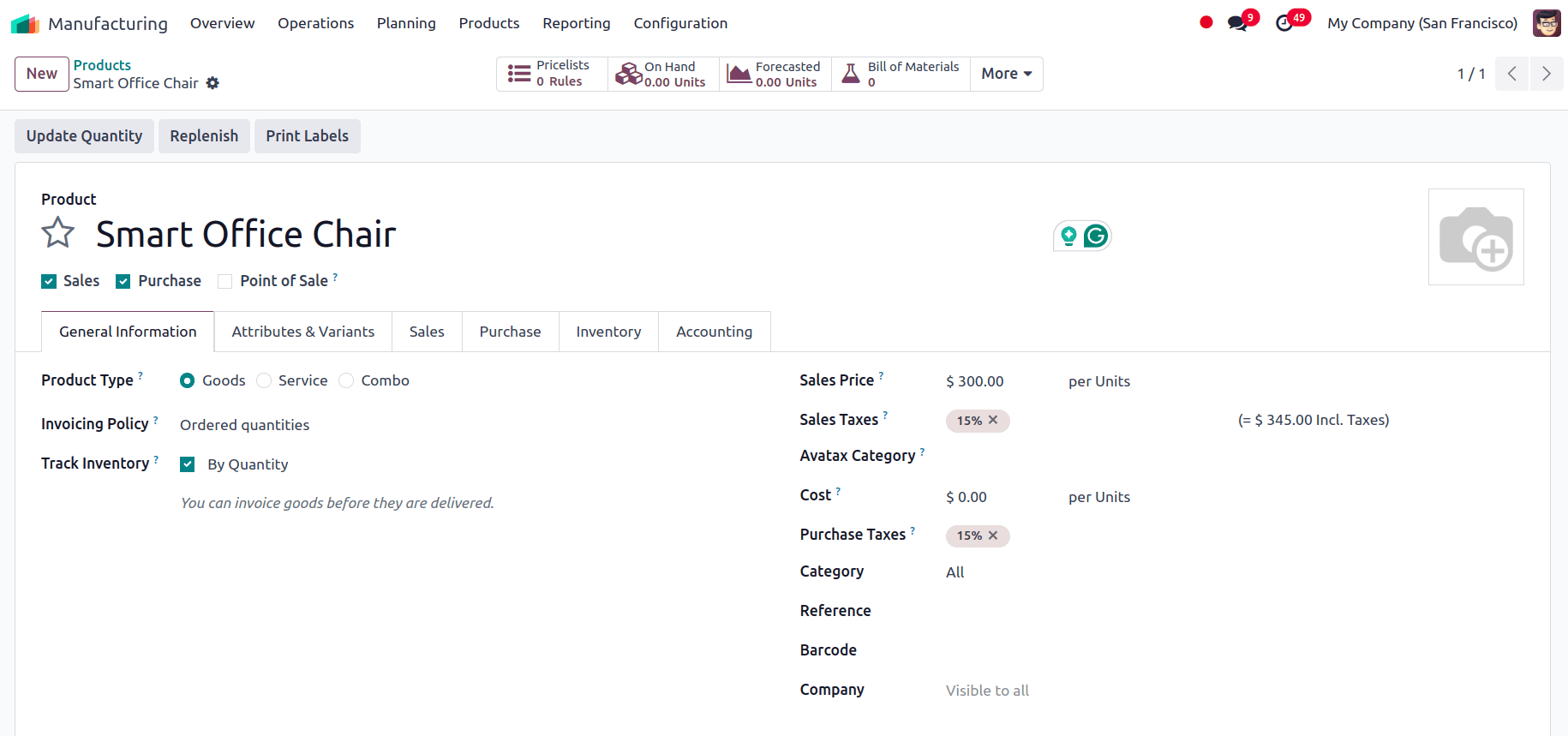

The product creation form appears. Add the name of the product and select the Product Type and also enable the Track Inventory if the product needs to be tracked and also select whether it has to be tracked By Quantity, By Unique Serial Number or By Lots.

