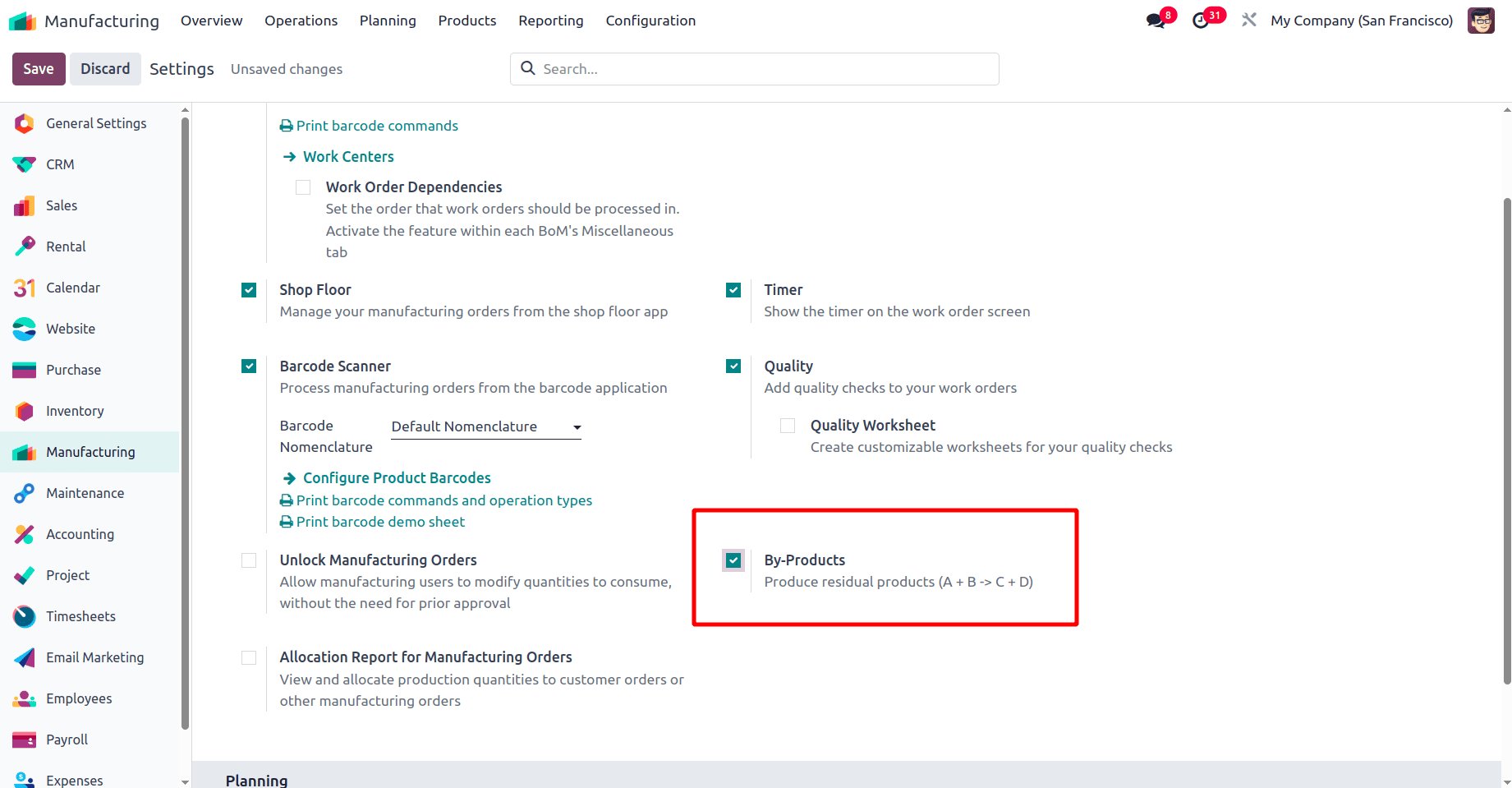

By-products are additional goods produced during the manufacturing process, in addition to the primary final product in Odoo Manufacturing (MRP). Despite not being the main objective of production, these still have economic worth and can be sold, recycled, or used again. To create byproducts in Odoo 18, move to the Configuration Settings of the manufacturing application, and under the Operation section, there is an option By-Product with a checkbox. To use the by-products inside a manufacturing order, we can enable the checkbox as shown in the screenshot below.

