Alternative Workcenter is a really useful solution that Odoo has developed. The Alternative WorkCenter in Odoo 18 Manufacturing setup and operation will be covered in this post. An essential component of the production process is the workspace.

Odoo considers a work centre to be a manufacturing workstation. A business may have one or several workstations. A business needs multiple warehouses because it needs more than one to manufacture more goods. As a result, warehouses are crucial components of a manufacturing business.

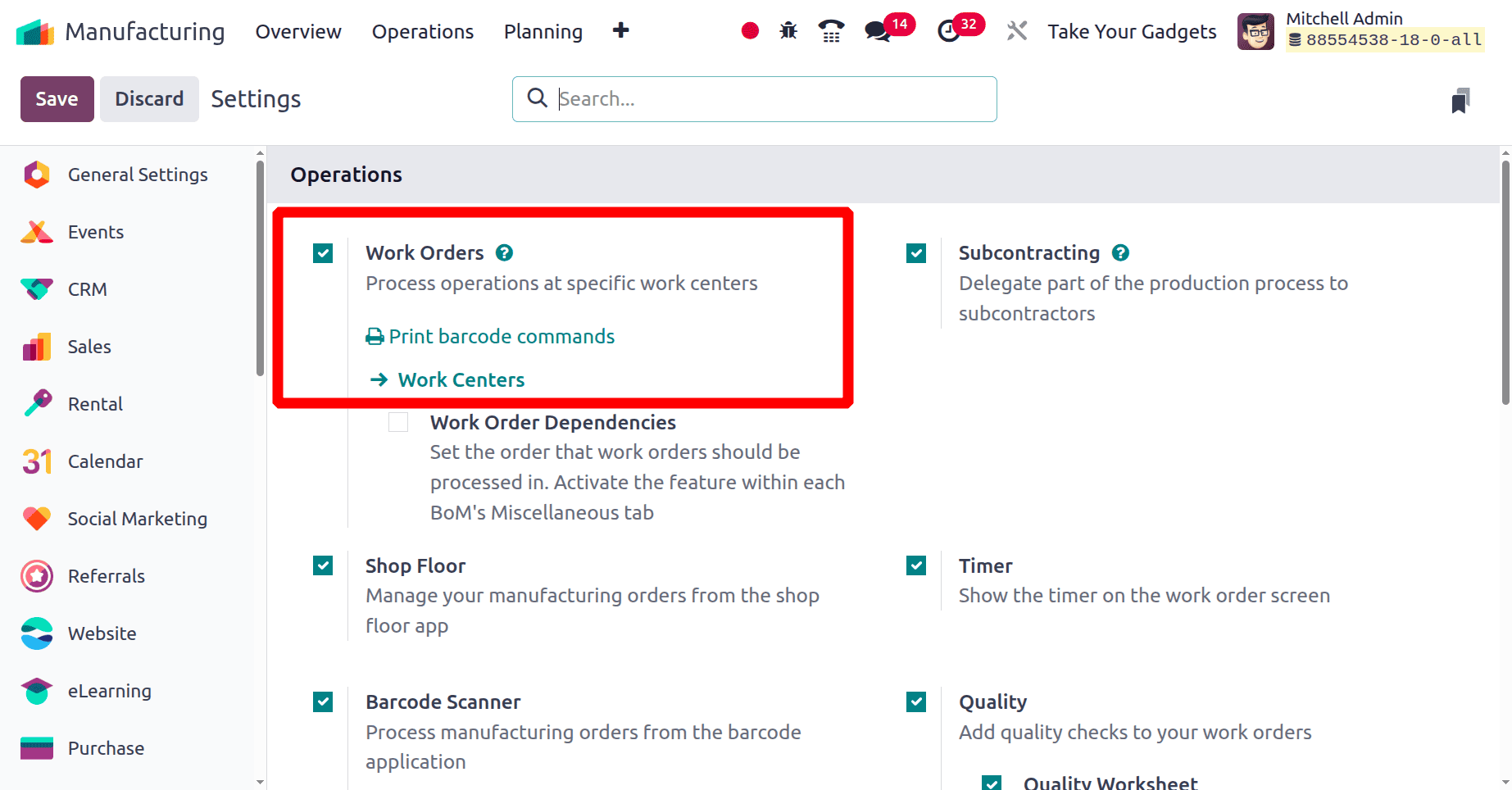

Therefore, before we can construct a new work centre, we need to set it up. To make such a setup, go to the settings of the manufacturing module.

Navigate to Configuration > Settings > Work Orders enable > Save modifications.

Users can block one operation with another by utilising Work Order Dependencies, which is used to add an order for the work orders to perform. For instance, Operation_1 can only be carried out when Operation_2 is finished if Operation_1 is prevented by Operation_2.