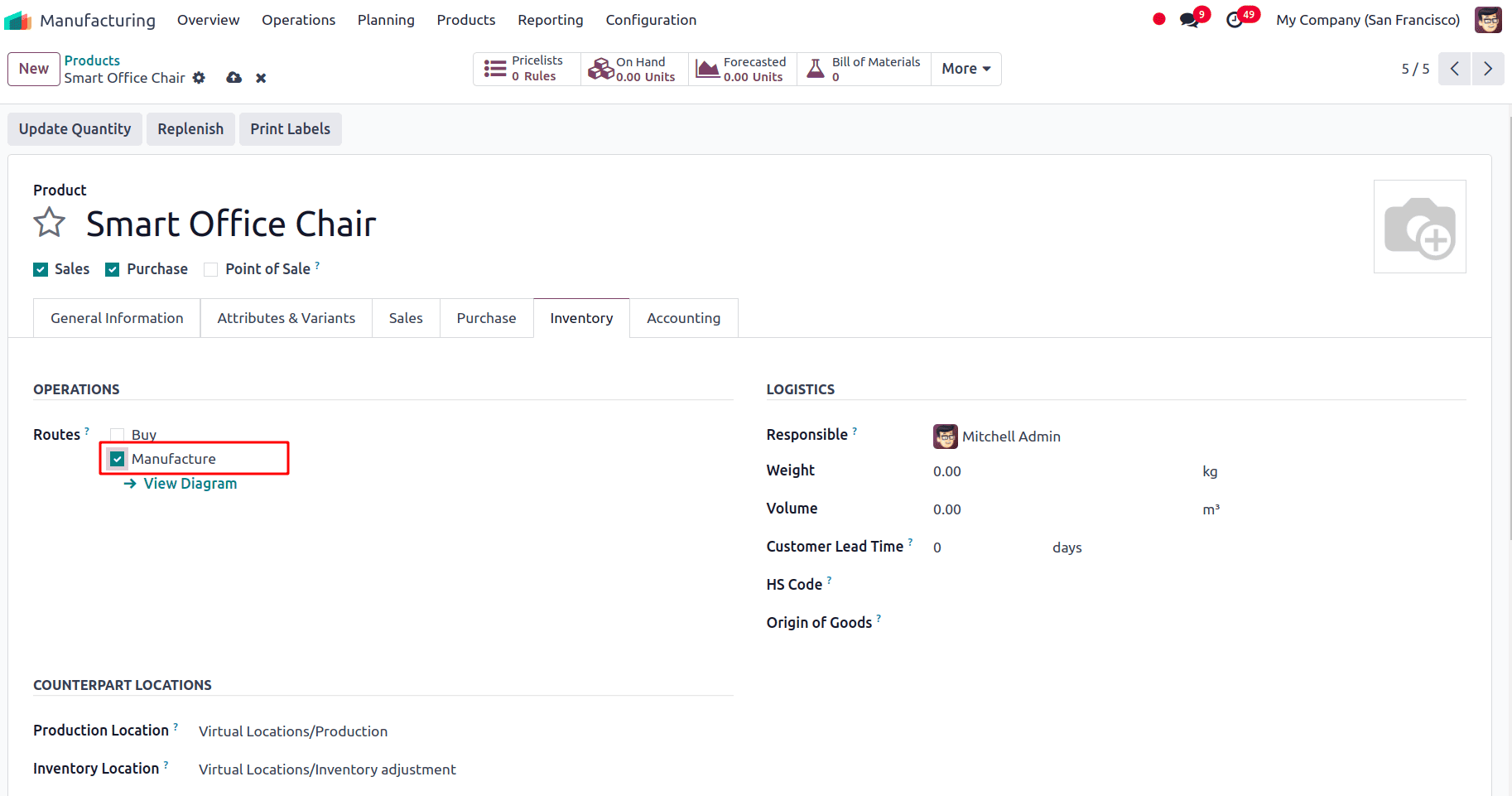

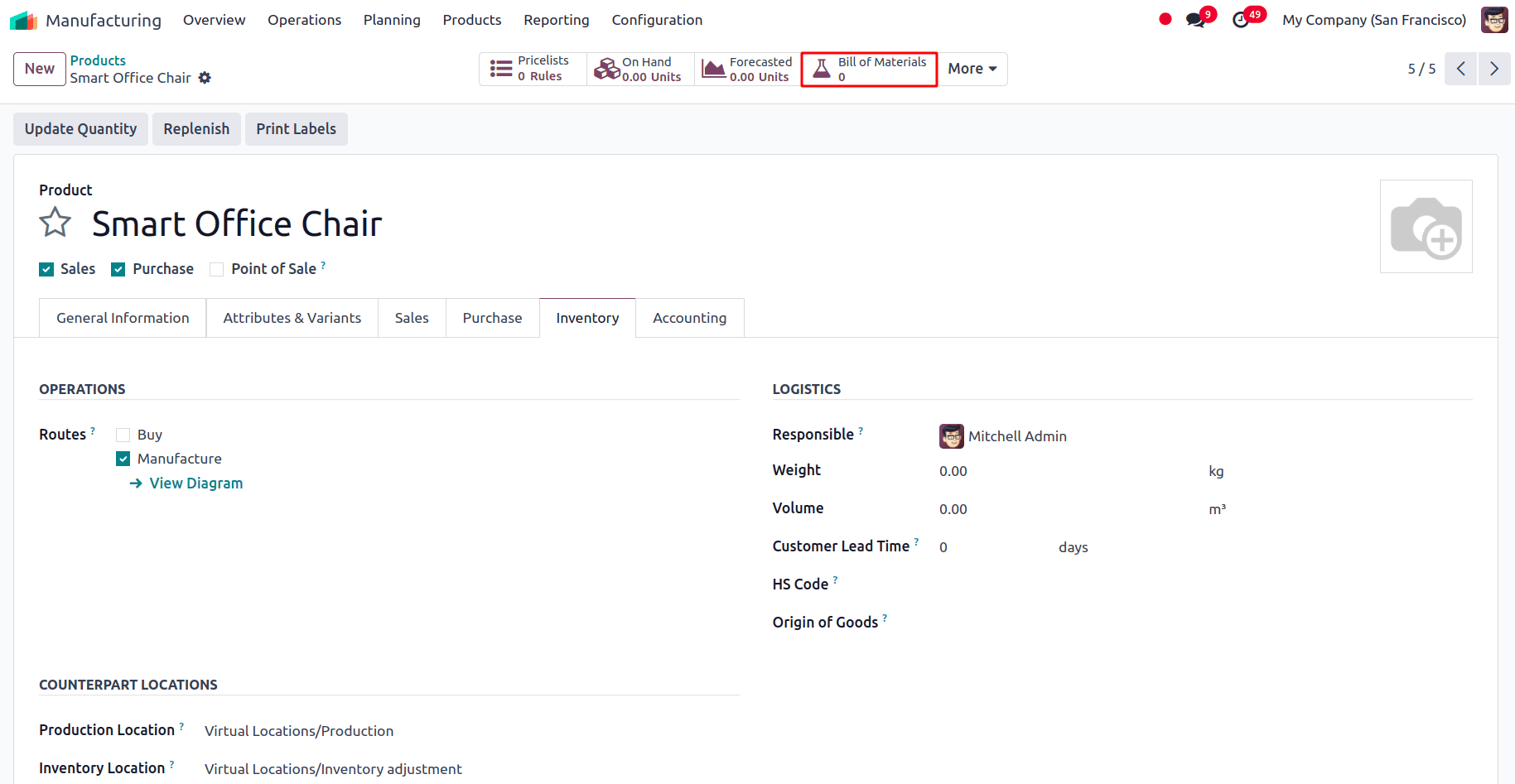

Now, the route of the product has to be configured. The Route determines whether the product is manufactured, purchased, or replenished from another location. To set the route of the product, go to the inventory tab of the product page and enable the boolean for Manufacture.

