The term "InventoryOperations" refers to the multiple procedures that control the flow of inventory between various locations, warehouses, and through activities like internal transfers, acquisitions, and sales. In inventory control, the reservation method is used to assign products for particular transactions or activities, guaranteeing that the requested stock is set aside and unavailable for other uses until the process is finished.

The reservation method is used in inventory control to assign products for specific transactions or activities, ensuring that the requested stock is set aside and unavailable for other uses until the process is completed. The term "inventory operations" refers to the various procedures that control the flow of inventory between various locations, warehouses, and through activities like internal transfers, acquisitions, and sales.

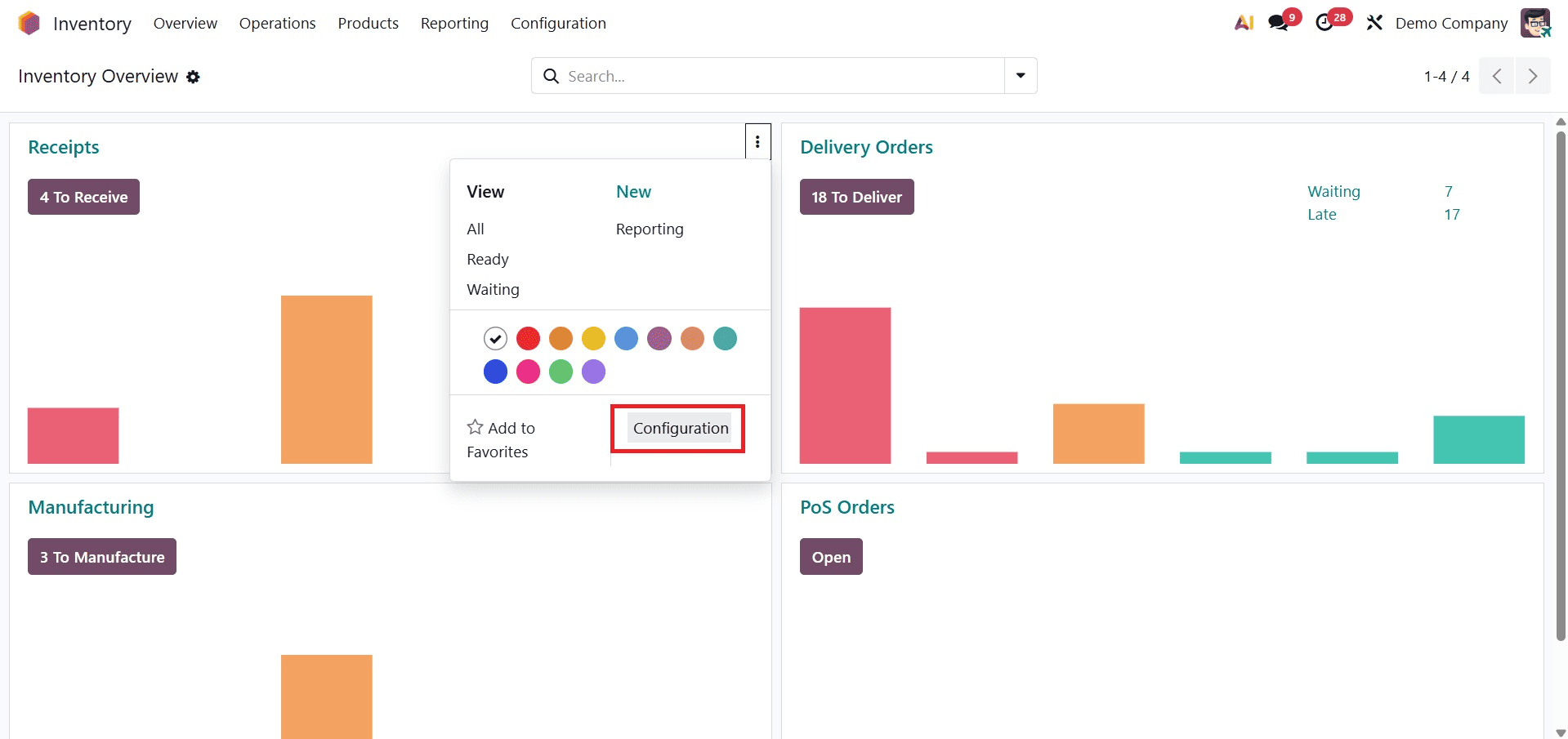

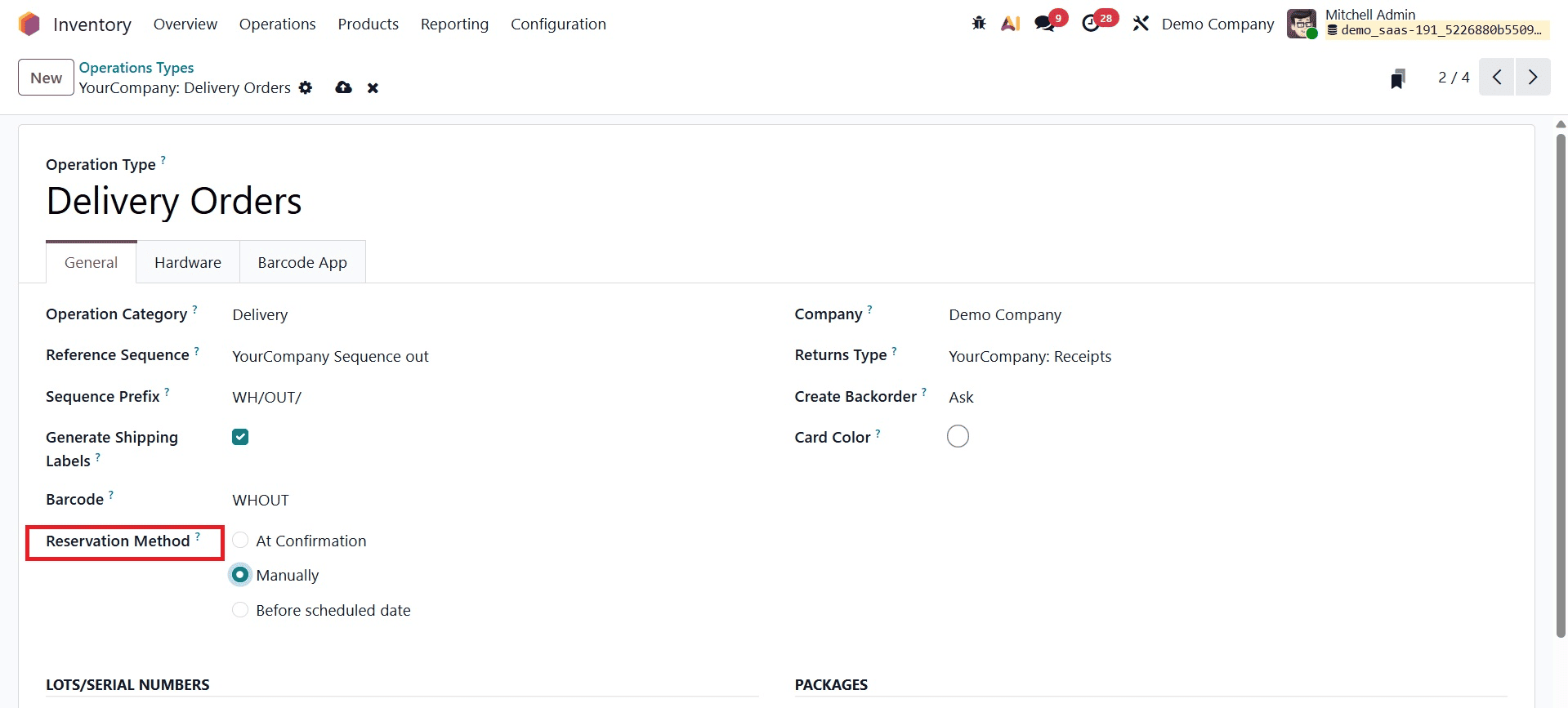

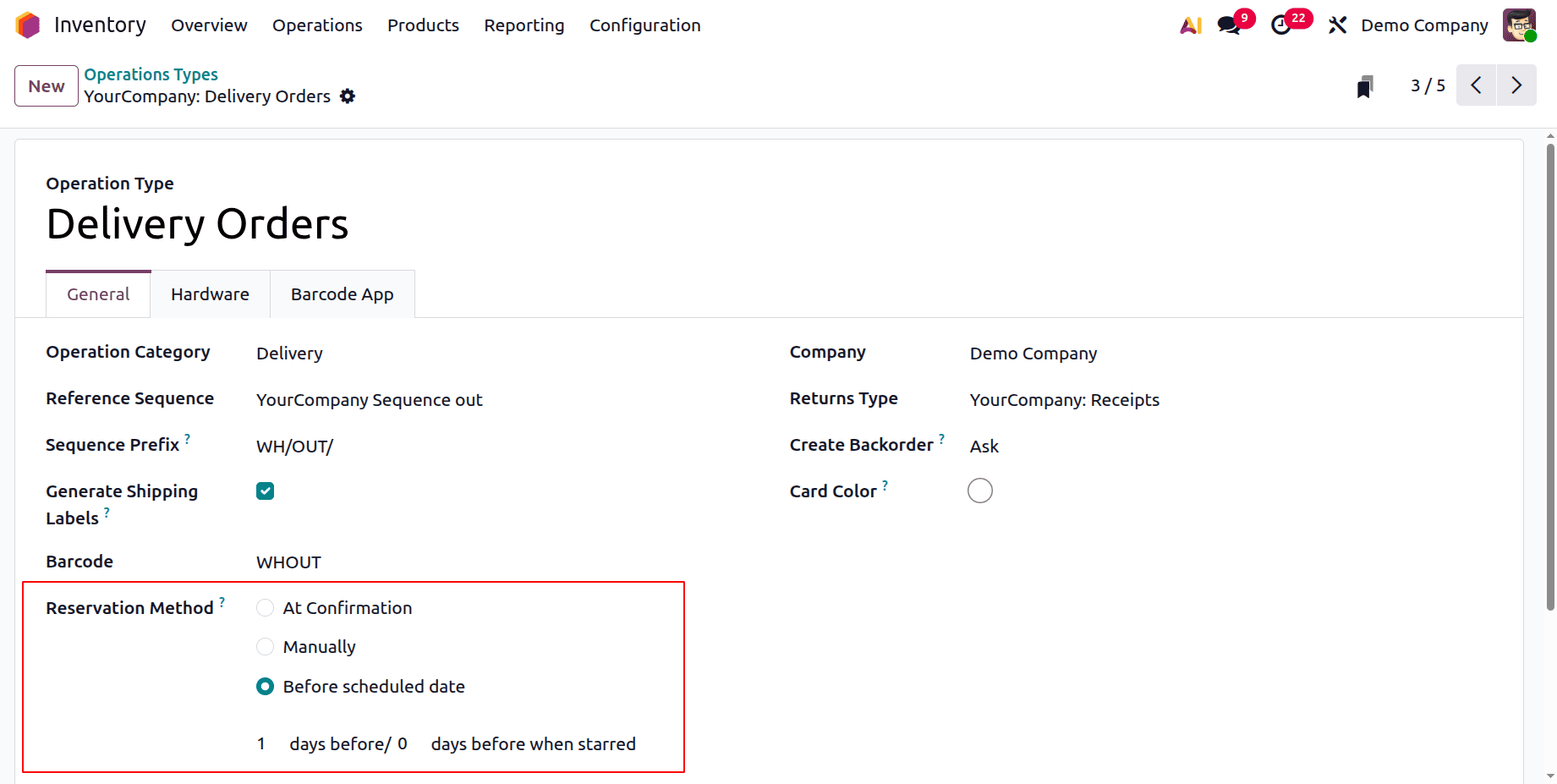

Users can modify the operation kinds, including reservation techniques for different inventory operations, by selecting the configuration option.

Reservation methods

Before starting any operations, businesses must make sure that products are available because this is crucial to inventory management. In order to guarantee that goods are set aside