Manufacturing is the process of creating new products or goods from raw materials. This is a complex process, and there are numerous processes and raw materials used in the production process. In addition to the primary product, some byproducts can also be manufactured. In certain cases, the by-product could also be expensive. The Odoo 18 Manufacturing module makes it simple to handle such production and expenses.

Assume that the final product was made using some components and that a new byproduct was also created during the manufacturing process. Here, as was already mentioned, in addition to creating the final product, a byproduct was also produced, but its creation came with costs. The cost of producing the final product includes the cost of producing the byproduct. The Odoo 18 Manufacturing module makes it simple to handle such production and expenses.

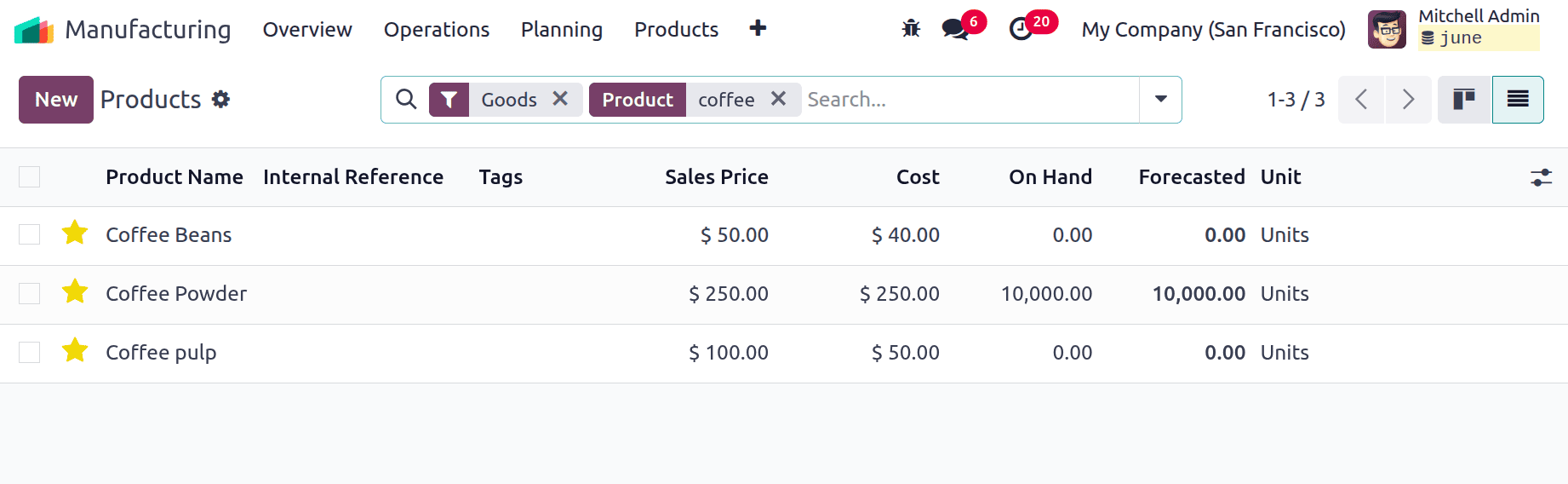

Let's create the products as well as the components. Under the Products tab, make new products for that. A Coffee Powder, which costs $250, is the manufacturing item in this case. From the Inventory tab, manufacturing is selected as the product's route. Coffee beans, a product that may be stored, are the ingredients used to make coffee powder. Additionally, the item's price of $40.00 is stated. The By-product created during the manufacturing of Coffee Powder is Coffee Pulp. All the products are created as shown below.

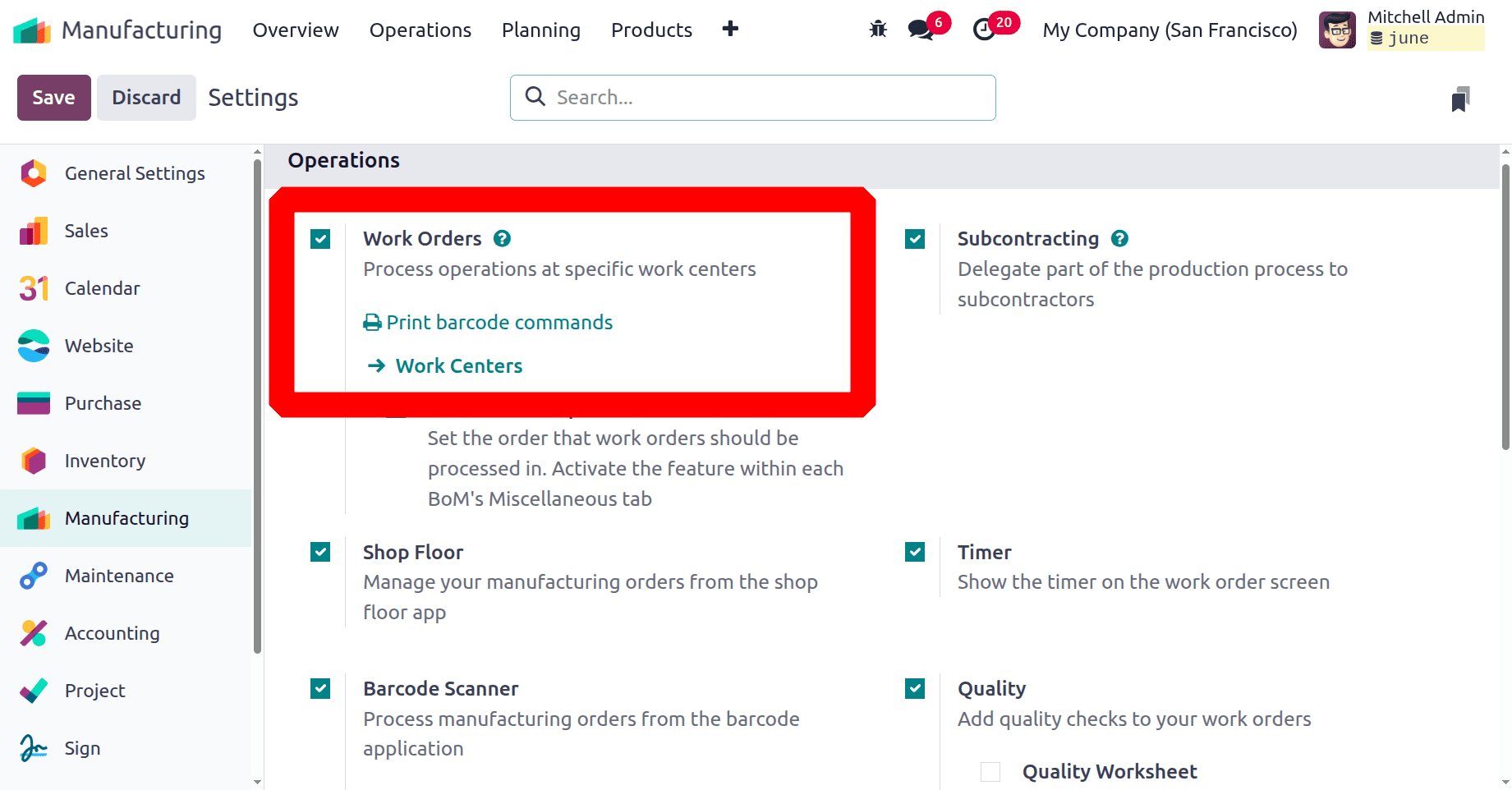

Before the process begins, a number of settings must be changed. From the Configuration tab, select the settings option. There are a lot of options on that page. The Work Orders and By-Products choices ought to be enabled.

At some work centres, work orders are utilized to process particular operations.