Then the Bill of Material for this product must be configured. A Bill of Materials (BoM) in Odoo Manufacturing is a list of all the materials, components, and steps needed to make a product. It helps organize production by defining what is required for the manufacturing process.

It can be configured directly from the product. There is a smart tab for the Bills of Materials at the top.

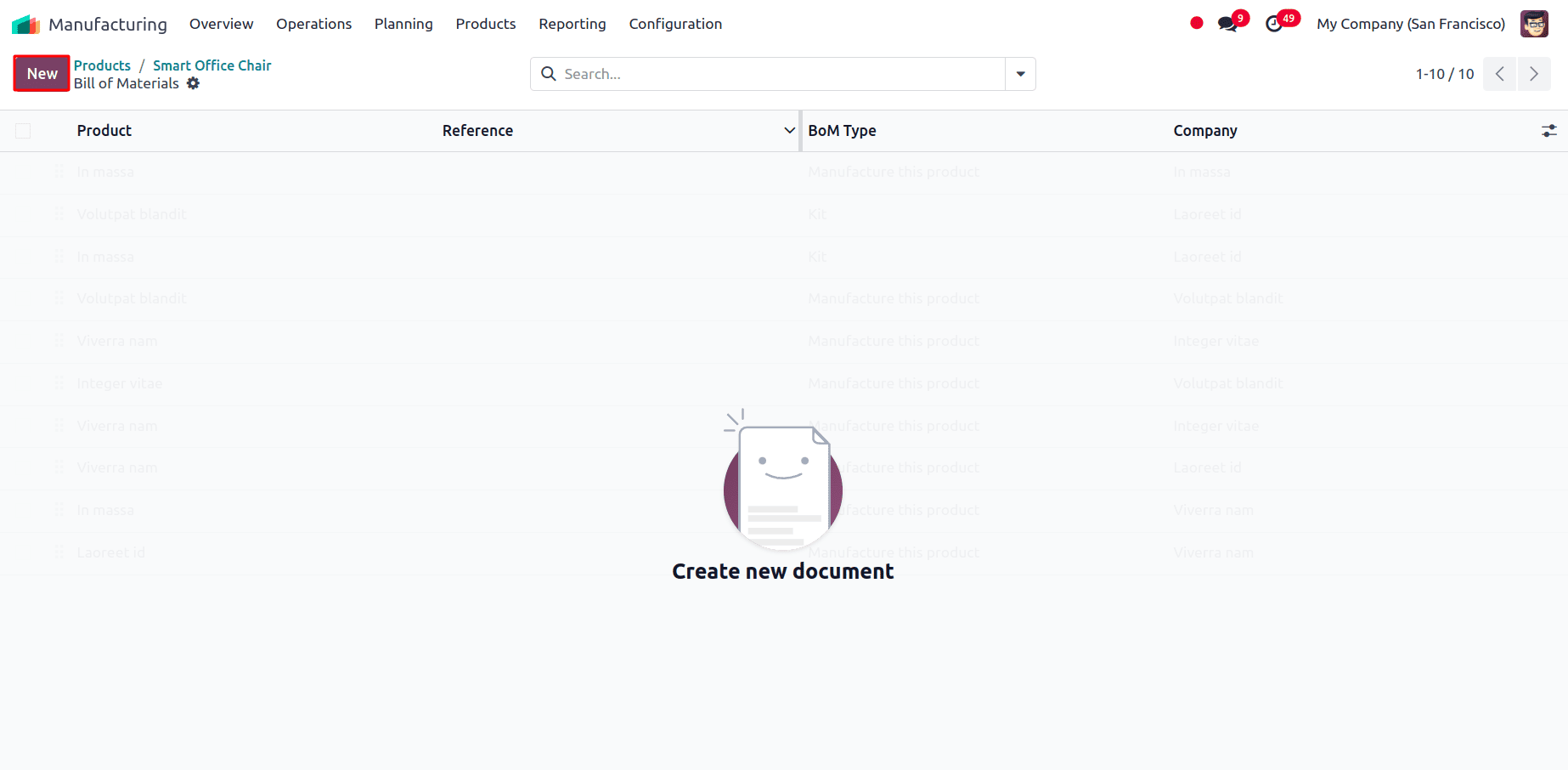

Click on that and a new page appears where all the Bills of Materials that have been configured for the product can be viewed and to create a new bill of material for the product, click on the New button.

