Efficient inventory management is critical for businesses handling serialized or batch-tracked products. Odoo 18 provides an efficient way for a Lot and Serial Number Tracking system that enhances traceability and improves stock management. This feature is particularly beneficial for industries dealing with perishable goods, electronics, pharmaceuticals, and manufacturing, where tracking product movement is essential for quality control and regulatory requirements. This blog explores the configuration and utilization of Lot and Serial Number Tracking in Odoo 18 for accurate inventory control.

Odoo allows businesses to track products either by Lot Numbers or Serial Numbers, depending on their needs:

- Lot Numbers: Used to track a batch of identical products. Ideal for perishable items, food, pharmaceuticals, and bulk goods.

- Serial Numbers: Assigned to individual products, allowing unique identification and tracking. Commonly used in electronics, machinery, and high-value items.

Using this tracking system, businesses can easily trace the origin, movement, and status of products, ensuring greater operational efficiency.

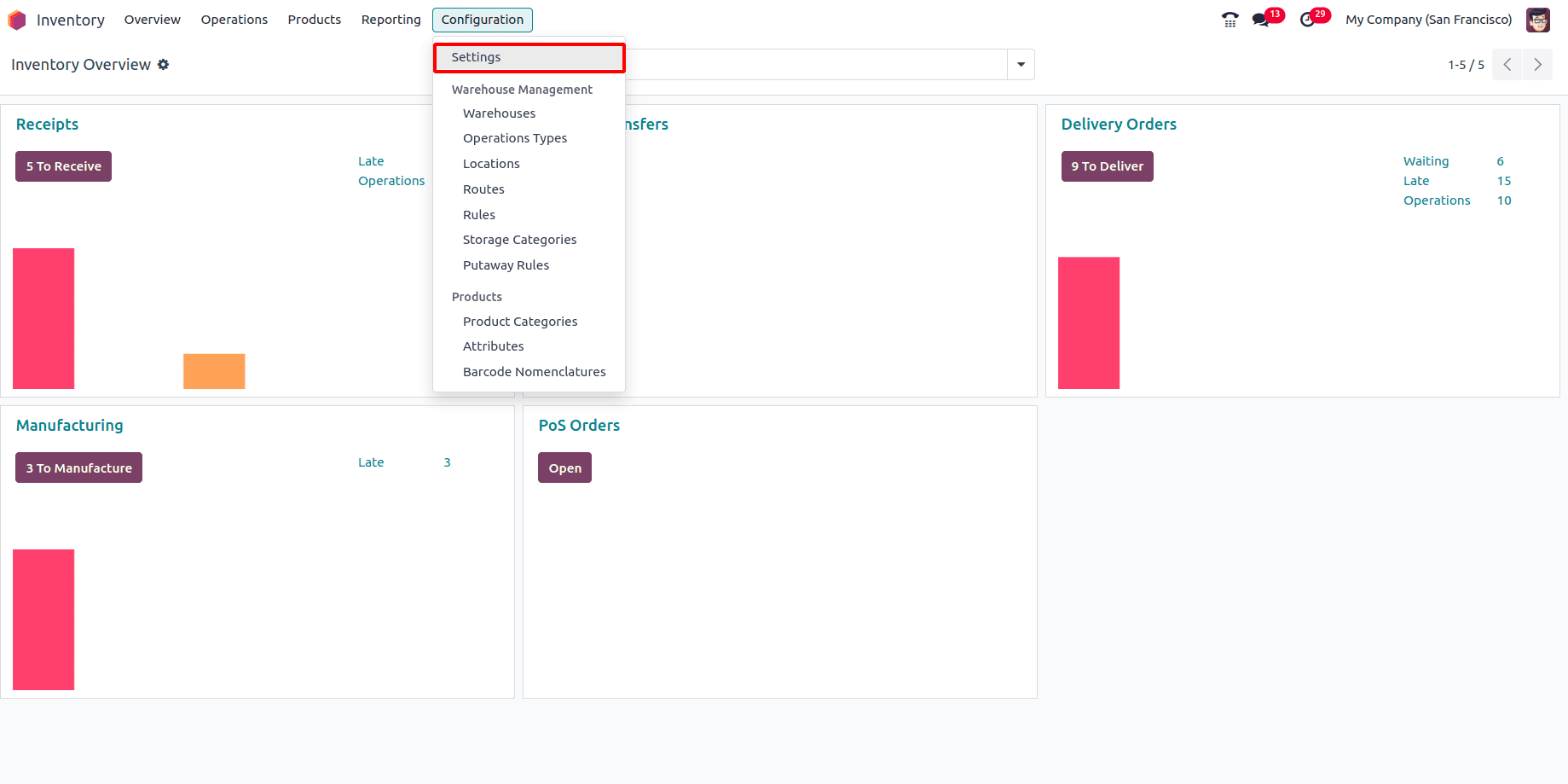

To begin tracking products with Lot or Serial Numbers, first, the Lot and Serial Number feature must be enabled from the Inventory module’s settings. Navigate to Inventory > Configuration > Settings.

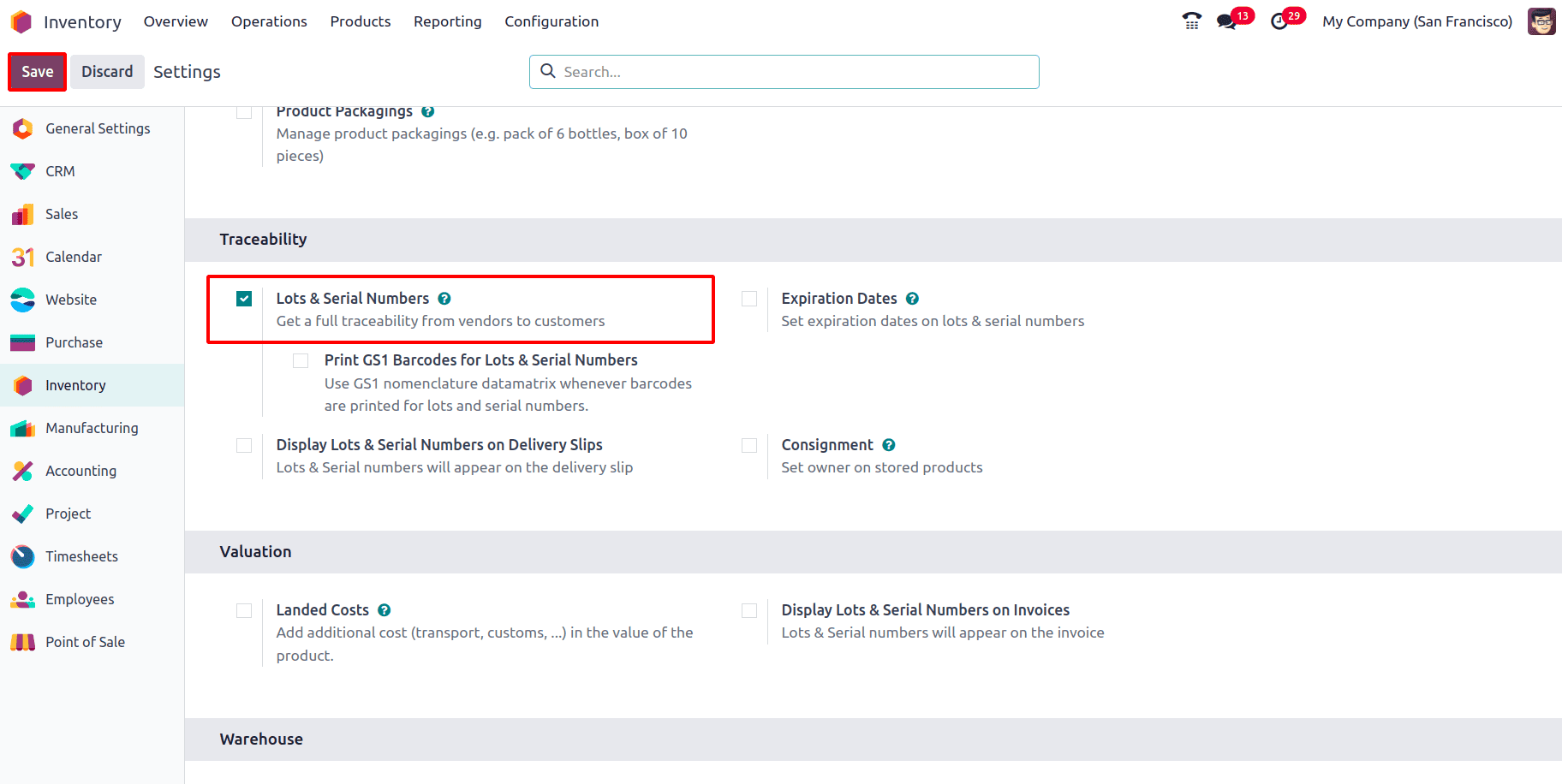

Scroll down to the Traceability section and enable the Lots & Serial Numbers option, then click on the Save button to apply the changes.

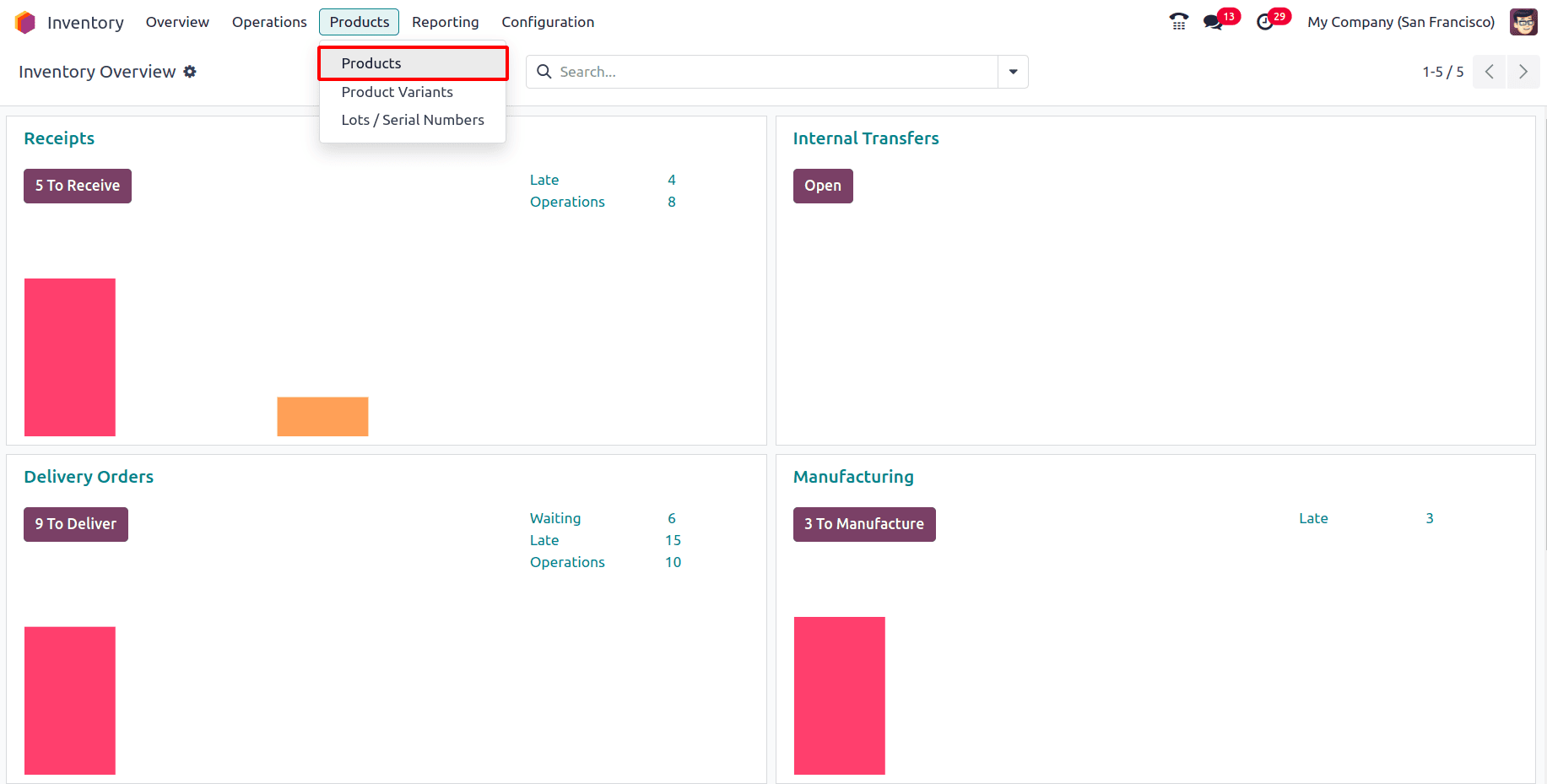

Once enabled, Odoo will provide the ability to assign lot numbers and serial numbers to products during stock operations. To track products with Lots and Serial numbers, it must be assigned to the product, so navigate to Inventory > Products > Products.

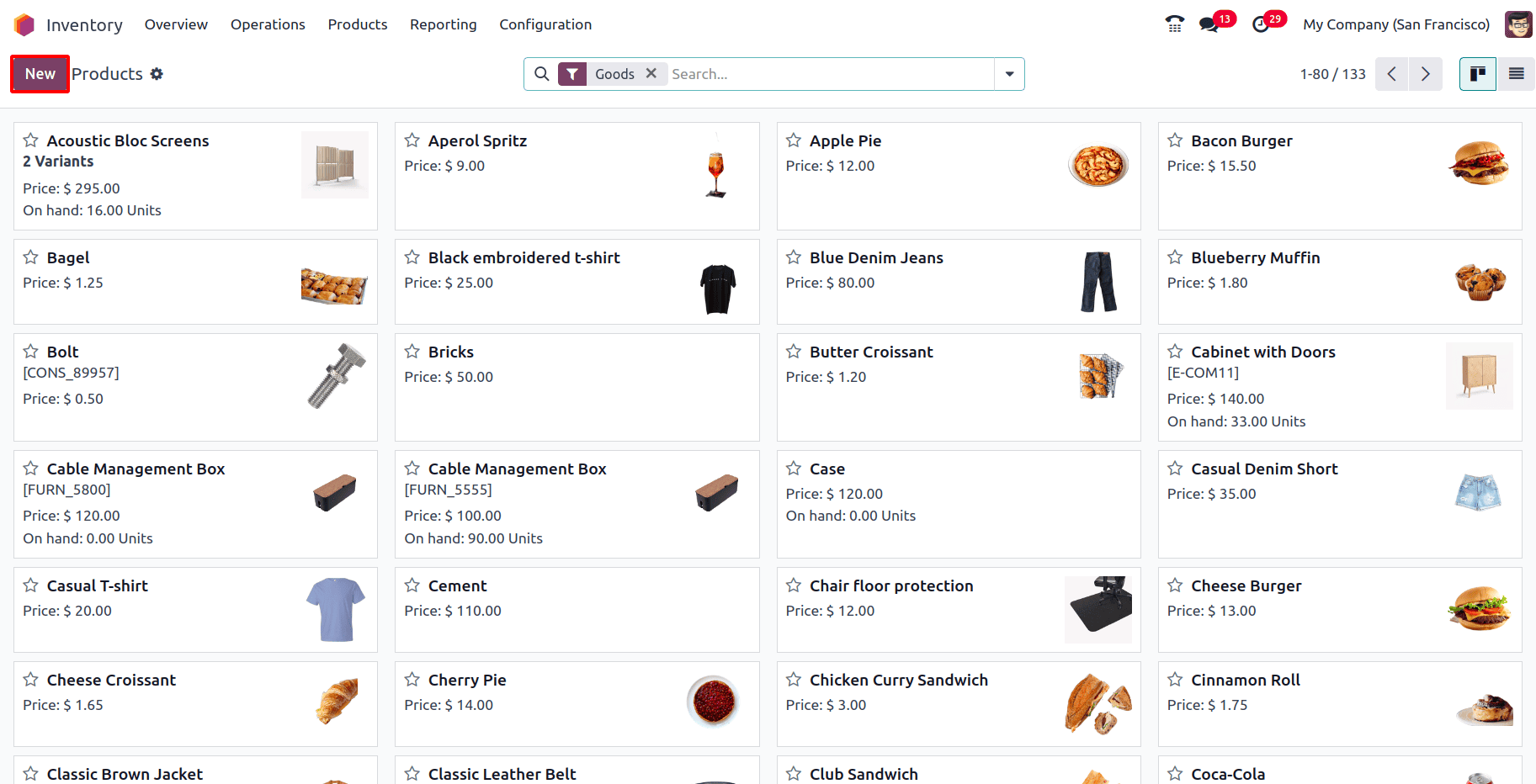

Select the product to be tracked or create a new one by clicking the New button.