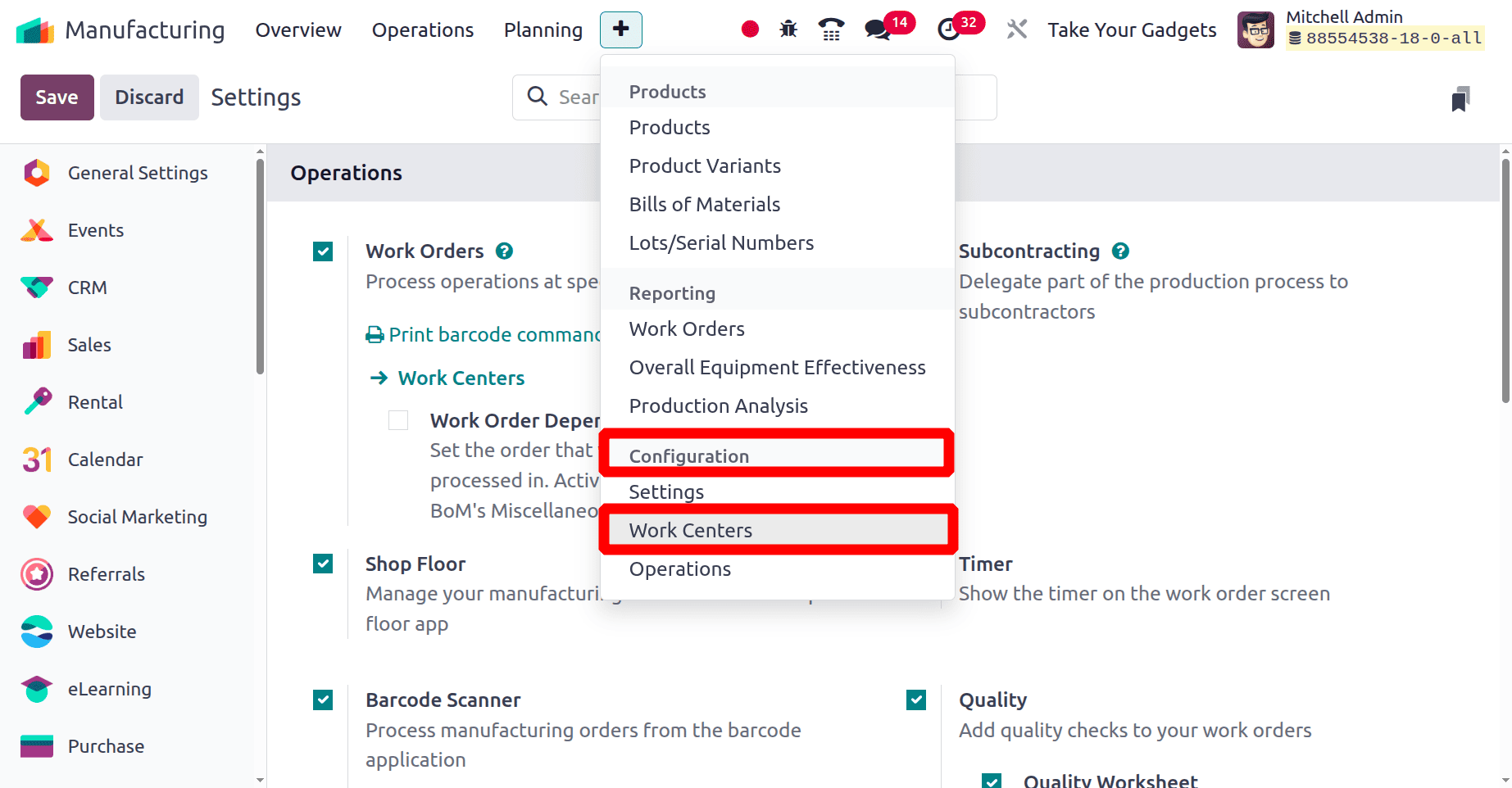

All of the Workcenters that have been built are displayed in the manufacturing module's overview. From there, users may also plan work orders in the work centre. Next, choose the configuration option. The Work Centres option is now accessible.

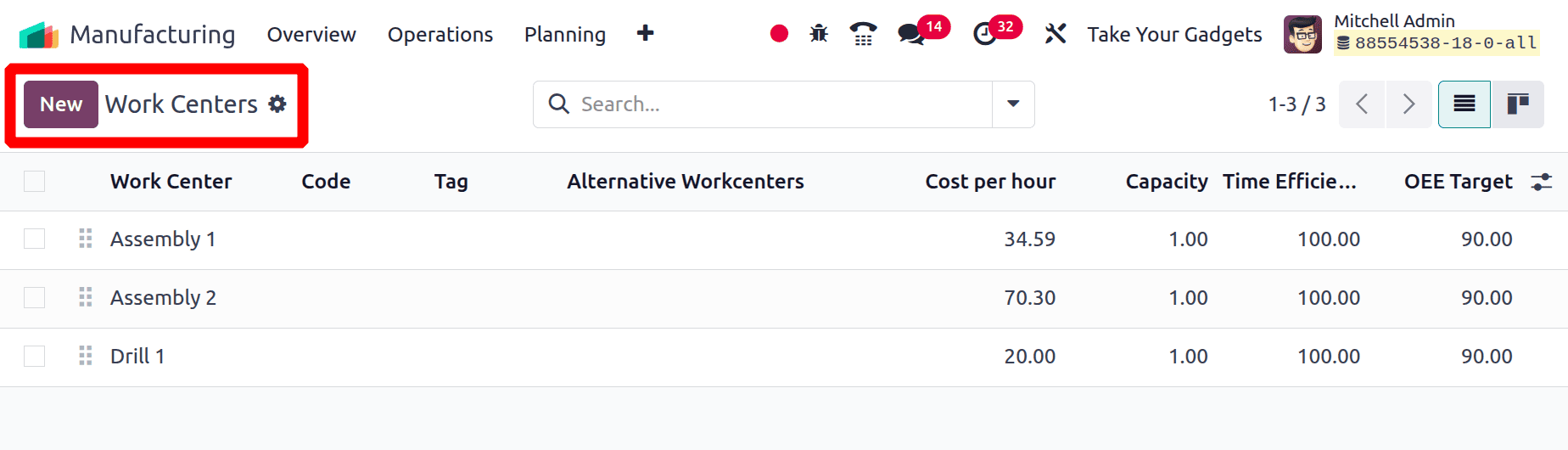

Navigate to Work Centres under Configuration > then click on the New button.

When you select this option, a list of the company's existing work centres appears. By choosing the New button, we can make a new one.

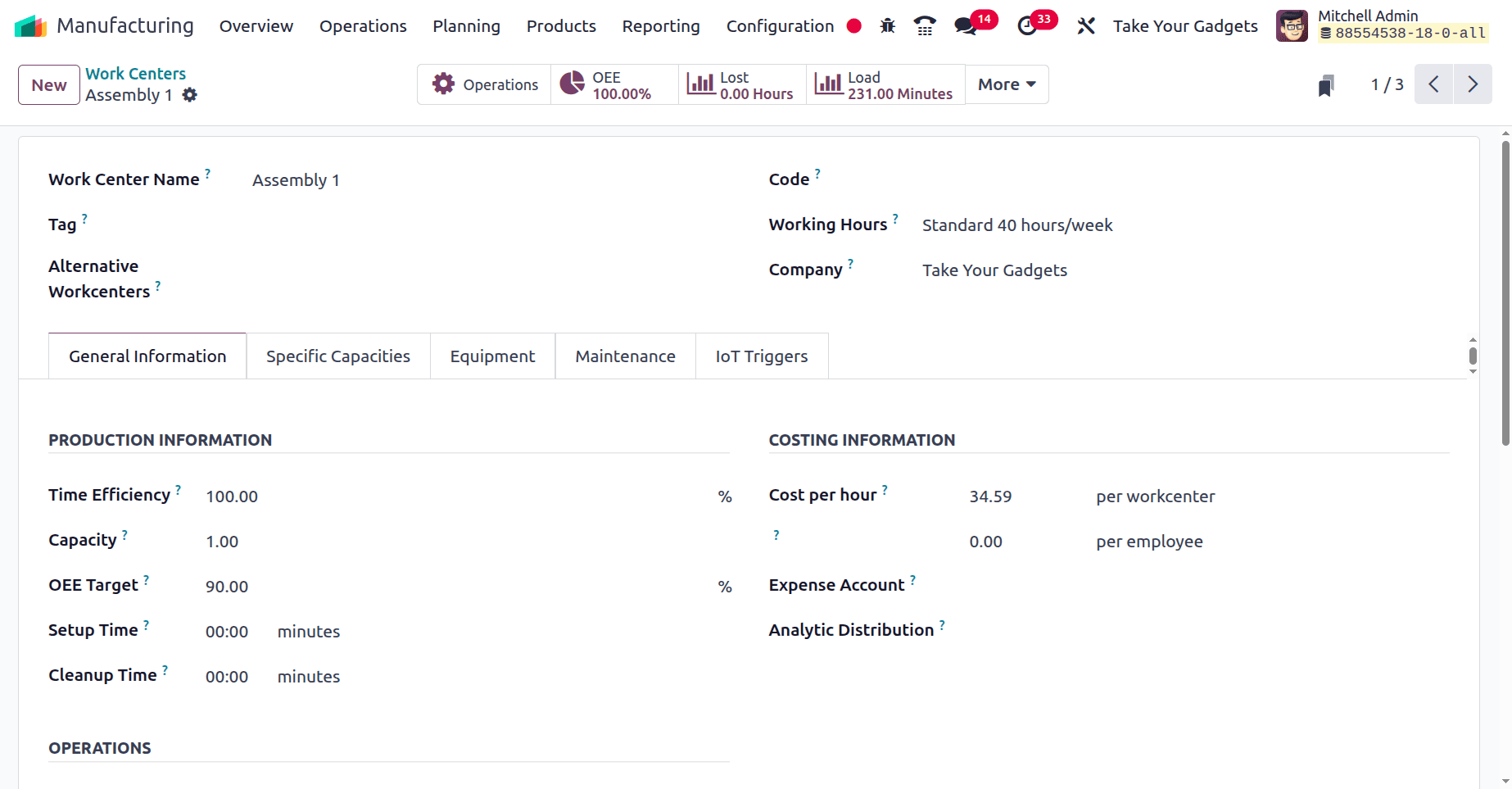

When creating a new work centre, the name of the centre must be input first. You can choose from the list and add any tag that is used to search the workcenter to the Tag field. To indicate the new workcenter, add a code next to it. Next, list the work center's hours of operation. If required, the company's name may also be mentioned.