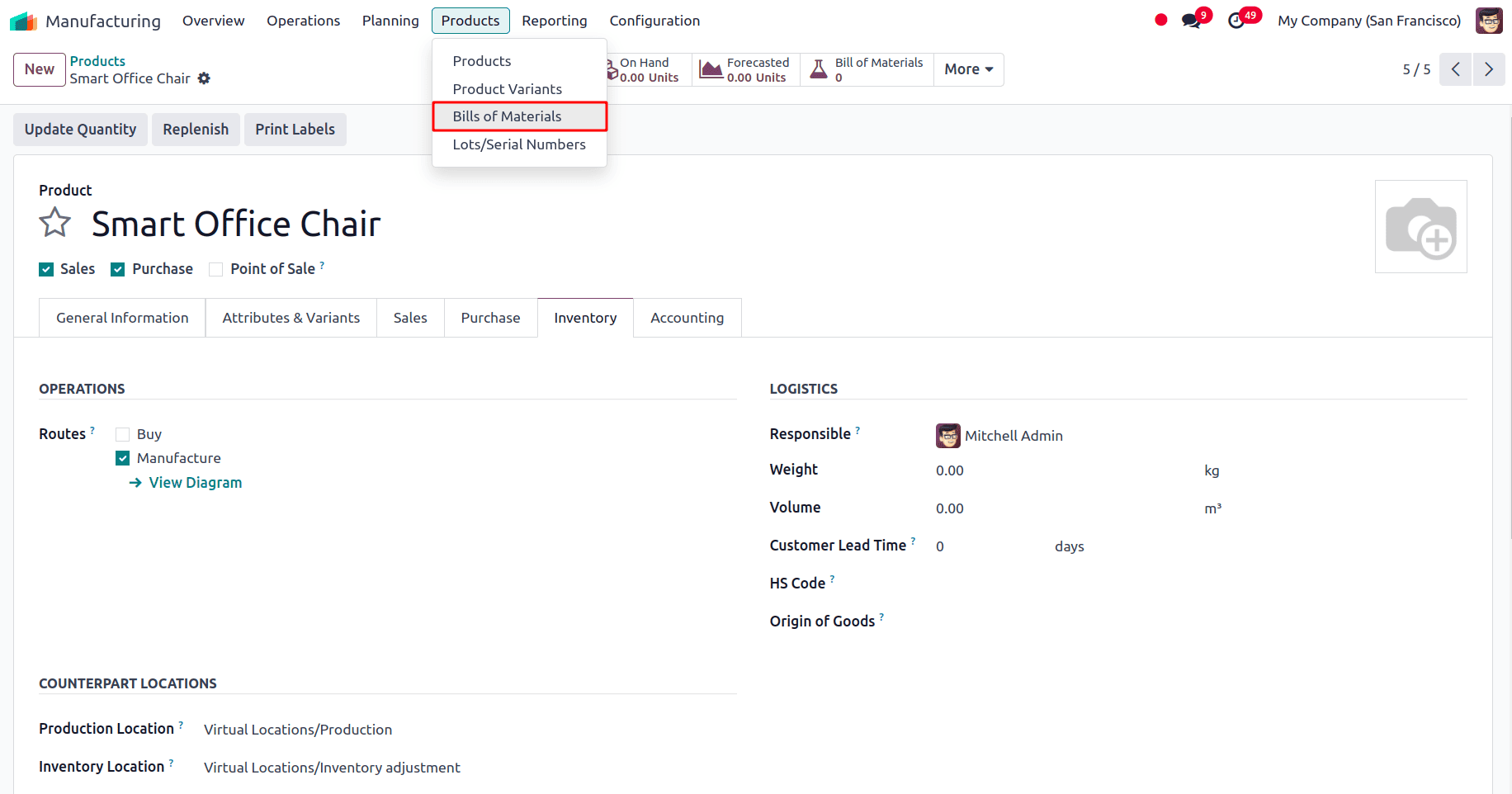

The Bill of Materials can also be accessed from the Products menu, Navigate to Products > Bills of Materials.

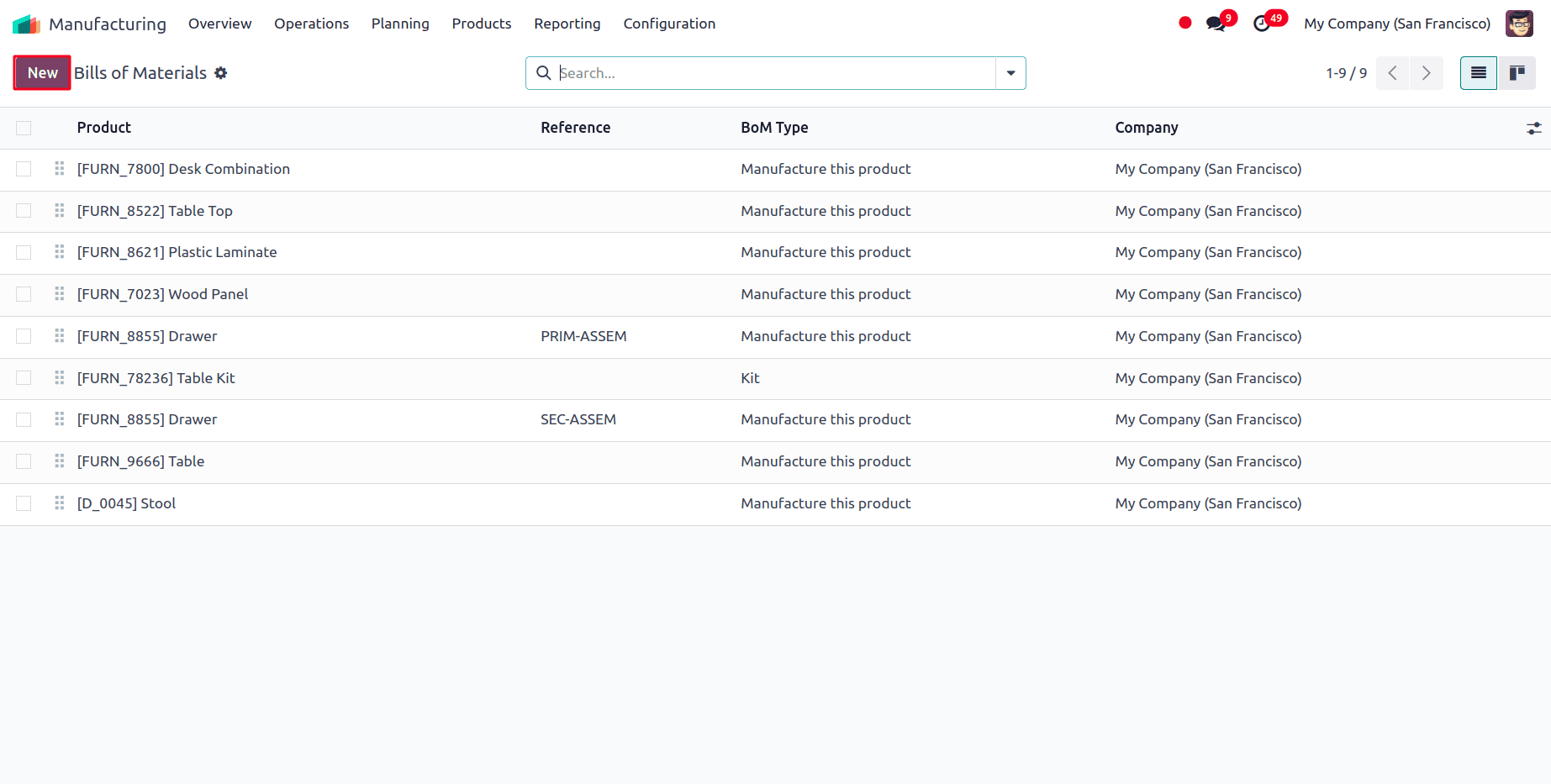

From there all the existing BoMs of the product can be viewed. To create a new BoM, click on the New button.

