The world economy is changing constantly, as a result, the needs of the customers too. Keeping up with the changing aspects of this competitive environment is very challenging. When the business world is shifting from paper documents to virtual databases, if you’re not prepared to welcome the technology to your business, without any doubt your company’s future is non-existent. With the increasing demand for goods and services, the contemporary economy and society are very much in need of efficiently operating business firms to serve their needs. Without adapting to the changes companies can collapse to nothing within a few years. In such a crucial situation, ERP software is the foundation for new-age business operations. With its accurate functional prospects along with highly specific and detailed functionalities, your business can flourish into a not an expected status with little effort.

Enterprise Resource Planning(ERP) software allows the manufacturers to keep their costs, and stock levels under control. With every passing day, the count of satisfied customers is hiking up as it provides a greater edge in the competition. Managing a manufacturing business cost-effectively is very complicated, especially when it is expanding. So to avoid the risk and help you run your company in the best and most effective way opting for manufacturing ERP software is the wise option.

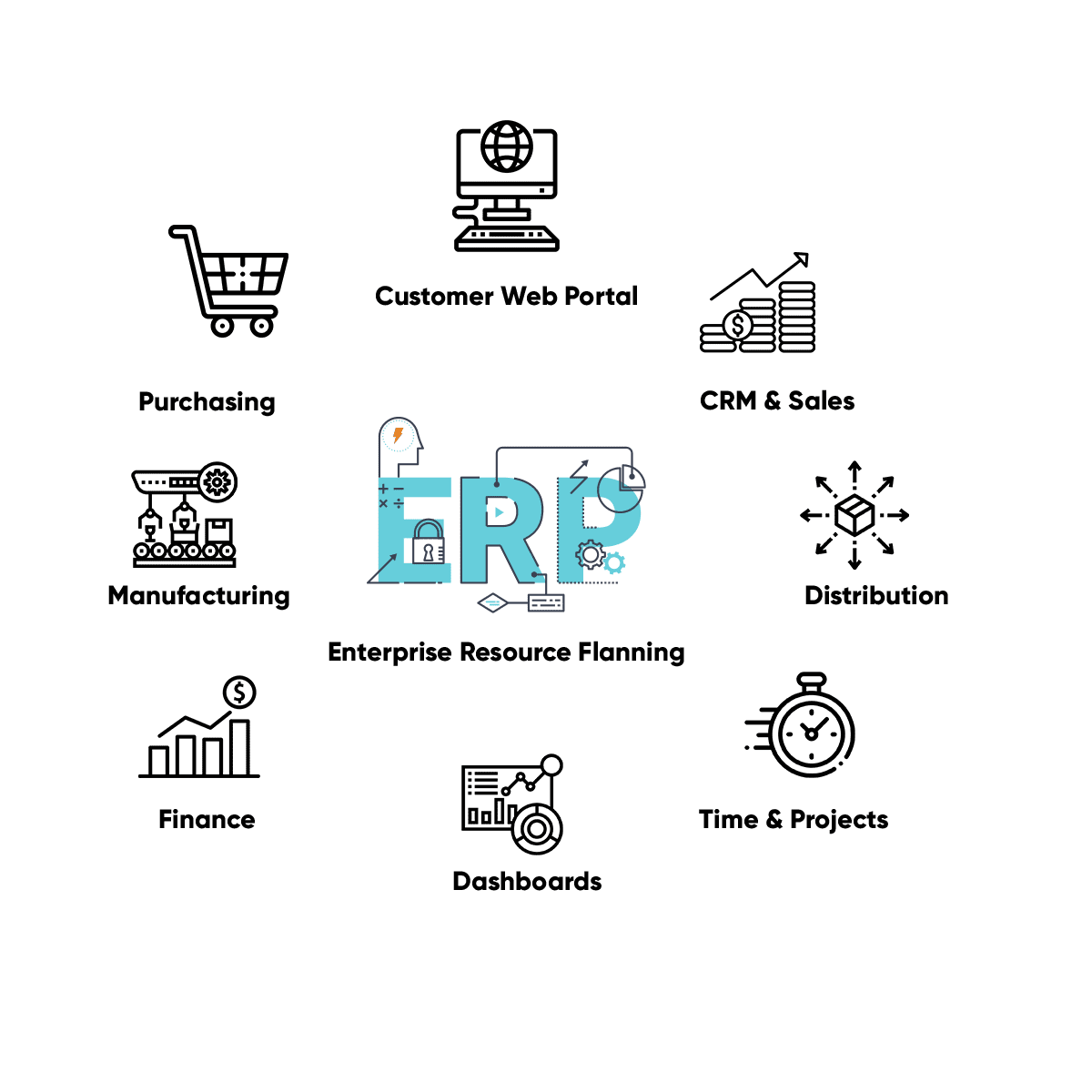

ERP For Your Business

At the end of the month, it takes a stretch of time to resolve financials. Your sales projections are more focused on prediction than solid figures. Your company is struggling to keep up with its volume of orders and as a result, customer satisfaction is fluctuating. You do not understand what kind of inventory you have in your warehouse, and finding it out is a pain. If this really sounds like this to your business, then it might be time to consider an ERP system.