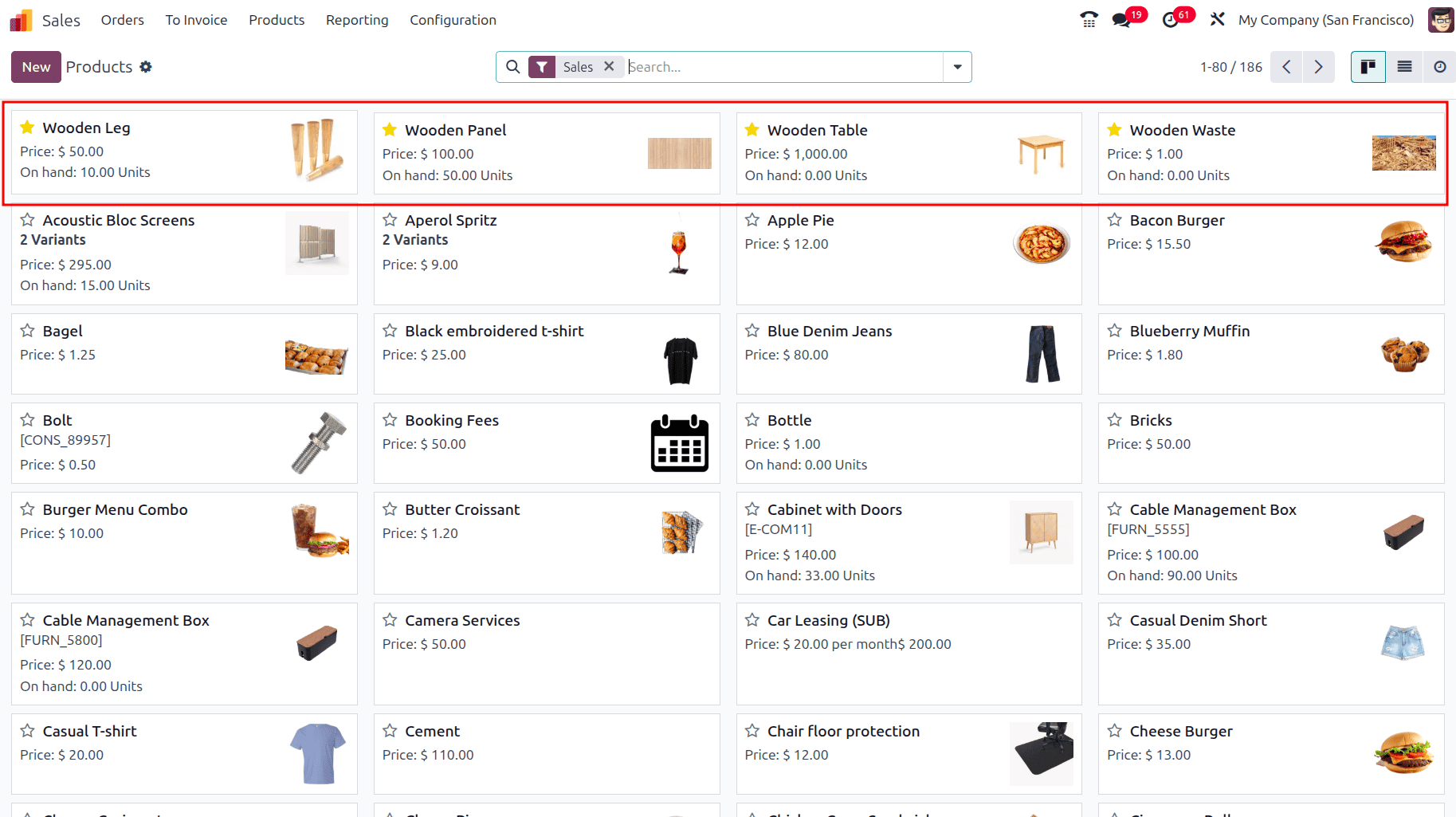

Once the by-products option from the configuration settings is enabled, just move to the products list and configure the main products, the components needed to create the main product, and the by-products.

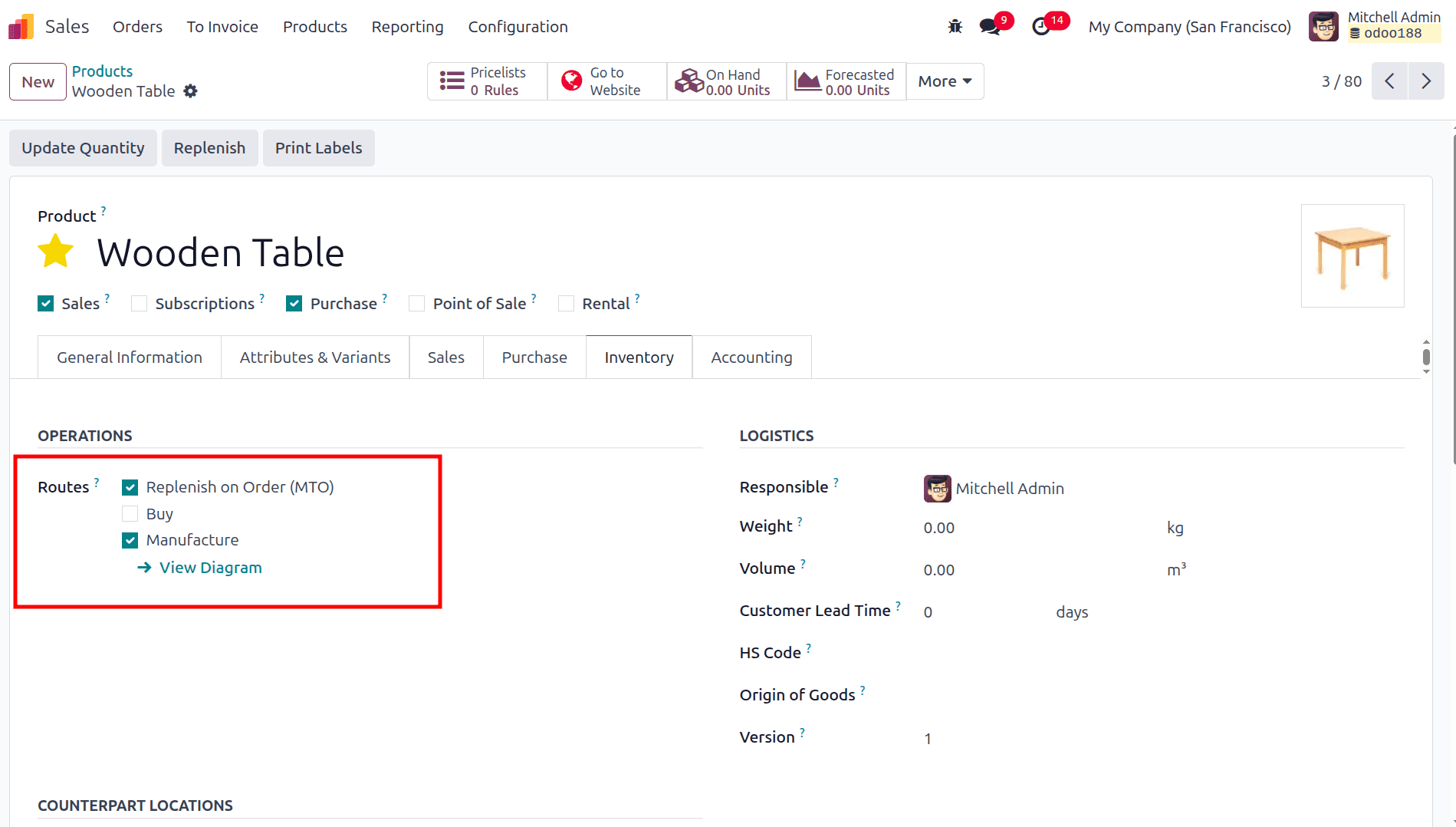

Then, open the main product for which you need to set a manufacturing order and open its inventory tab.

There is the option to set the route for the product. This route tells Odoo to generate a Manufacturing Order whenever the product is required. To use this manufacturing order or to create a manufacturing order automatically, along with the route ‘Manufacture’, Replenish on order (MTO) should be enabled.