:Configuration > Settings > Work Orders

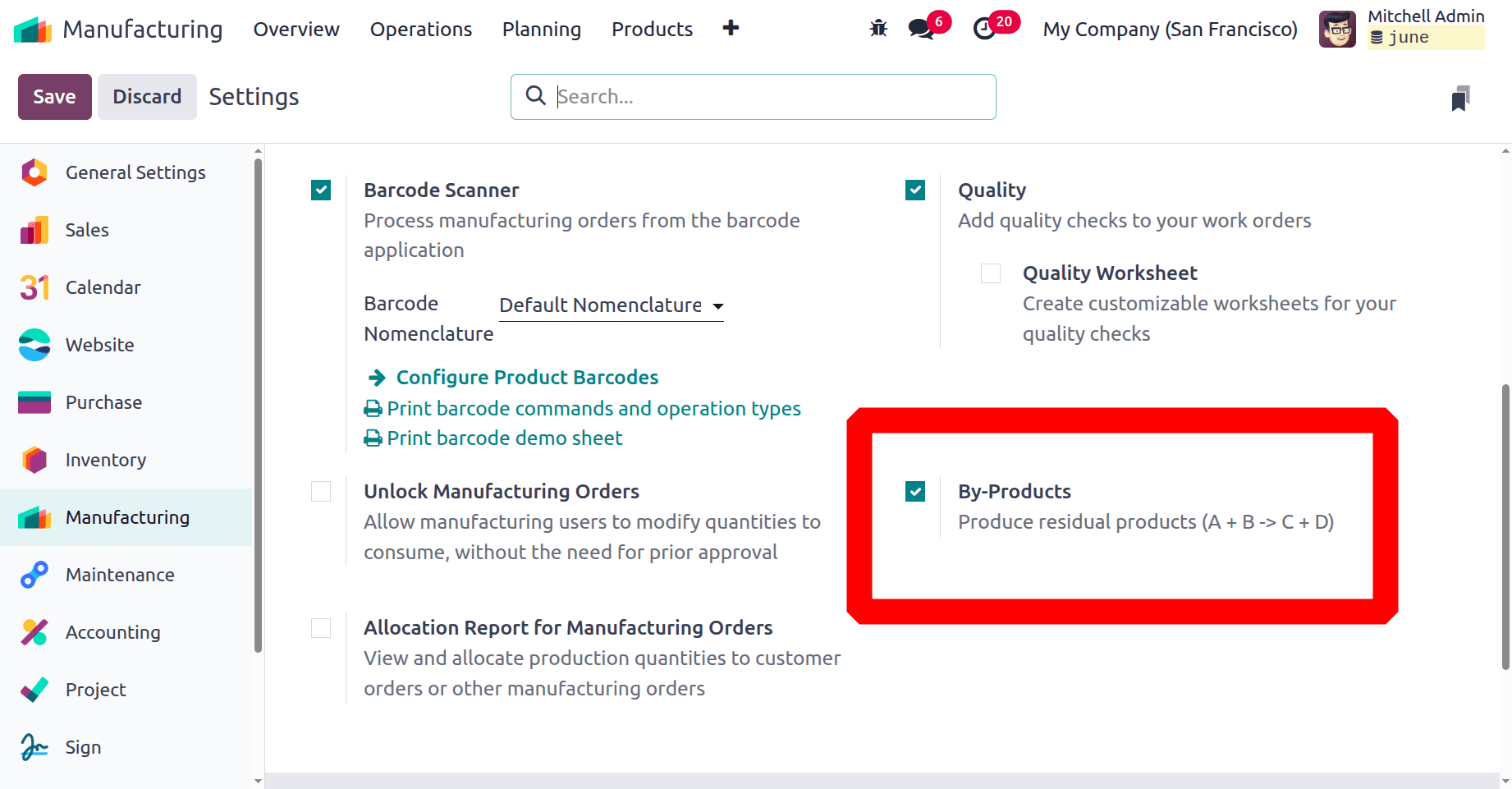

Throughout the production process, By-Products will allow you to specify the by-products that were produced alongside the finished product. Once the option to save the changes has been enabled, click the Save button.

:Configuration > Settings > By-Products > Save

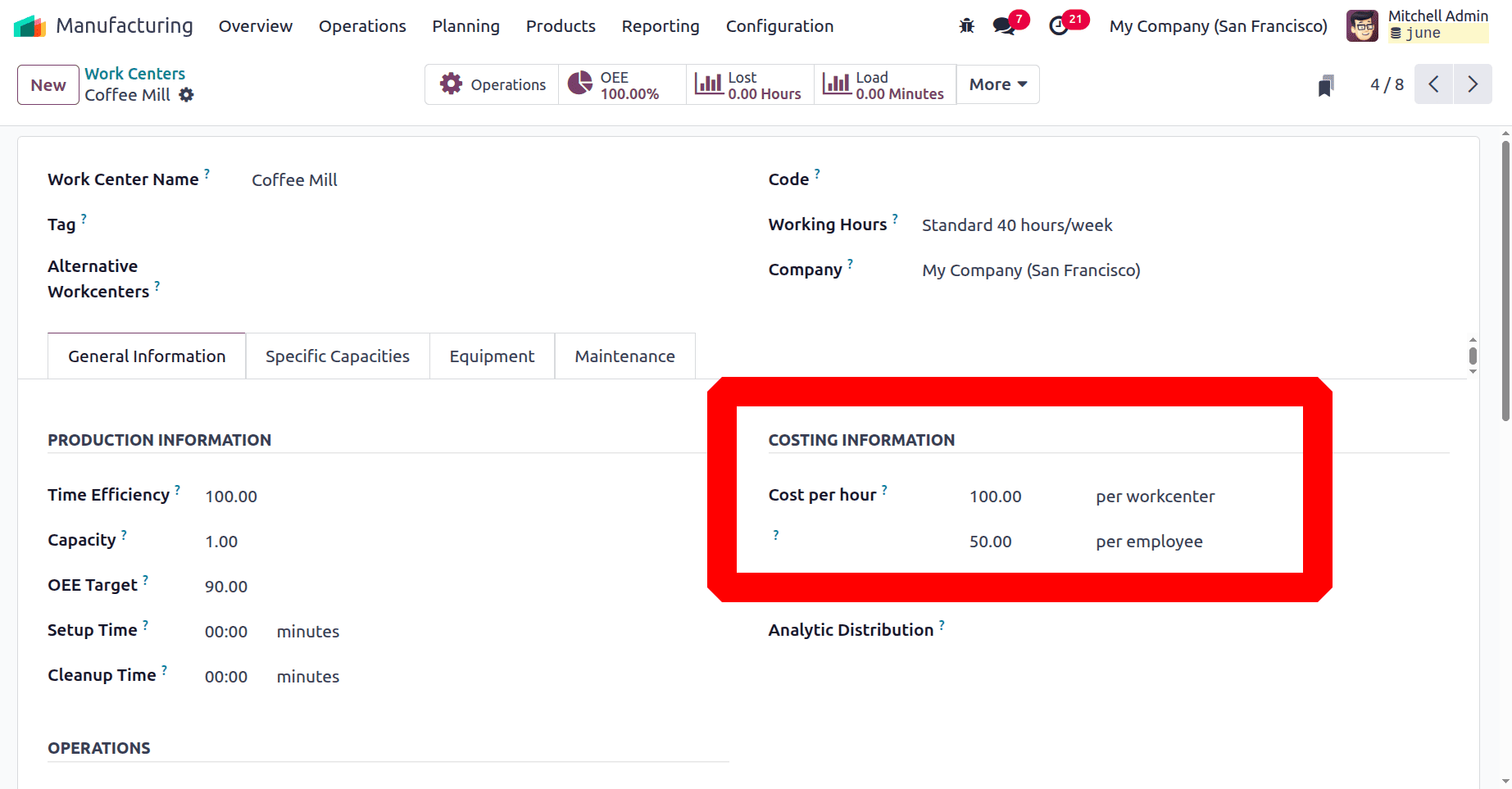

Setting up a work environment is the first step in any production process. It is believed that a work centre is where all operations are carried out. Consequently, we must first establish a work centre for our production processes. From the settings menu, let's select the "Work Centre" option.

The newly constructed work centre is up and running. The name, tag, code, working hours, and alternative work centers of the work center are displayed. Additionally, the work center's cost details can be specified there. The cost of the employee and the work center are included in this section. The price increases to $100.00 for an hour of work center use, and the hourly wage for employees in the same workcenter is $50. We can specify the Time Efficiency, Capacity, and OEE Target in the Production Information. This section also specifies how long it will take to clean and prepare the workplace.