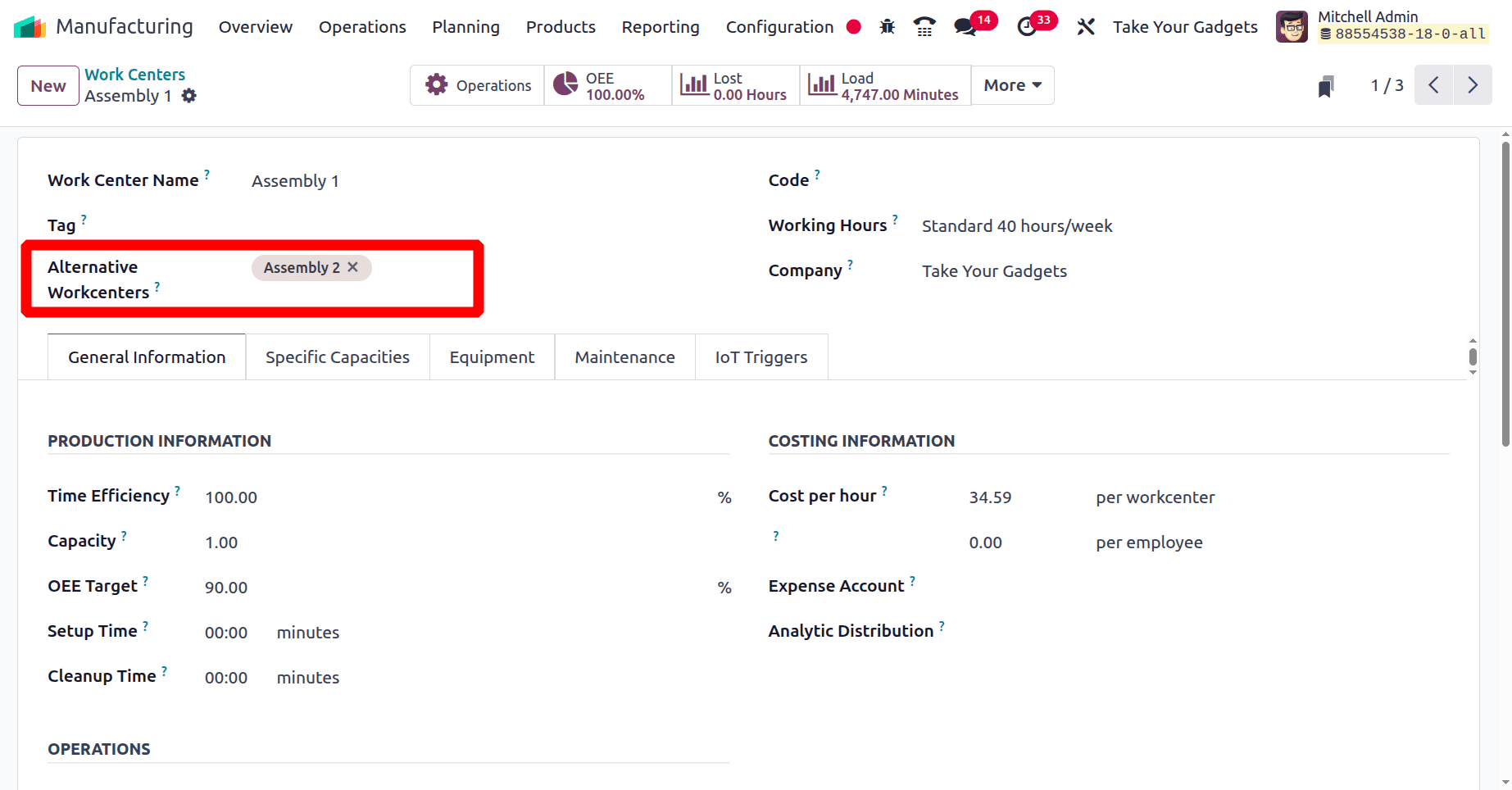

The ability to select a different work centre from the newly constructed one is another essential feature. The established work centre is replaced with a different one.