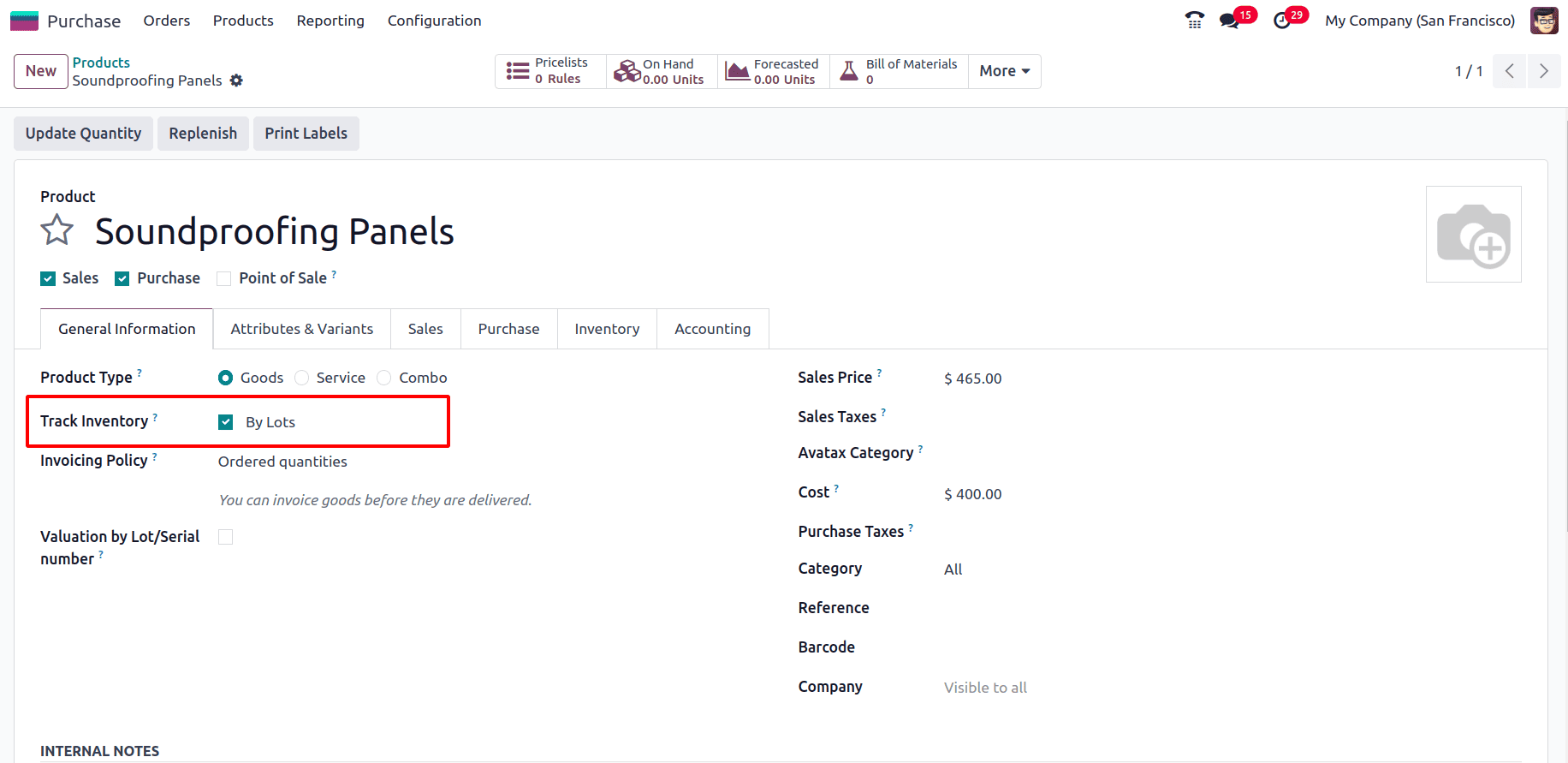

In the Product form, ensure the product type is set to Goods, and enable the Track Inventory option.

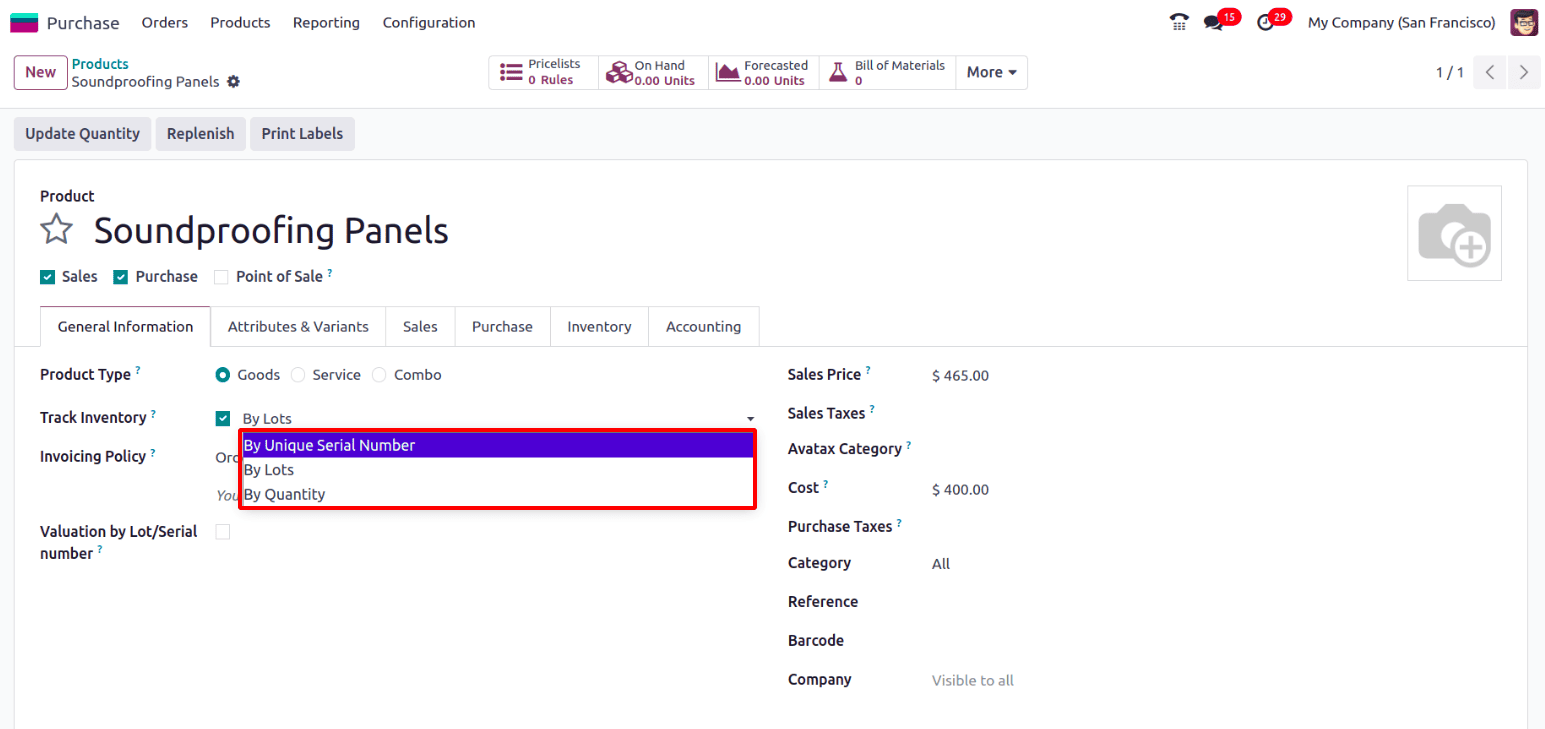

There are three different options for tracking the product inventory, which are: By Quantity, By Unique Serial Number, and By Lots.

In Odoo 18, to update the quantity of the products, the Track Inventory option must be enabled. The "By Quantity" option enables tracking inventory by quantity. It helps to monitor and manage stock levels based on available units without assigning lot or serial numbers. Tracking By Lots is useful when managing products in batches or groups, especially for items with expiration dates, and when it's important to track the movement and status of each lot individually. Lot tracking is crucial for monitoring the expiration date of each batch, ensuring products are sold or used before expiration, and enabling traceability for products that may need to be recalled. This feature is particularly beneficial for industries such as pharmaceuticals, food items, and others where products must be used within a specified expiration period.

Tracking products By Serial Numbers provides enhanced traceability. Unlike lot tracking, where multiple items share the same lot number, serial number tracking assigns a unique identifier to each individual unit, and it can be used for products that require post-sales services like electronics.

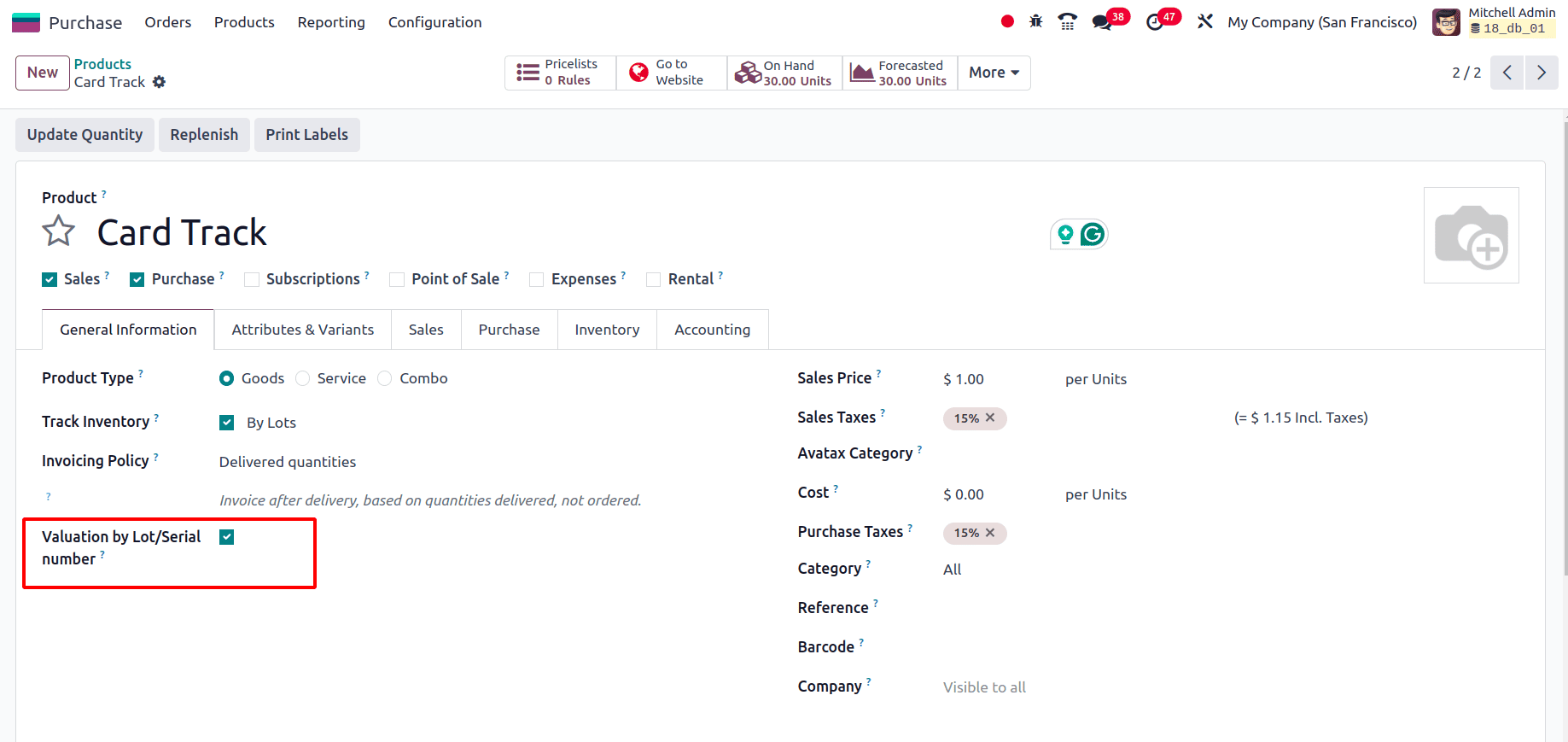

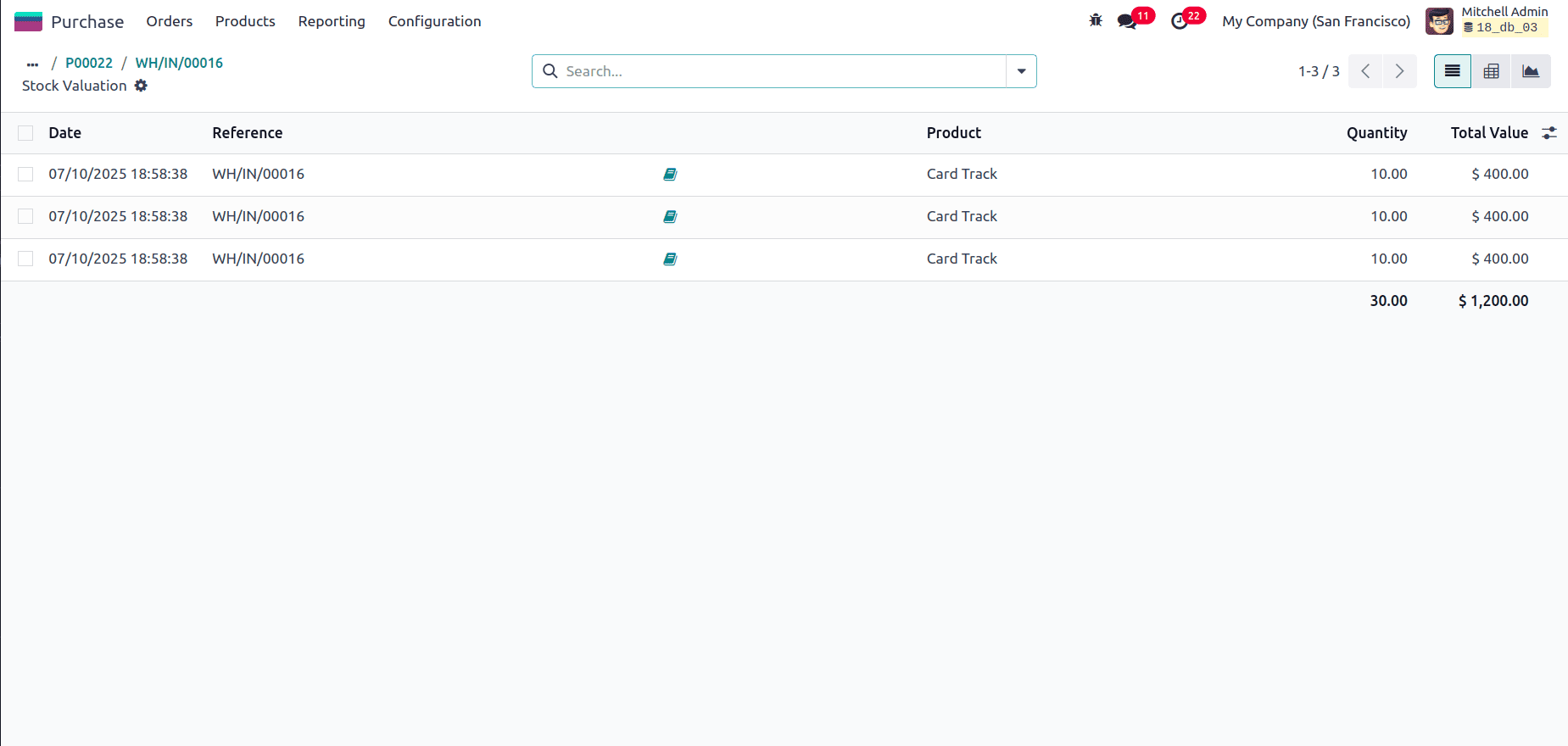

Valuation by Lots/ Serial Number

When tracking has been enabled and Lots or Serial numbers have been selected for tracking, an additional field called 'Valuation by Lots/Serial Number' is added. When this is enabled, each lot or serial number of the same product will have a separate valuation. That is, when 30 units of a product are purchased, and for each 10 units, different lot numbers are assigned, there will be different valuations for each lot. For example, consider a product, and enable Valuation by Lot/Serial number.