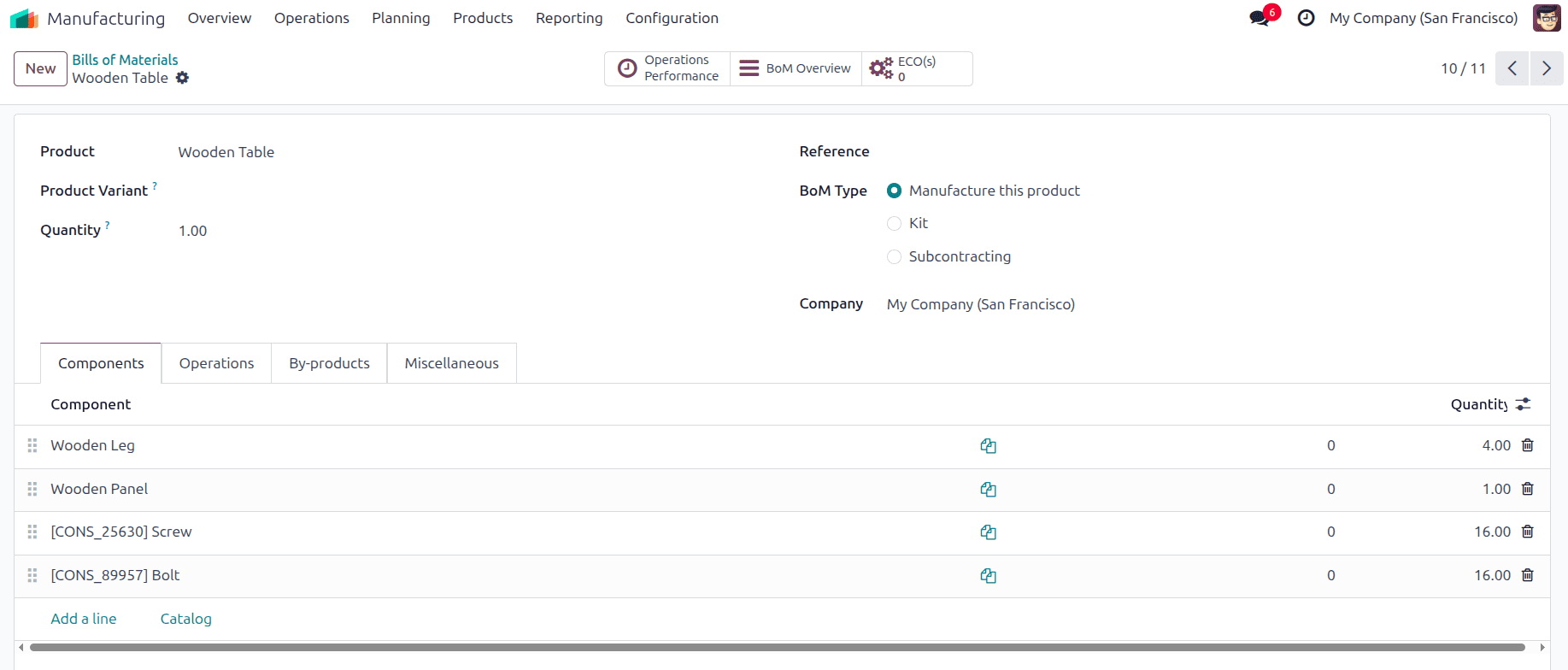

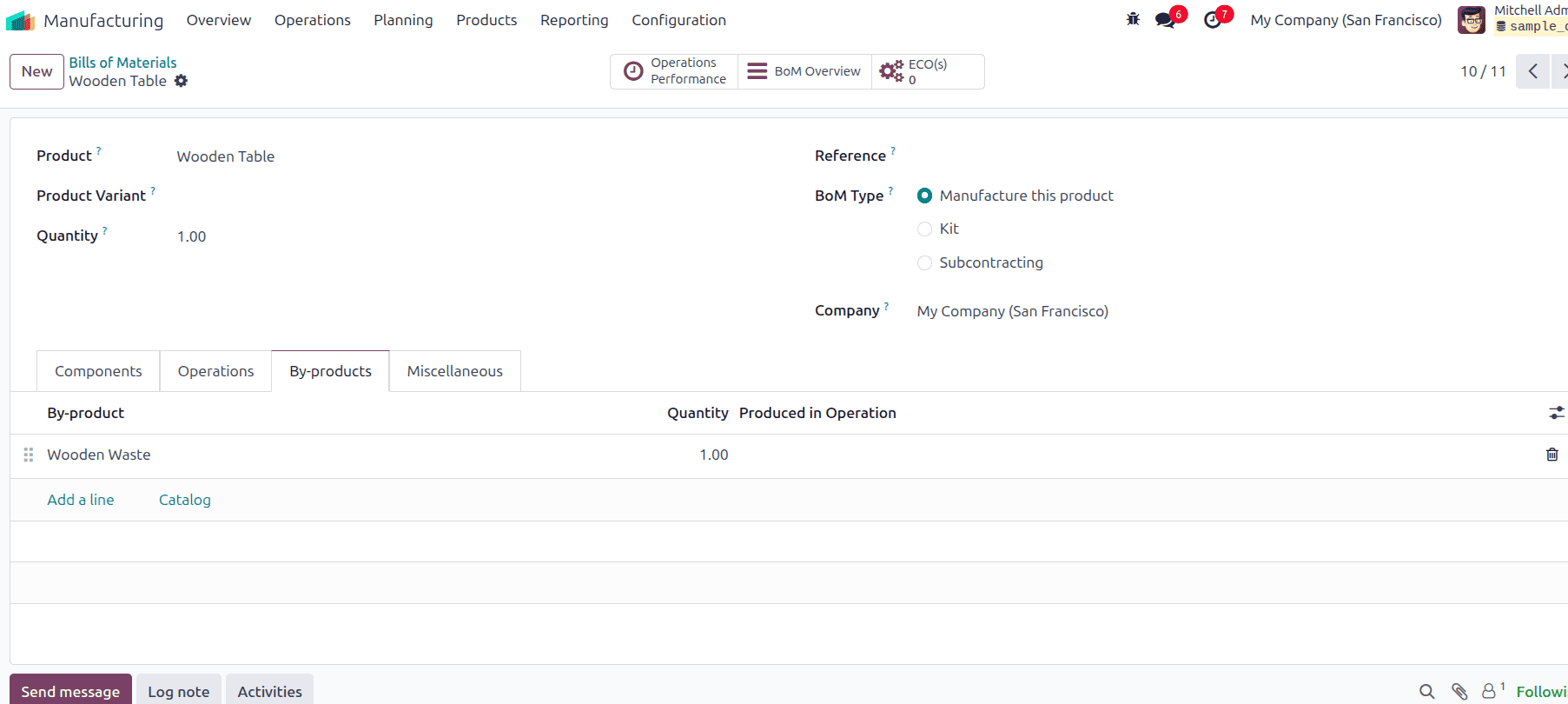

Moving to the manufacturing process, we must create a new Bill of Materials for the main product, ‘Wooden Table’.