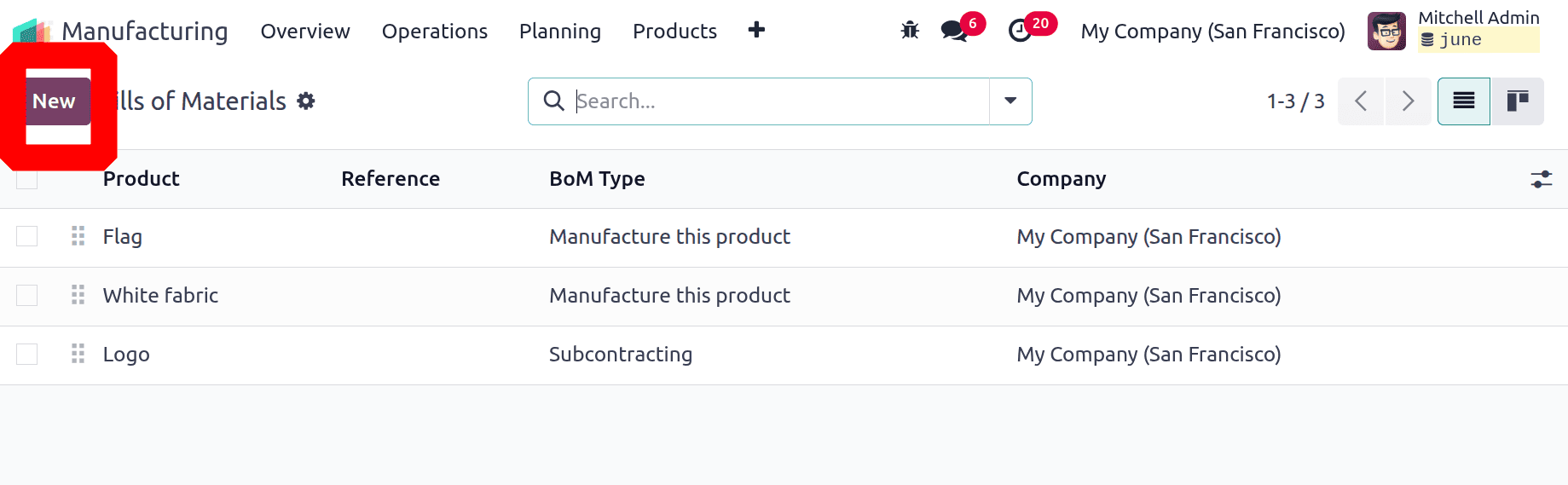

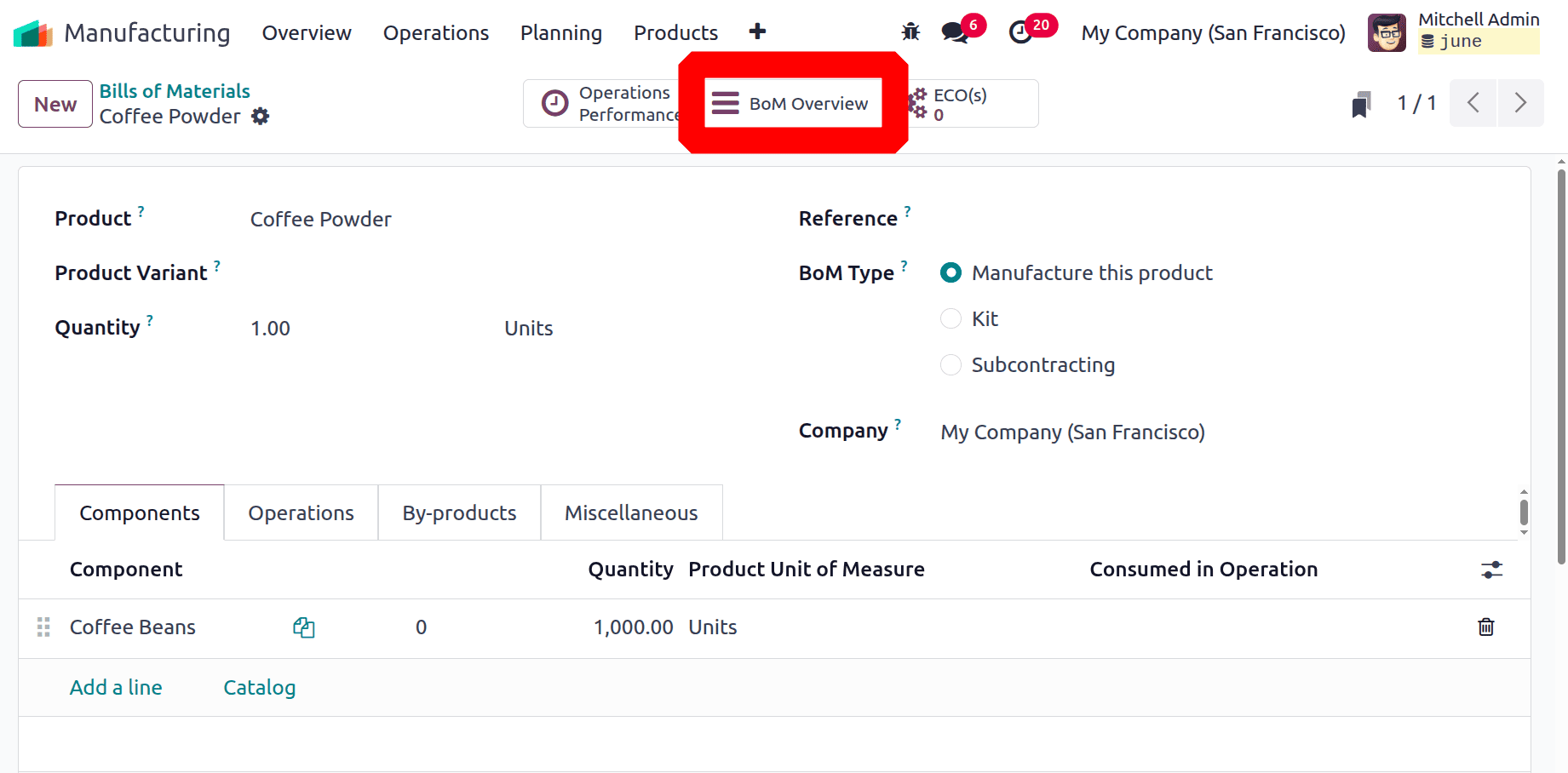

Before we begin manufacturing, let's draft a bill of materials. The item "Coffee Powder" has the following bill of materials as an example. From the product tab, select Bill of Material for this. To begin a new bill of materials, click the New button; by default, all previously created ones are displayed.

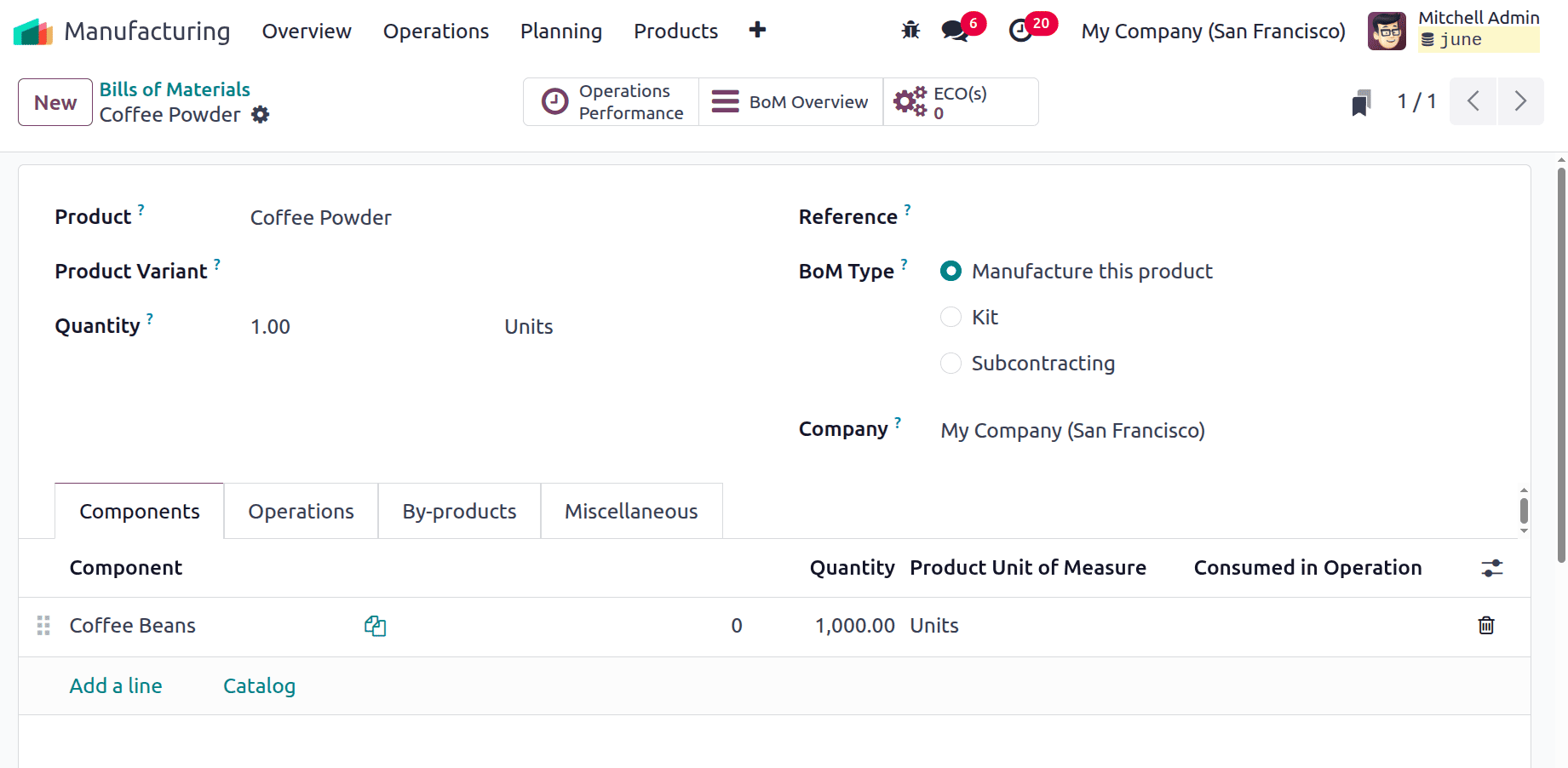

The product's name, components, and production processes are listed in the bill of materials. The product we will be producing in this case is a single quantity of coffee powder. If required, include the reference. Click Add after selecting the BoM type as Manufacture this product, and adding the raw material list and amounts to the components tab. Here, 1000 quantities of Coffee Beans are added as a component.