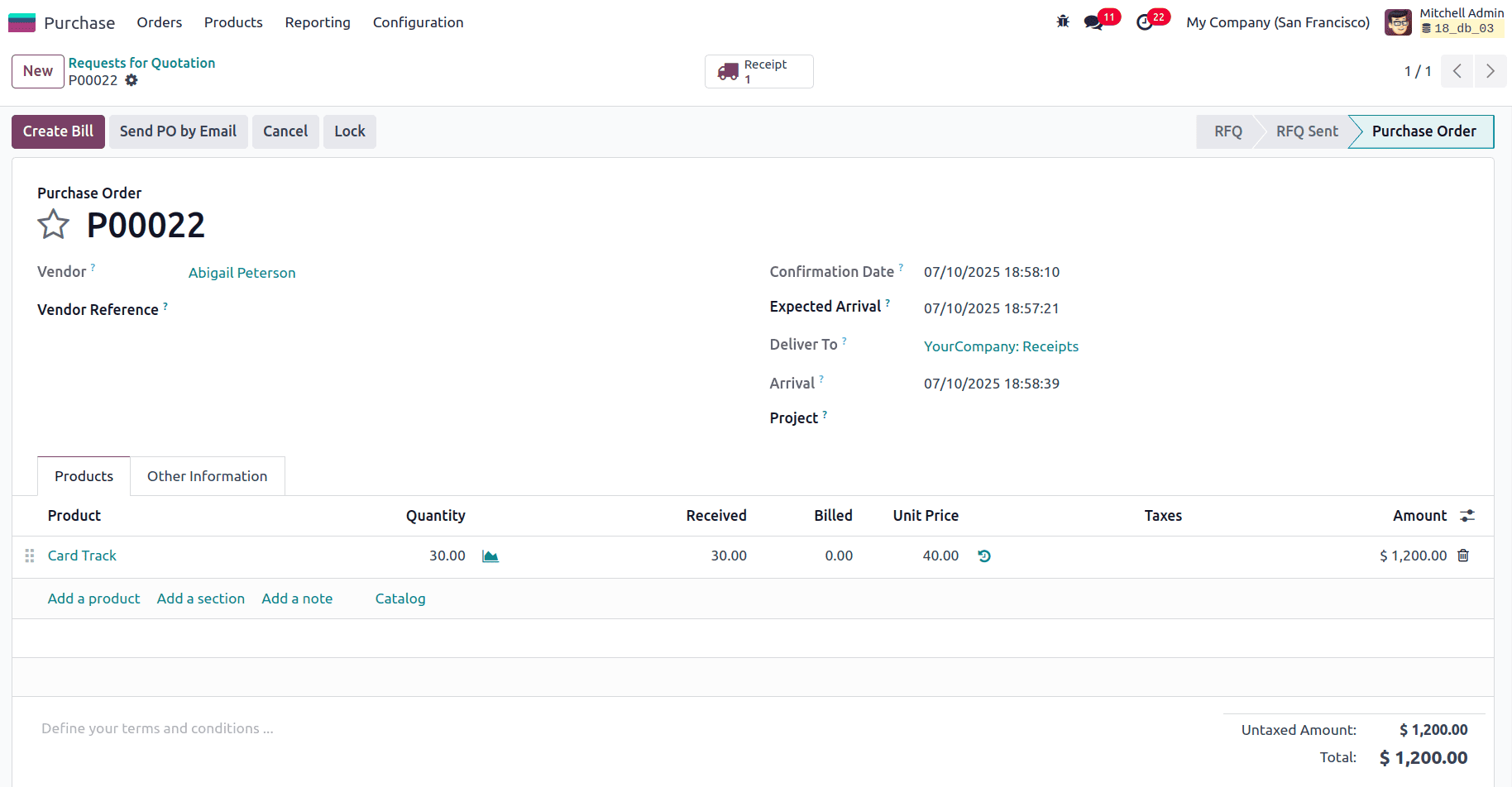

Create a request for a quotation and confirm it. Then receive the products.

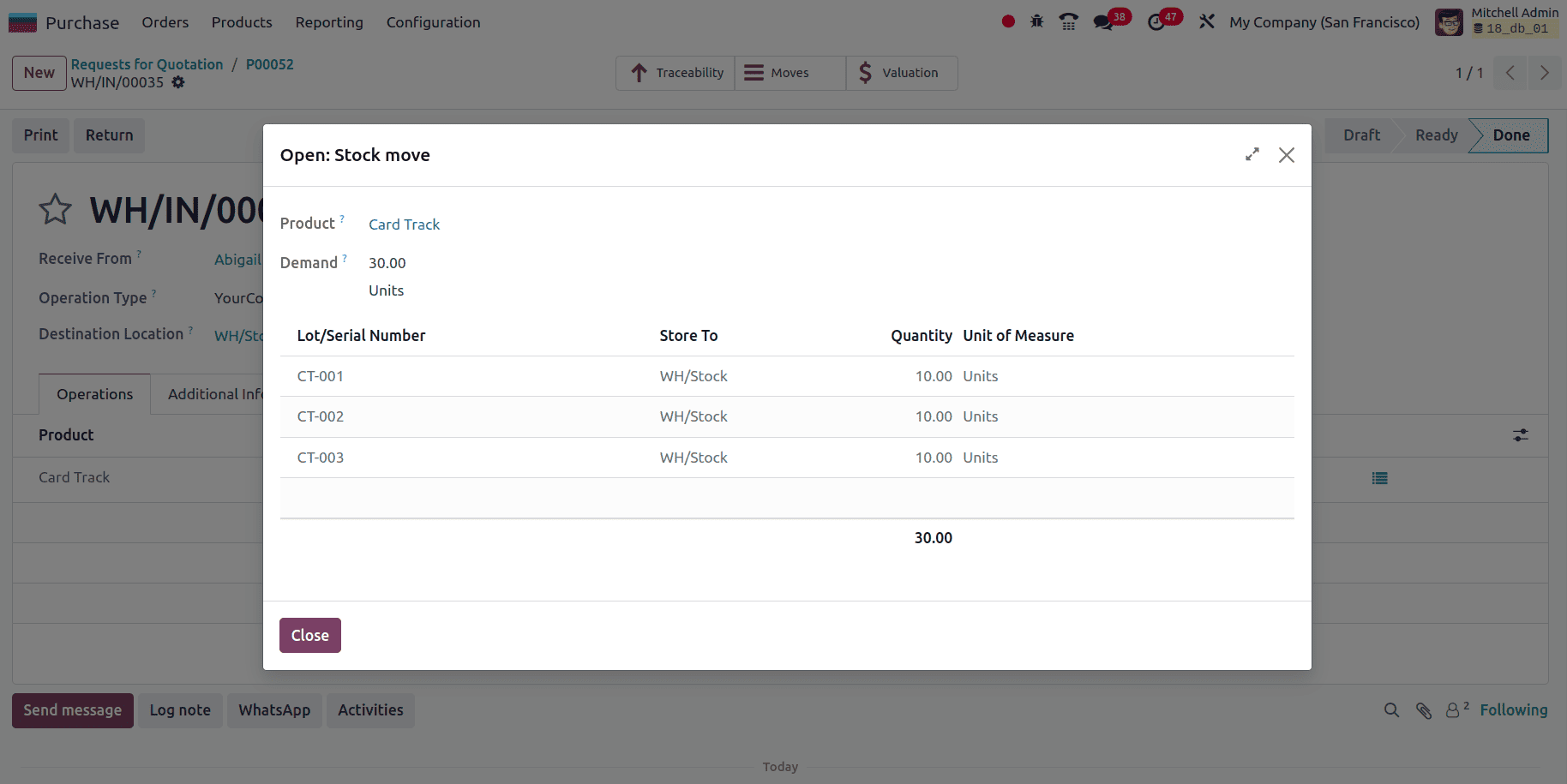

While receiving the product, add the lot number for the product.

So, for each lot number that has been provided for the product ‘Card Track’, there will be separate valuations. Here in the screenshot below, the valuations for the different lots can be viewed since ‘Valuation by Lots’ has been enabled.

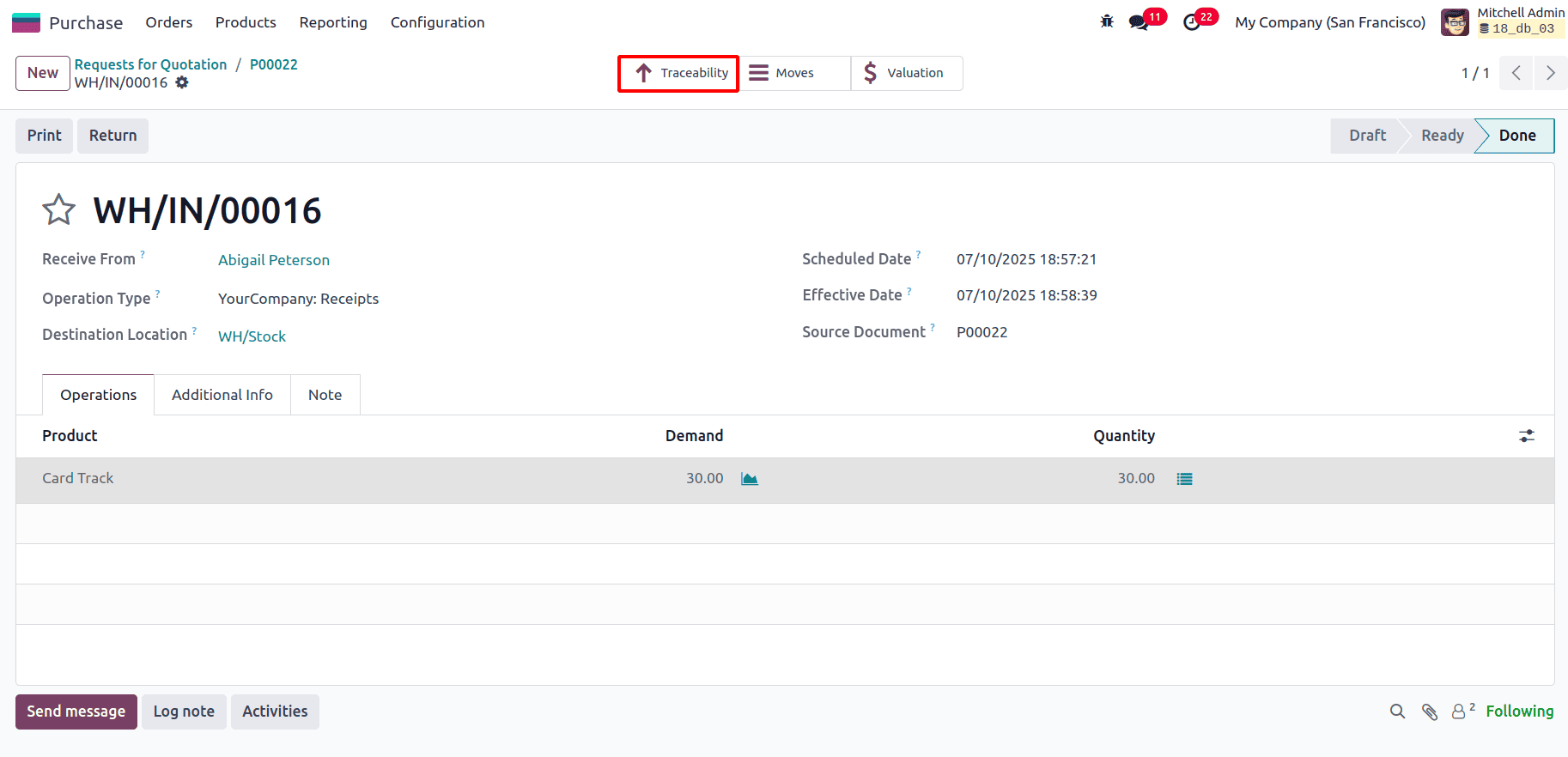

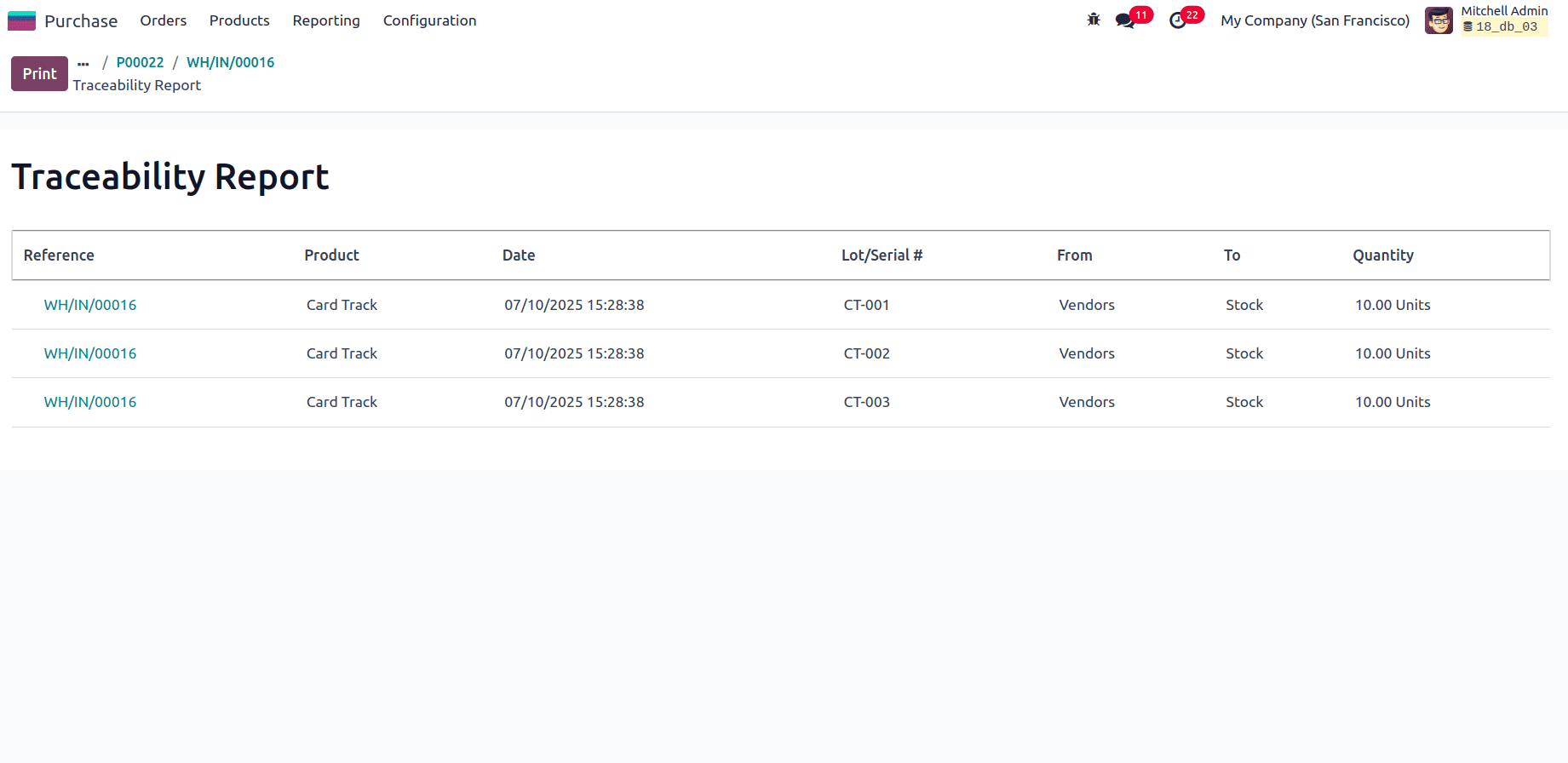

Also, the traceability report of the product can be viewed by clicking on the ‘Traceability’ smart tab.

Here, it can be seen that the products can be easily tracked by this report.

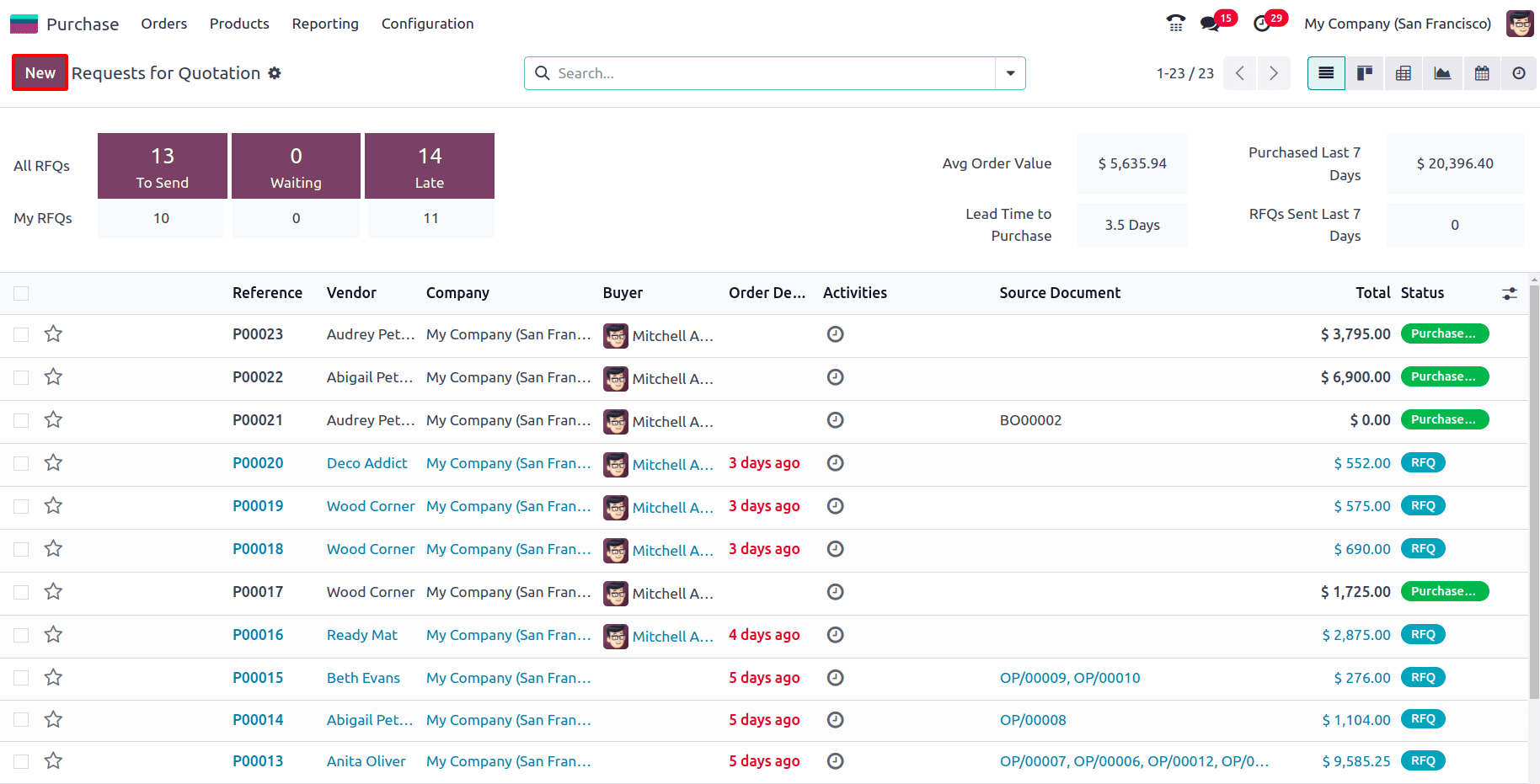

Now, for the product ‘Soundproofing Panel’, select the Track Inventory By Lots, and create a Purchase Order for the Product. To do this, navigate to Purchase Module > Request for Quotation and click the New button to create a new purchase order.