Once the components for the bill of material are set, move to the By-Product tab in the Bill of Materials, and there we have the option to configure the By-product available on the manufacturing process of the wooden table.

Once the components are added in the components tab, move to the By-product tab. There will be an add a line option to add the by-product produced as a result of the manufacturing of the main product. The operations required to manufacture the product table can be added in the Operations tab of the bill of materials. The other details of the bill of materials, like the manufacturing lead time, Manufacturing readiness, and Flexible consumption of the components, can be added in the Miscellaneous tab of the Bill of Materials

Now in the inventory, the on-hand quantity of the main product, the wooden table, and the on-hand quantity of the by-product, the wooden waste, are zero.

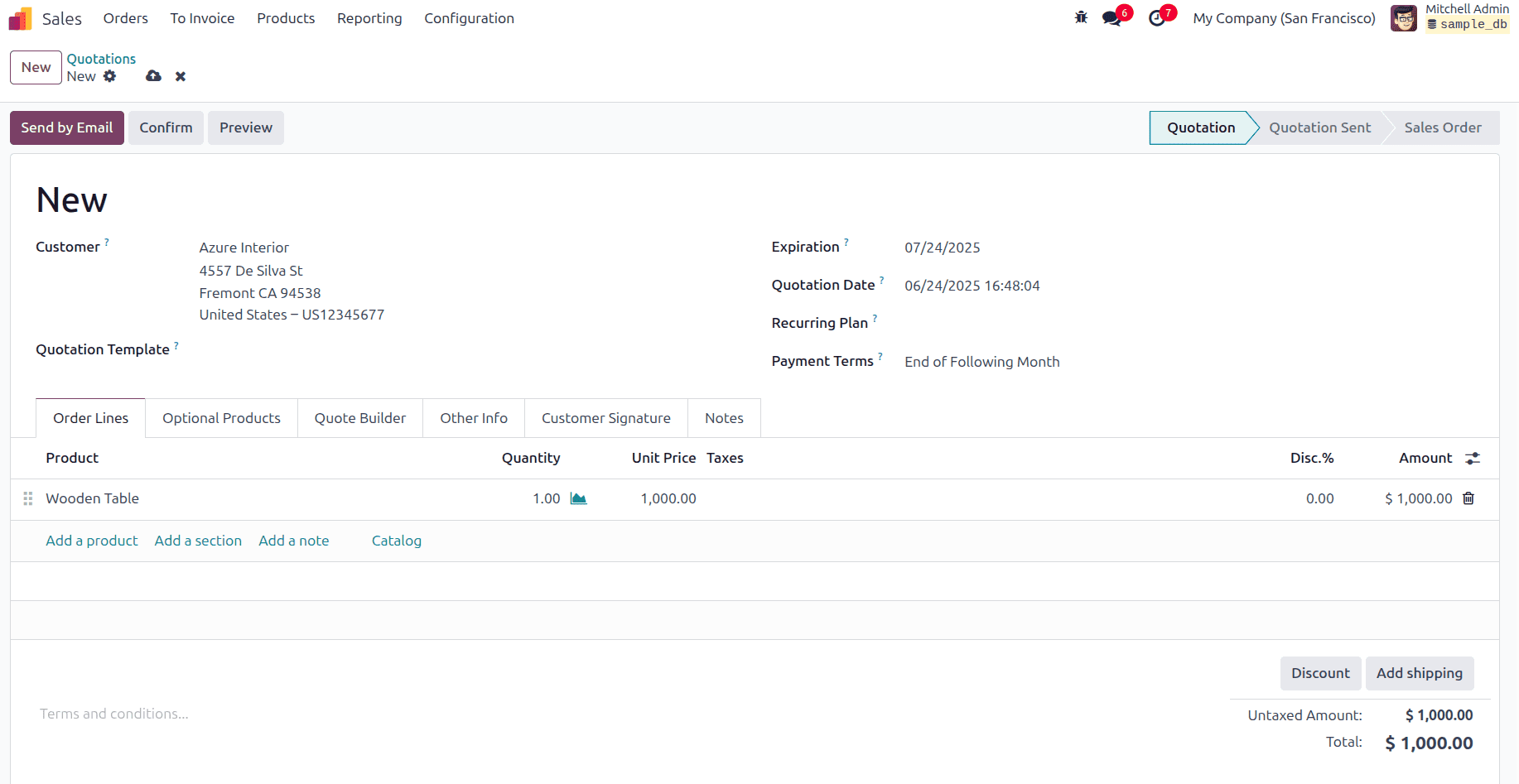

So whenever a sales order for the product, a wooden table, is created by a salesperson, a manufacturing order will be automatically created for the product, a wooden table. Move to the sales module and create a sale order for the product wooden table.