for particular sales or production orders, the Reservation Method assists with stock allocation in advance. This procedure ensures that stock is available for the planned operations, avoiding inconsistencies and improving the effectiveness of inventory management. Businesses can better control inventory levels, prevent stockouts or overbookings, and guarantee efficient operations by reserving stock, all of which eventually result in the prompt fulfillment of customer orders.

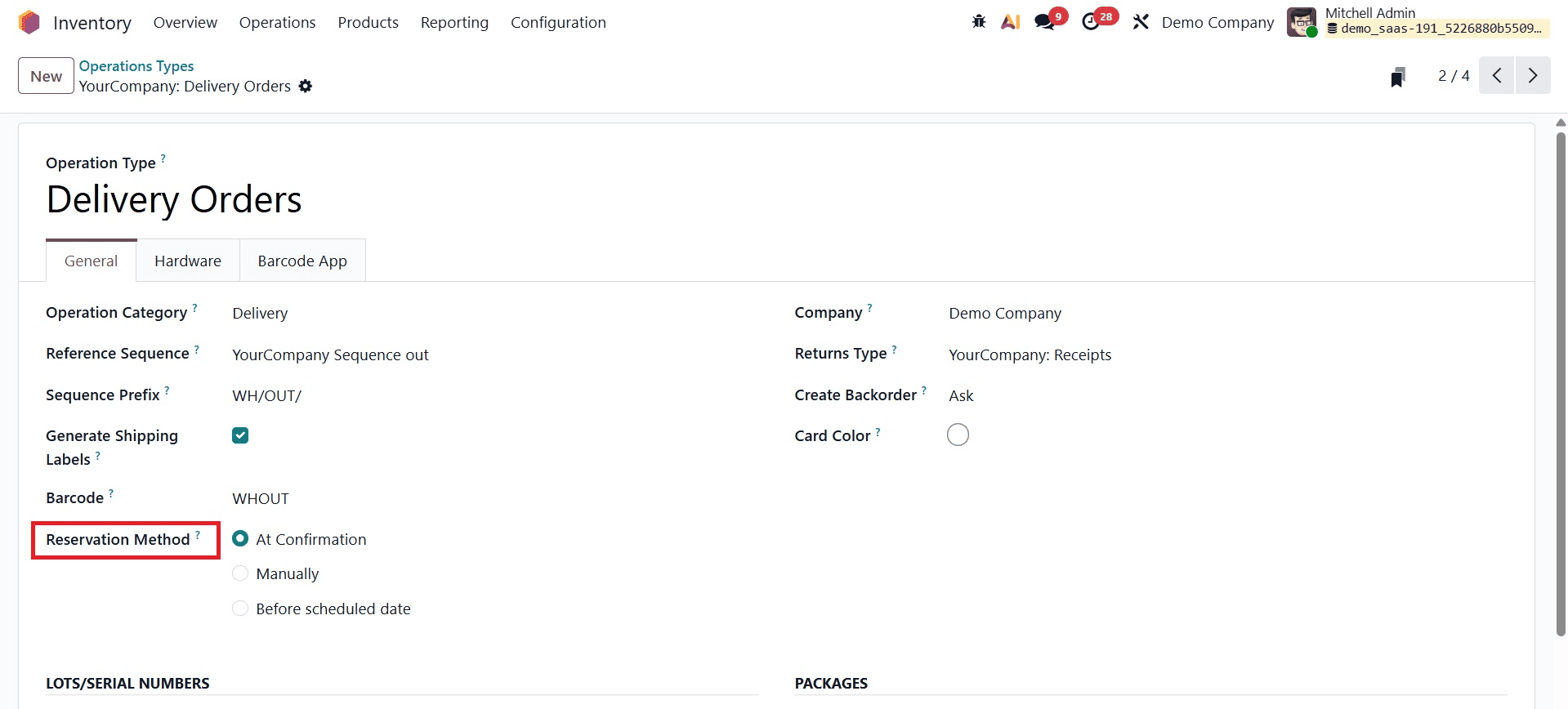

The Odoo Inventory offers three primary reservation options:

- At Confirmation: Stock is set aside as soon as the production or sales order is verified.