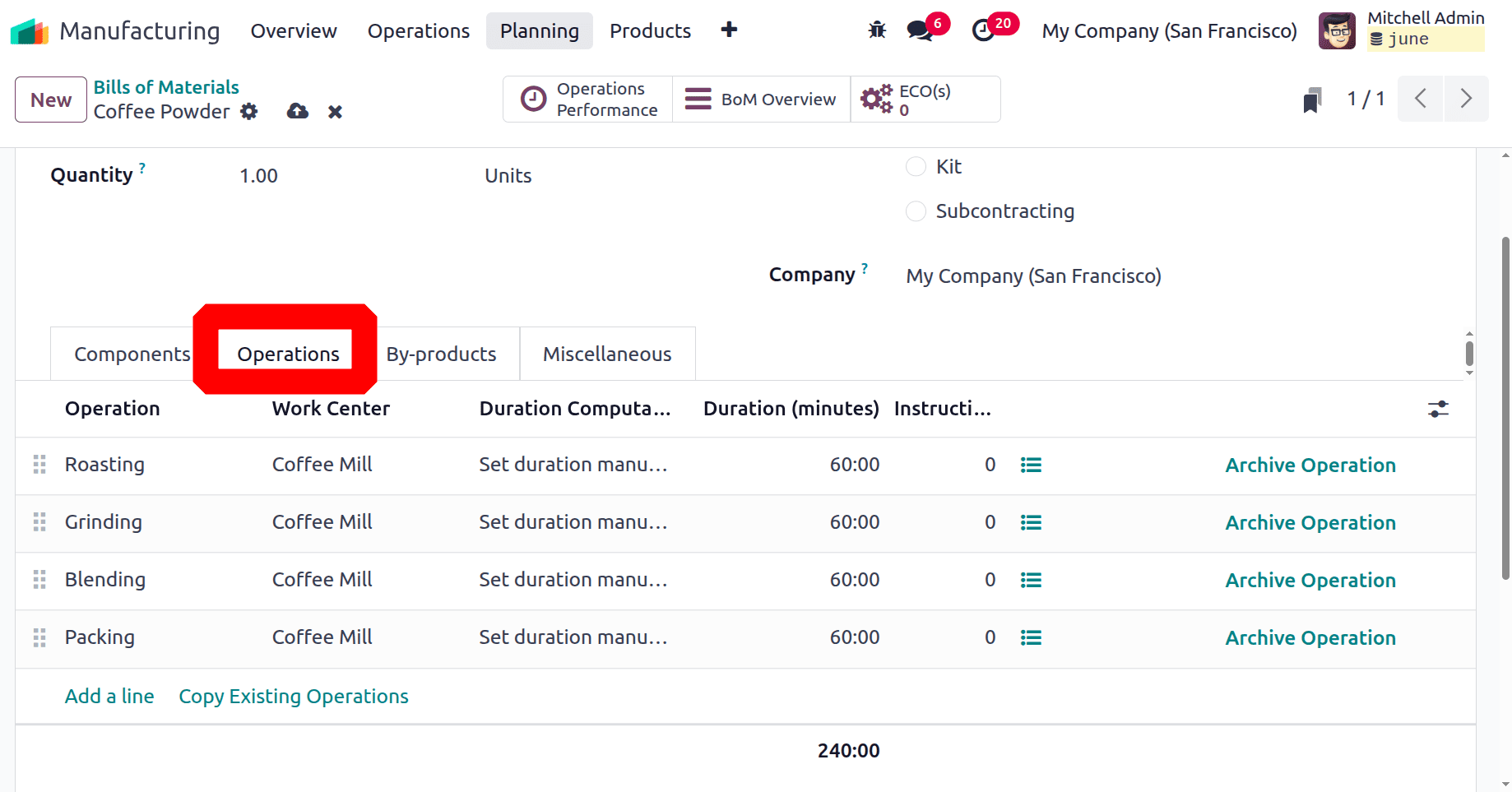

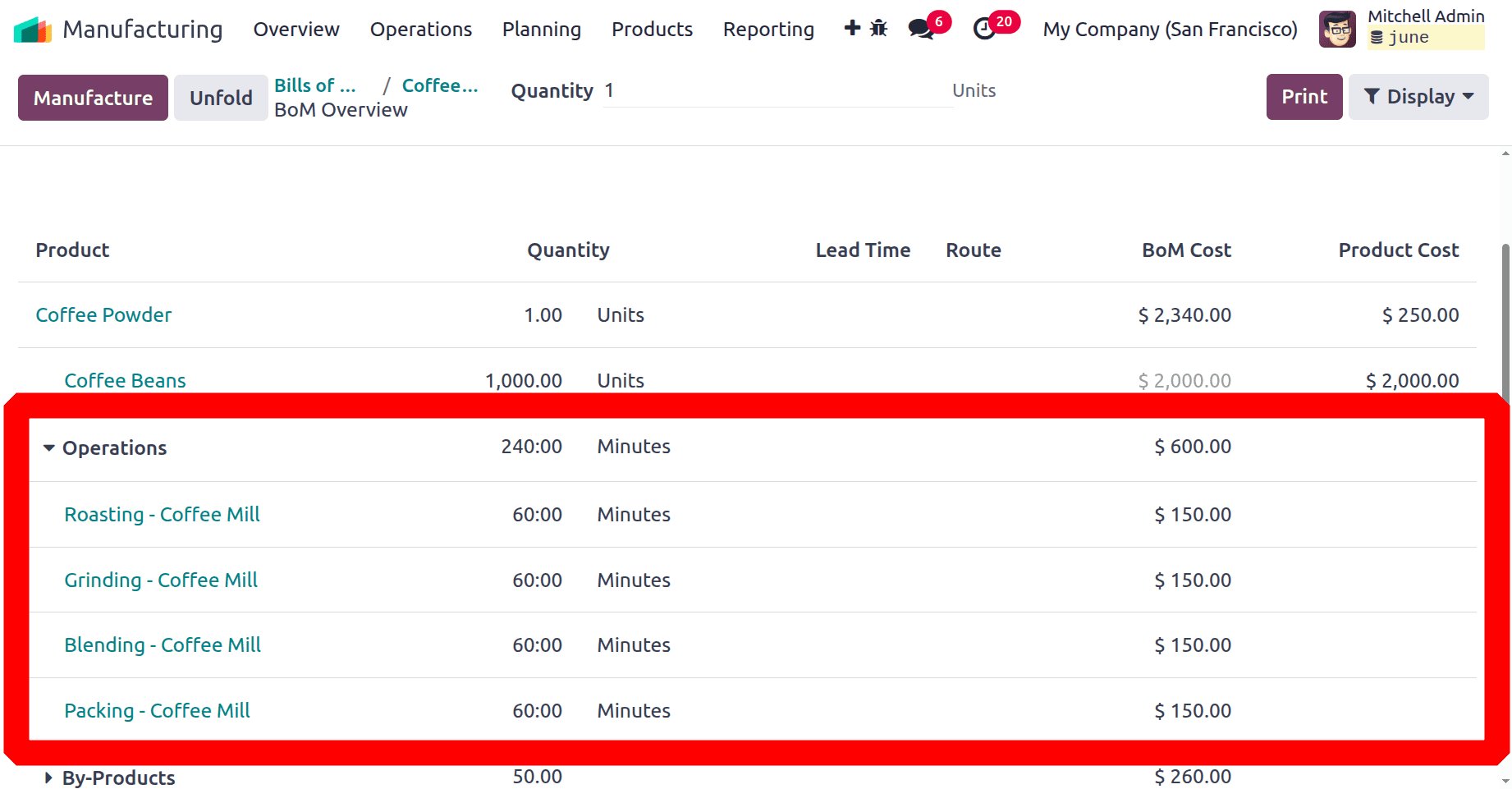

Click the operations tab after that. Selecting ‘Add a line’ will create a new operation, while selecting ‘Copy Current Operations’ will copy existing operations. When creating a new one, you need to include the operation name, sequence number, and other information. The name of the workplace where the action was finished can be entered here under the WorkCentre option. Talk about how long it took to complete the process. The duration can be calculated using recorded time, or it can be adjusted explicitly. In this instance, we manually set it to 60 minutes.

Here the Operations for making the Coffee Powder are Roasting, Grinding, Blending and Packing. Each operation is performed inside the same work center, which is Coffee Mill.