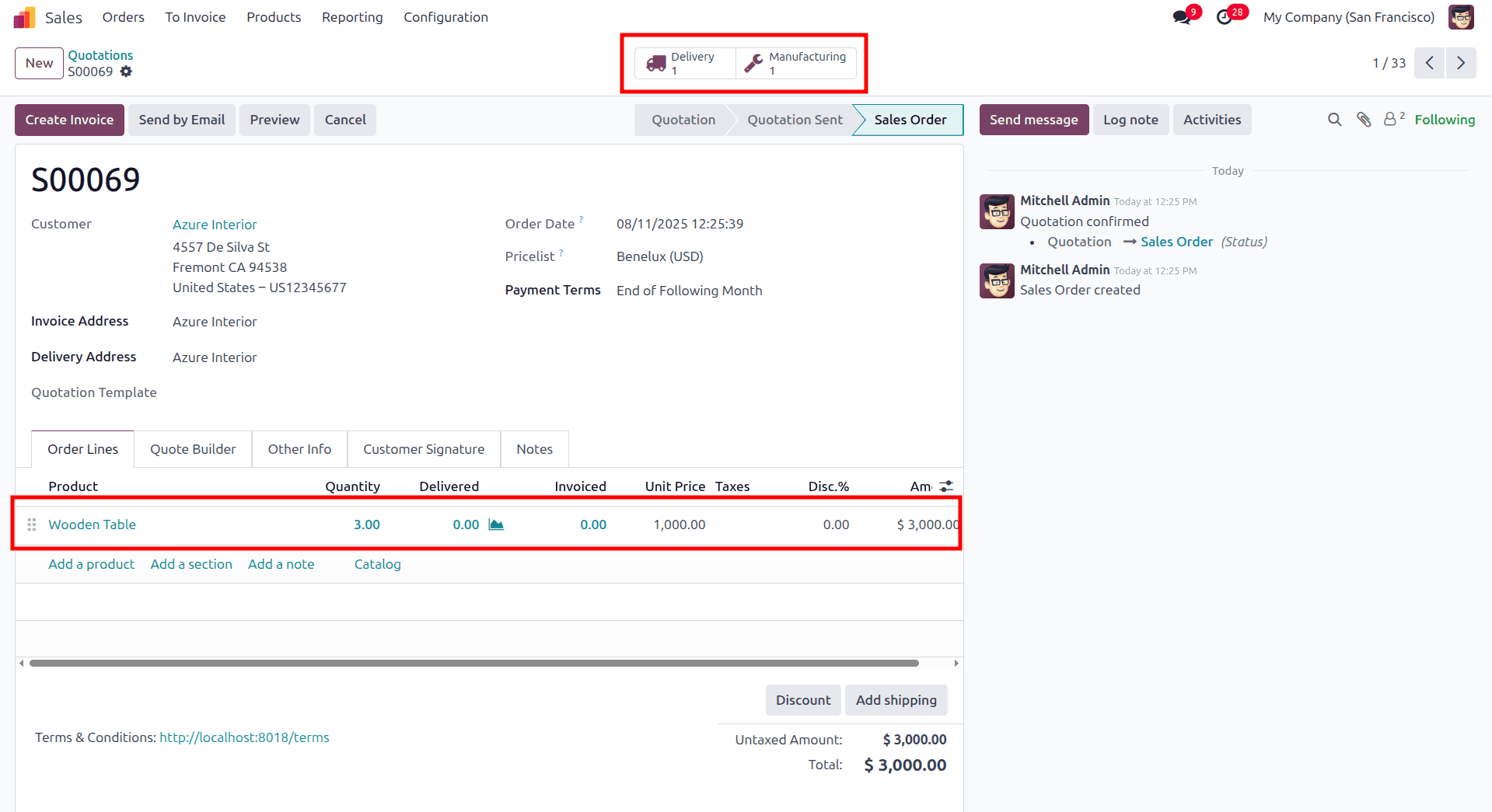

Then click the confirm button to confirm the sales order. On clicking the confirm button, due to the unavailability of the product in the stock of the company, odoo will automatically trigger a manufacturing order for that product. The delivery is only possible if the manufacturing order is completed.

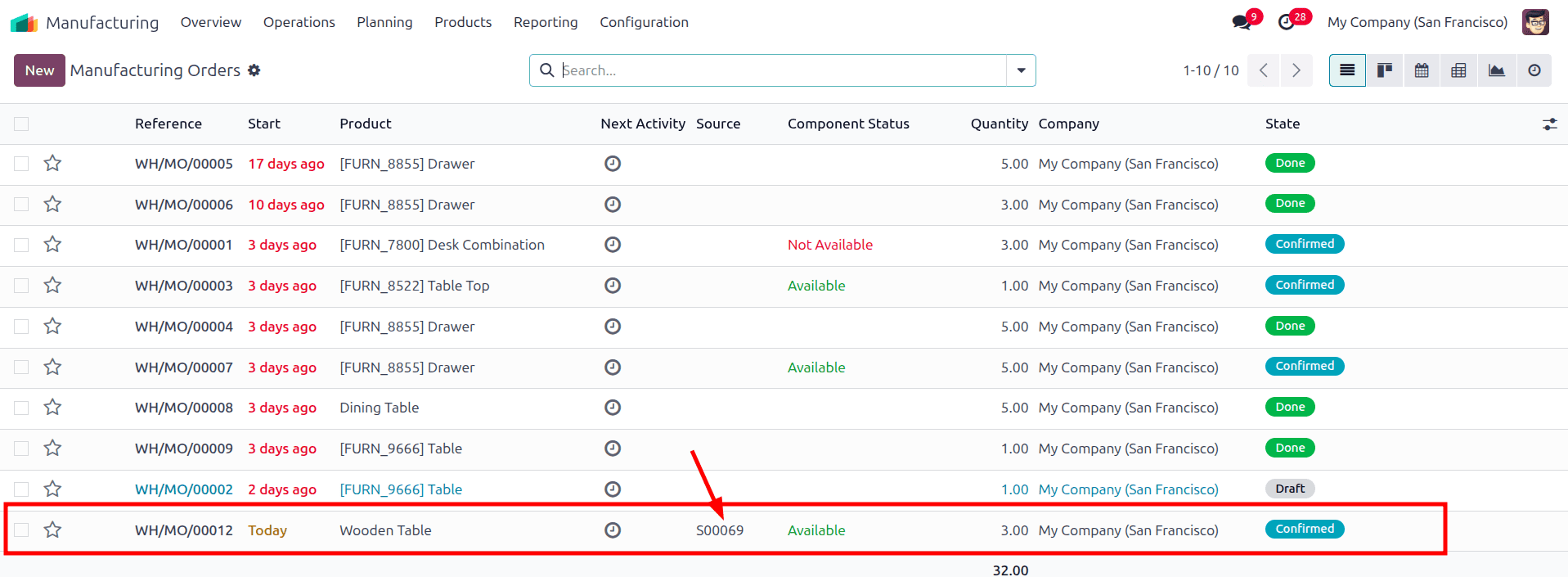

To complete the manufacturing order, either click the manufacturing smart tab in the sale order template, or if we move to the manufacturing module, there, we can see the manufacturing order for that product.

From the list view, we can see the source of the manufacturing order. Here, this manufacturing order is created from the sale order, as shown in the above screenshot. To manage that manufacturing order, open that order first.