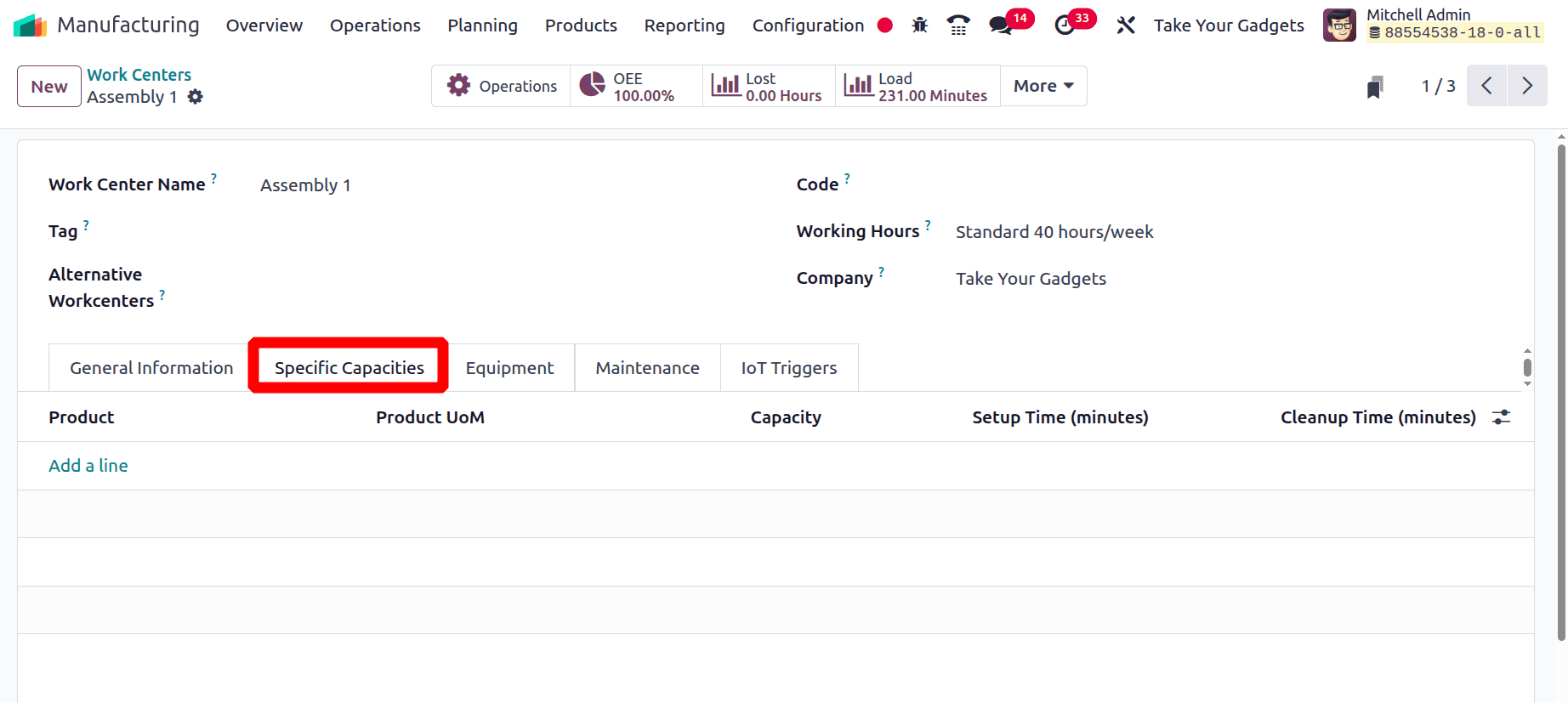

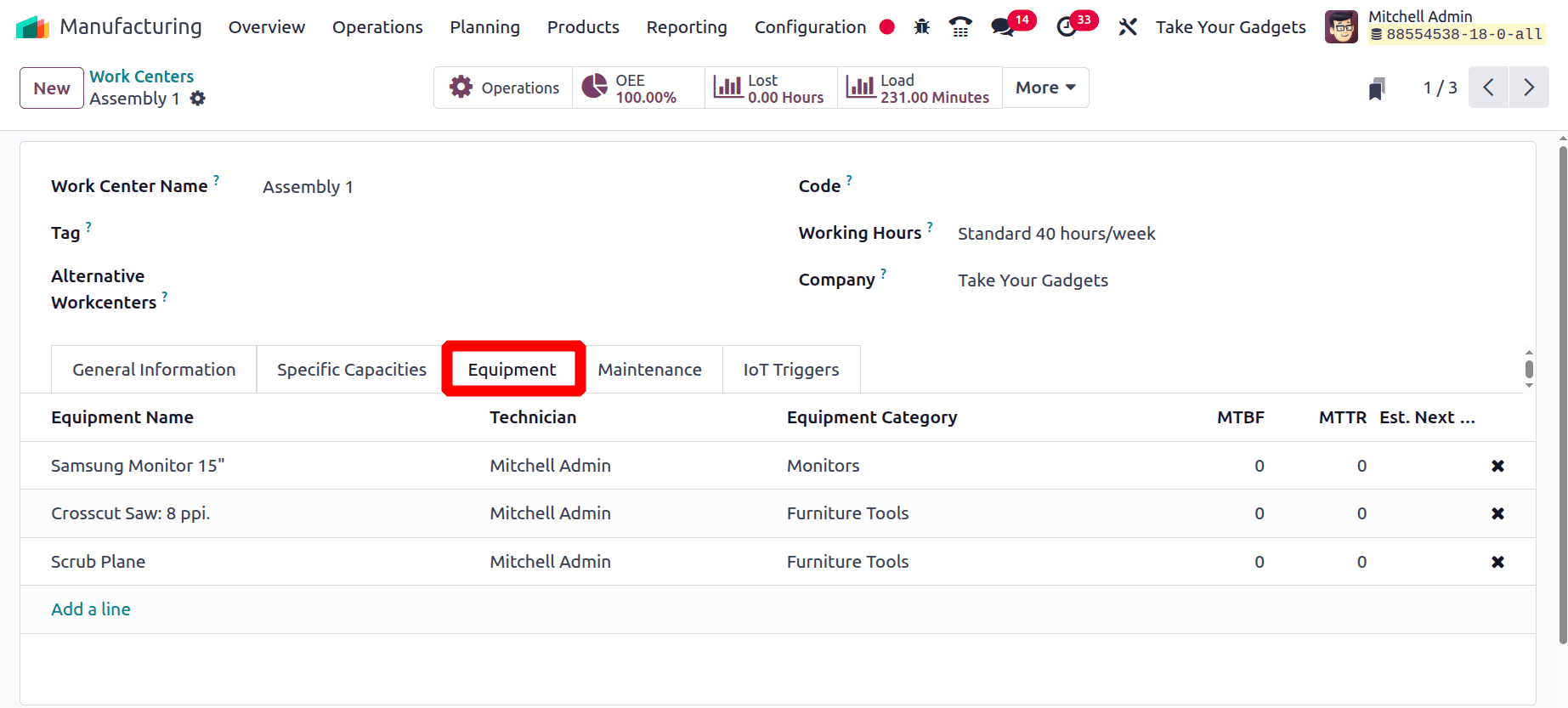

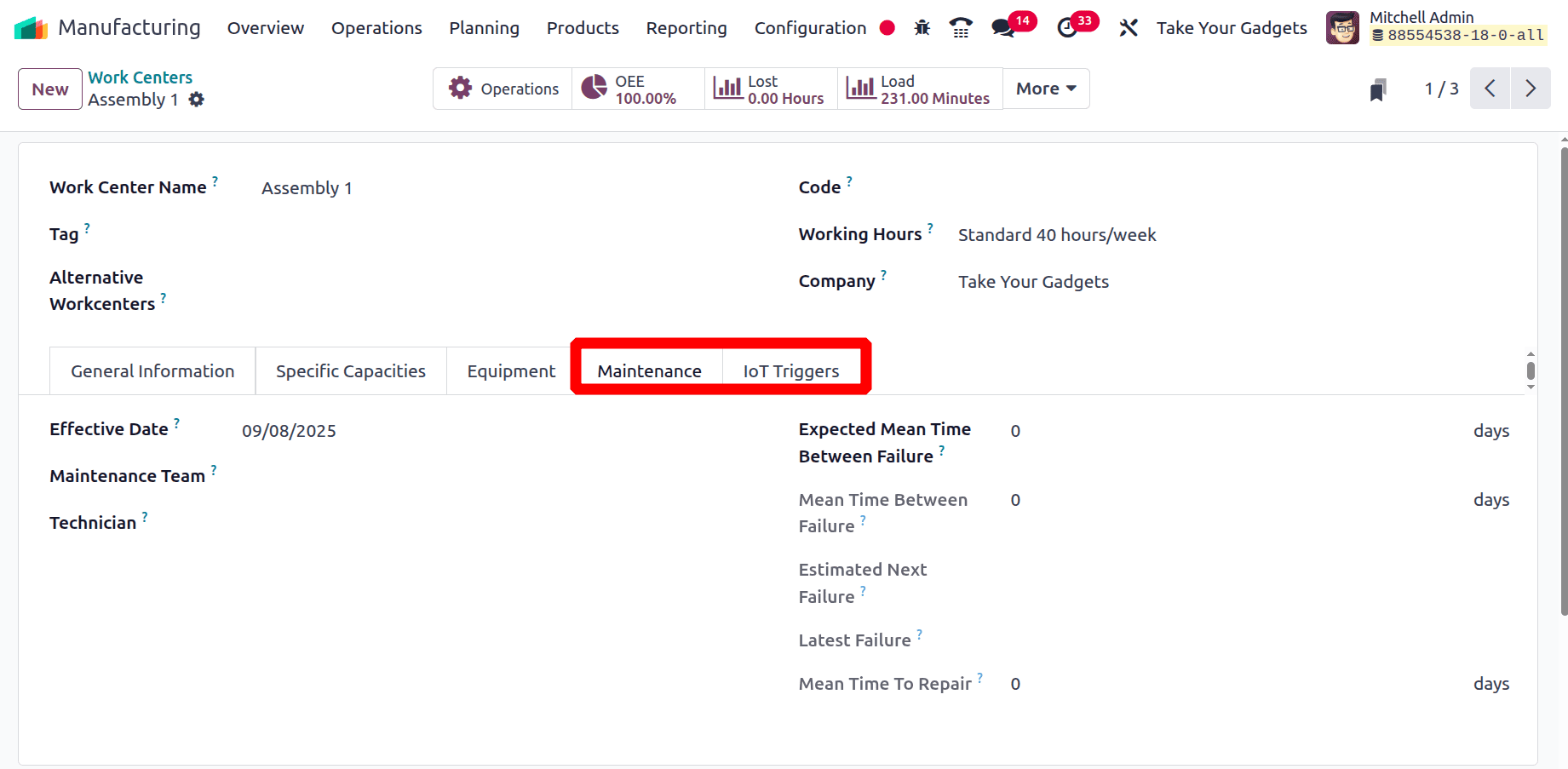

There are then five tabs on the window. These headings are IoT Trigger, Maintenance, Equipment, Specific Capabilities, and General Information. The first tab now includes general information about the work centre.