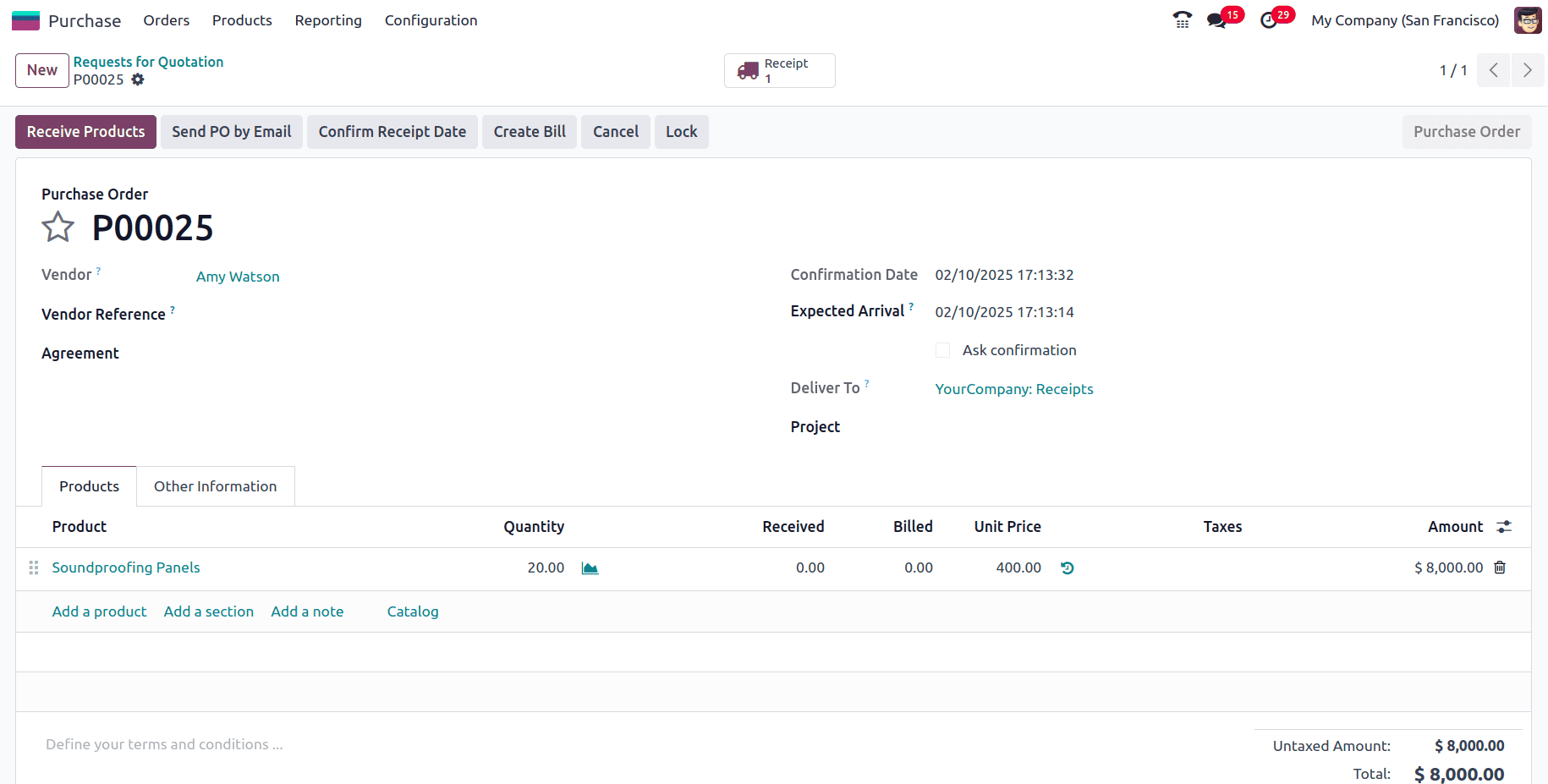

Add the customer and other required details, then add the product and give its quantity as 20. Then click on the Confirm button.

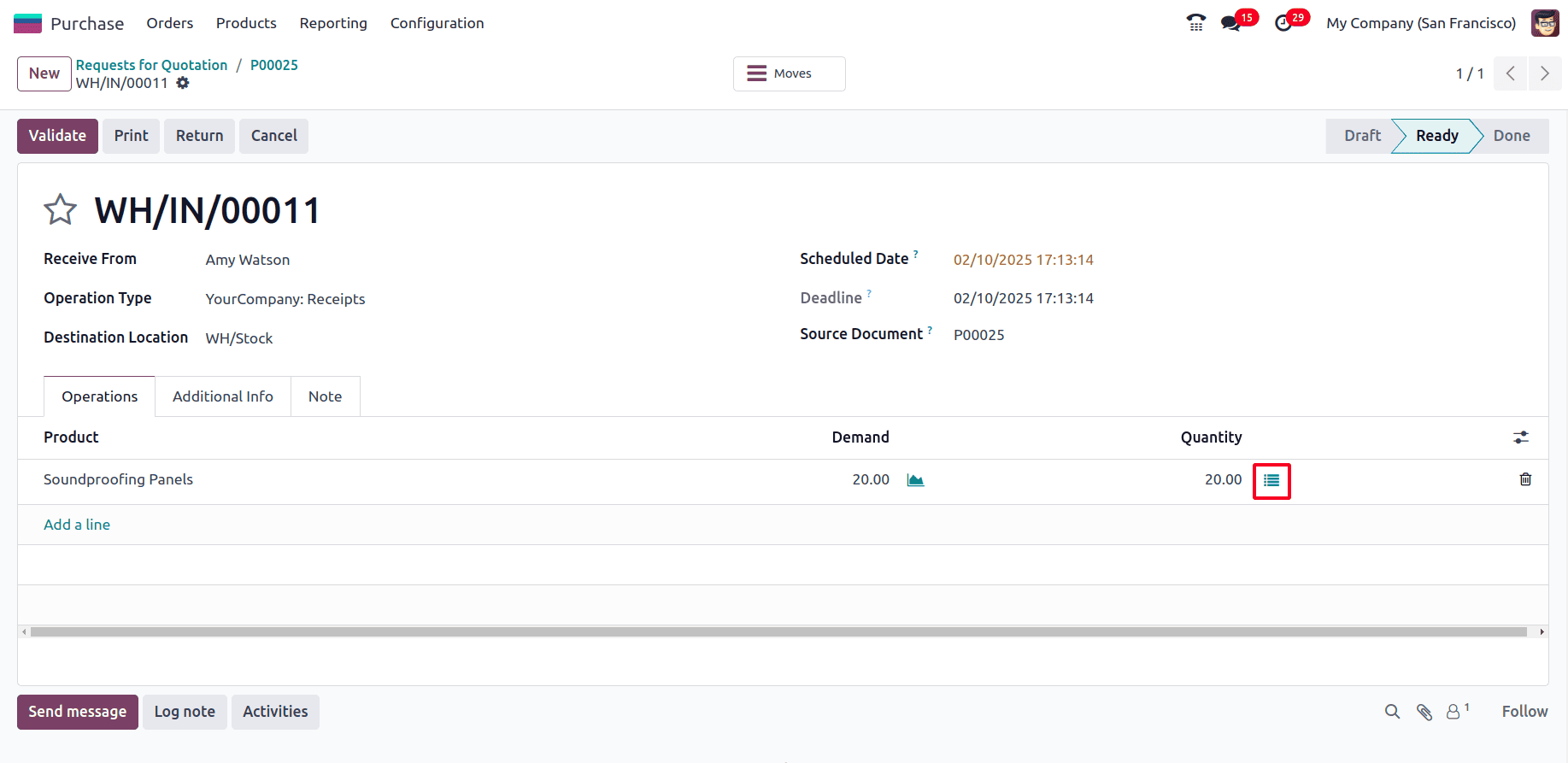

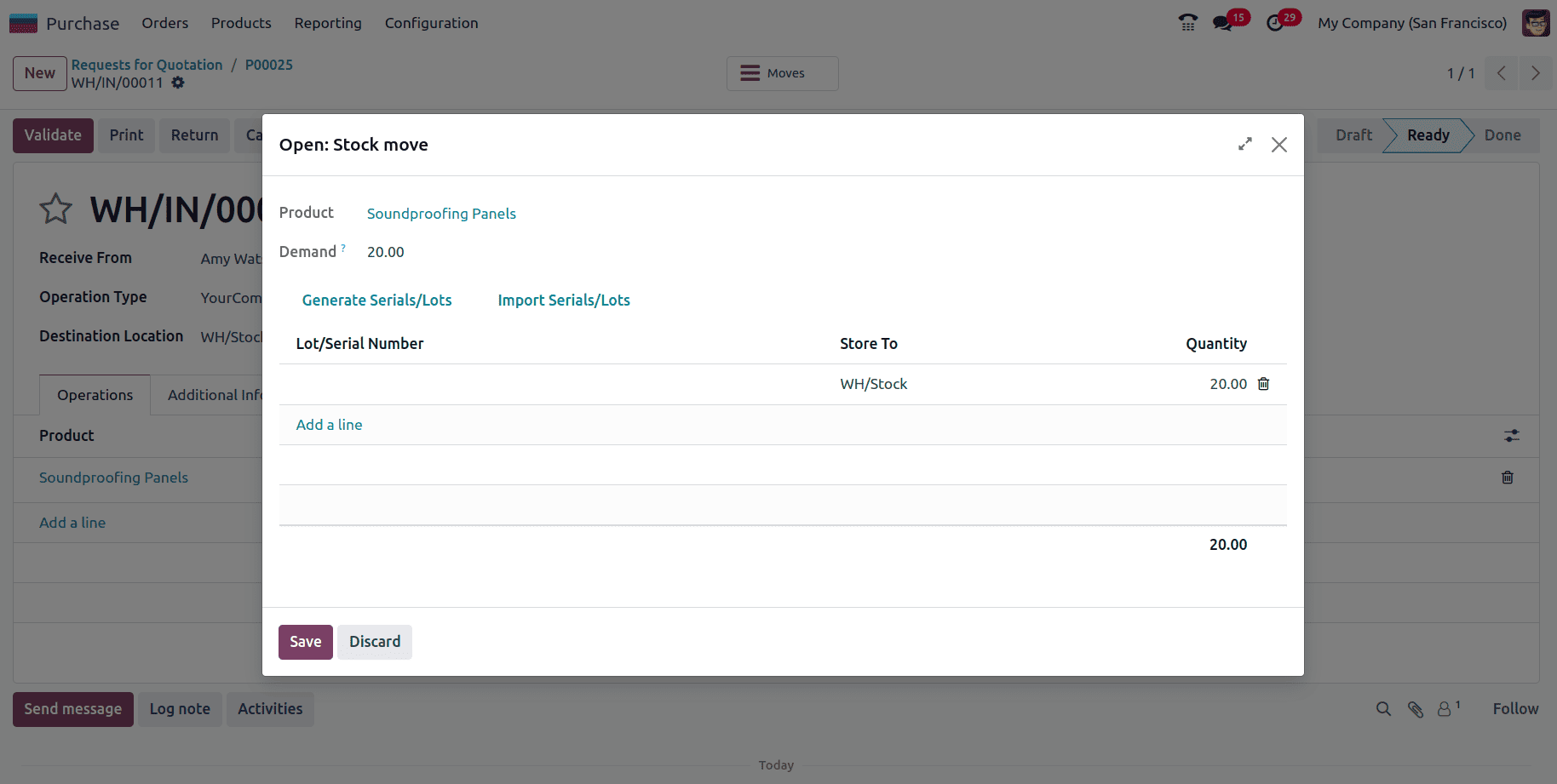

Next, click on Receive Products and we will be directed to a new page where the products can be received. Before validating the receipt, the lot number must be added to the product by clicking on the icon marked in the screenshot below.

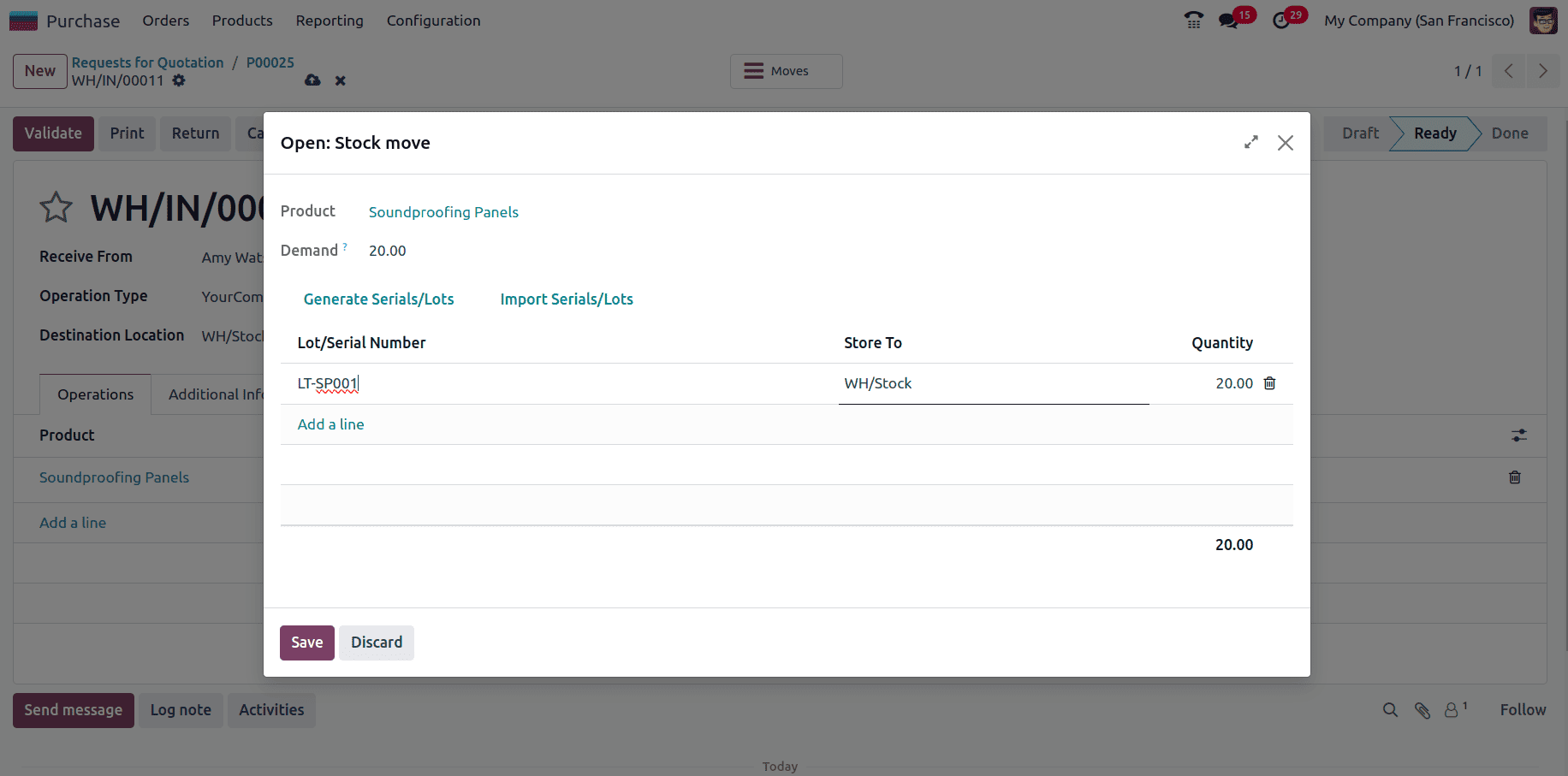

A wizard appears where the Lot/Serial Number can be added to the product.