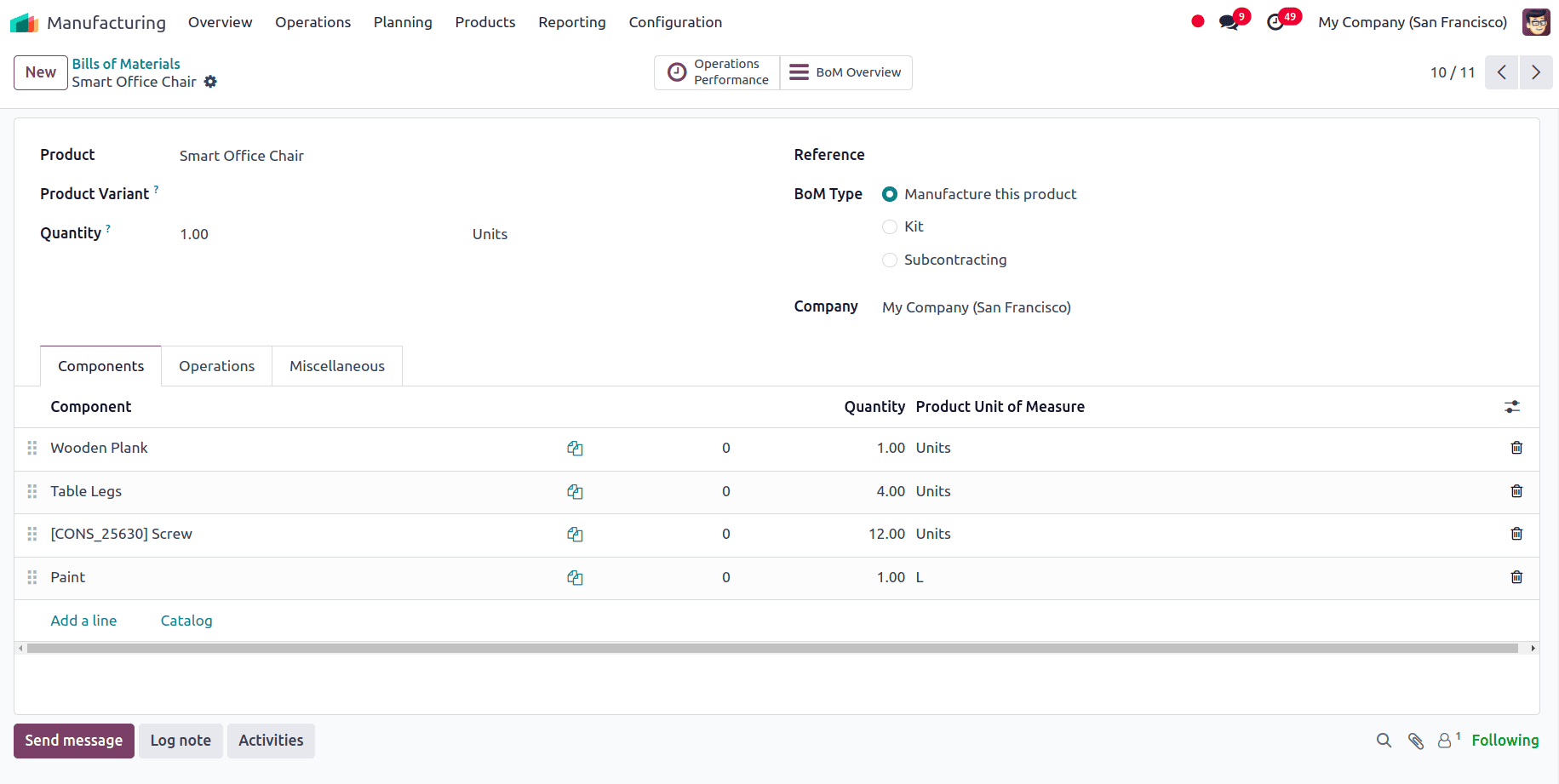

When the BoM is accessed from the product page, the Product name will be auto-populated in the Product field. And all the other required fields must be filled, such as:

- Product: The finished product that this BoM is for.

- Product Variant: If the product has variants, this field specifies which one the BoM applies to.

- Quantity: The number of finished products that this BoM defines materials for.

- Reference: A unique identifier or code for this BoM.

- BoM Type

- Manufacture this product: Used when producing the product in-house.

- Kit: Used when selling a product as a kit, where components are delivered instead of being assembled.

- Subcontracting: Manufacturing is outsourced to a third party.

- Company: The company responsible for manufacturing the product.

There are 3 tabs for the BoM: Components, Operations, and Miscellaneous.

In the Components tab, the components that will be used to manufacture the given product have to be added. The specific quantity of the component that will be required to manufacture the product should also be added to the BoM. To add the component, click on Add a line or on the catalog to view all the products and select the product that needs to be added as the component and then set the quantity required to manufacture the given product. In the Product Unit of Measure field, specify the unit in which the component is measured.