The time required to finish work orders at this work centre was estimated using time efficiency. Therefore, if a procedure takes an hour to finish and the efficiency factor is 100%, the time efficiency factor is 200 percent if the procedure only takes 30 minutes.

Capacity is defined as the number of items that can be produced in a given period of time. If the work centre has a five-unit capacity and we need to generate 10 units for a work order, the maximum capacity will be doubled by two.

OEE Target: The overall efficiency goal for the workspace is known as the OEE Target.

After the production process is over, some workstations need to be cleaned. In these situations, the amount of time required to clean the workstation determines the cleanup time. The time required to set up the workstation before production begins is known as the setup time. The cost per hour is the amount that would have been incurred if the workstation had been used for an hour.

The individual Capacities tab can be expanded to include any individual product, and in this case, any product capacity in this workcenter. Capacity, setup time, and cleanup time can all be discussed separately here.

The Equipment tab may include descriptions of any equipment utilised in this workcenter. Details regarding the equipment's impending failure are provided, including the equipment name, category, estimated MTBF, and MTTR.

The Maintenance tab explains the details about the workcenter maintenance. And the IoT Trigger tab shows the details about the IoT Devices.

There are four smart tabs in the Work Centre. The first is Operations, then overall equipment efficiency, or OEE, which is given as a percentage after any tasks are finished. The two others are Load and Lost. The last one is the performance. In this instance, the work center's performance is examined using the performance tab. Here, the percentage is displayed. (Expected Duration / Real Duration) * 100 is the formula used to calculate performance.

The generated workcenter details are displayed in the work centres. In this case, Assembly 2 serves as a substitute workcenter for Assembly 1's workcenter.

Let's examine the Alternative workcenter's behaviour during a production process.

Opportunities may arise in a business to complete numerous production orders simultaneously. Therefore, a company needs a lot of work centres. As noted above, we can establish a capacity for our work centres. Orders must be moved to another workcenter when they arrive at the same time as a workcenter that is already overloaded. As a result, Odoo introduced Alternative Work Centre, a brand-new solution designed to assist in handling the above mentioned situations. If we decide to replace the current work centre with a different one, then any new orders that are delivered there while the first one is still being processed will be moved right away to the new one.