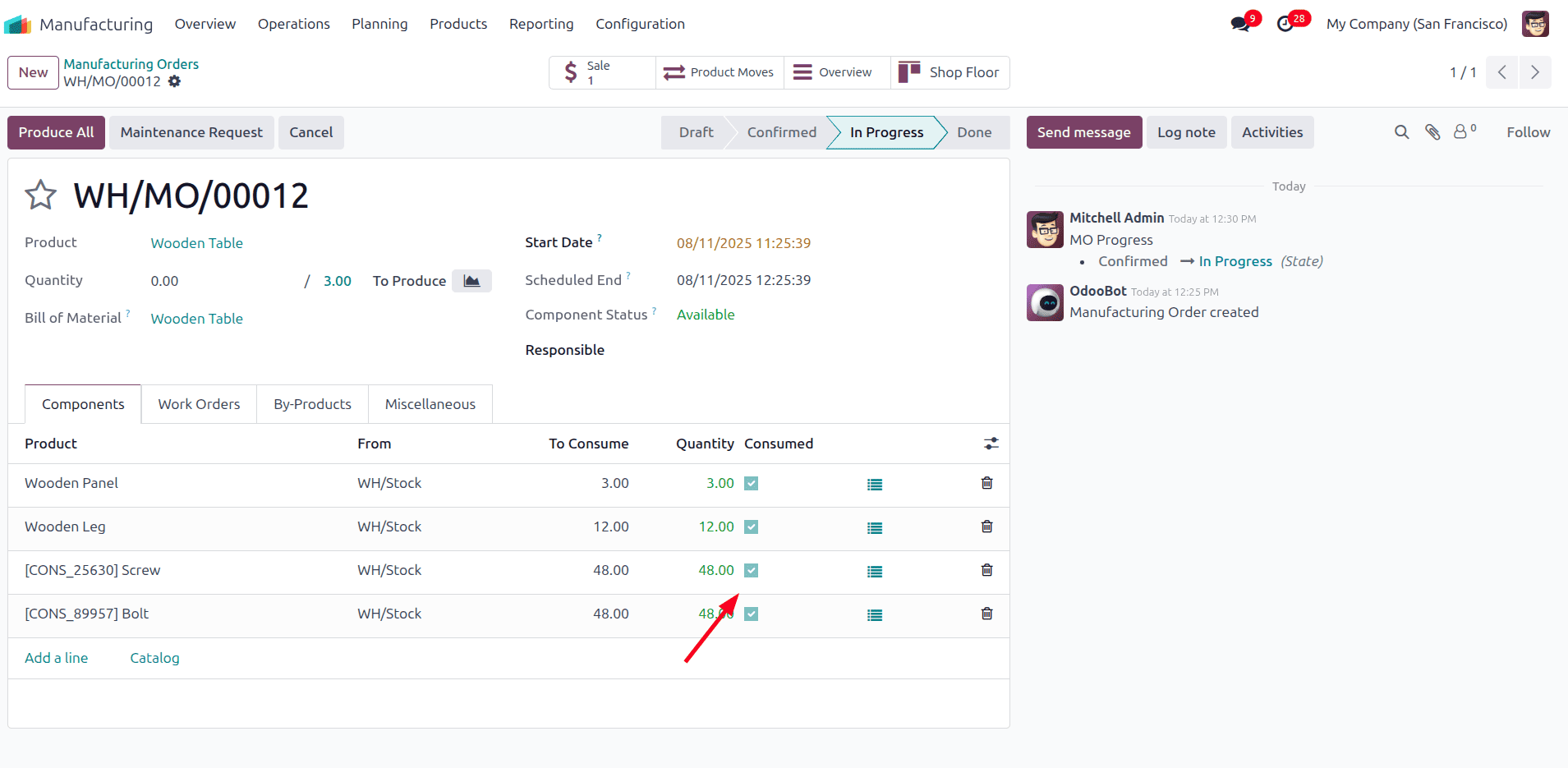

There are different options in the manufacturing order, quantity of components to consume, and then we can enable the checkbox under the consumed tab. If the checkbox is enabled, it means that the component is used for the manufacturing process of the main product.