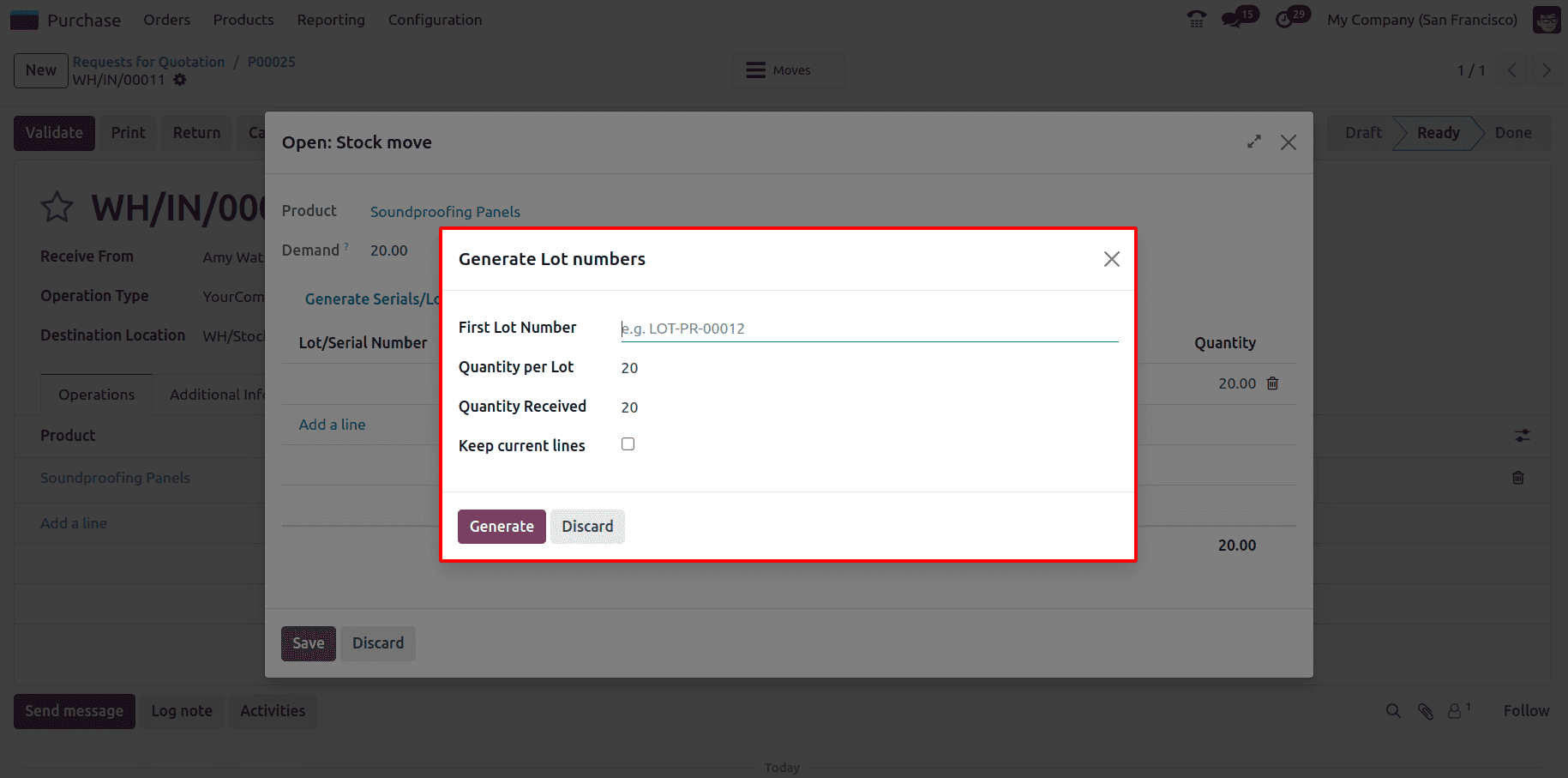

Either the Lot/Serial Number can be generated by providing the First Lot Number and specifying the quantity per Lot that has to be assigned.

Once the Lot Number has been given for the batch of products, click on the Save button.

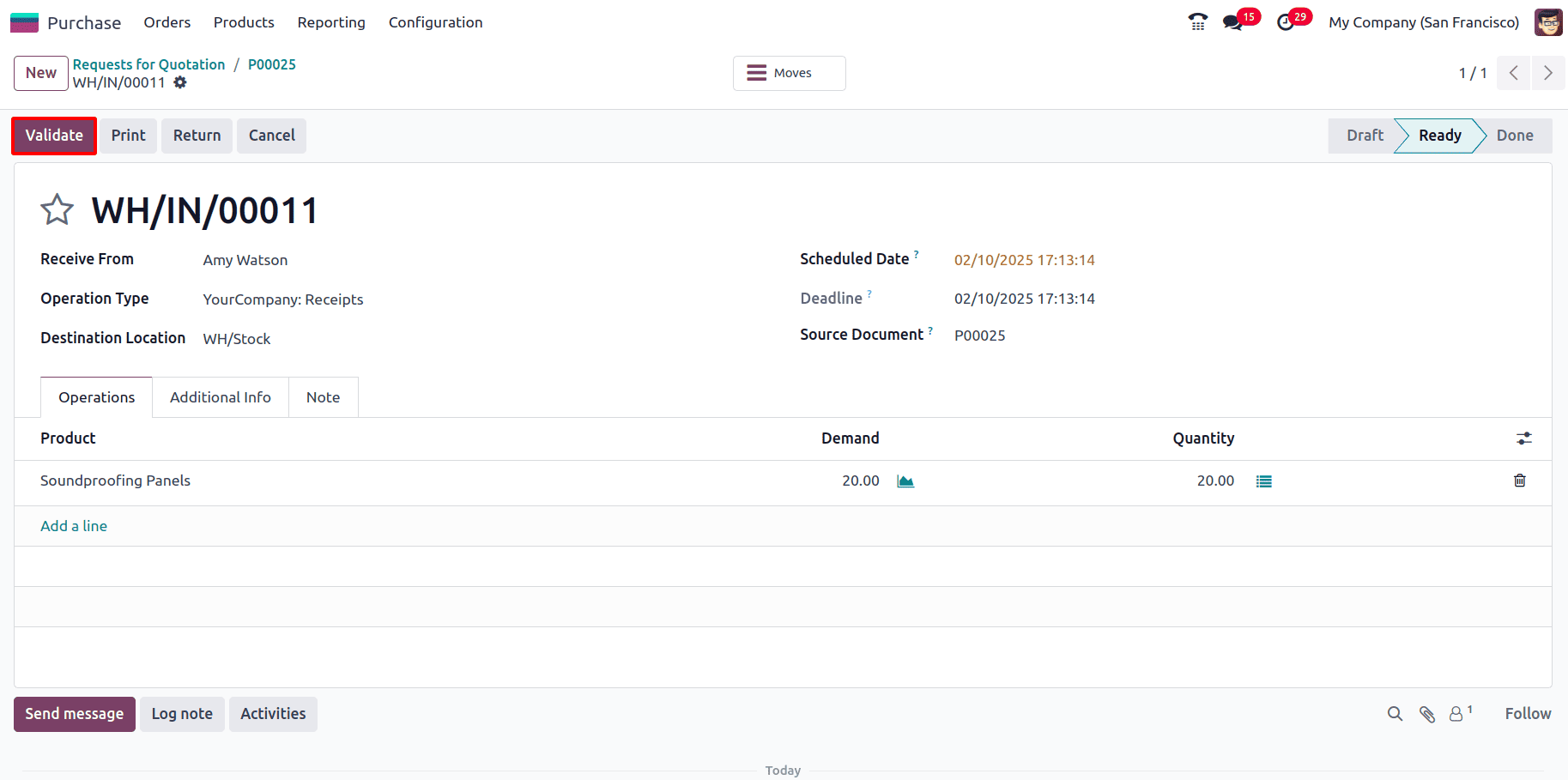

Here, all the 20 quantities purchased belong to this lot ‘LT-SP001’. Now, the receipt of the products can be validated by clicking the Validate button.

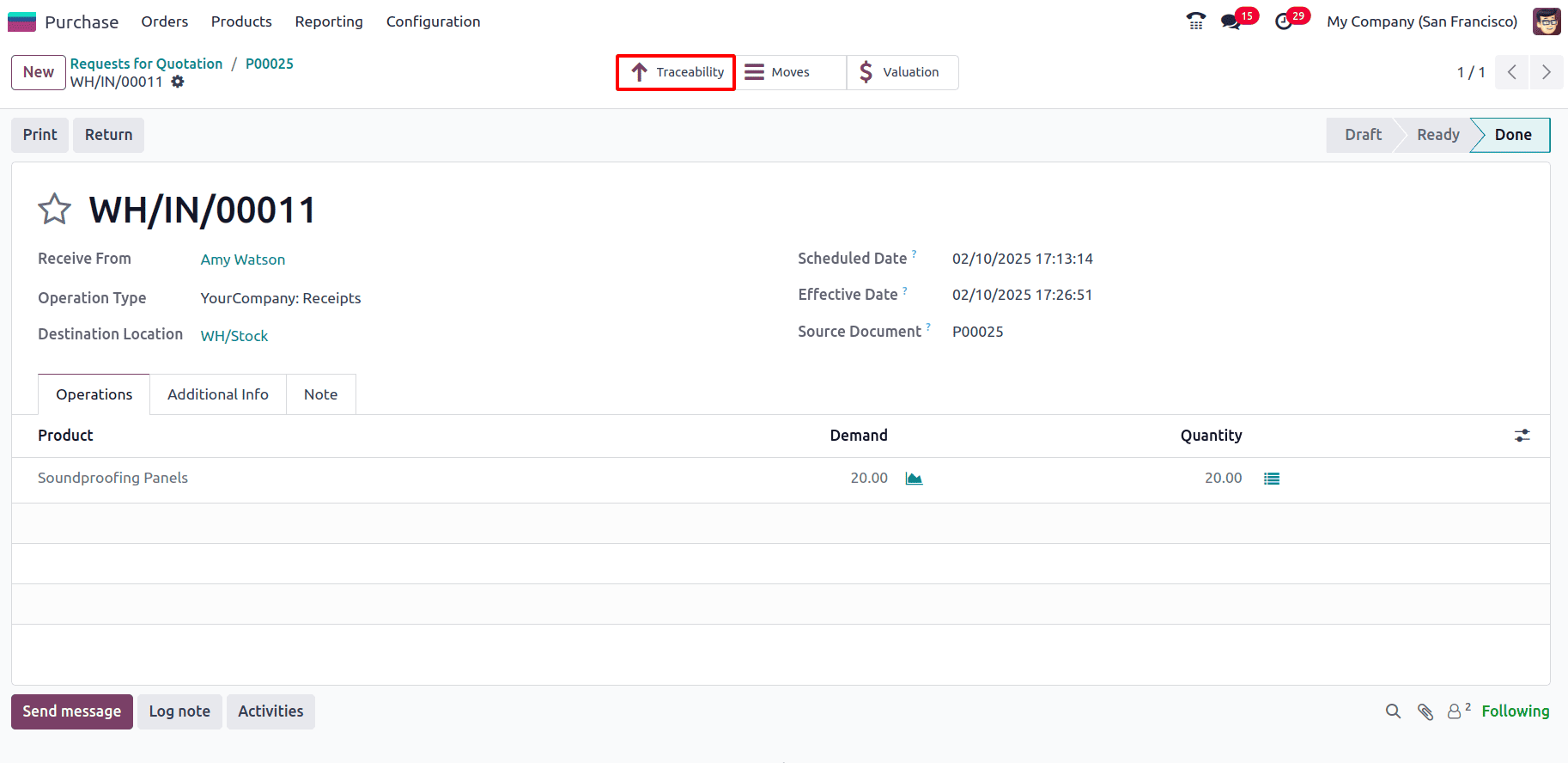

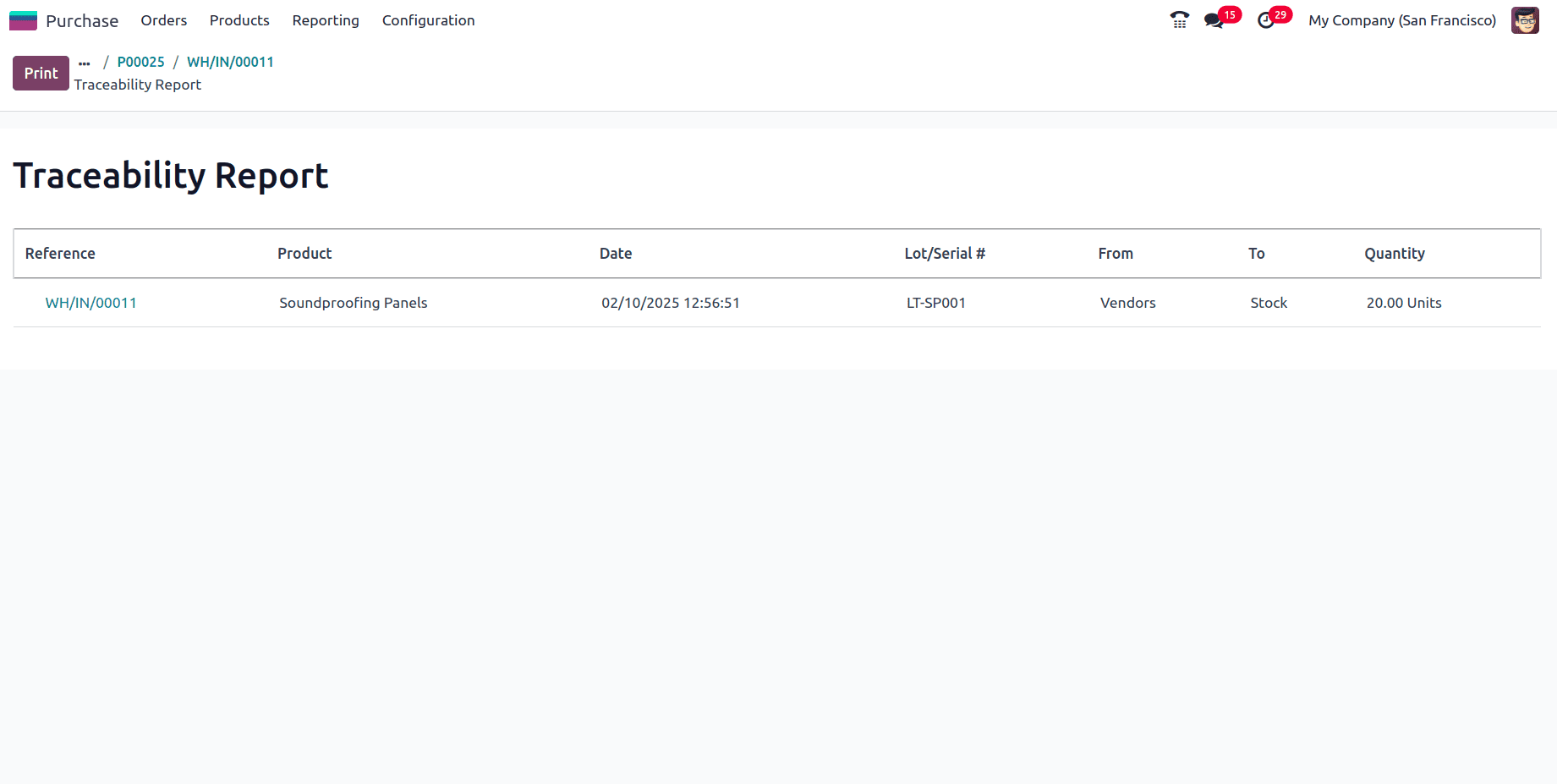

Once the receipt has been validated, the Traceability smart tab appears at the top, which shows the Traceability Report of the purchased products.

The Traceability Report provides a detailed record of the movement of products tracked by Lots or Serial Numbers. It allows the monitoring of the origin, movement, and destination of specific products.

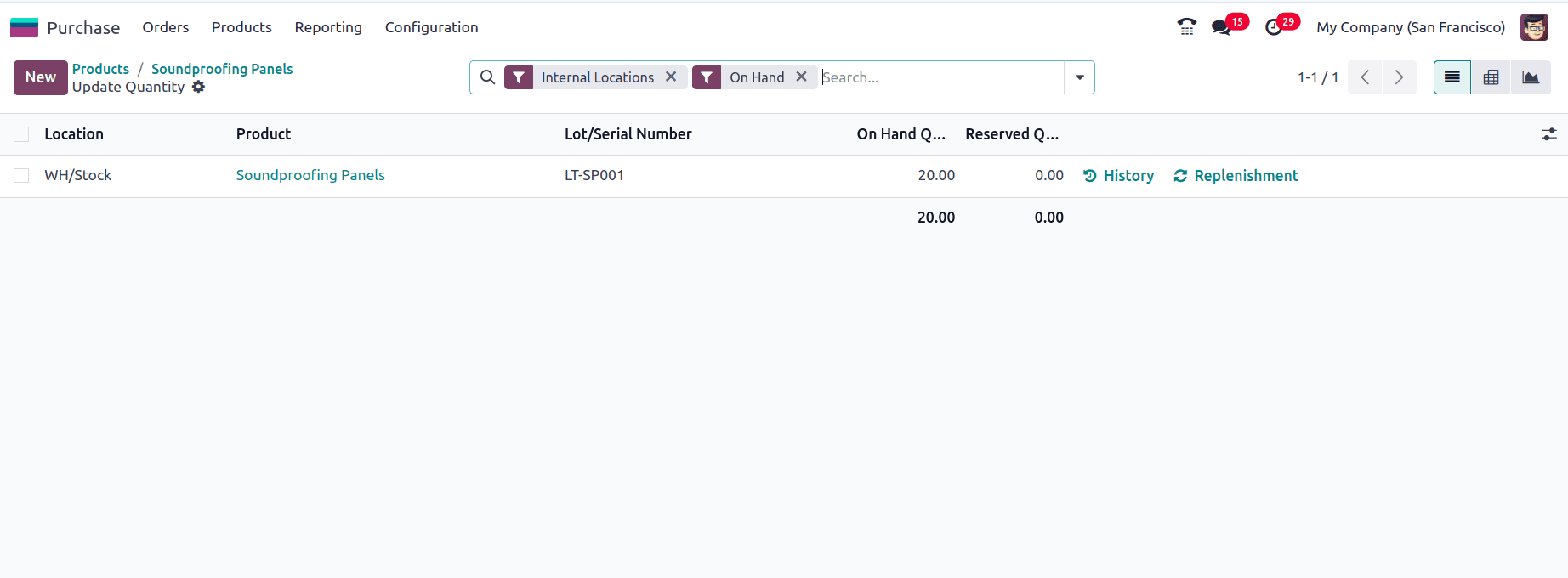

Now, in the product form, when the stock of the product is viewed, the lot to which the product belongs can also be viewed from there.