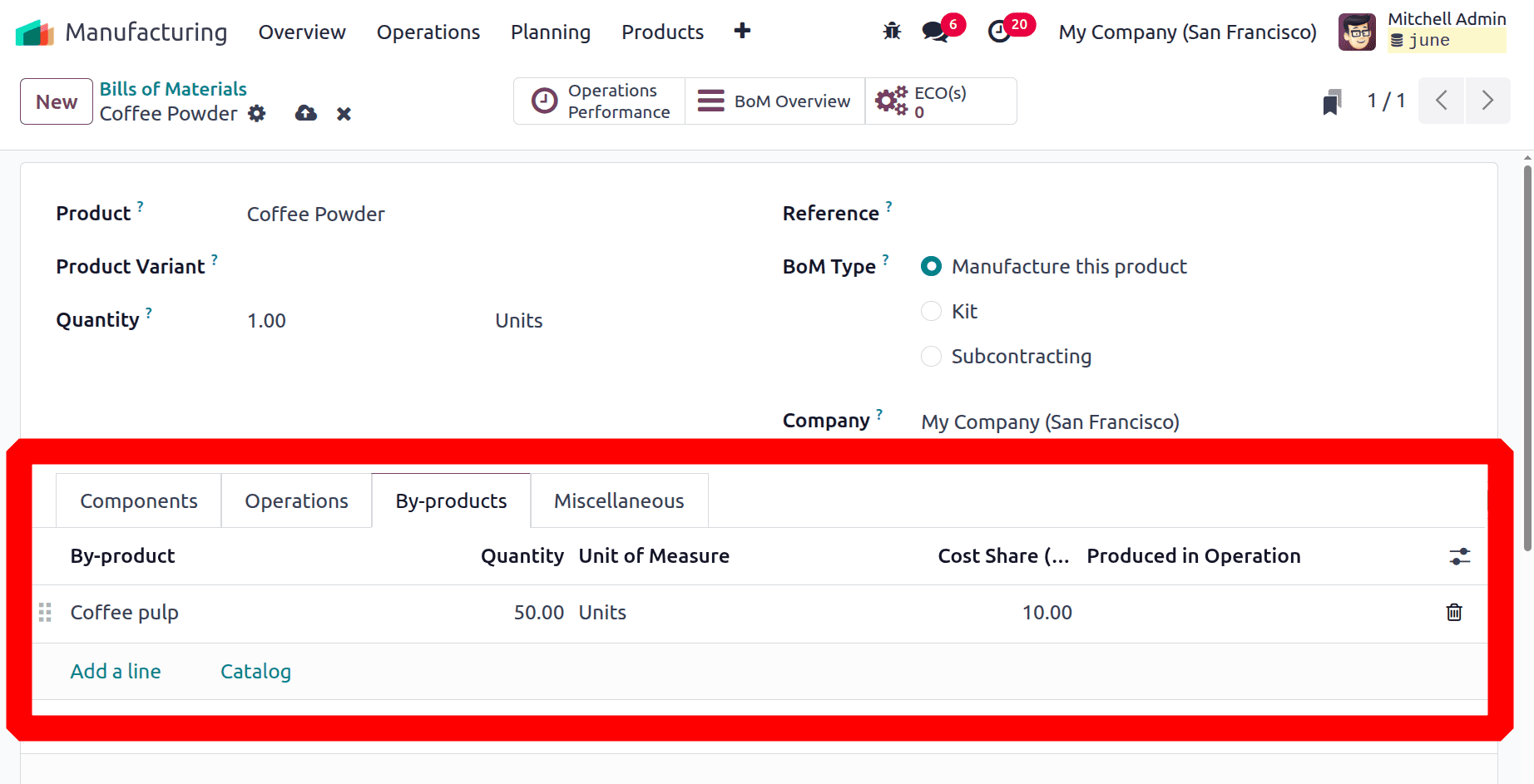

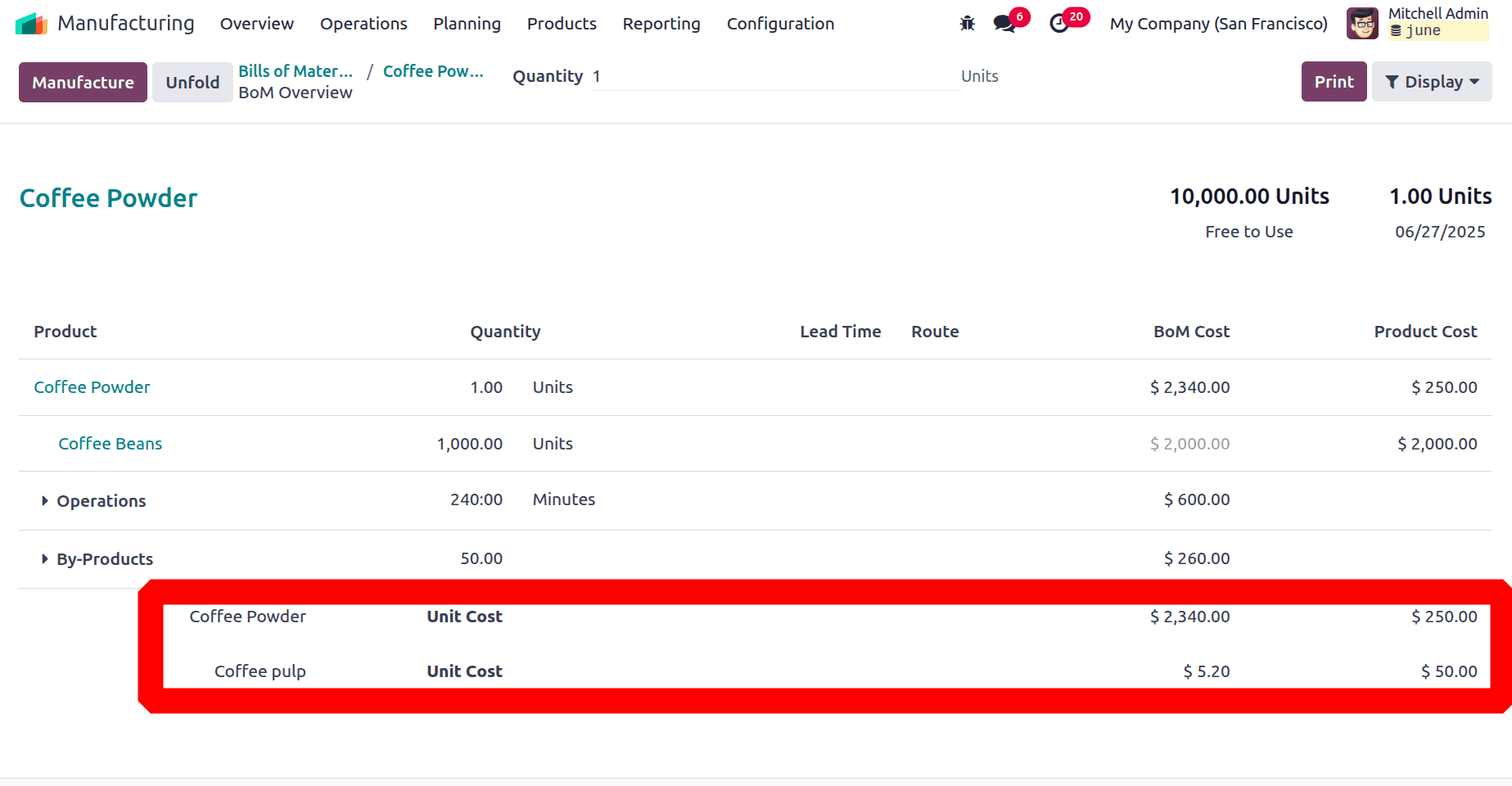

The product that is created as a byproduct during the production of coffee powder can be specified in the By-products tab. As a byproduct, 50 amounts of coffee pulp are stated here. Another alternative is to present the Cost Share as a percentage. Since 10% is indicated, the product's creation cost is reduced by 10% of the entire cost.

Simply save the bill of materials after providing the necessary details. Two smart tabs are displayed on the screen: "Operations Performance," "Overview," and "ECO." To learn more about the expected expenses associated with producing the goods, let's examine the Overview smart tab.

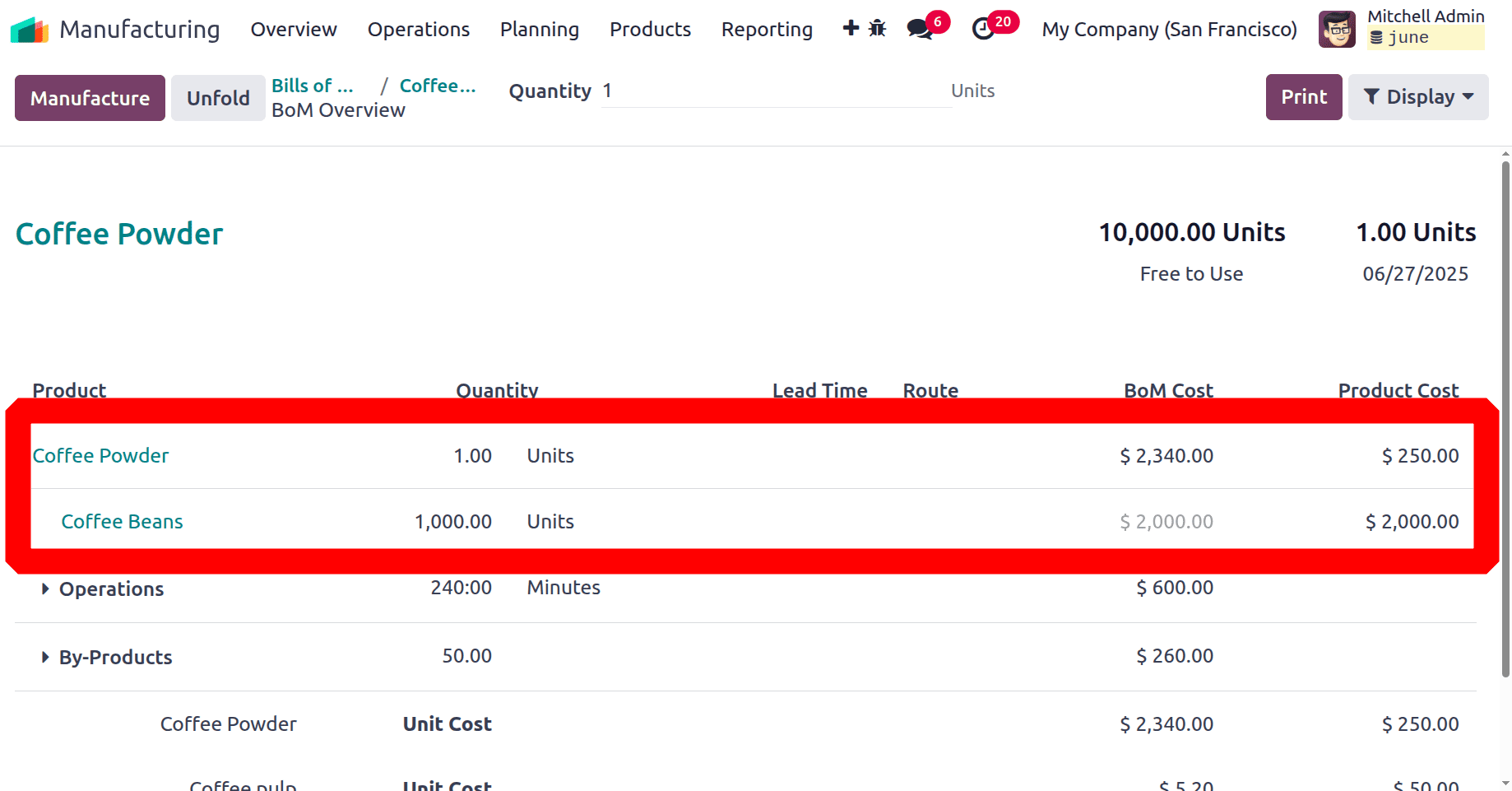

The cost of producing a single item is given here. The raw material is coffee beans. The price of the coffee beans is $2. Since 1000 quantities are required, the total cost of the components is $2000.