Enterprise Resource Planning is exactly what it sounds like: it is a way to ensure the coordination of everything you need for your business. It goes much further than your business strategy and takes you into the basics of day-to-day operations management.

ERP and Manufacturing

Each year the manufacturing industry is growing bigger and bigger, worldwide. With such an adept progression, manufacturers are benefited from an upswing in business. This indicates that there is an excessive need to assemble daily business processes that one person or a small team of people can not handle. Manufacturers should turn their attention to robust software like Enterprise Resource Planning (ERP) which is designed to help the manufacturing industry attain flourishing growth in a short time span.

ERP software in manufacturing offers priceless benefits to manufacturers wishing for low-cost methods to handle the business which also ensures growth by fixing every problem. It also offers centralized processes and thus plays a pivotal role in achieving competitive advantage.

To understand precisely the Key Signs that your manufacturing business needs an ERP, initially, we should understand the challenges faced by the manufacturing industry.

Let us have a look at it.

1. Working Cost

2. Traceability and regularity

3. Development of production

4. Consideration of the environment

5. Efficient processes

6. Quality of the product

7. Shortage of product

Key Signs that your manufacturing business needs an ERP

Manufacturing hold-ups are expanding, quality standards are falling, delivery schedules are not being met and your customers are getting more and more unhappy. Does your manufacturing business sound familiar to this? The above mentioned are the basic signs that Enterprise Resource Planning software is required for your manufacturing business.

Now let us discuss some more:

Constant production scheduling problems

The surveillance and efficiency of your manufacturing business are directly proportional to the capability to make products beneficially and delivering them on time. Your company may fail to meet the customer's needs when you have no idea about what raw material you have on hand, do the machines and workers are available for the manufacturing process. Or in case if you do not have proper production scheduling.

To avoid this, ERP systems include fully integrated Master Production Planning(MPS). It offers an important planning function that helps to achieve actual supply. As well as to forecast, accurate delivery, and proper time production plans. Enhancing the Master Production Planning system can be recognized as crucial for boosting the competitiveness of your business. Along with satisfying the current customer requirements on time.

Let us take a closer look. If your manufacturing company shows the signs, as said below its high time, for opting Master Production Planning to your firm.

> Lack of ability to make adjustments to fluctuations in demand while reducing waste.

> Failures to Prevent shortages and scheduling mishaps.

> More effective cost controls and more accurate estimates of material requirements and delivery dates etc. could not be given.

Lack of Control over Inventory

If you have a Lack of Control over your Inventory, it may negatively affect on keeping your precise inventory counts. Excess inventory occupies more storage space and can be damaged or outdated. On the other hand, extremely limited inventory can halt manufacturing lines, create expedited shipping costs, and lag customer deliveries resulting in customer satisfaction declines.