- Manually: The user reserves stock by hand, giving them greater flexibility and control.

- Before Scheduled Date: In order to guarantee availability for scheduled operations, stock is reserved before the scheduled date.

These reservation techniques aid companies in improving operational effectiveness and inventory management.

1. At Confirmation

Products or services are reserved using the "At Confirmation" reservation method as soon as the order is confirmed. This guarantees that the necessary stock is automatically assigned to the particular sales or delivery activity upon order confirmation, resolving any stock shortages or inconsistencies throughout processing.

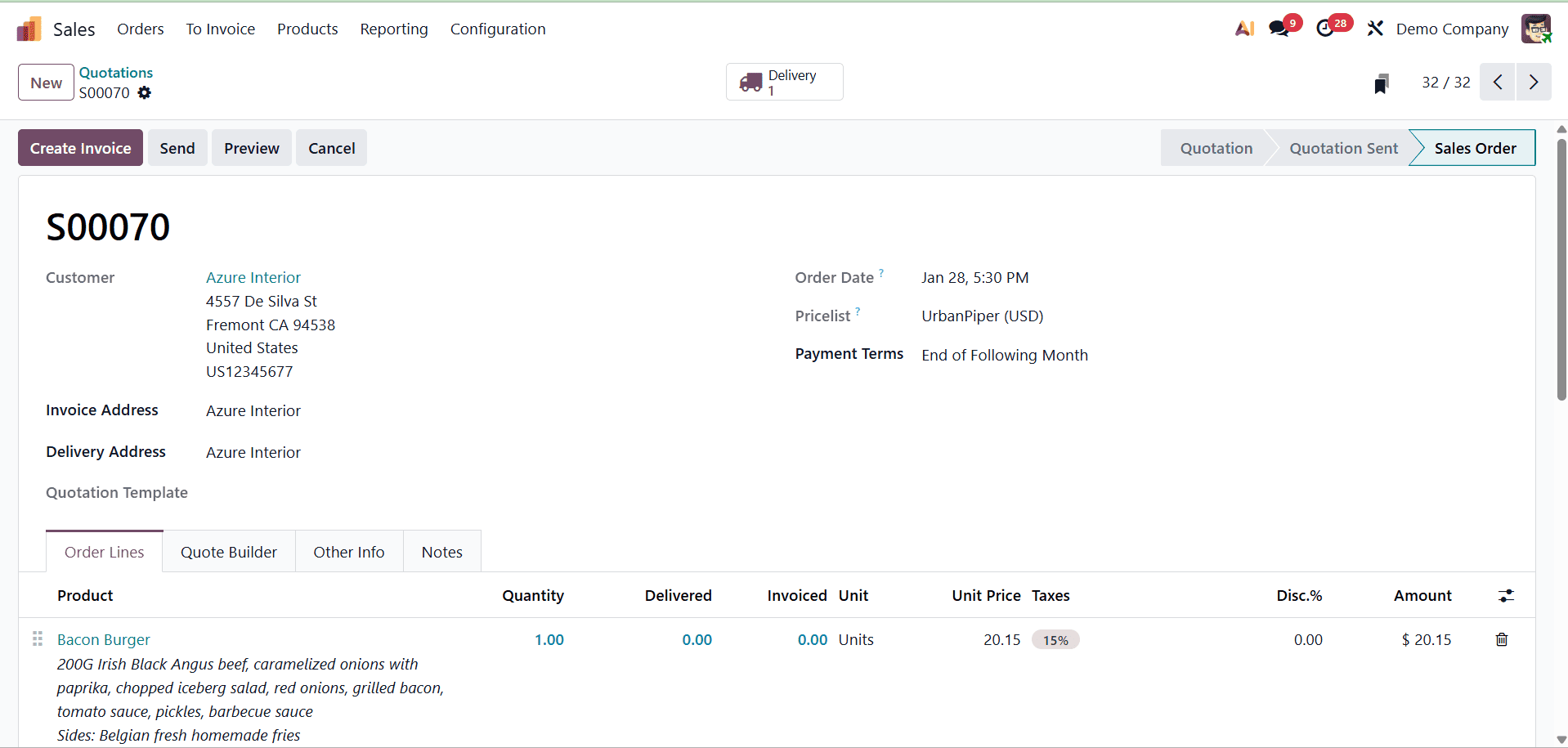

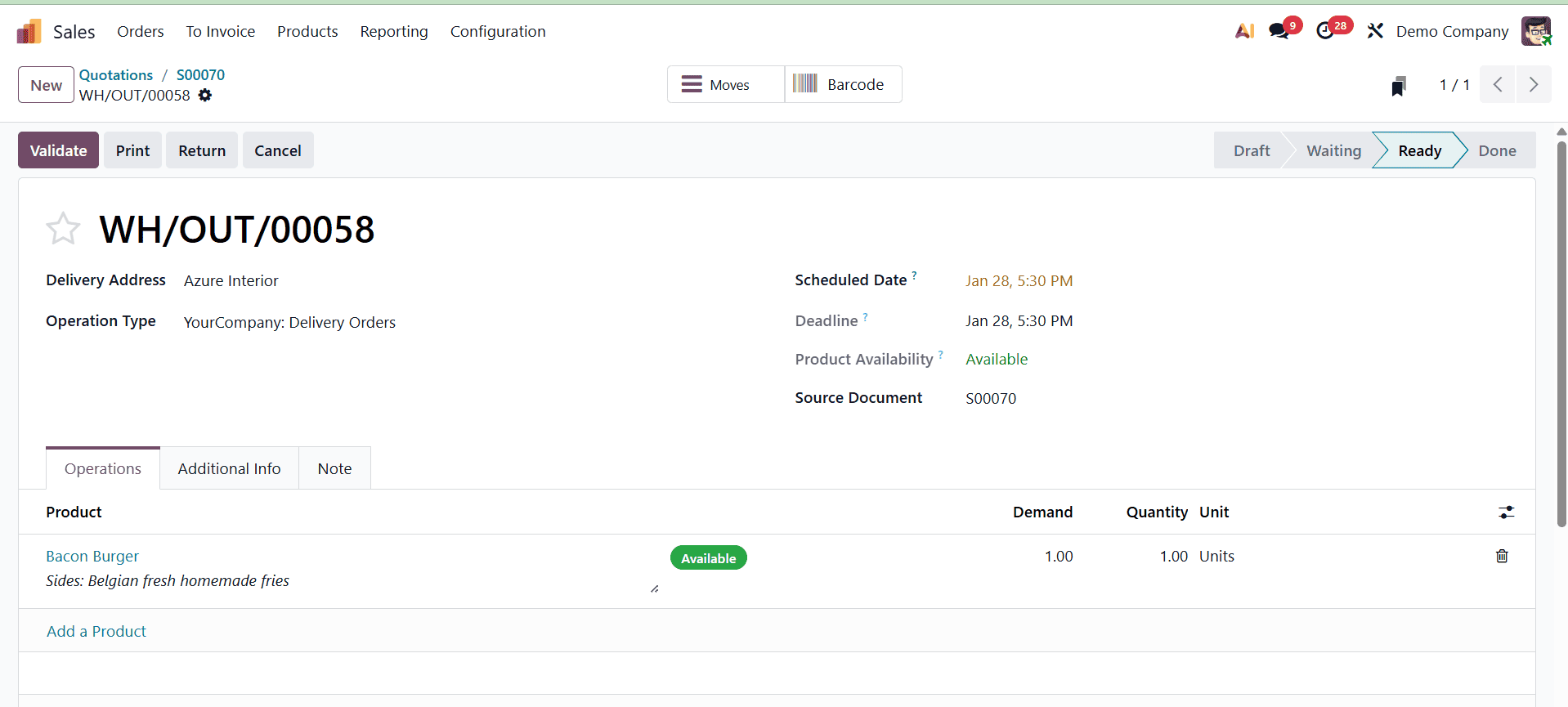

A delivery order smart tab is triggered when new quotations are created and the order is confirmed.

The delivery details will then be displayed by the "Transfers" smart button. In order to validate the delivery order, we can observe that the product is automatically reserved while conforming the sale order. When the sale order is confirmed using the confirmation method, the product is immediately reserved because it is available.

2. Manually

Products are not automatically reserved when using the "Manually" reservation option. Rather, you must manually verify the product's availability and reserve the desired amount once the order has been verified. You can respond to inventory only when needed using this strategy, which gives you more control over stock allocation.