The computation of operating costs is the next stage. In this case, four operations have been added. This implies that it will take 60 minutes to do each process. As we previously stated, the Coffee Mill Work Centre is where the procedure is finished. The employee costs $50 per hour, whereas the Work Centre is estimated to cost $100 per hour. Therefore, the overall cost of the surgery is $600, with each operation costing $150.

The costs of each procedure and component are added up to determine the overall cost. proving that $2600 is equal to $600 + 2000. According to the bill of materials, the cost share was 10%.

Consequently, 10% of the total is expected to be spent on By Product. This indicates the by-product cost, which is $2600 * 10% = 260.

BoM Cost of the finished product = (Total cost- By product Cost)

BoM Cost Coffee Powder = 2600 - 260 = 2340

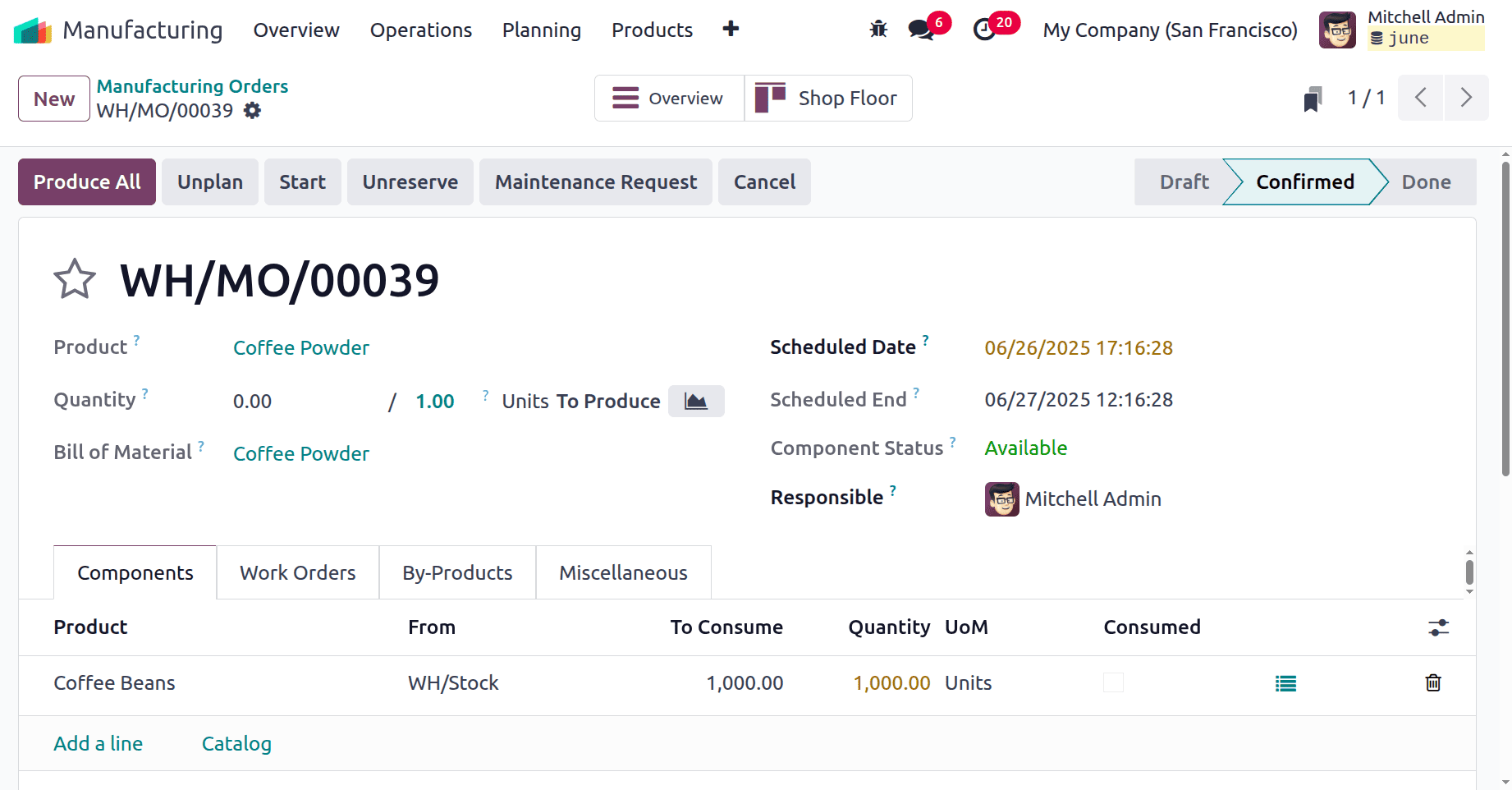

Let's draft an order for the coffee powder's production. To accomplish this, select the Manufacturing Orders option from the Operation menu. When you create a new manufacturer and select the Coffee Powder Product option, the Bill of Material will be selected by default. Finally, confirm.

Then let's complete the Work Orders to complete the Manufacturing of Coffee Powder.