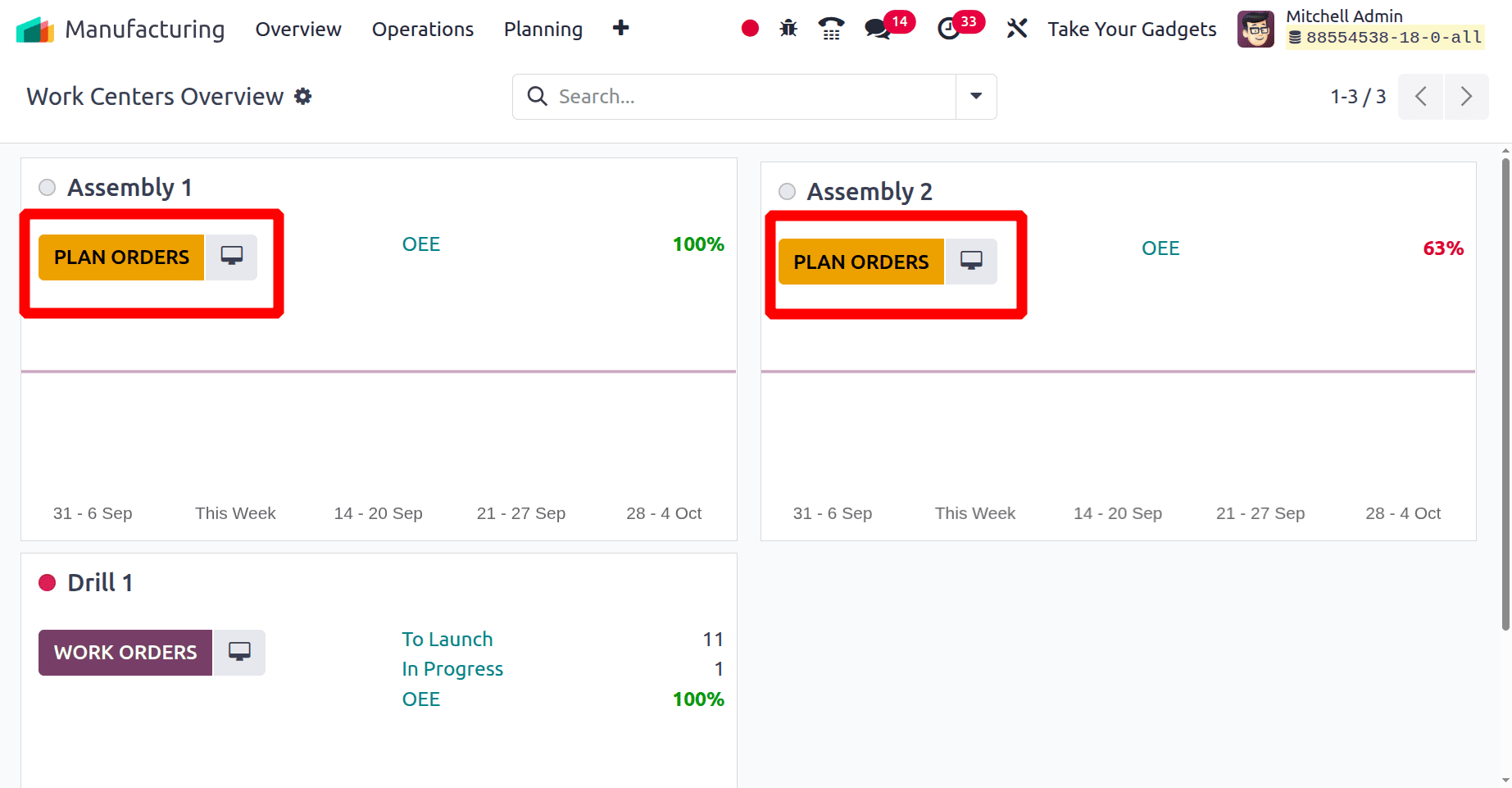

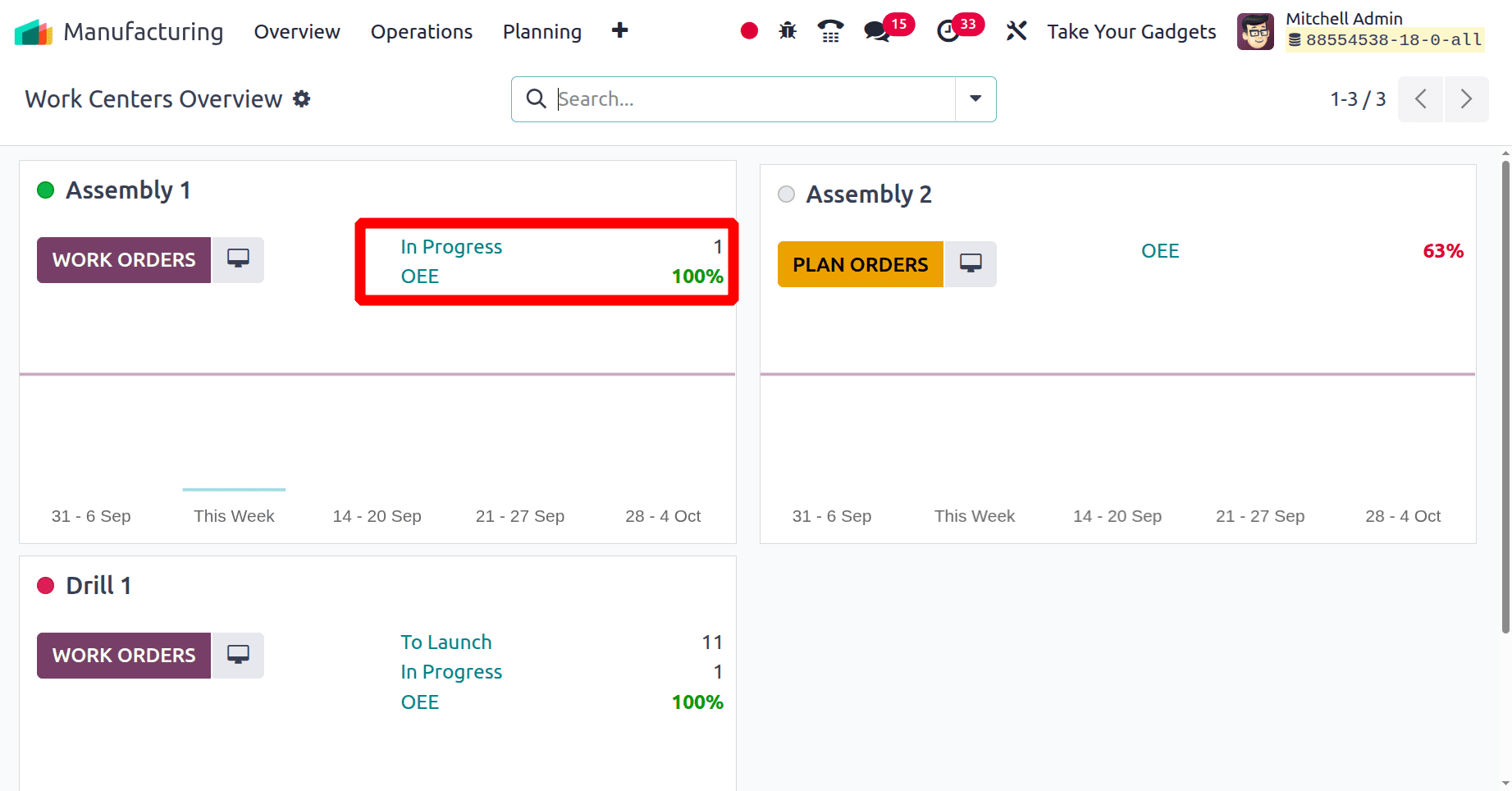

Those recently constructed work centres are included in the overview. The status indicates that both are currently available. The Plan Orders button indicates that they are not functioning at the moment. We will be able to place new orders for them.

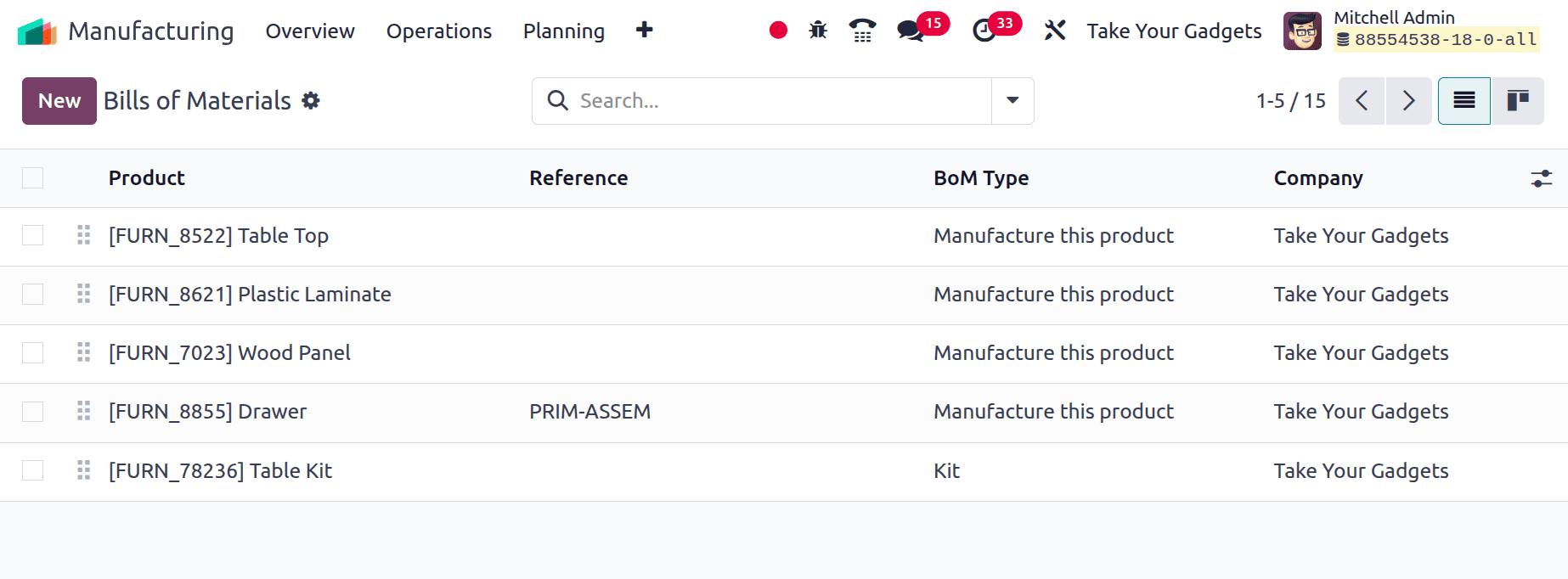

A new bill of materials must be generated before anyone may start a production process inside the work centre. Select Bill of Material from the product tab to accomplish this. By clicking the New button, you can create a new Bill of Material or choose from a list of ones that have already been prepared.