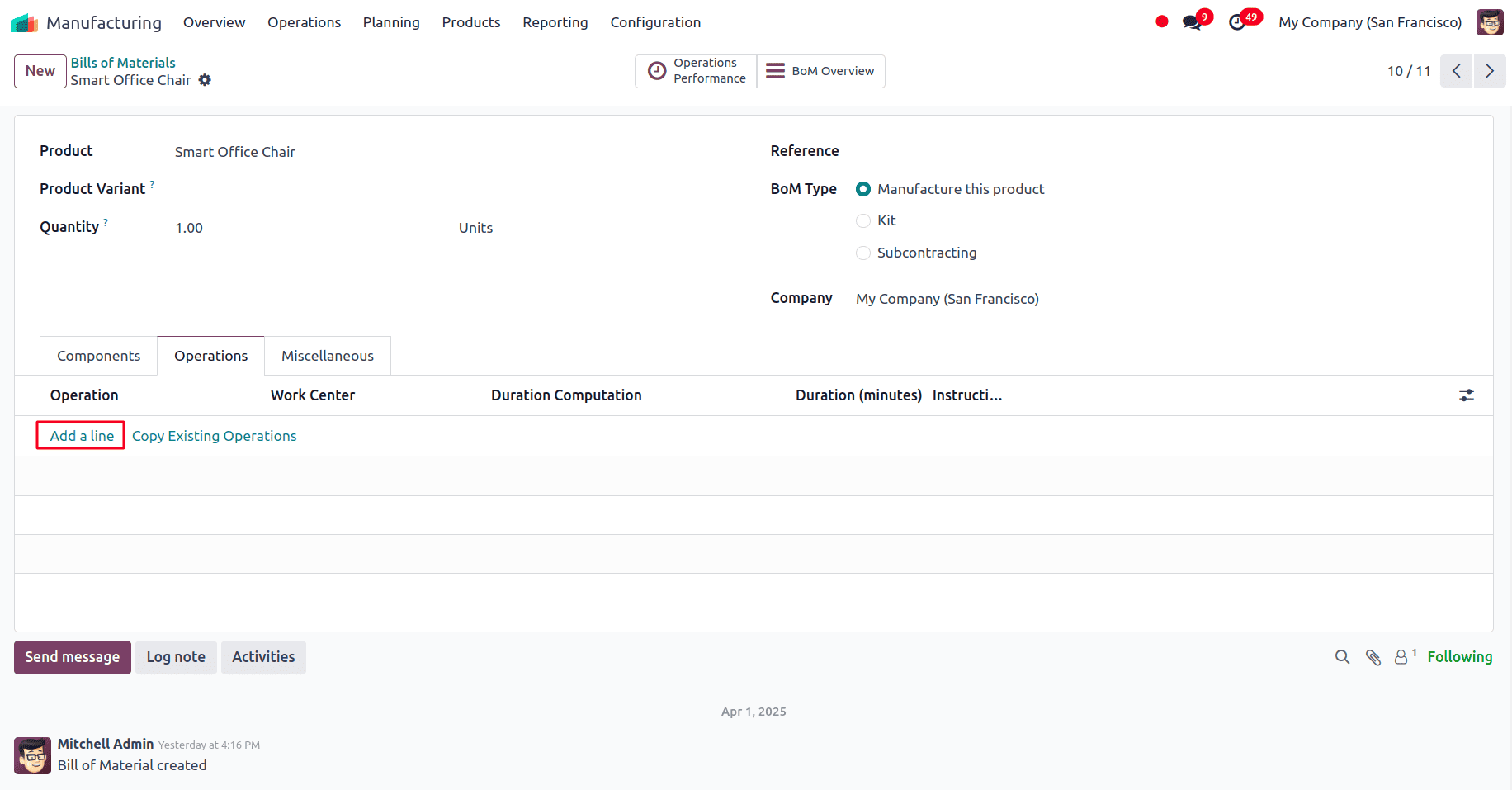

In a manufacturing process, multiple operations are required to complete the final product. The Operations tab in the BoM allows users to define these manufacturing steps along with their respective Work Centers. Here, all the operations required to complete the manufacturing of the product have to be added. It allows users to define different tasks required for production.

Click on Add a line, and a new pop-up will appear to create the operation.