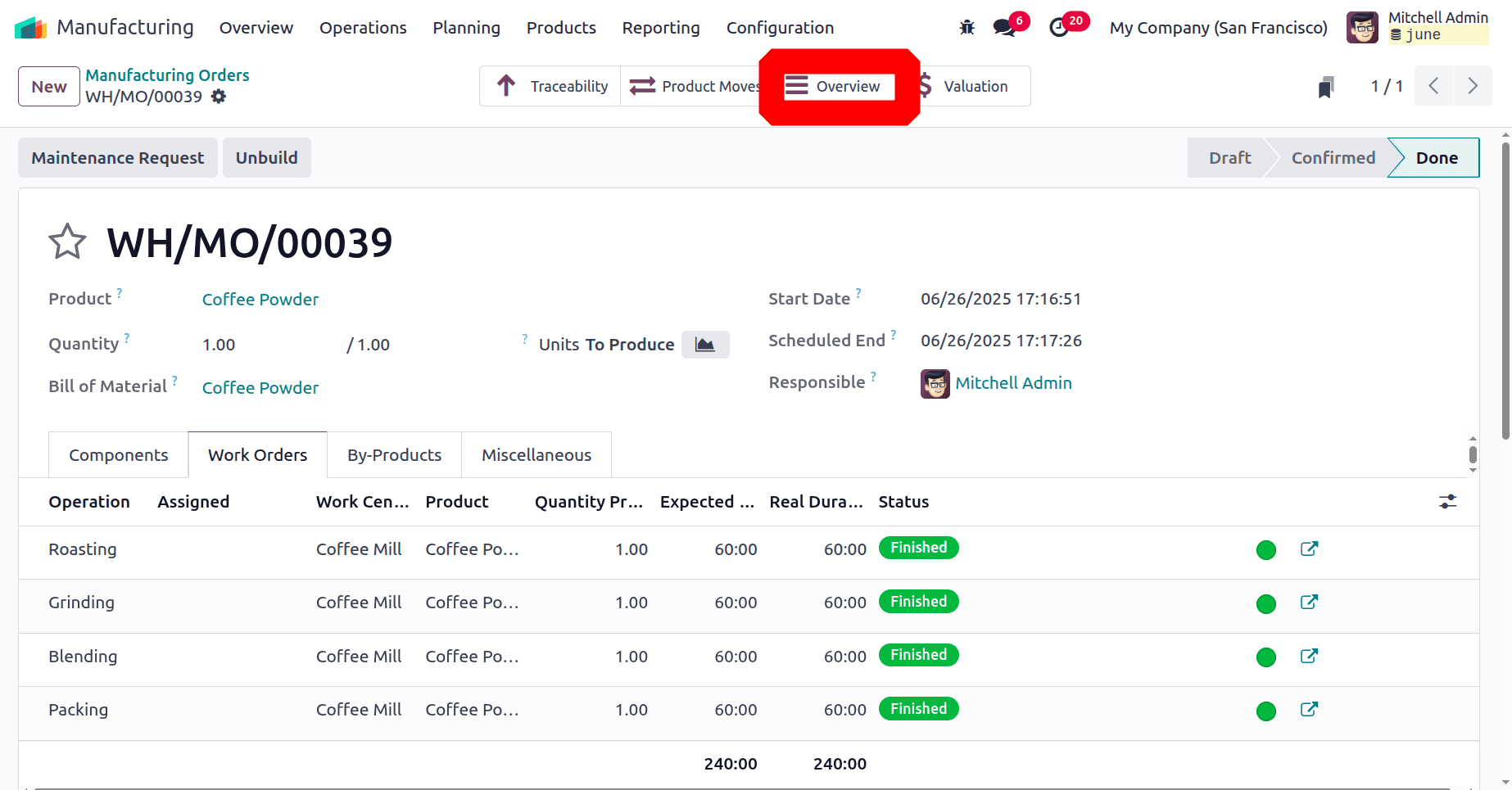

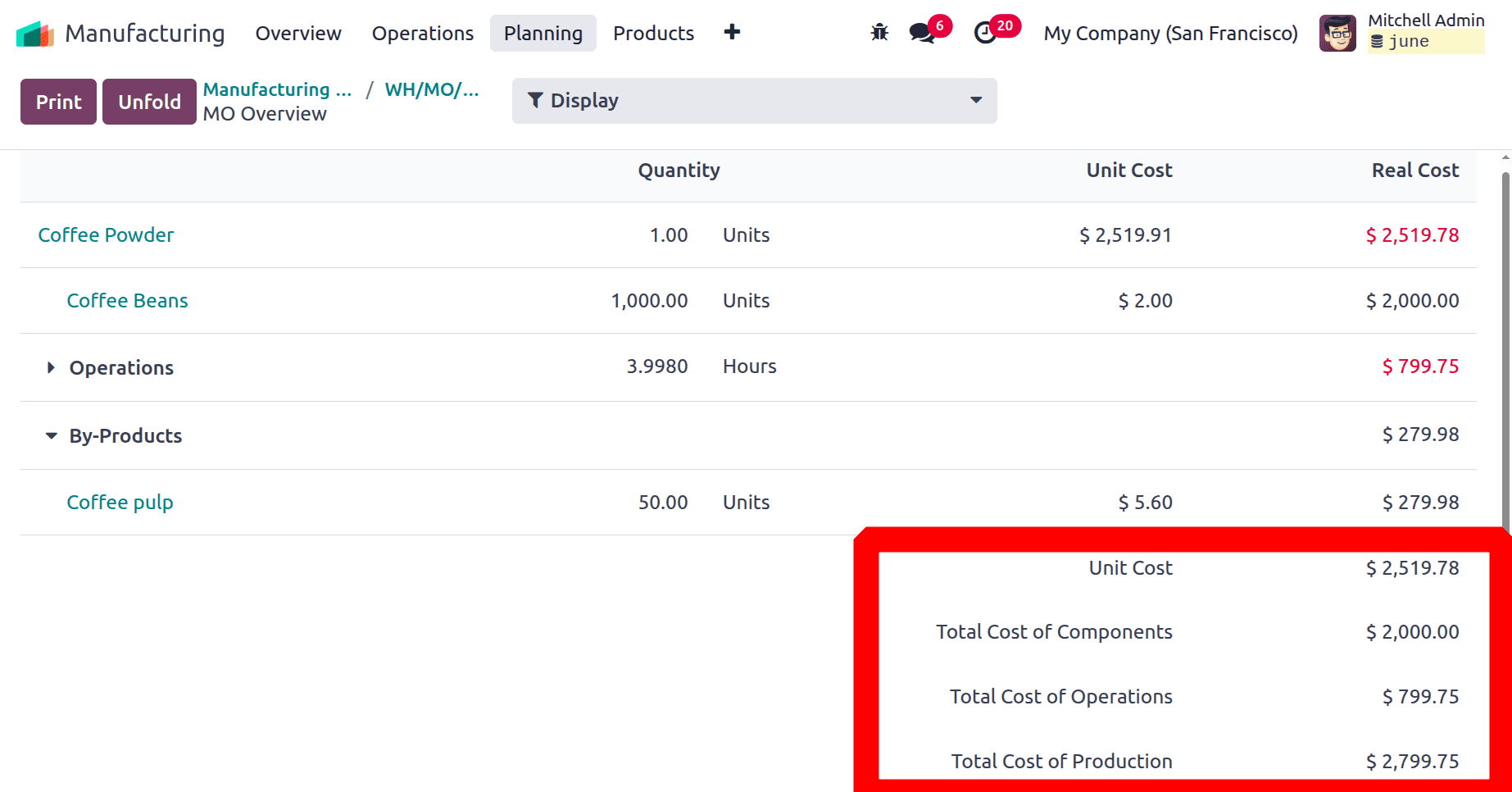

The above screenshot shows a completed Manufacturing Order. All the operations take 60.00 minutes to complete. Then check the Smart tab named Overview.

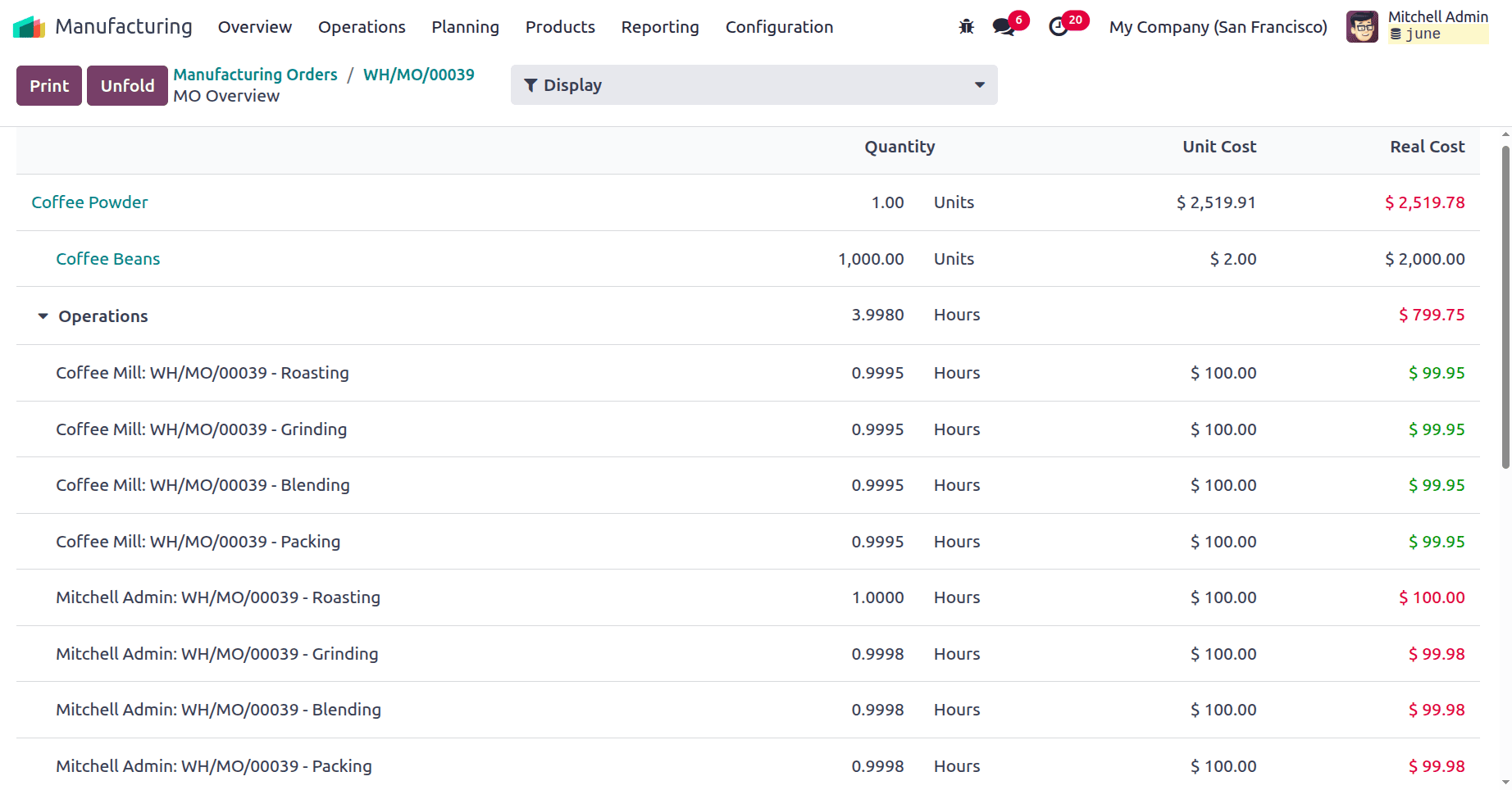

The overview shows the cost details of components, operations, and by-products separately. Here, the total component cost is $2000.

The total time taken to complete the manufacturing operations is 3.9980 hours, and so the total operation cost is $799.75.