Product < Bill of Materials < New

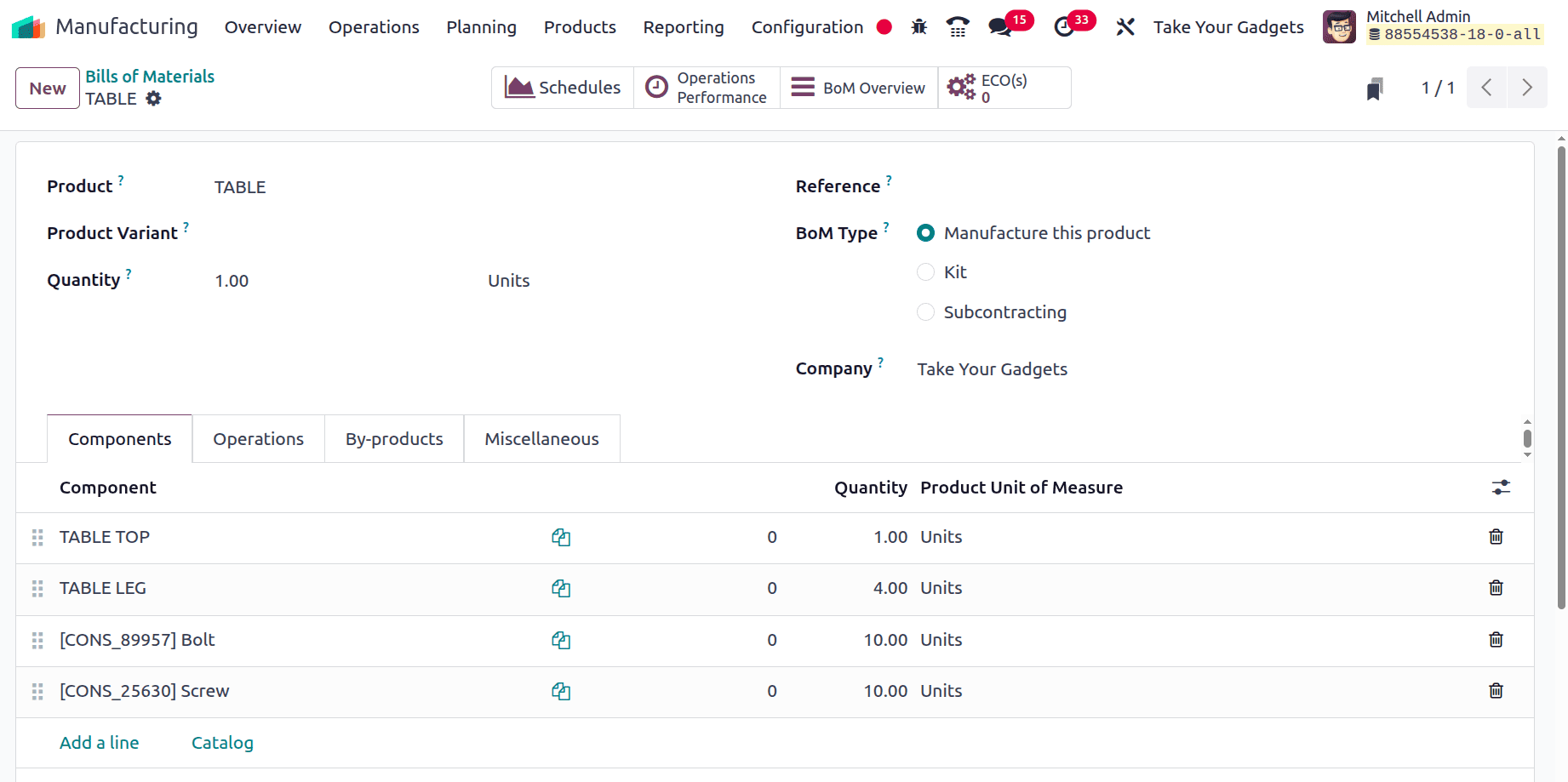

To create a product table, create a bill of materials here. One quantity of the Table will be produced if the product name is selected in the product section. Select the BoM Type for manufacturing this product. Table_Manufacturing_1 has been included as a reference. The required amounts of various parts, such as the table top, table leg, bolts, and screws, are listed on the Components tab.