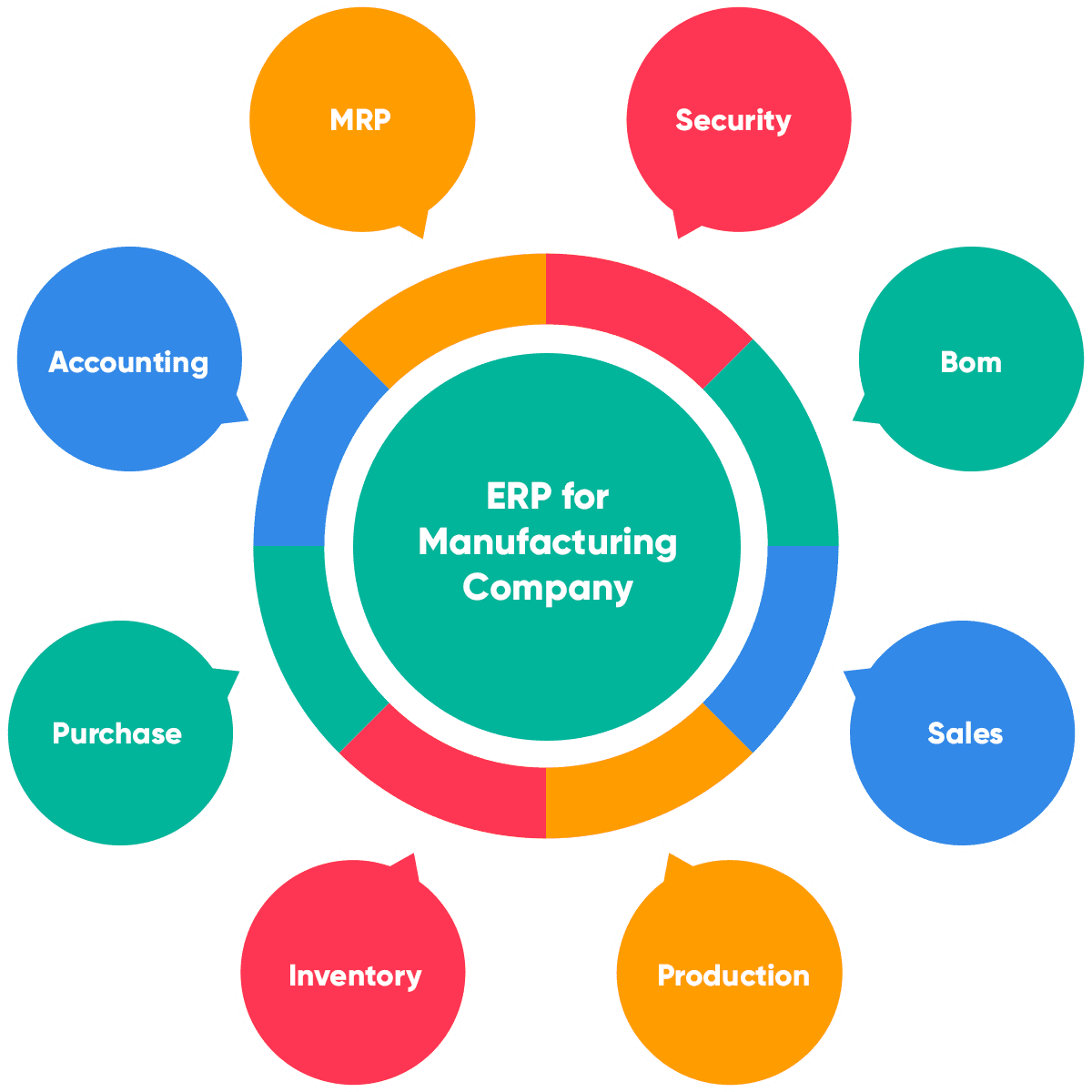

Here comes the importance of Manufacturing ERP. It helps you with improving the visibility of your inventory on hand, enhancing accuracy, and reducing overheads. So, managing inventory is an inevitable part of enhancing your business. This can be done through effective Materials Requirement Planning(MRP) and a Bill of materials(BoM).

In case if you are not able to have quick and easy access to data

Waiting until manual reports are generated slows the decision-making process and lowers the company's overall productivity. If you need to operate your business effectively, Instant access to business data is important in obtaining valuable insight. Only a manufacturing ERP can provide you with overall visibility over every aspect of your operation on time which is an indispensable necessity.

In the case of hindrance in Tracking

Erp system now streamlines serial and lot tracking and traceability, rapid product recall process, suspect product quarantine, and extensive audit trails.

When the delivery of a product is not on time

With an ERP, the calculations of time needed for sudden manufacturing of products is just a piece of cake. The planning and predictability of manufacture and shipment of products using ERP provisions delivery of products and services on time without any delay.

If Fulfilment never carries out

For allowing greater visibility in manufacturing processes, like inventory, supply chain, and external market demand Erp enables us to connect data from different sources. All from one system.

If you can’t maintain reduced the costs

With traditional paperback management, the cost of commencement and the maintenance of your business are relatively high. Using the ERP system you can reduce administrative and operational costs with real-time information. It allows manufacturers to do operations, data deadlocks to break up.

Fail to improve the business results

For businesses struggling to keep the growth rate steady and up, ERP is a great boon. You can boost profit in business, ROI (Return on Investment), with the help of ERP Solution.

Lack of Improved manufacturing performance

The actual-time process data such as the stage of the current process and what needs to be produced, as well as the raw material, can be made visible to you by ERP guides you towards taking the right decision.

In the case of Less Security

Security for important financial documents in traditional business management is highly questionable. The perishable nature of documents is risky and keeping them safe is a bit tricky. But ERP systems allow you to keep documents safe and employee accounts can be assigned with only to processes suited to their roles to avoid spilling of information and/or misuse.

Now let us look at the significance of Key Signs that your manufacturing business needs an ERP

There is tight competition among all business enterprises in today's world. For the survival of organizations, they need good systems that enable them to fight in the aggressive competition. Staying competitive in the manufacturing industry is becoming much harder. Companies are trying hard to become more productive, guaranteed compliance monitoring, enhanced customer service, and efficient usage of resources to remain competitive. Luckily there is a solution to help achieve all of those goals.

A manufacturing company has to manage a variety of processes, like Inventory Management, Design Process, Procurement, Quality Control, Order Management Processes, etc. And in order to cover all these equally integral aspects, your business is in the necessity of a challenging tool. If your business has ERP, the Manufacturing department can perform its actions in an effective and highly productive manner. An ERP enhance your business processes like;

1. Improves communication

2. Make accounting easier

3. Better production control

4. Streamlining and Automation of Business

5. Maximize cash flow

6. Improve your business efficiency and competitive nature

7. Efficiently manage the inventory levels

8. Flexibility

So we had already said above that Erp in such an inevitable part in manufacturing. Now let us examine, how effective Odoo Manufacturing ERP is for your manufacturing business already showing the signs of the need for Enterprise Resource Planning.

In addition, Odoo offers you many advanced features such as by-products, Master production scheduler, routing facilities, MRP II scheduler, Kanban planning, single BOM for multiple product variants, production calendar, backward scheduling, job order, repair, etc.

So in simple words, enterprise resource planning (ERP) a software application for manufacturing is needed by emerging companies that make things or have works orders, jobs, production orders, and/or projects.