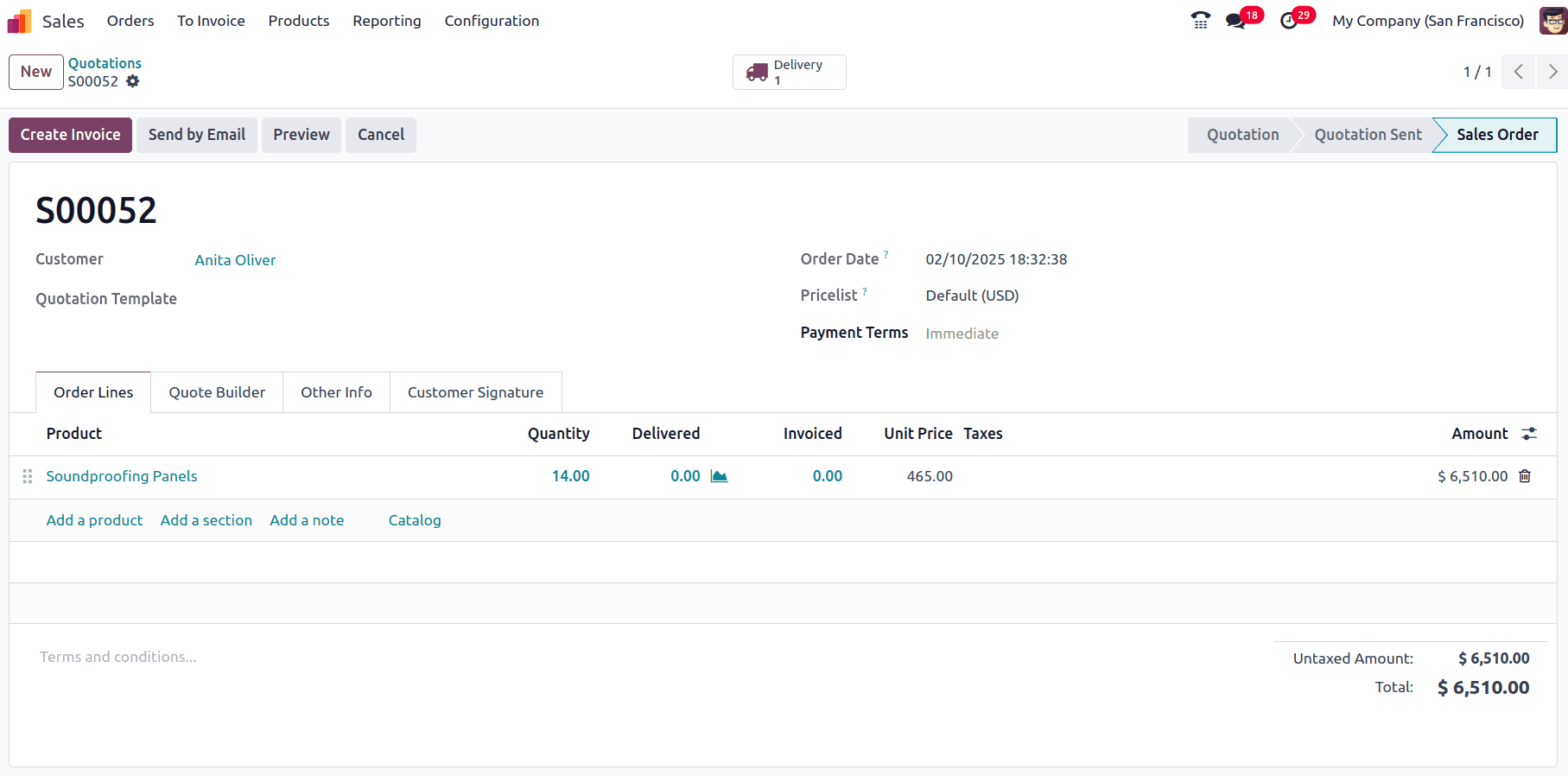

Now create a sale order for the product, for that navigate to the Sales module > Quotations > New and add the customer details and the product, then confirm the sale order.

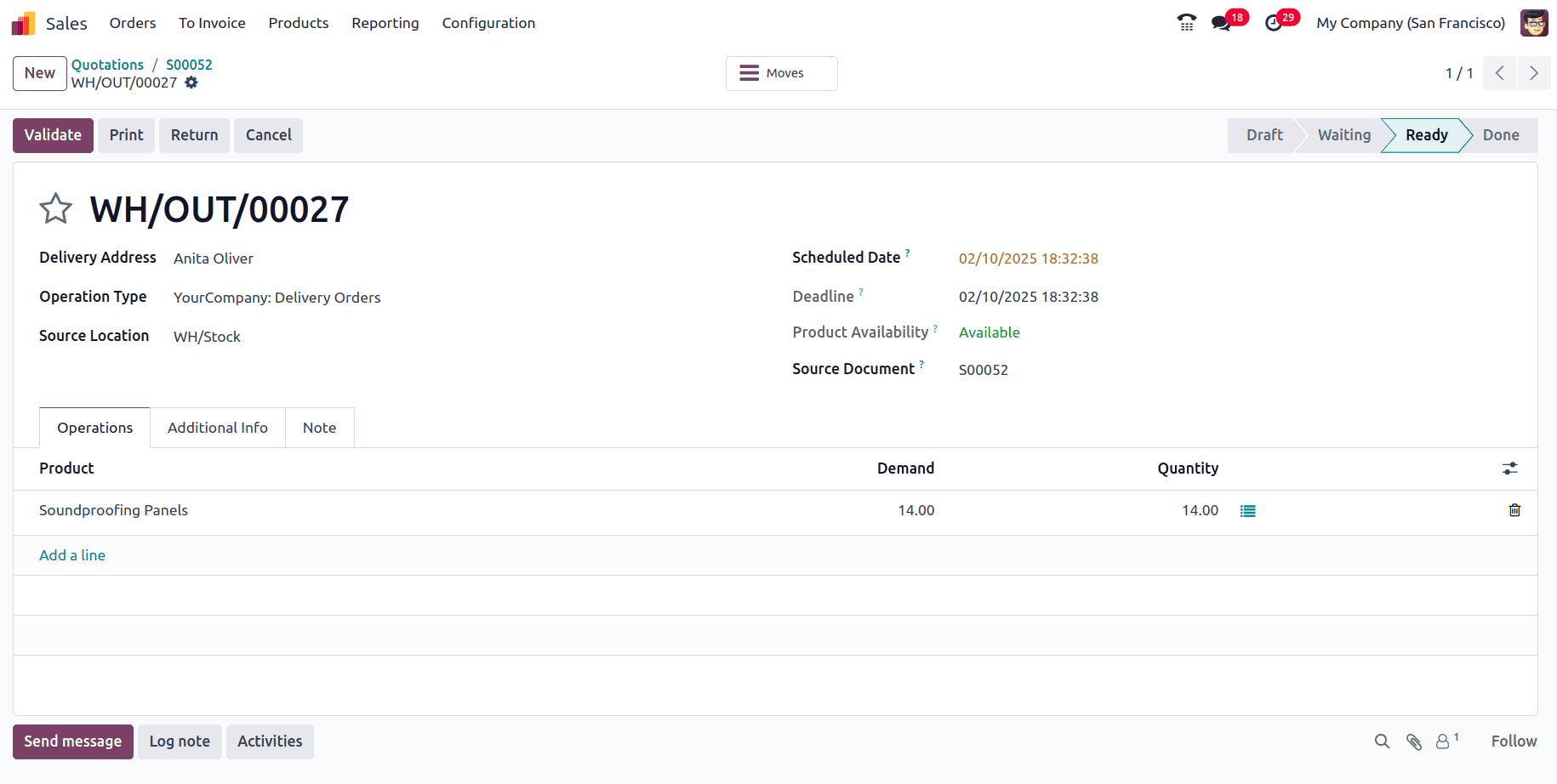

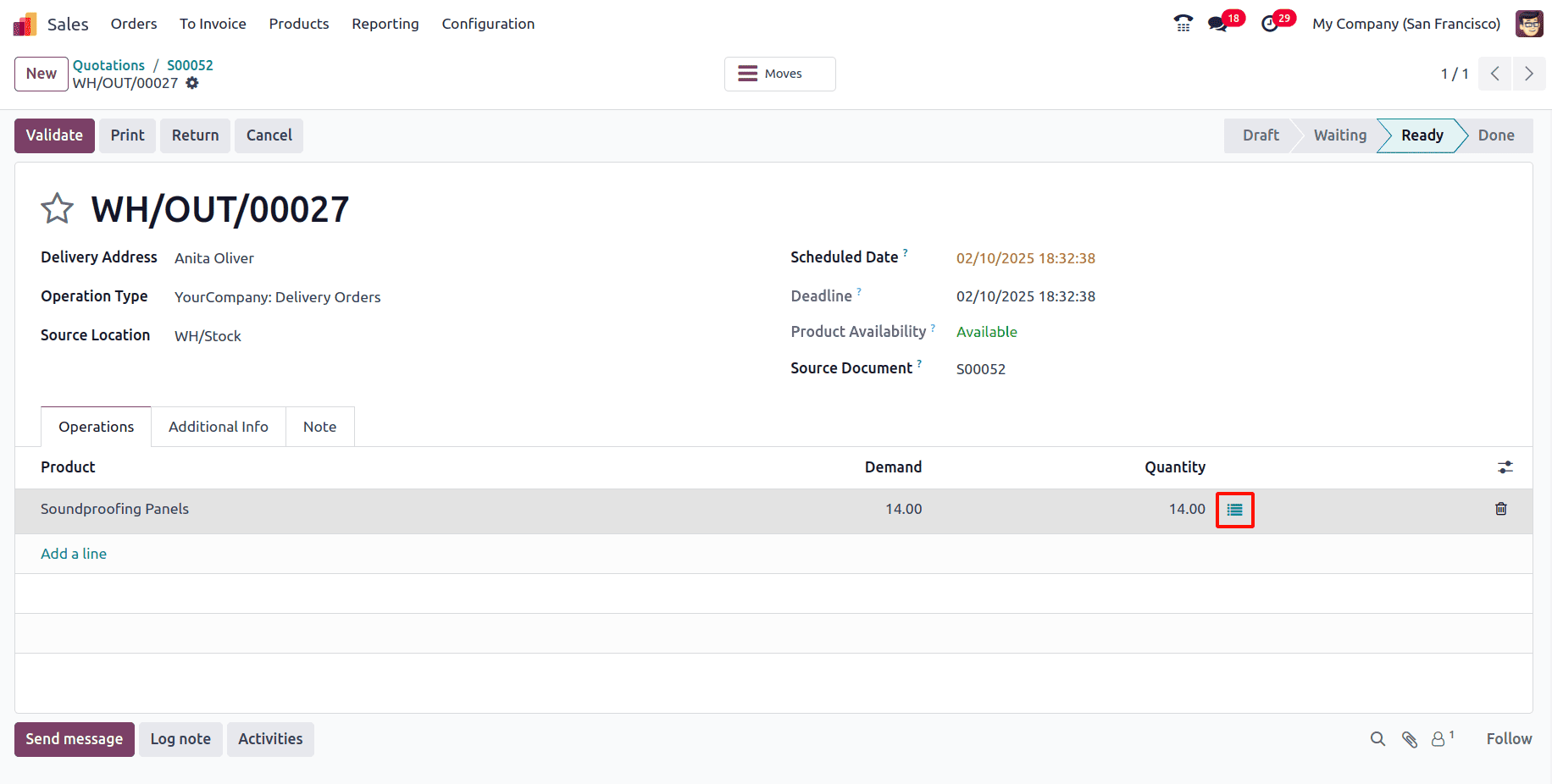

To create the invoice for the product, click on the Create Invoice, and to deliver the product, click on the Delivery smart tab. And the delivery window appears.

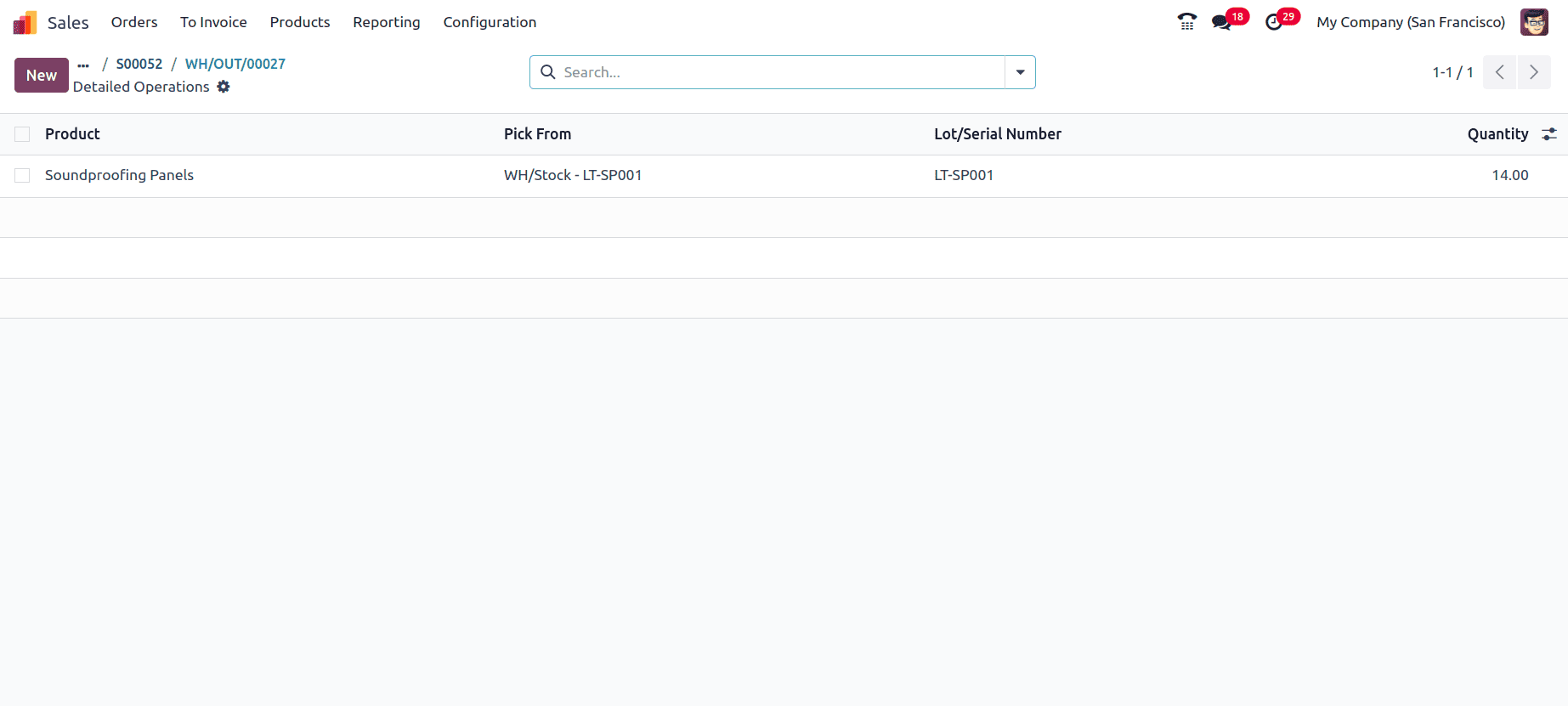

In the Moves smart tab, the movement of the product from the stock can be seen. It will specify which lot the products are taken from.