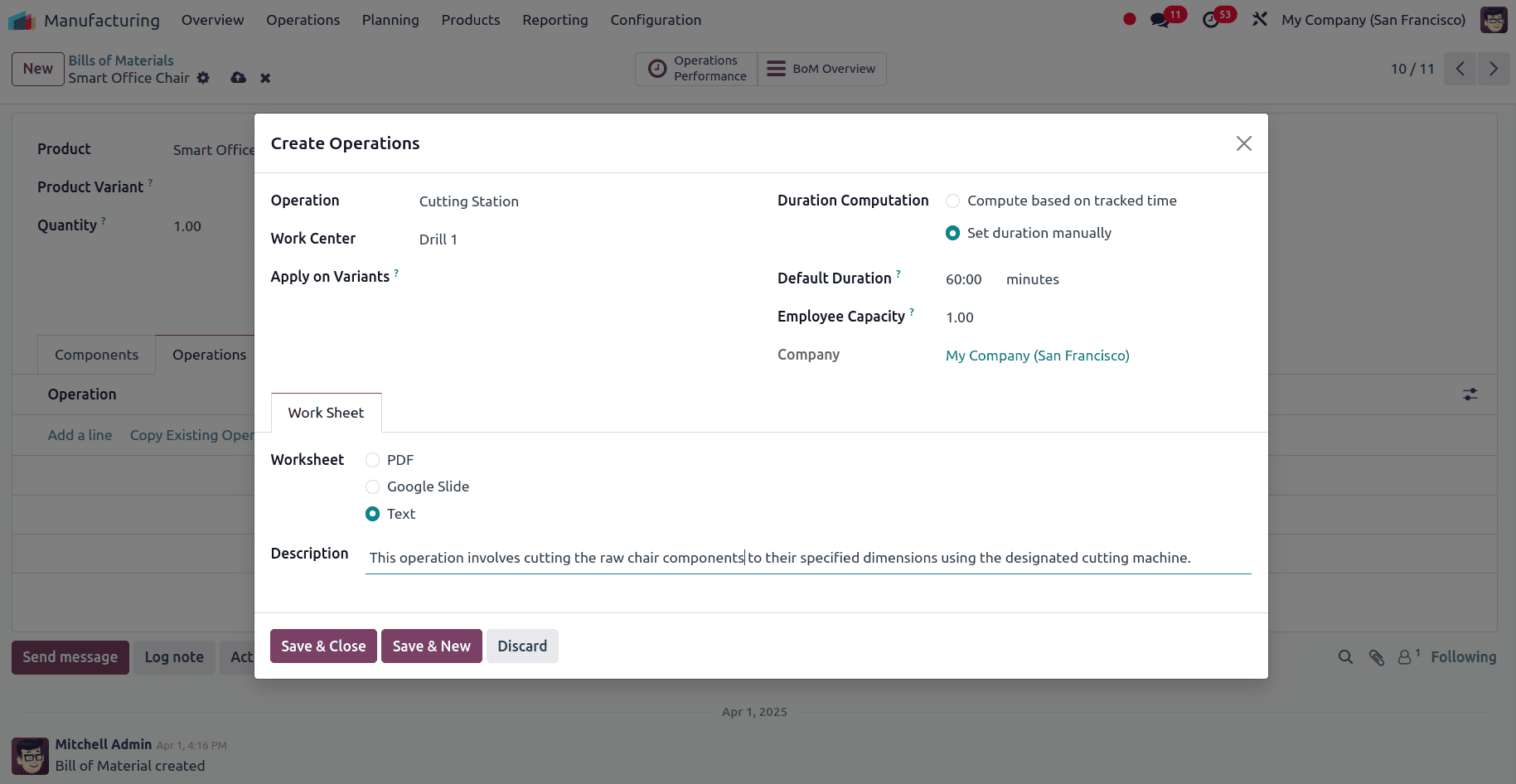

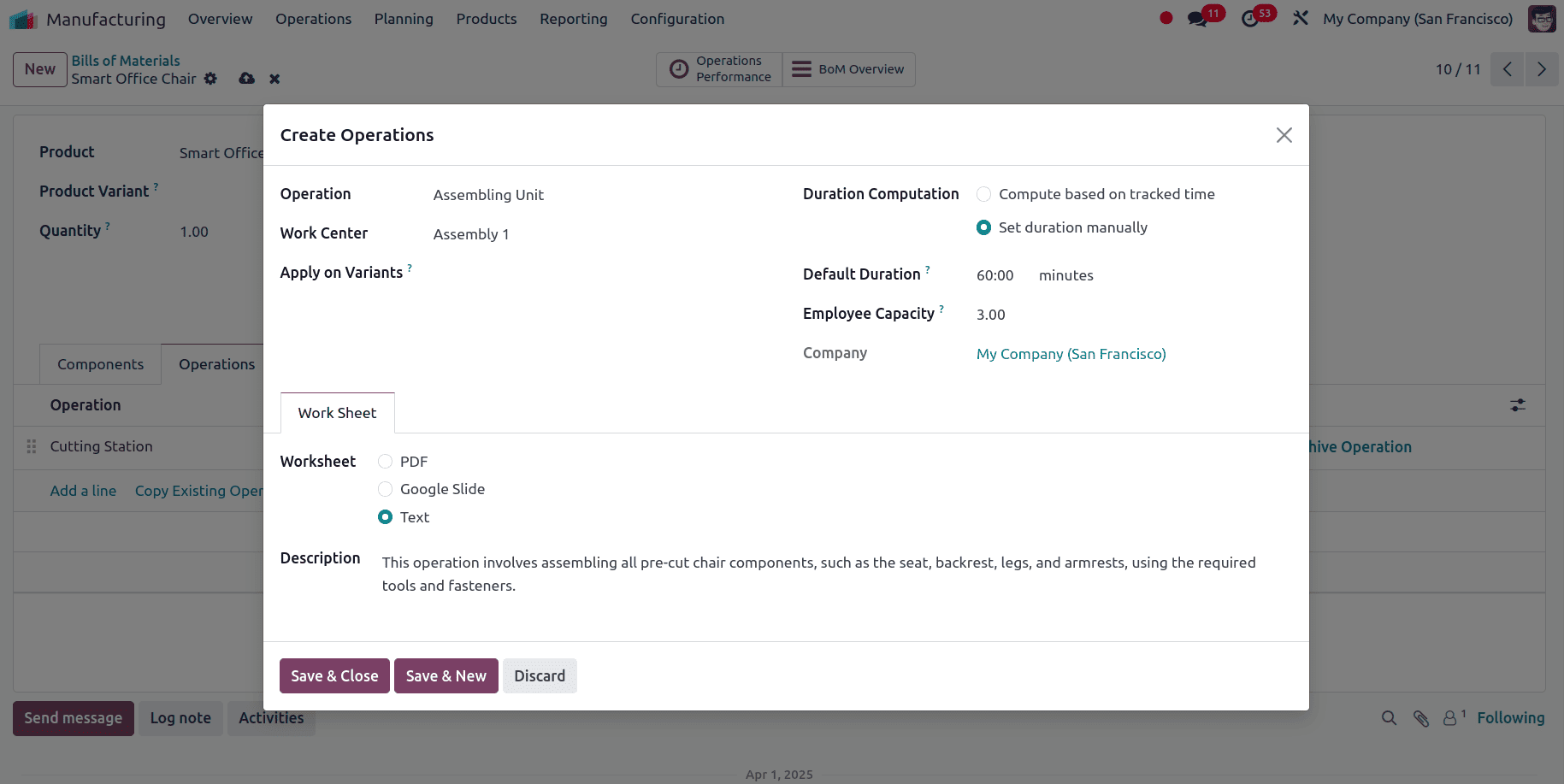

Here, the following details have to be added:

- Operation: Name of the task performed during manufacturing.