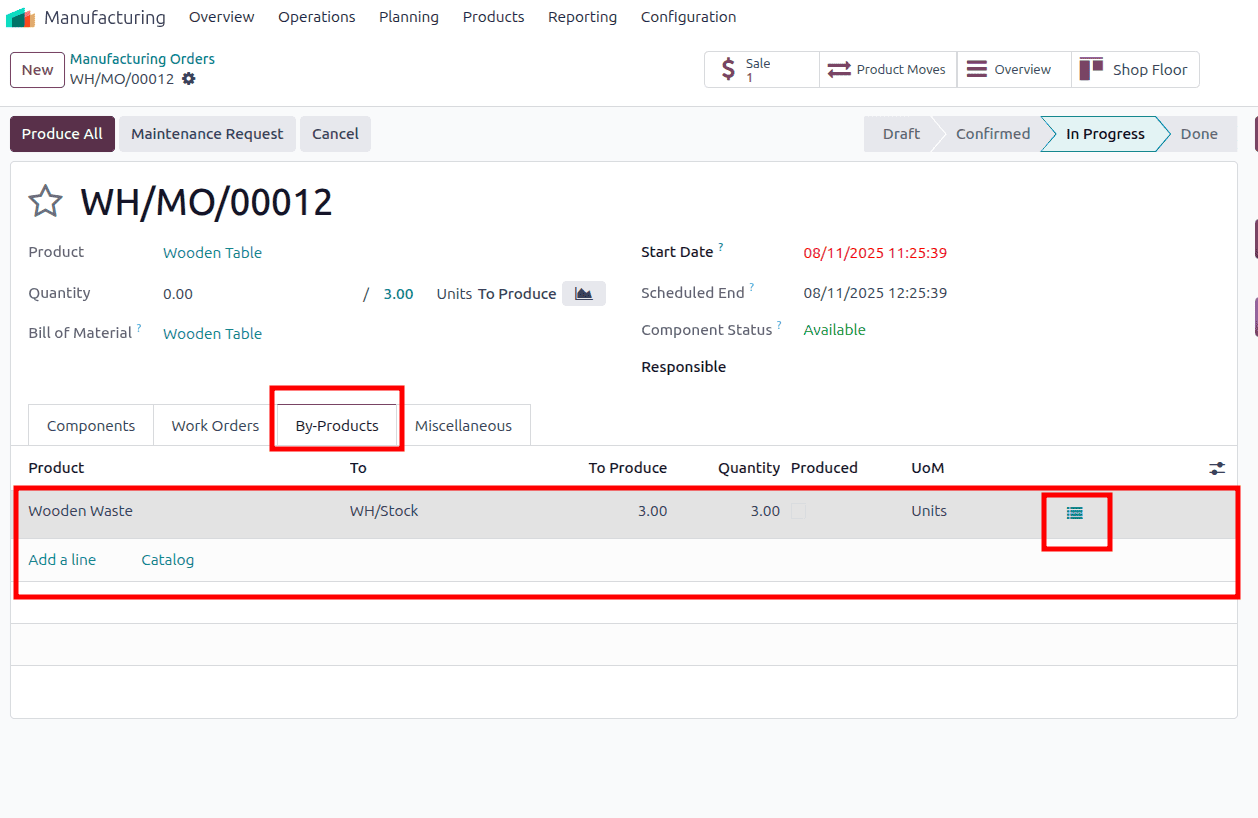

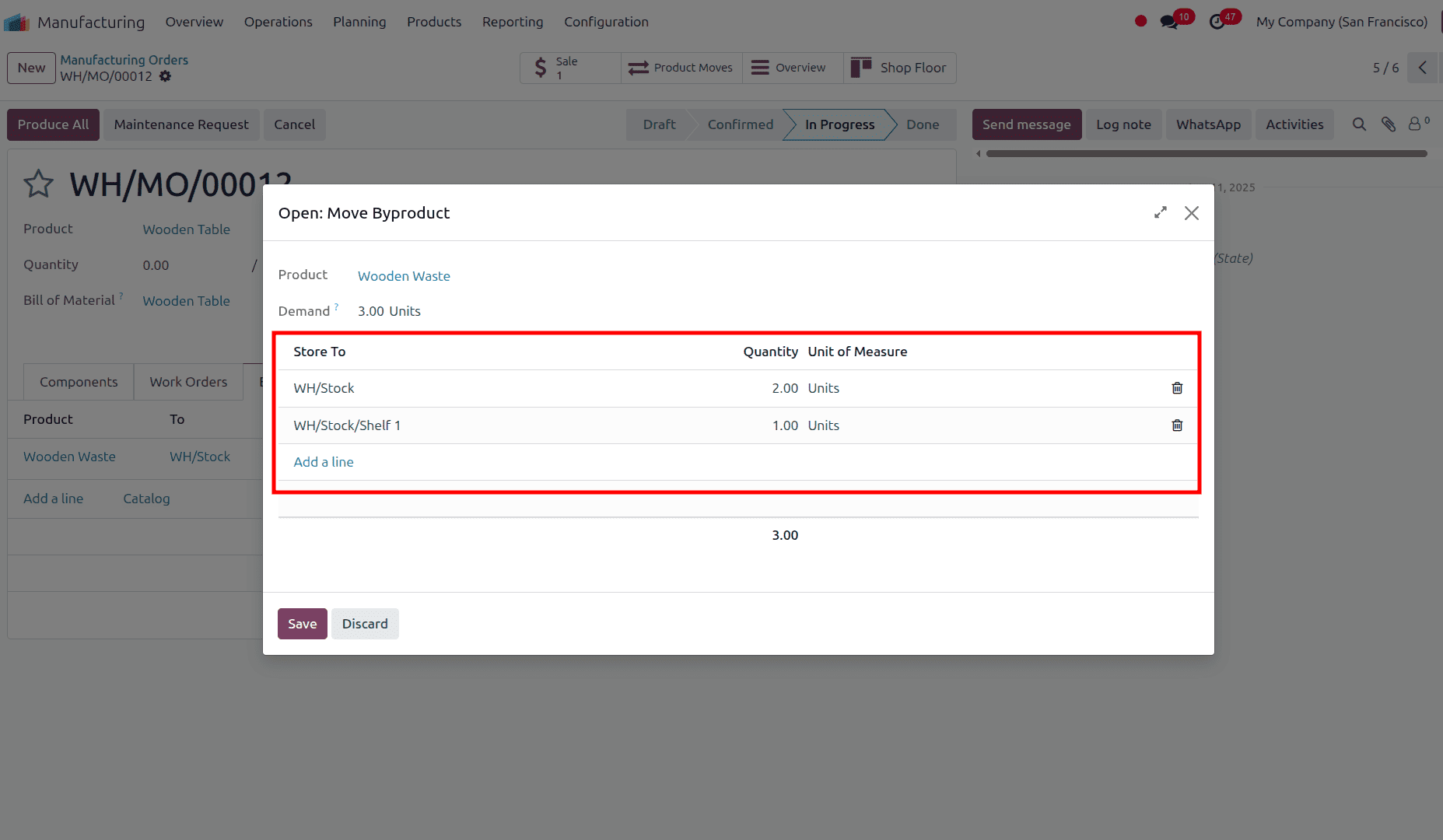

Once we move to the By-Product tab of the manufacturing order, the by-product produced as a result of the manufacturing order is added automatically. If we need to produce more by-products from this manufacturing order, there is an add a line option. By using that option, we can add more byproducts to that manufacturing order. The quantity of by-product produced will be shown on this page. On clicking the three lines in the by-products line, we can choose the location to store the by-product.

Here, if we need to store these products in different locations, it is also possible through this process. Then, to manufacture this product, just click the ‘Produce All’ button.