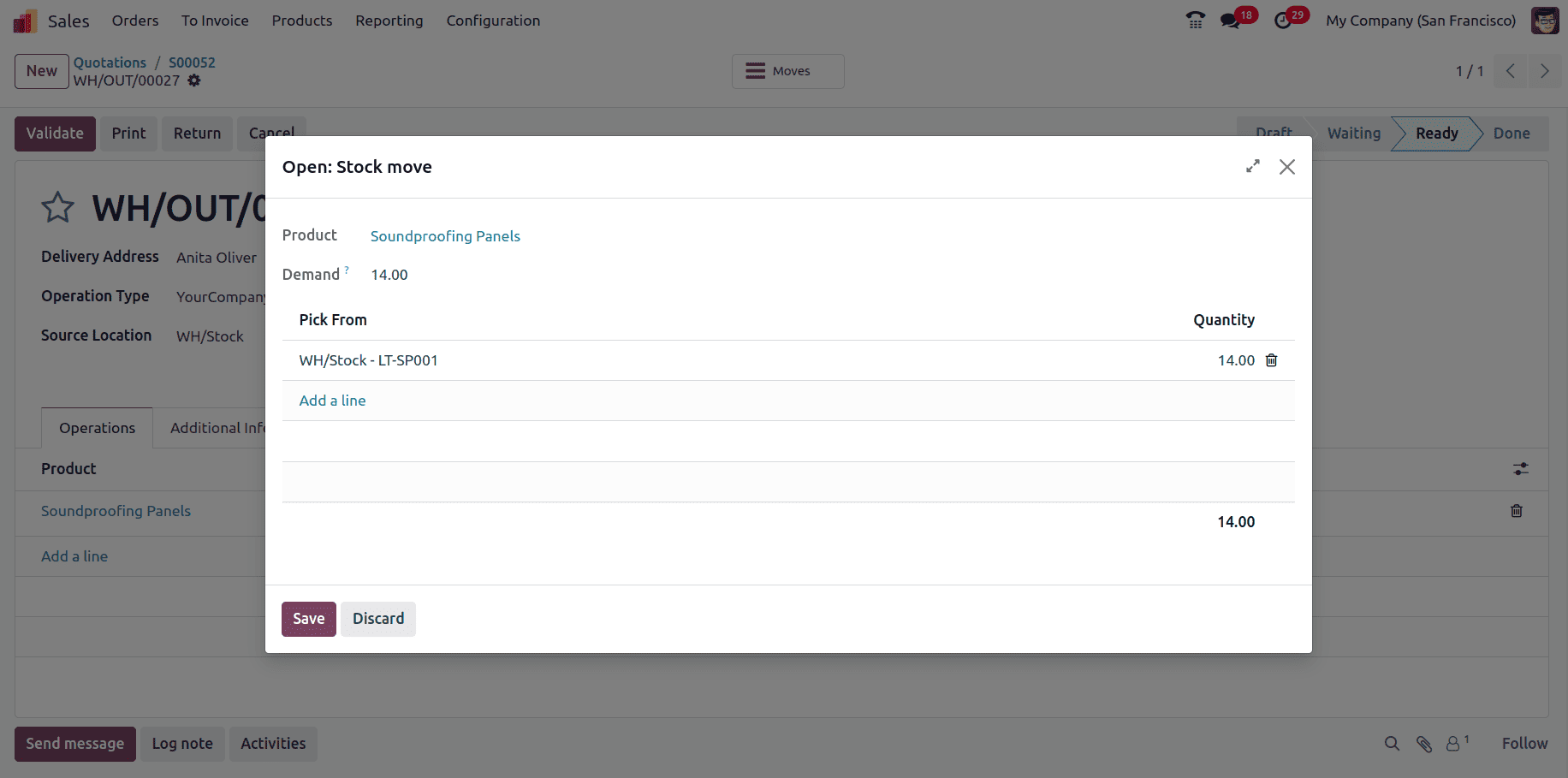

If the product needs to be taken from another lot, go back to the delivery window and click on the icon below.

If there are additional lots, click 'Add a line' and enter the required details for each lot.

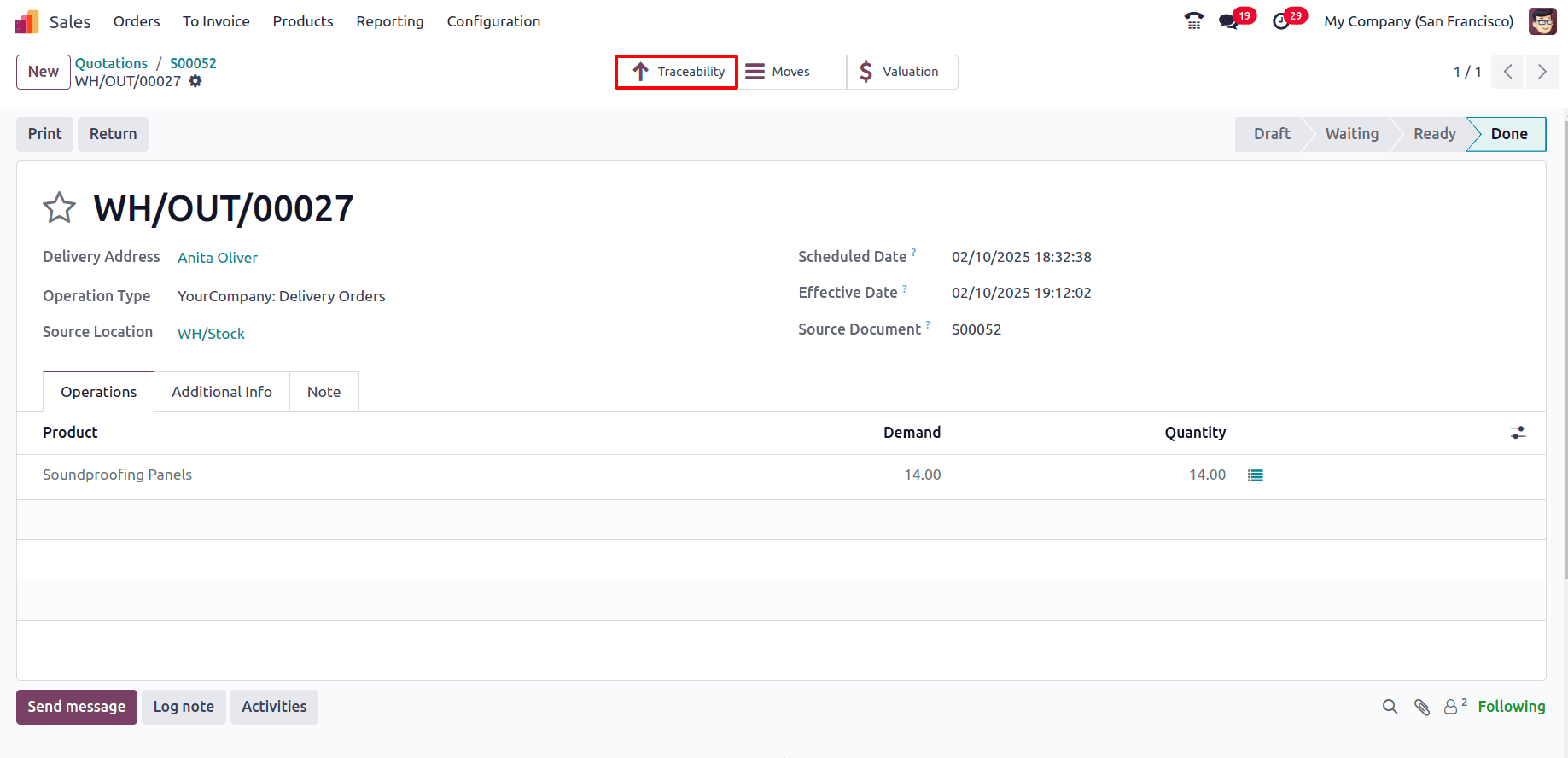

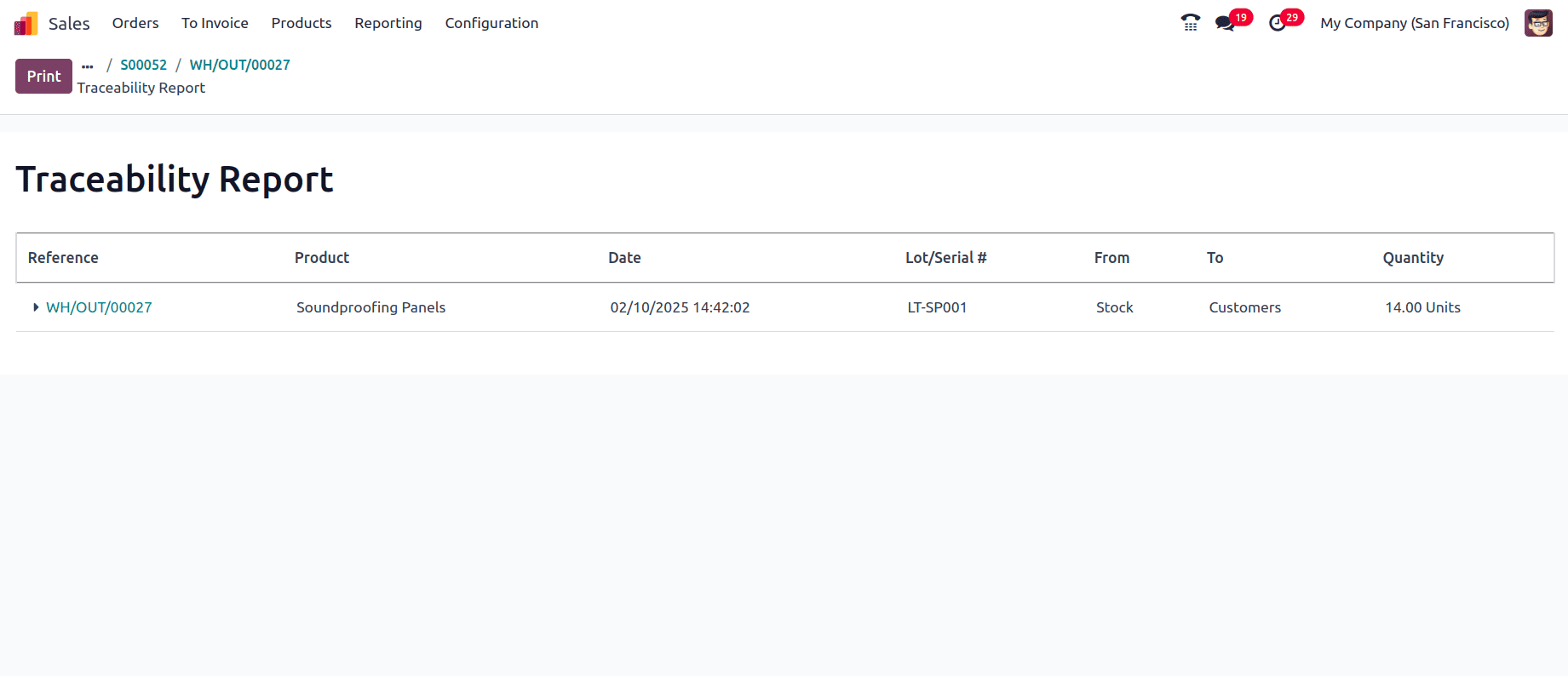

Now, validate the delivery, and the Traceability smart tab appears, with which the tracing of the product is possible.

In the Traceability Report, the lot from which the products are taken for Sale can be viewed.

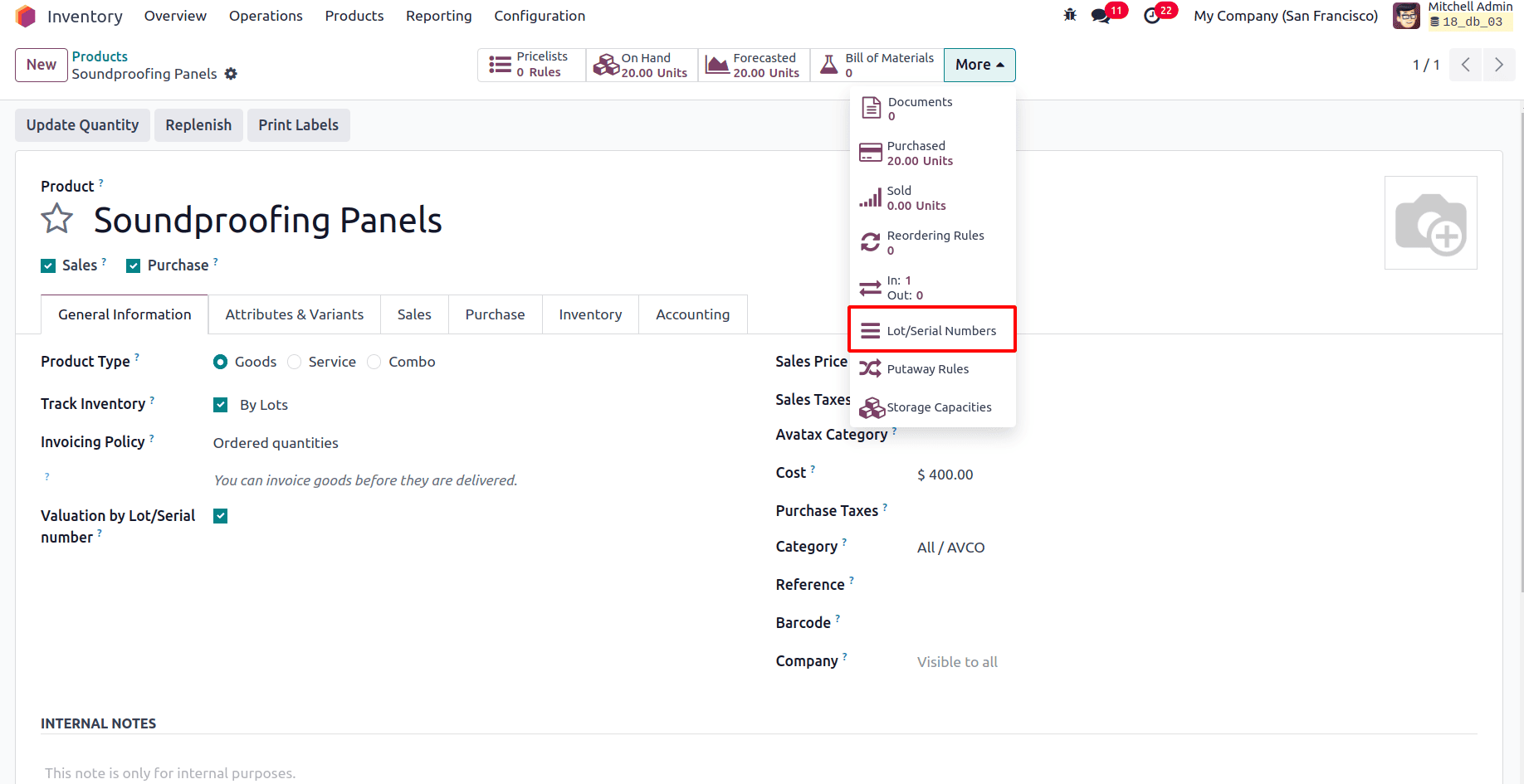

Additionally, the Lot/Serial Number of the product can be viewed from the product’s smart tab, under Lot/Serial Numbers.

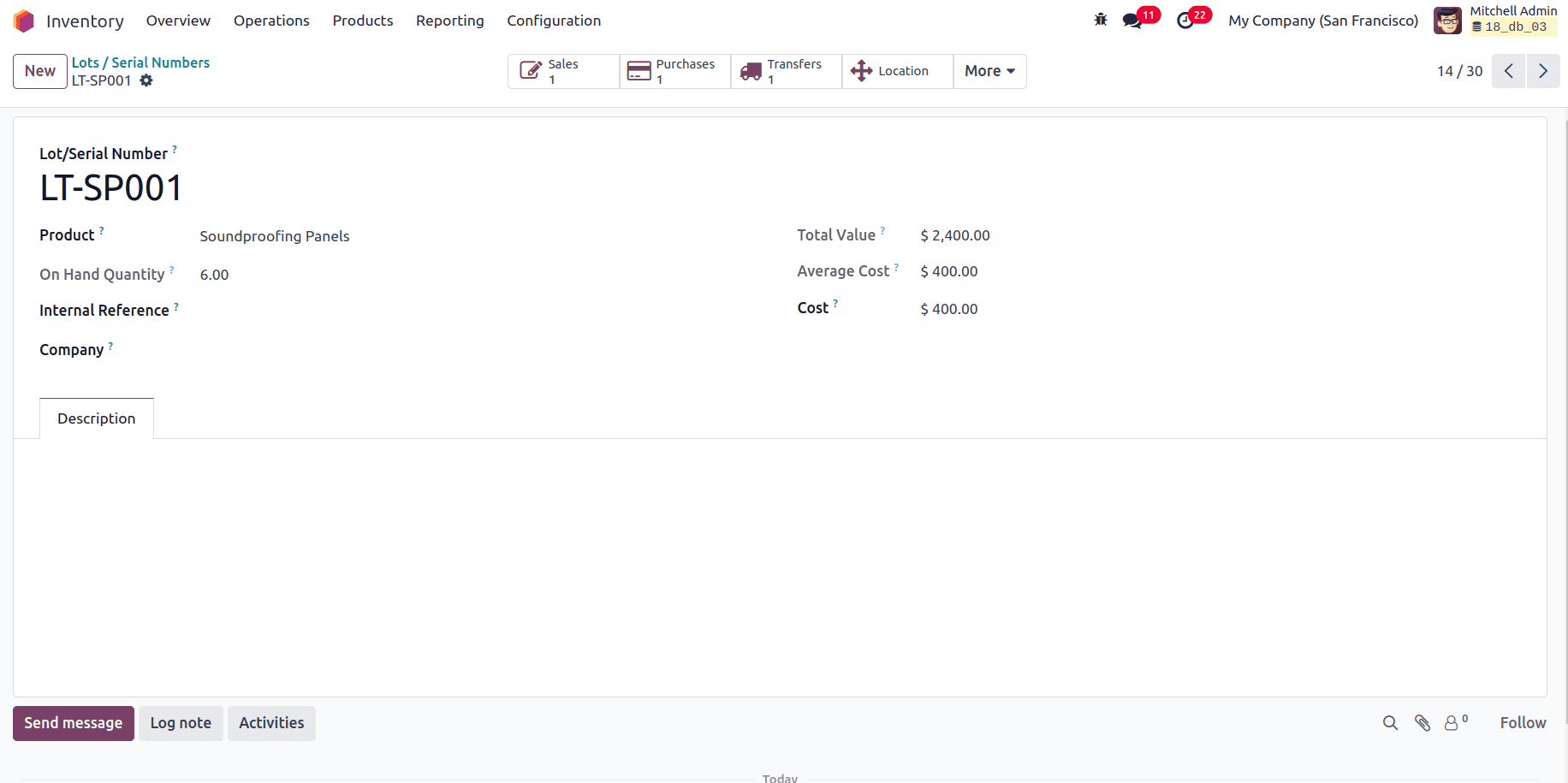

Here, the current On Hand Quantity, Total Value, Average Cost, and the Cost of the product can be viewed. Since 14 quantities of the product were sold from the purchased 20 quantities of the product, the On Hand quantity can be seen as 6 here. And since the 20 quantities were purchased for $ 400 unit price, now the total value for the remaining product in stock has been given as $ 2400 and the average cost has been calculated to be $400, which is the total cost of the product on hand divided by the quantities on hand.