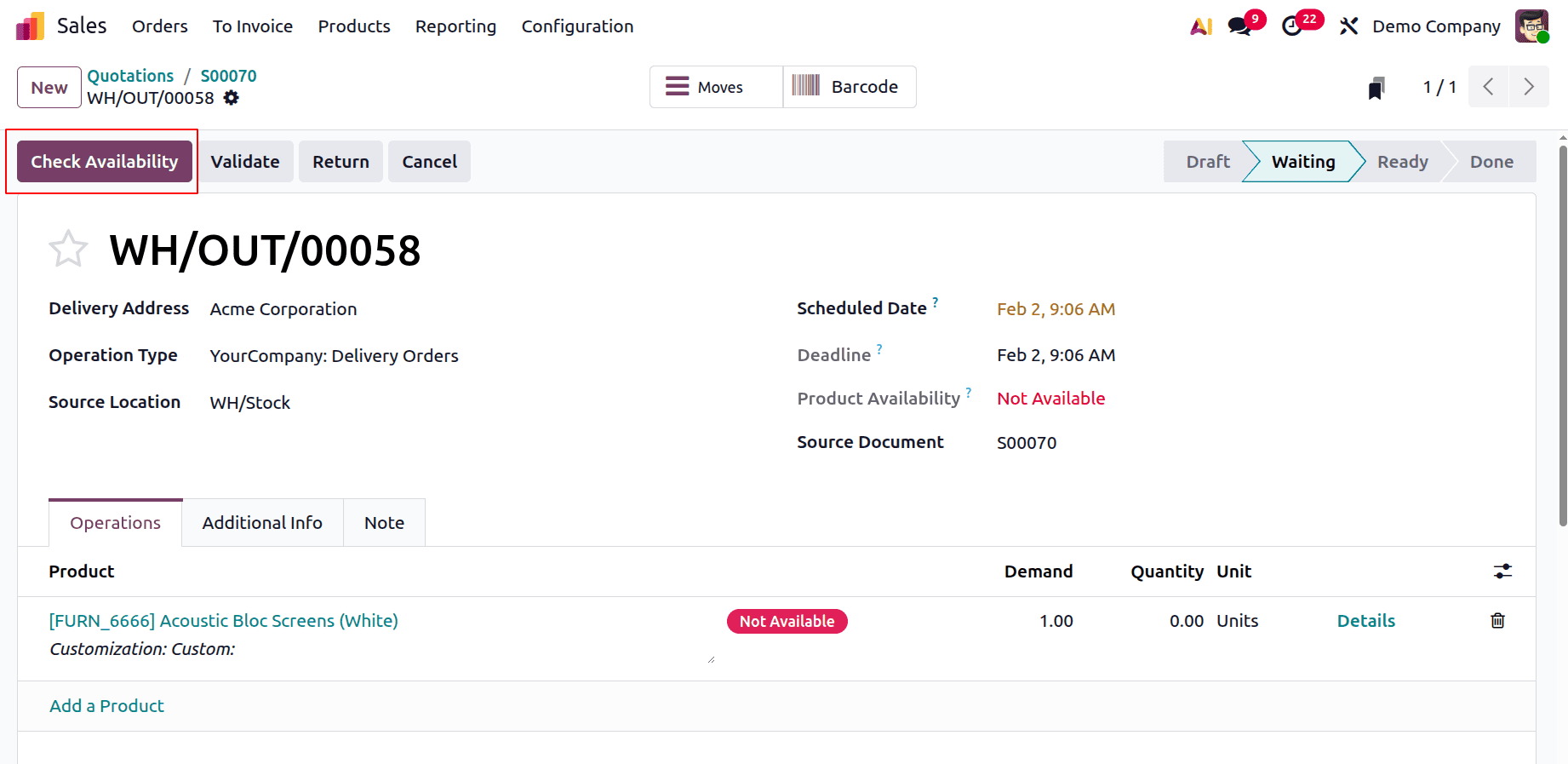

Generate a quote and confirm to generate a delivery order after selecting the manual reservation option. Before making a stock reservation, you must manually verify the product's availability because the reservation method is set to Manual. To accomplish this, click the "Check Availability" button in the production or sales order. You can reserve the product when availability has been confirmed, guaranteeing that enough inventory is set aside for the operation. Greater control is offered by this manual method, which enables you to verify stock levels before completing any inventory transactions. This helps to customize stock imbalances and guarantees that inventory levels are recorded and managed.

The Product Availability status is updated if the product is available. You can validate the order after the product has been reserved and its availability has been verified. This guarantees that inventory is updated, orders are handled, and stock is assigned appropriately while adhering to the production schedule, supplier, or customer commitment.

3. Before Schedule Date

Products can be reserved ahead of time using the Before Scheduled Date reservation technique, up to a predetermined number of days before any inventory operation. You can customize this reservation technique to meet your operational demands by specifying how many days in advance goods should be reserved. This makes it possible to plan more effectively and guarantees that inventory is distributed in advance, fulfilling the demands of your manufacturing, sales, or delivery schedules.