- Work Center: The machine or station where the task is executed.

- Apply on Variants: Limits the operation to specific product variants.

- Duration Computation: Method for calculating operation time.

- Default Duration: Estimated time to complete the task.

- Employee Capacity: Number of workers needed for the operation.

- Company: The company responsible for this operation.

- Worksheet: Format of task instructions (PDF, Slides, or Text).

- Description: Brief instruction about what the operation involves.

Once the details have been provided, click on Save & Close to save this operation or click on Save & New to save this operation and create a new one. Add the next required operation for this BoM.

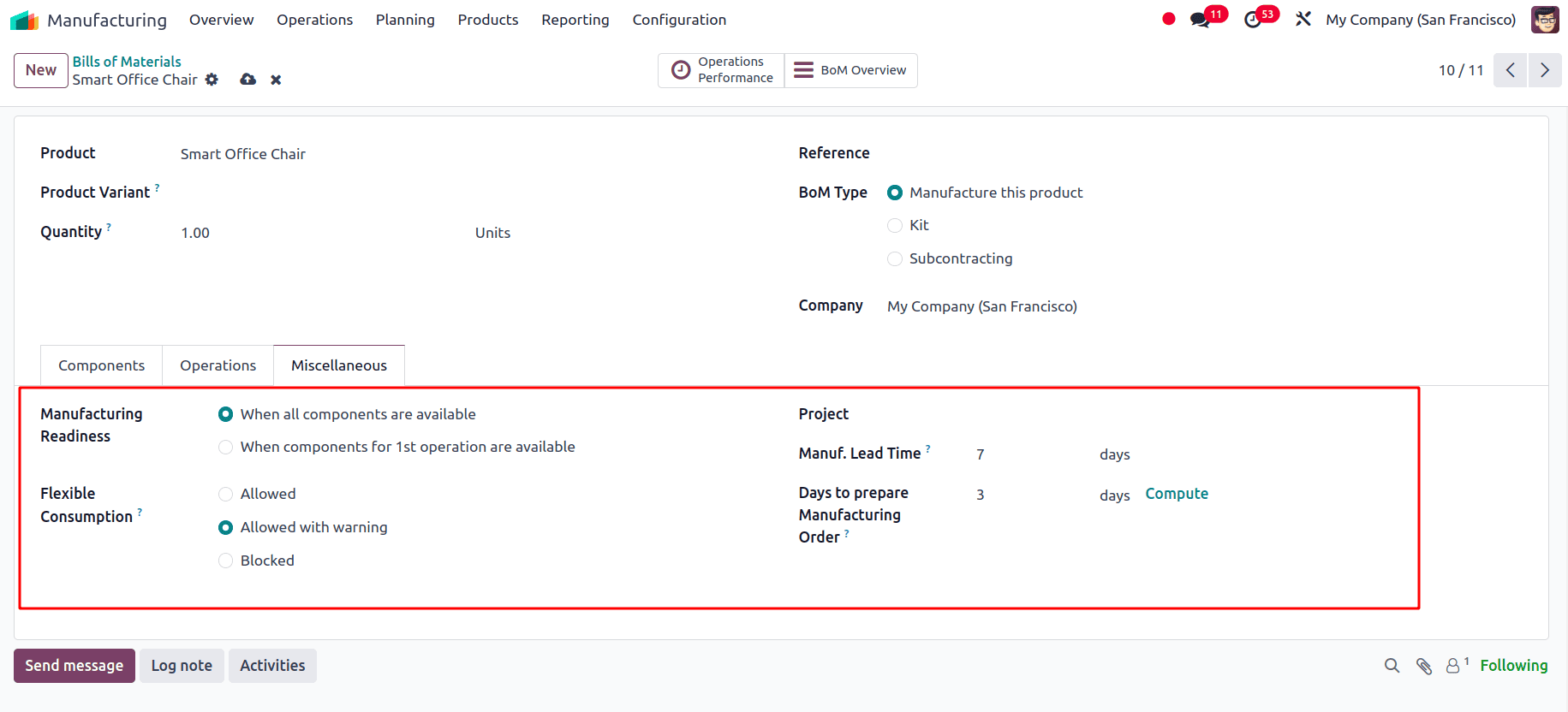

After the operations have been added, go to the Miscellaneous tab of the BoM, where the users can set the following configurations:

- Manufacturing Readiness

- When all components are available: Manufacturing can start only when every required component is available.

- When components for 1st operation are available: Manufacturing can begin as soon as the components for the first operation are ready, even if others are pending.

- Flexible Consumption

- Allowed: Extra consumption of components beyond the planned quantity is permitted for all the manufacturing users.

- Allowed with warning: Extra consumption is allowed for the manufacturing users but will trigger a warning message.

- Blocked: Only the admins will be able to close the manufacturing orders when the quantity of the component has been updated other than the value given in the BoM.

- Project

- Links the manufacturing order to a specific project (useful for tracking and costing in project-based manufacturing).

- Manuf. Lead Time

- The number of days needed to manufacture the product, from start to finish. It can be configured so that the scheduling and planning of the manufacturing order can be done properly.

- Days to prepare Manufacturing Order

- The time required to prepare for production (e.g., staging components, setting up machines) before actual manufacturing begins.

This is how a product can be configured for Manufacture in Odoo 18. Setting up products for manufacturing in Odoo 18 is simple and helps make the production process smooth. By marking a product as Manufacture and creating a proper Bill of Materials (BoM), you can easily manage how items are made and what materials are used. With features like Manufacturing Orders and Work Centers, Odoo 18 lets you track every step, from using raw materials to producing the final product.

To read more about How to Handle Manufacturing with One-Step Warehouse Configuration in Odoo 18, refer to our blog How to Handle Manufacturing with One-Step Warehouse Configuration in Odoo 18.