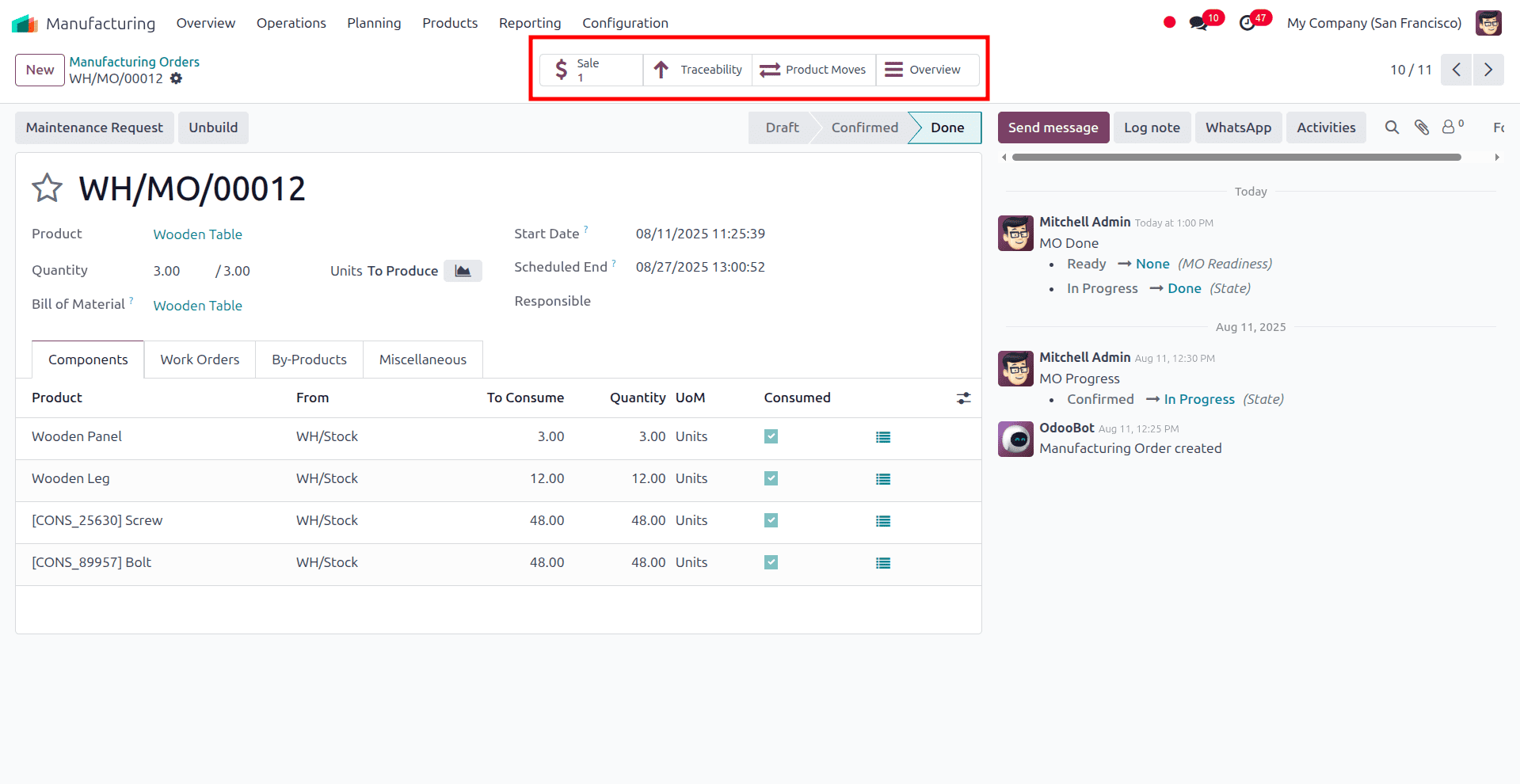

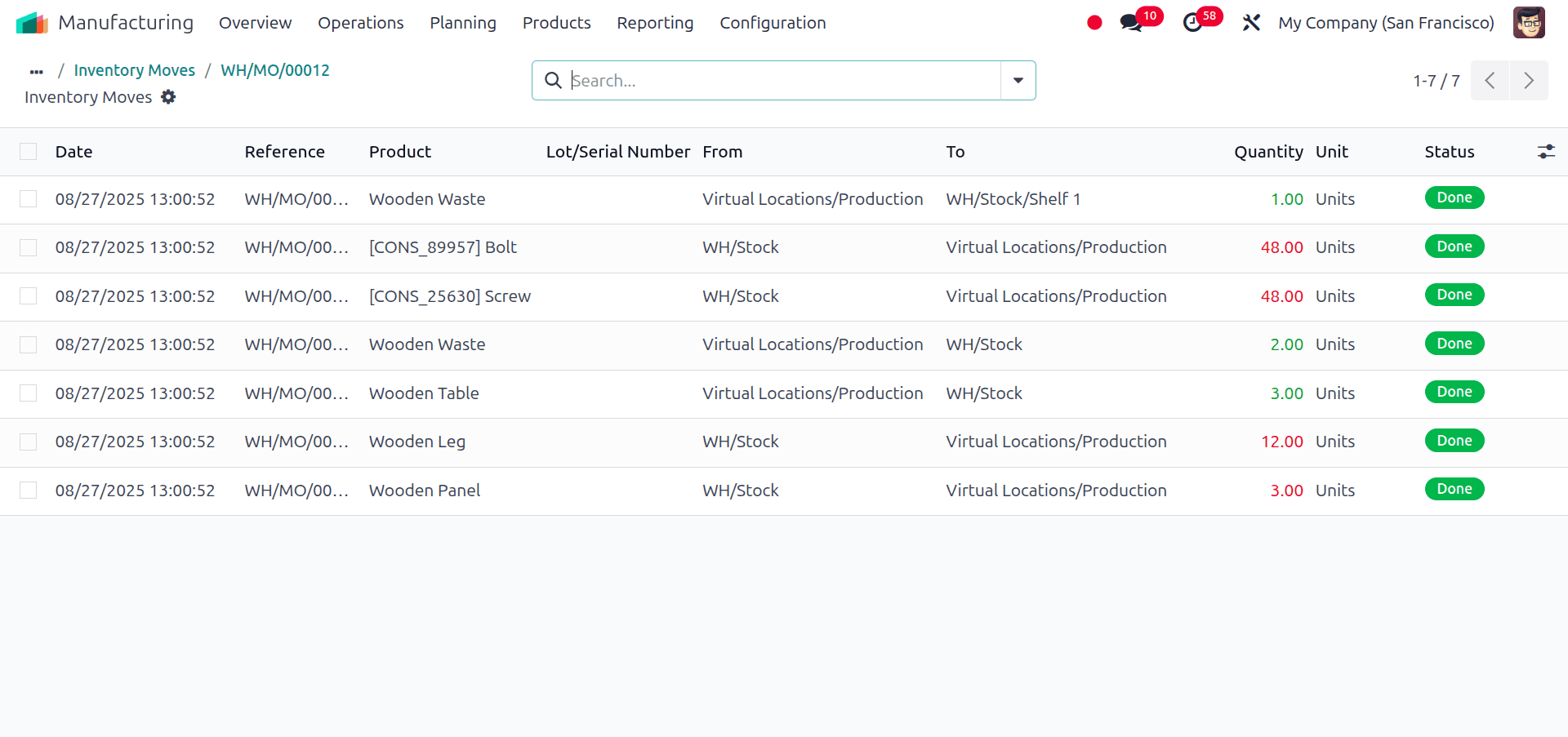

Sales smart tab, which shows the sales order that is responsible for forming the manufacturing order. The Traceability Report is used to track the flow of raw materials and finished products across the entire production process. On clicking the Product moves smart tab, the complete move of the entire product will be displayed, like the from location and the to location of the product involved in the manufacturing order.

Before creating the sale order for the product table, the on-hand quantity of the by-product wooden waste is zero. But after the completion of the manufacturing order of the wooden table, the on-hand quantity of the components in the bill of materials gets decreased, and the on-hand quantity of the by-product in the manufacturing order gets increased. We can also sell these by-products created as a result of this manufacturing order to any partner.

To read more about How to Analyse the Cost Share of By-Products in Odoo 18, refer to our blog How to Analyse the Cost Share of By-Products in Odoo 18.