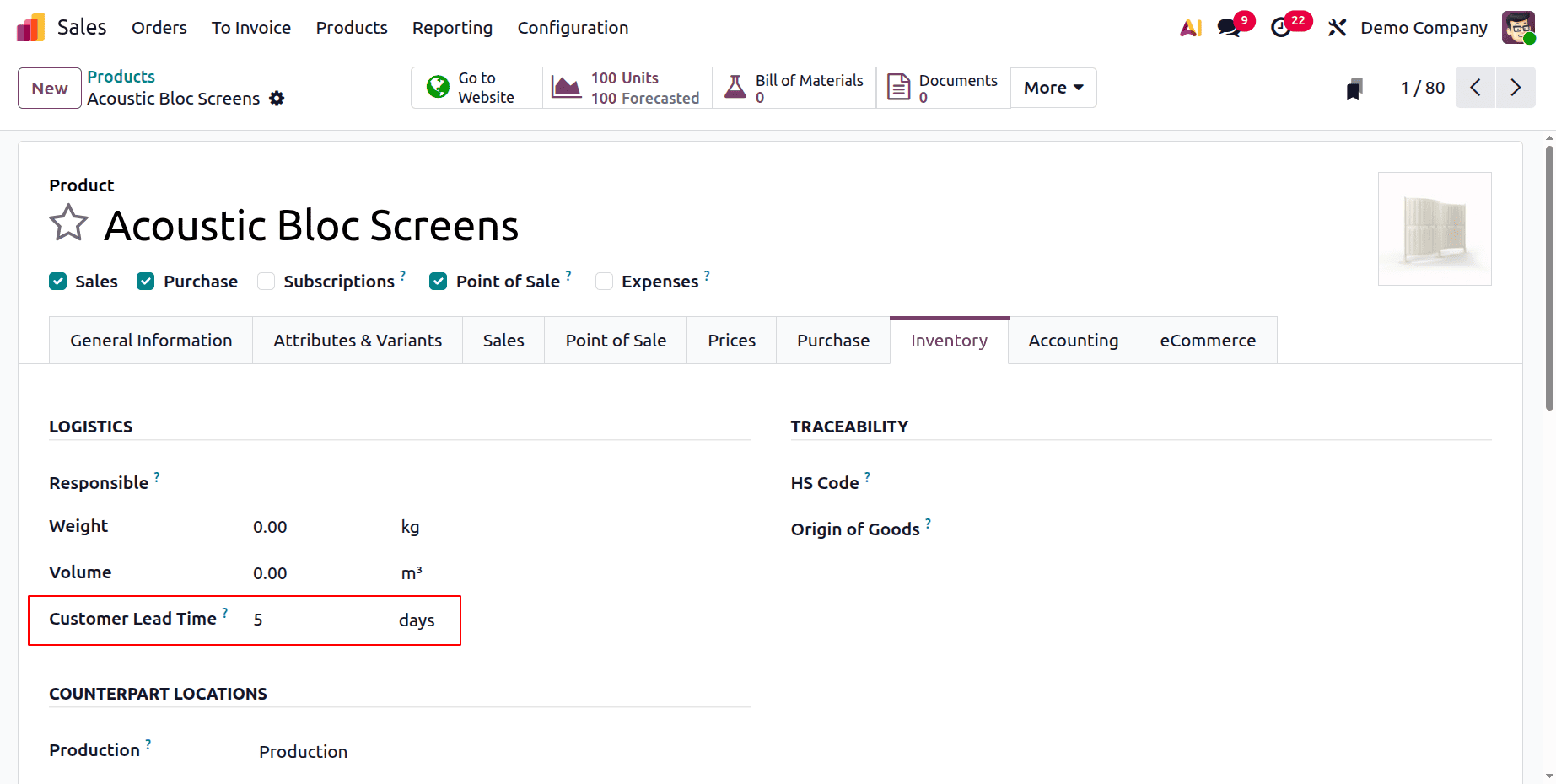

Establish the client lead time for the product after determining the number of days in the Before Scheduled Date reservation method. The agreed-upon time frame for the product's delivery to the customer is known as the customer lead time. Here the customer lead time is set as 5 days.

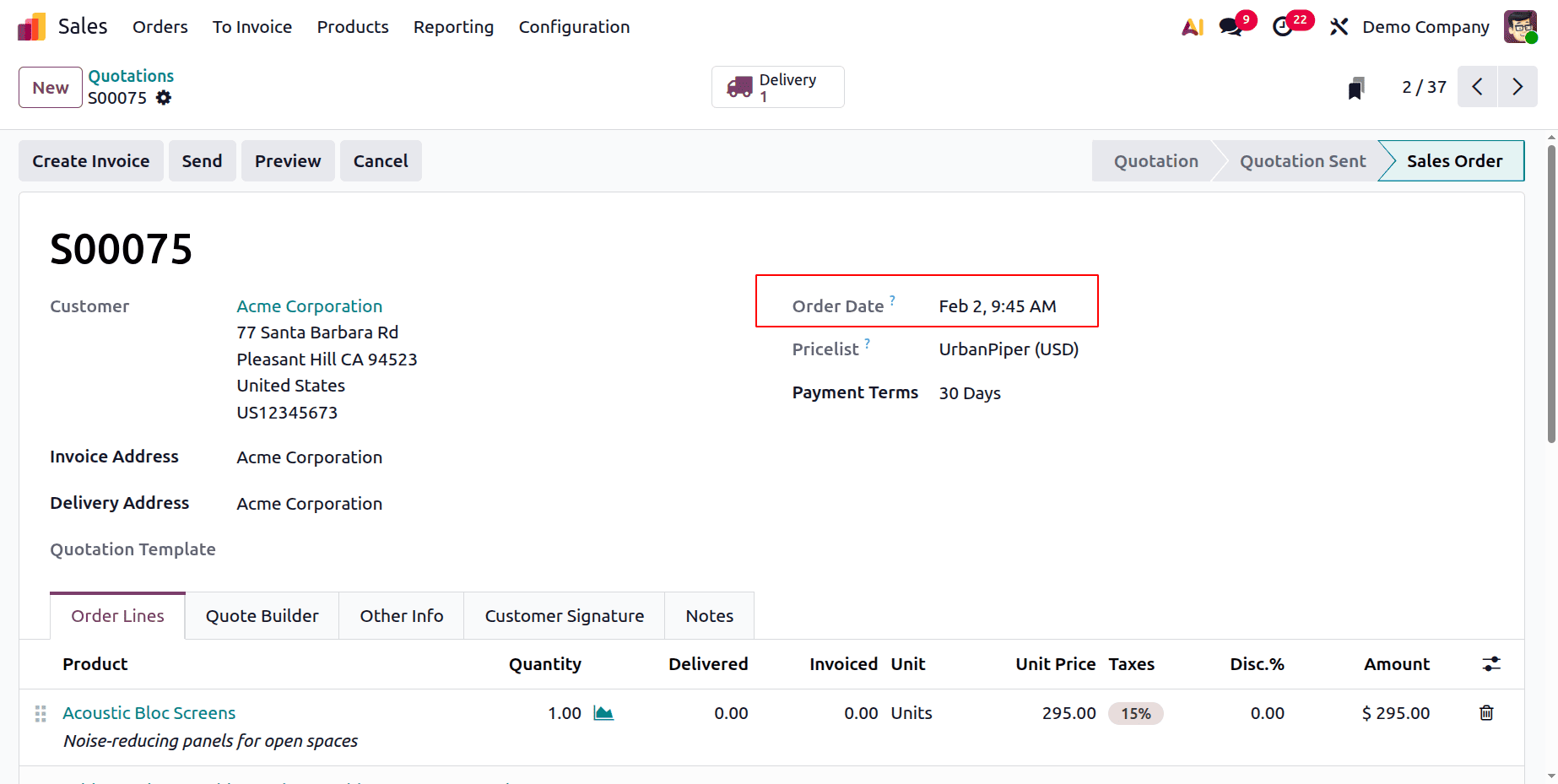

Create a sales order for the goods when the lead time has been determined, making sure that inventory is set aside and that the customer's expectations are met by the delivery schedule. This procedure guarantees on-time delivery and improves inventory planning. Here the sale order is created on February 2nd.