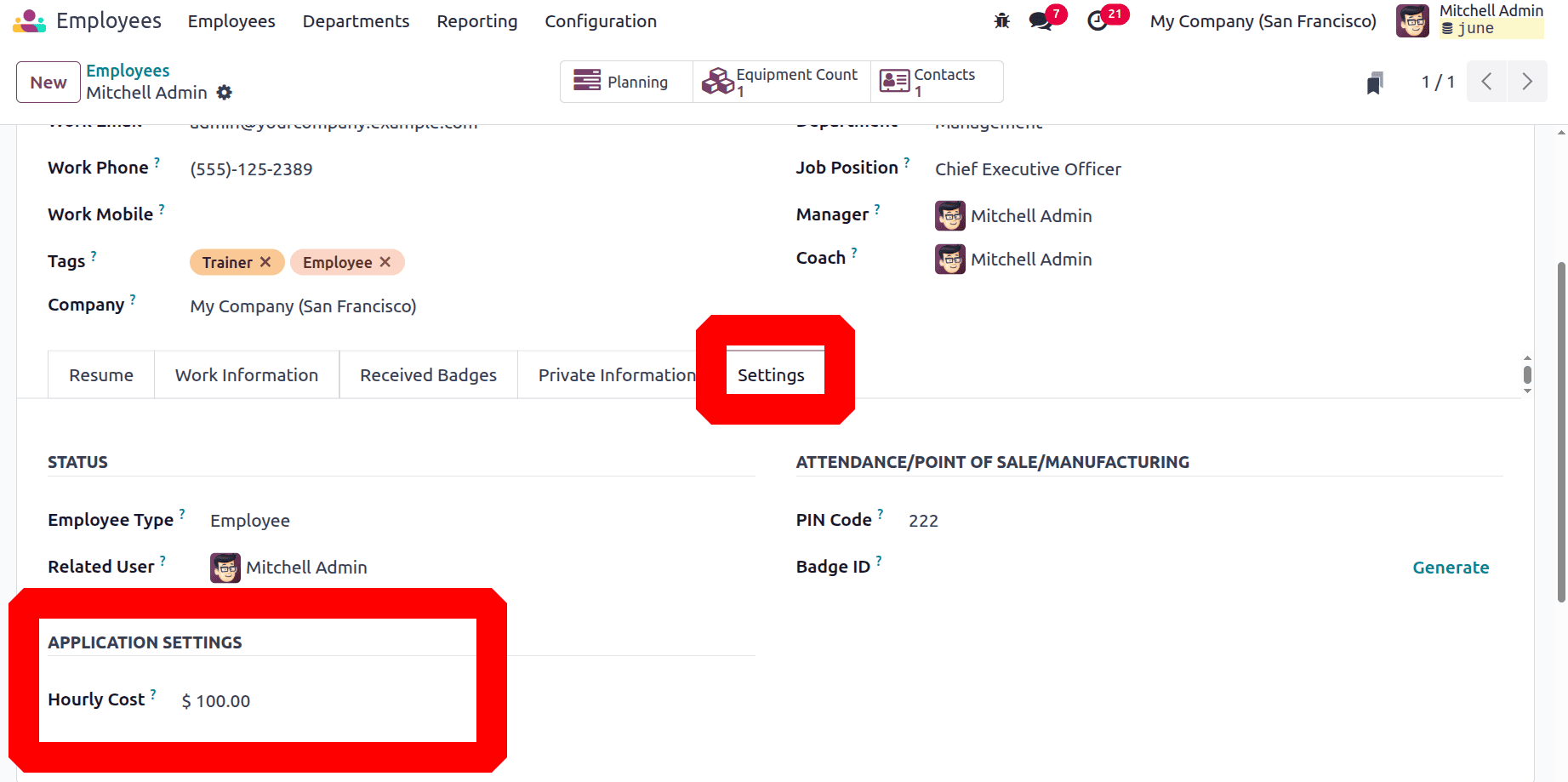

Here, the operator is Mitchell Admin, and the employee cost is added inside the Employee module. So here the per hour working cost of the employee is given as 100. So that cost is taken here as the employee cost.

So the Total Cost of Production = Cost of component + Cost of Operation

= 2000 + 799.75 = 2799.75

By-product cost is 10% of Total Cost of production = 2799.75 * 10% = $279.975.

BoM Cost of Final Product Coffee Powder = 2799.75 - 279.975 = $2519.78

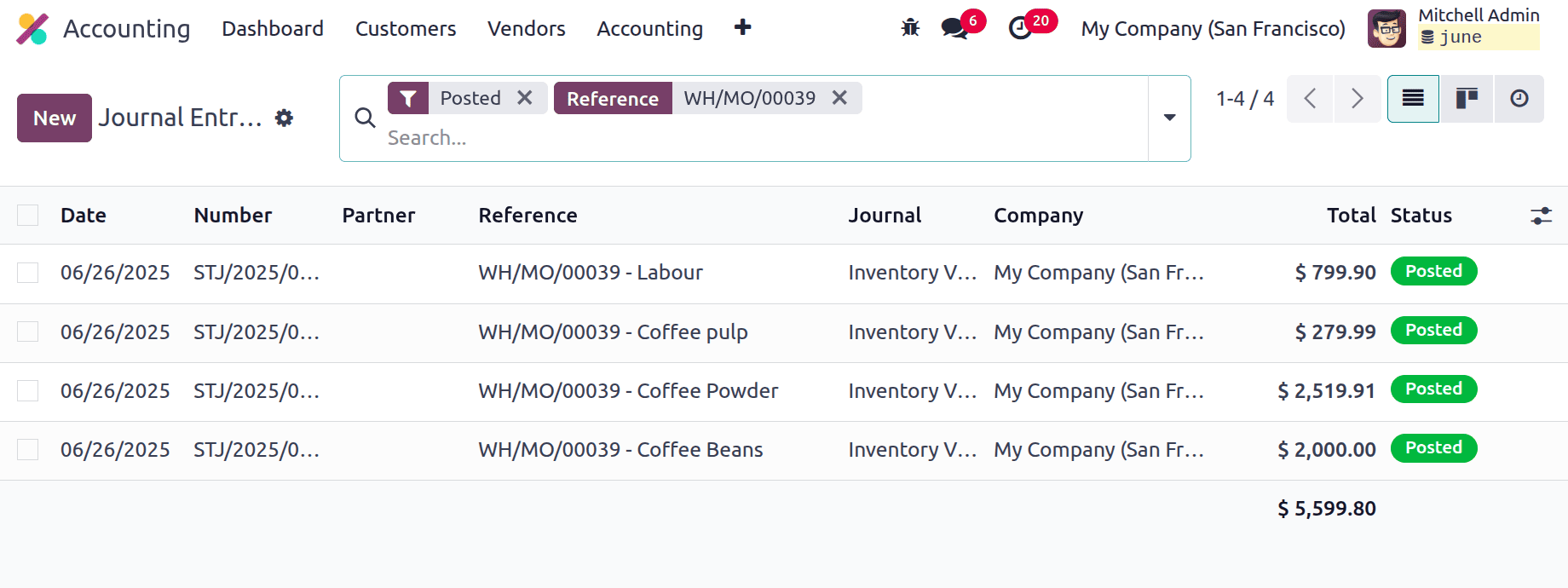

To confirm the journal entry, navigate to the Accounting section. Click on it, then from the Accounting tab, choose Journal Entry. There, you may see the journal entry made following the manufacture.

: Accounting > Journal entry

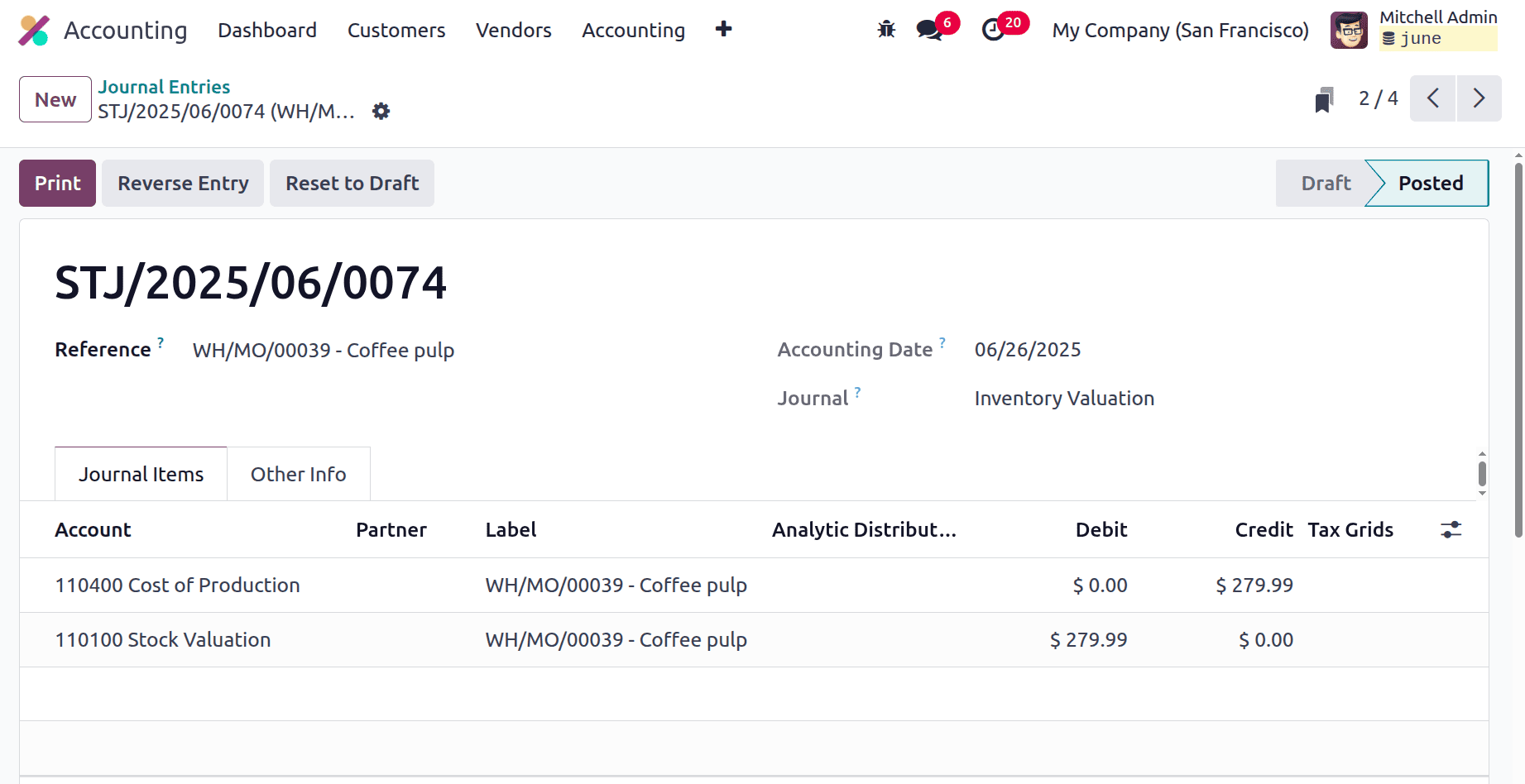

The screenshot given below shows the journal entry created for the By-Product. Here, the Cost of Production account and Stock Valuation account are Current Assets by nature. So the Cost of Production account Credited and Stock Valuation account debited with the by product cost.

The cost share at that time is also displayed in the journal entry. Consequently, a percentage of the overall cost is also allocated for the production of byproducts.

To read more about Cost Share Functionality in Odoo 16 Manufacturing Module, refer to our blog Cost Share Functionality in Odoo 16 Manufacturing Module.