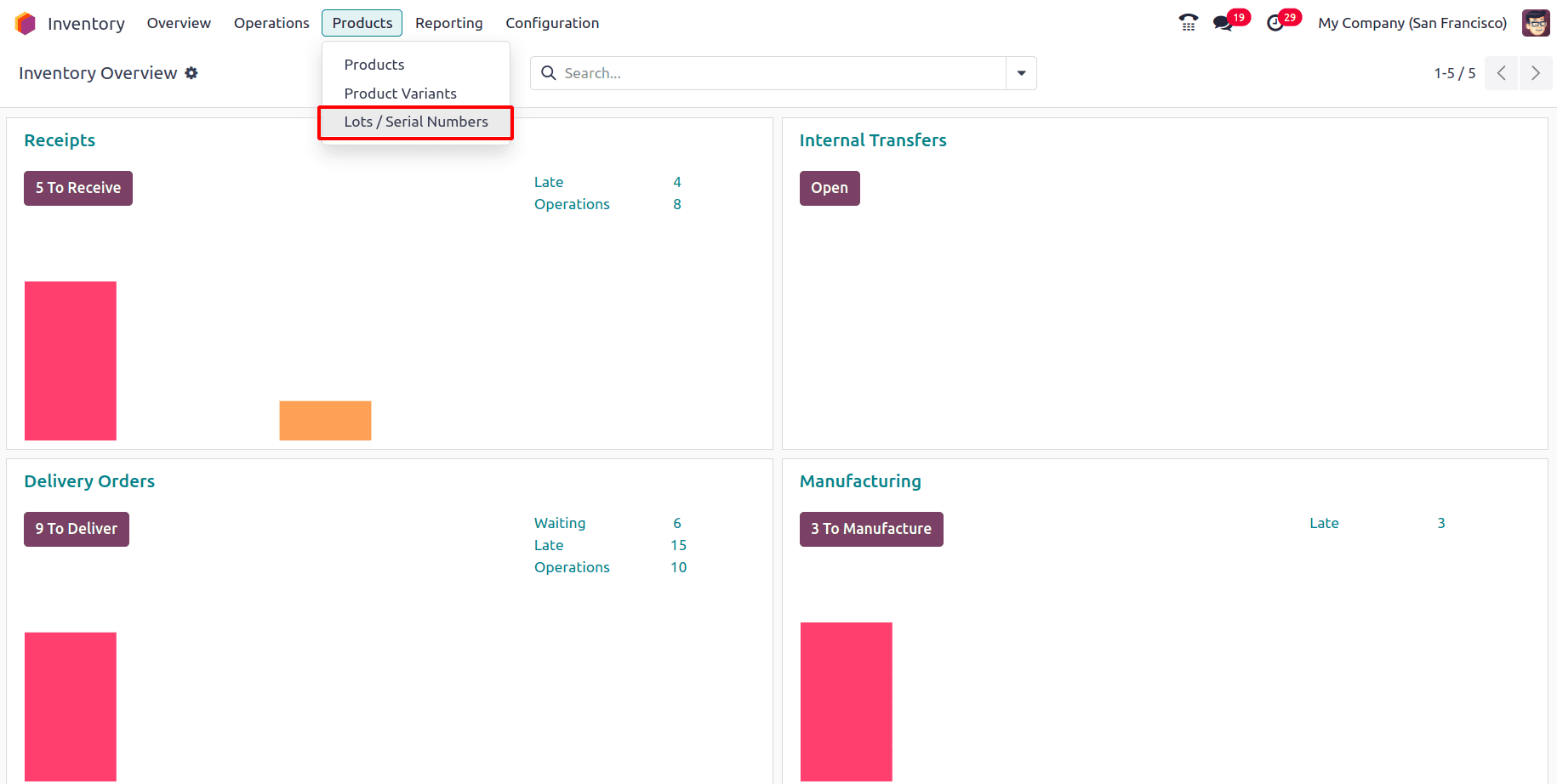

Also, when the Lots and Serial Number is enabled from the configuration settings, the Lots and Serial Number menu appears under the Products.

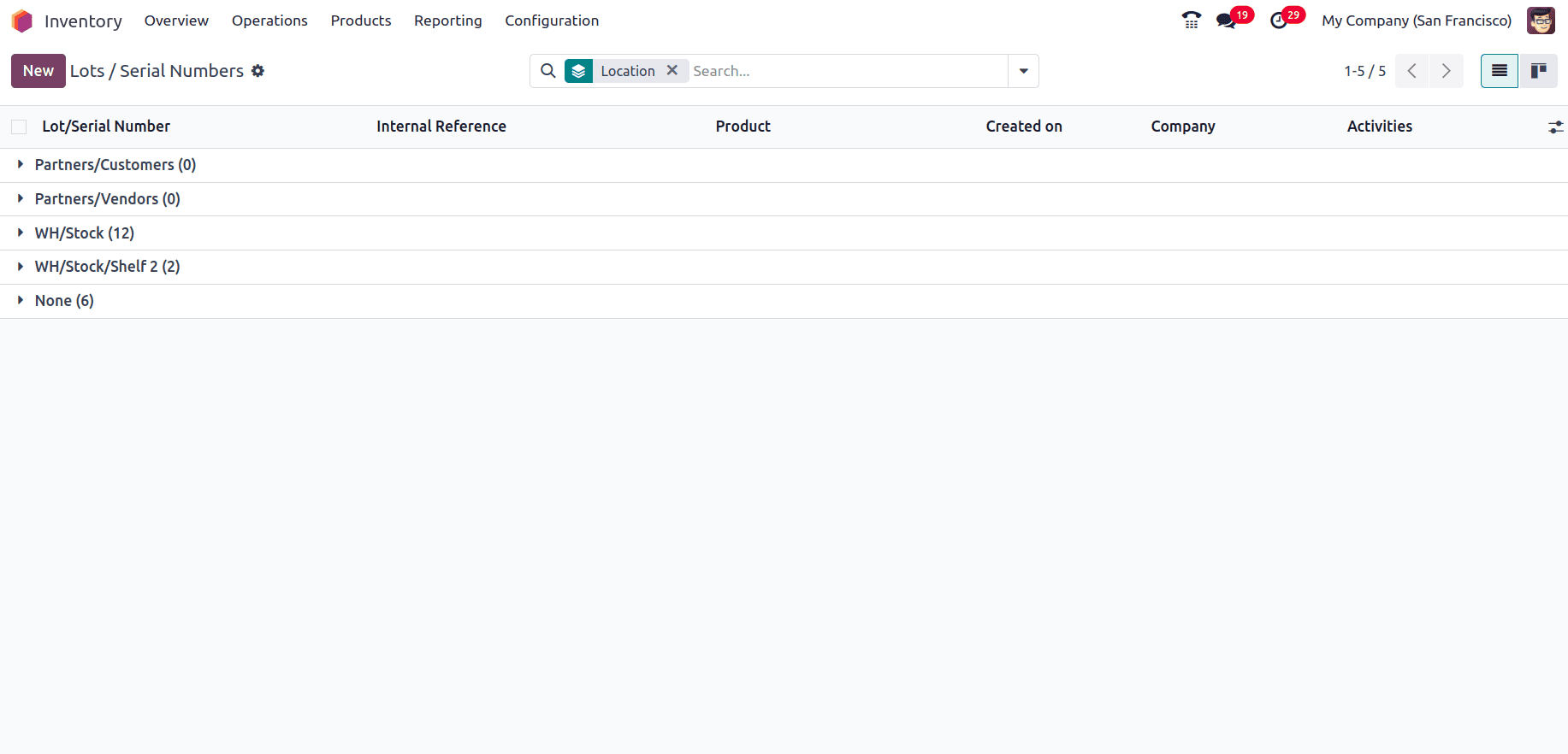

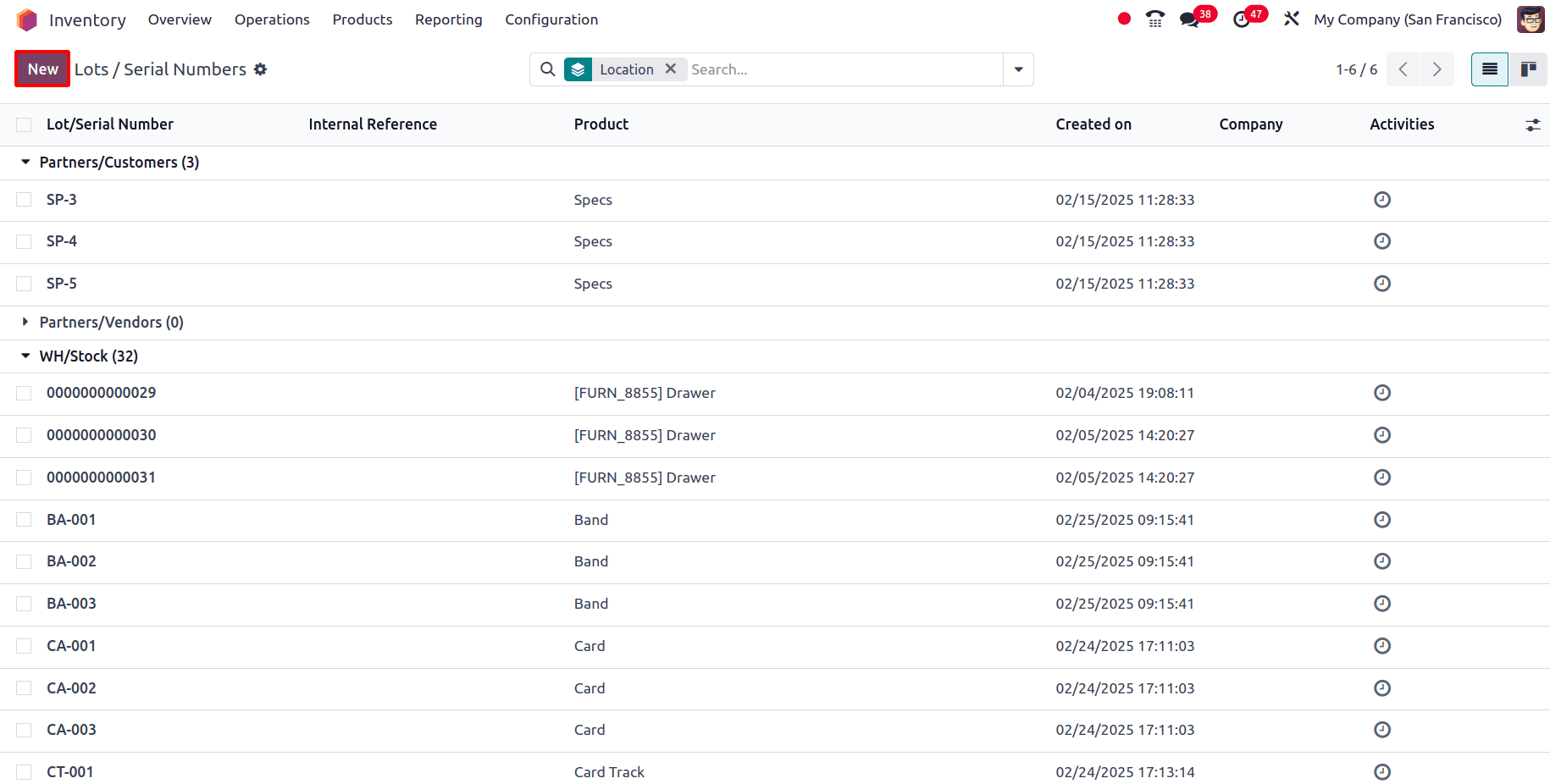

Click on that, and a new page appears where the Lots and Serial Numbers can be added and the page is by default filtered by Location.

The products with lots and serial numbers at each location can be viewed here, along with the Created On date.

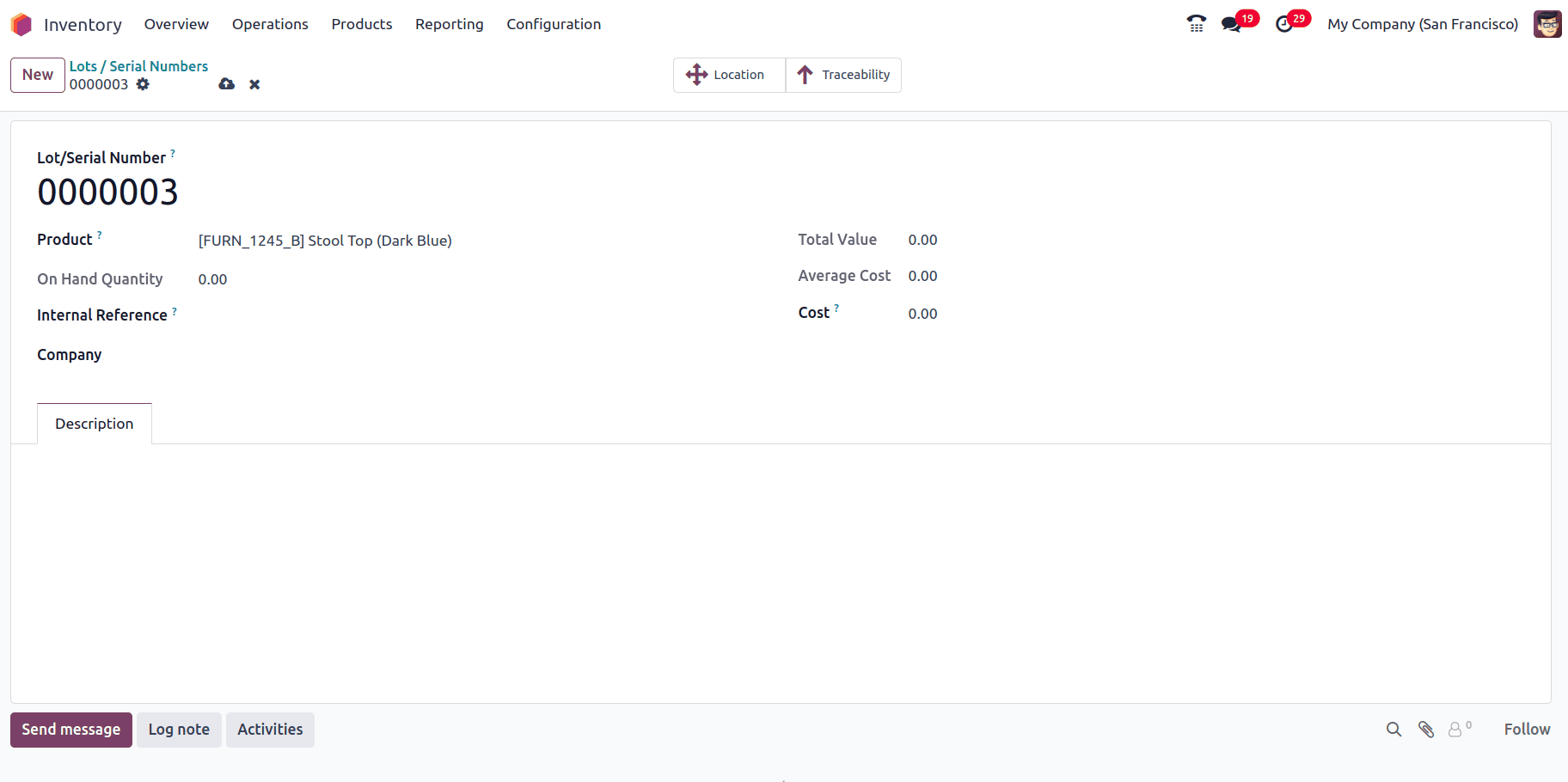

To create a new lot and serial number for the product, click on the New button, and a page appears where the lot and serial number for the product can be created.

- Lot/Serial Numbers: The unique identifier for a specific batch (lot) or individual unit (serial number).

- Product: The product associated with this lot/serial number.

- On-Hand Quantity: Displays the current stock available for this lot or serial number.

- Internal Reference: A reference field that may contain additional tracking information (e.g., supplier references).

- Company: The company associated with this product and its lot/serial tracking.

- Total Value: The total monetary value of the products in this lot/serial.

- Average Cost: The calculated average cost per unit for this lot/serial.

- Cost: The cost per unit for this specific lot/serial number.

Also, there are 2 smart tabs: Locations and Traceability. The location allows users to view where this lot/serial number is stored within the warehouse. Traceability opens the traceability report, which shows the full movement history of this lot/serial number, including purchases, internal transfers, and deliveries.

Implementing Lot and Serial Number Tracking in Odoo 18 enhances inventory accuracy, improves traceability, and ensures it aligns with industry standards. By enabling lot tracking, businesses can efficiently manage batches of products, monitor expiration dates, and streamline recalls. Meanwhile, serial number tracking enables the precise identification of individual units, making it ideal for high-value items, warranty management, and post-sales service.

To read more about How to Track Products With Lot & Serial Numbers in Odoo 17 Inventory, refer to our blog How to Track Products With Lot & Serial Numbers in Odoo 17 Inventory.