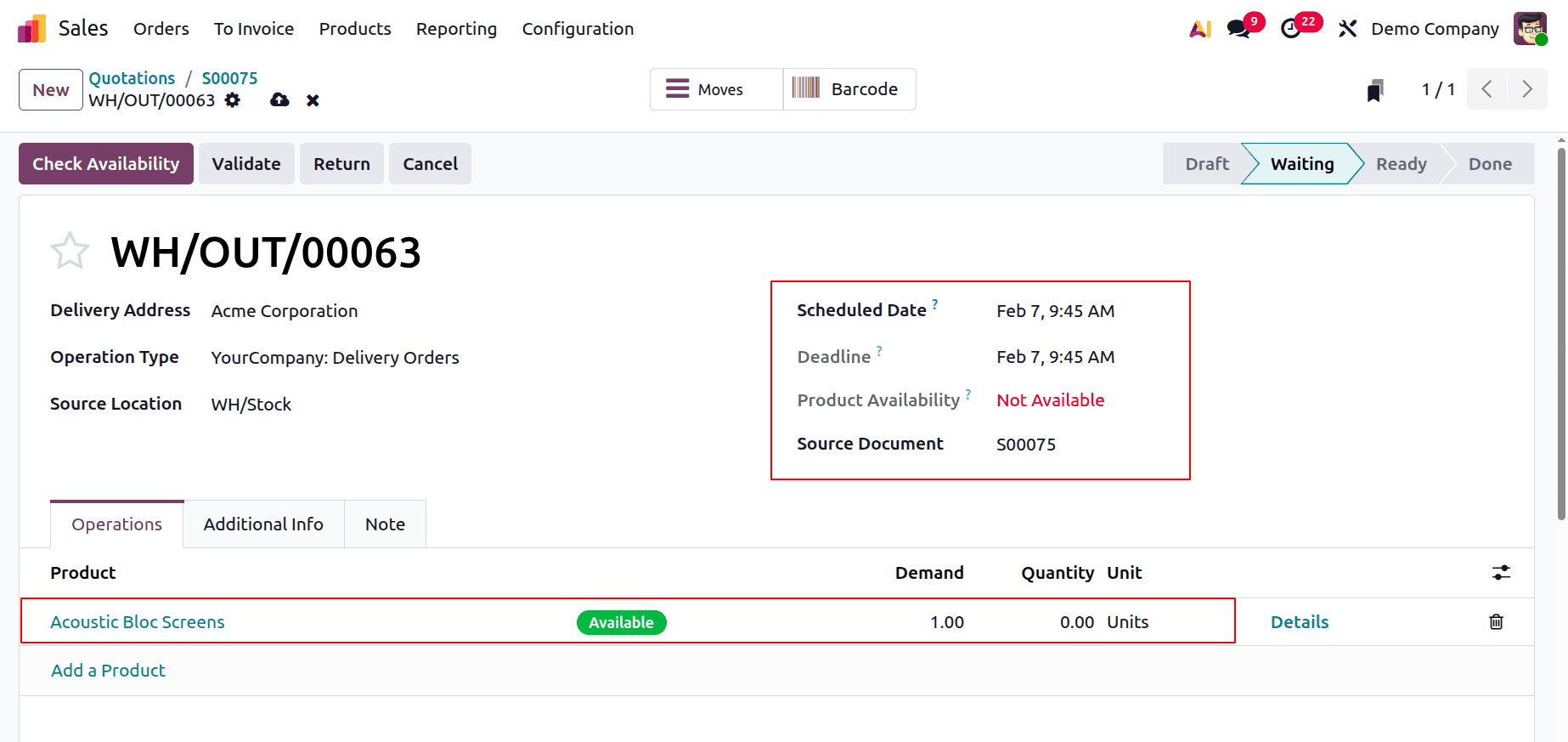

The product is reserved one day prior to the planned date, as we can see. After making the reservation, you can verify the delivery order and proceed with the next steps to finish the purchase.

Here the Scheduled Date is February 7th. The product will be reserved only one day before delivery date. Which means the product will be reserved on February 6th.

When it comes to resolution, the inventory management reservation methods—At Confirmation, Manually, or Before Scheduled Date—play a critical role in guaranteeing that stock is appropriately assigned and accessible for particular operations. These techniques assist companies in keeping inventory under control, avoiding stock imbalances, and guaranteeing prompt fulfillment of supplier commitments, manufacturing schedules, and customer orders. Businesses can increase overall operational efficiency, prevent stockouts, and optimize their operations by reserving products based on real-time availability and lead times. In the end, these inventory reservation procedures improve customer satisfaction, streamline manufacturing processes, and facilitate inventory management.

To read more about How to Use Various Reservation Methods in Odoo 18 Inventory, refer to our blog How to Use Various Reservation Methods in Odoo 18 Inventory.