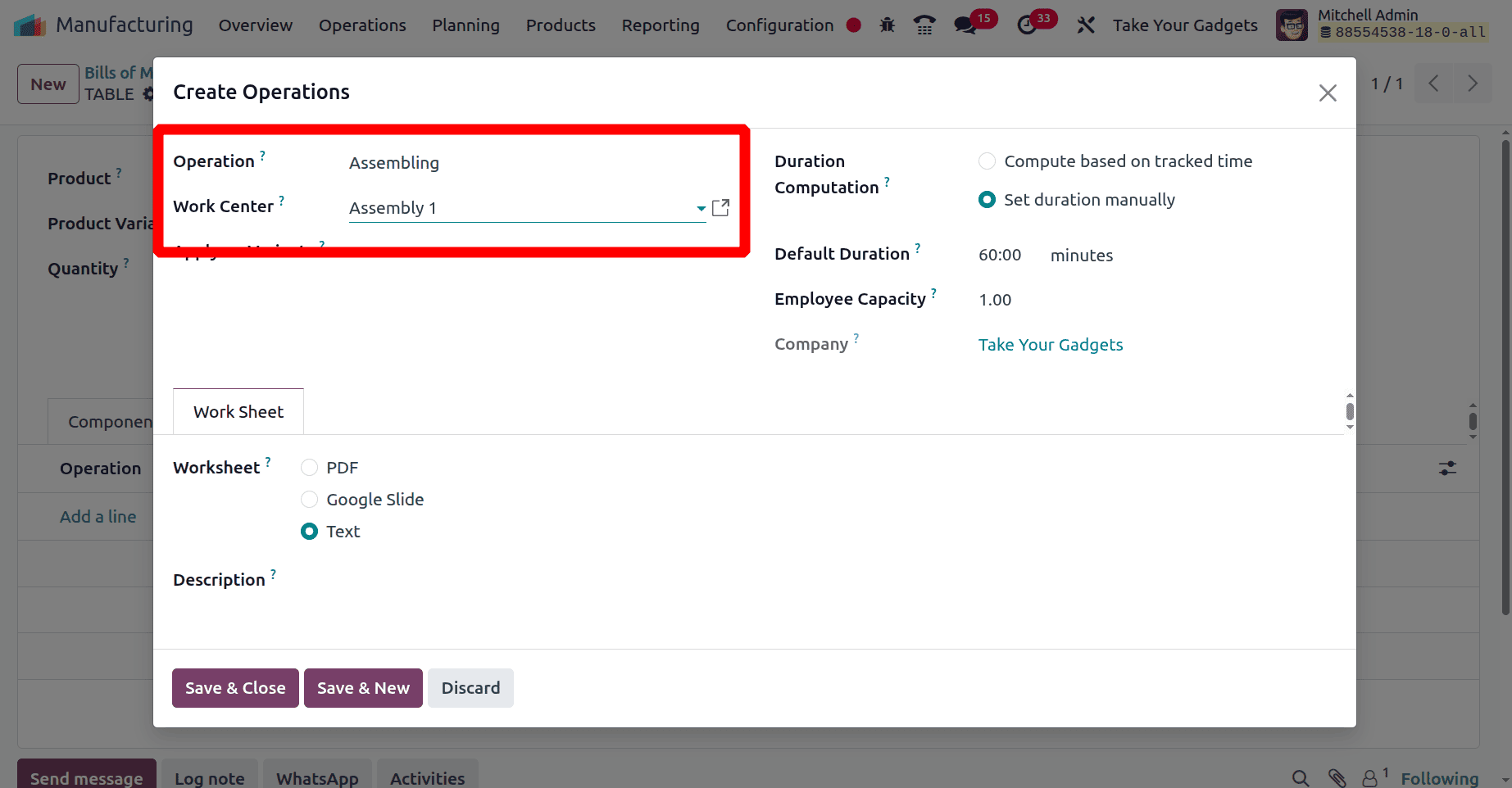

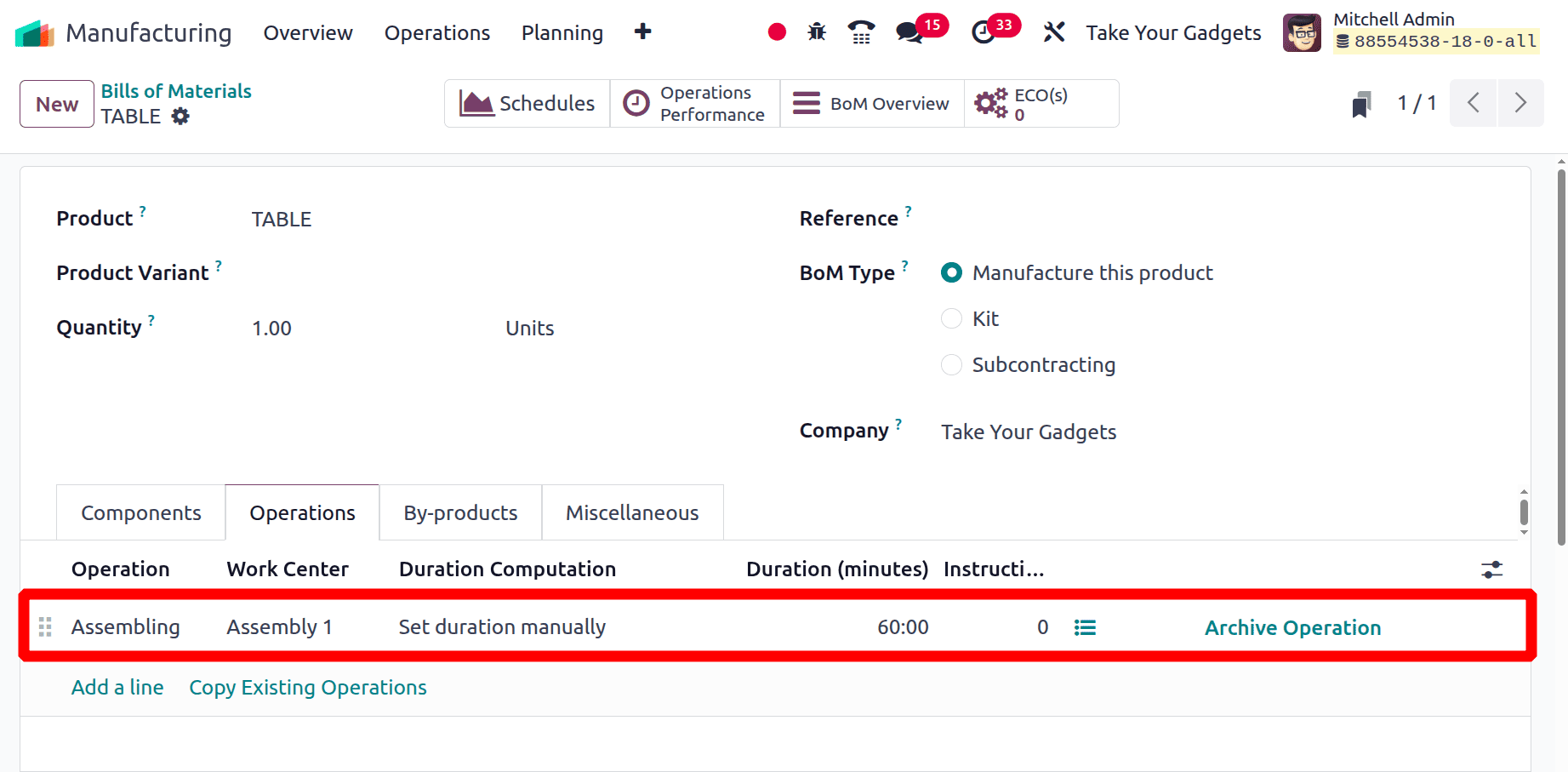

Next is the Operations tab, where users can choose the add a line option to add more operations. Give the operation's name. There, pick the configured work center's name. It's saved.

Under the operation tab, enumerate the procedures required to make this one. Only one operation was introduced in this case. The work centre where the operation was conducted was mentioned in the operation.

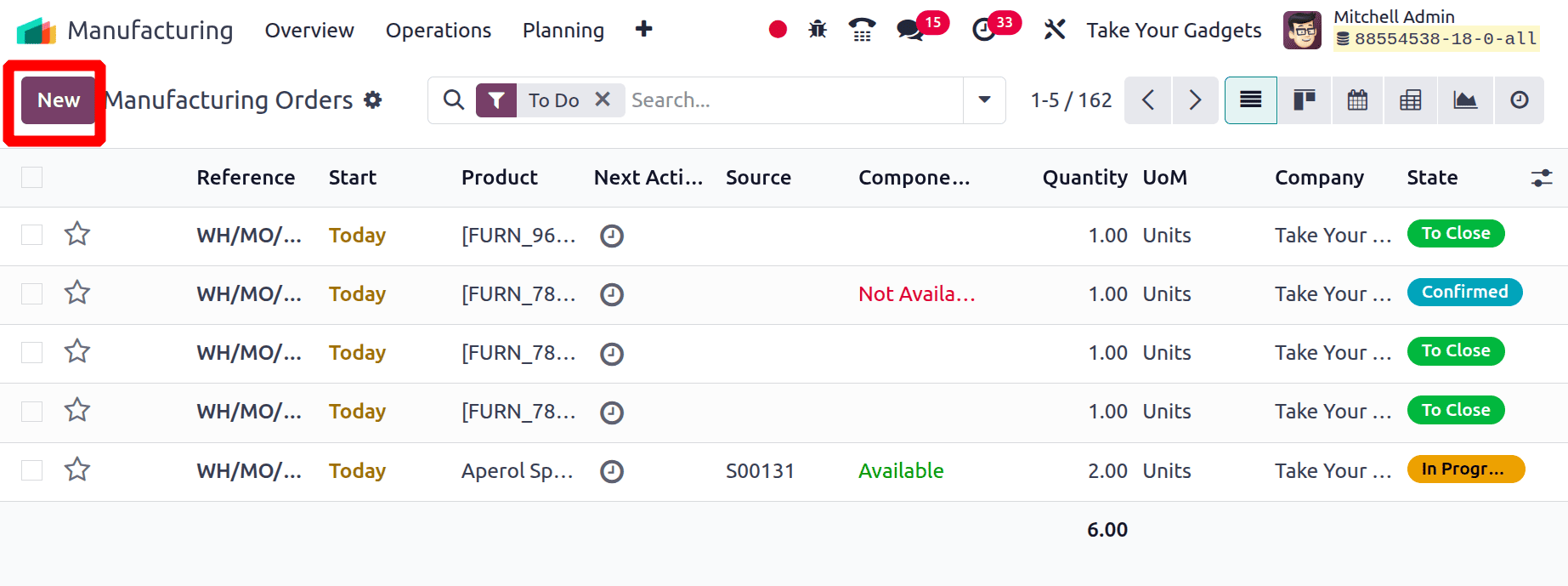

The Bill of Materials is then generated after the window has been saved. Using the bill of materials, a manufacturing order is then created. Select Manufacturing Order from the operations tab's drop-down menu to accomplish this. Then start afresh with a fresh one.

Operations < Manufacturing Orders < New

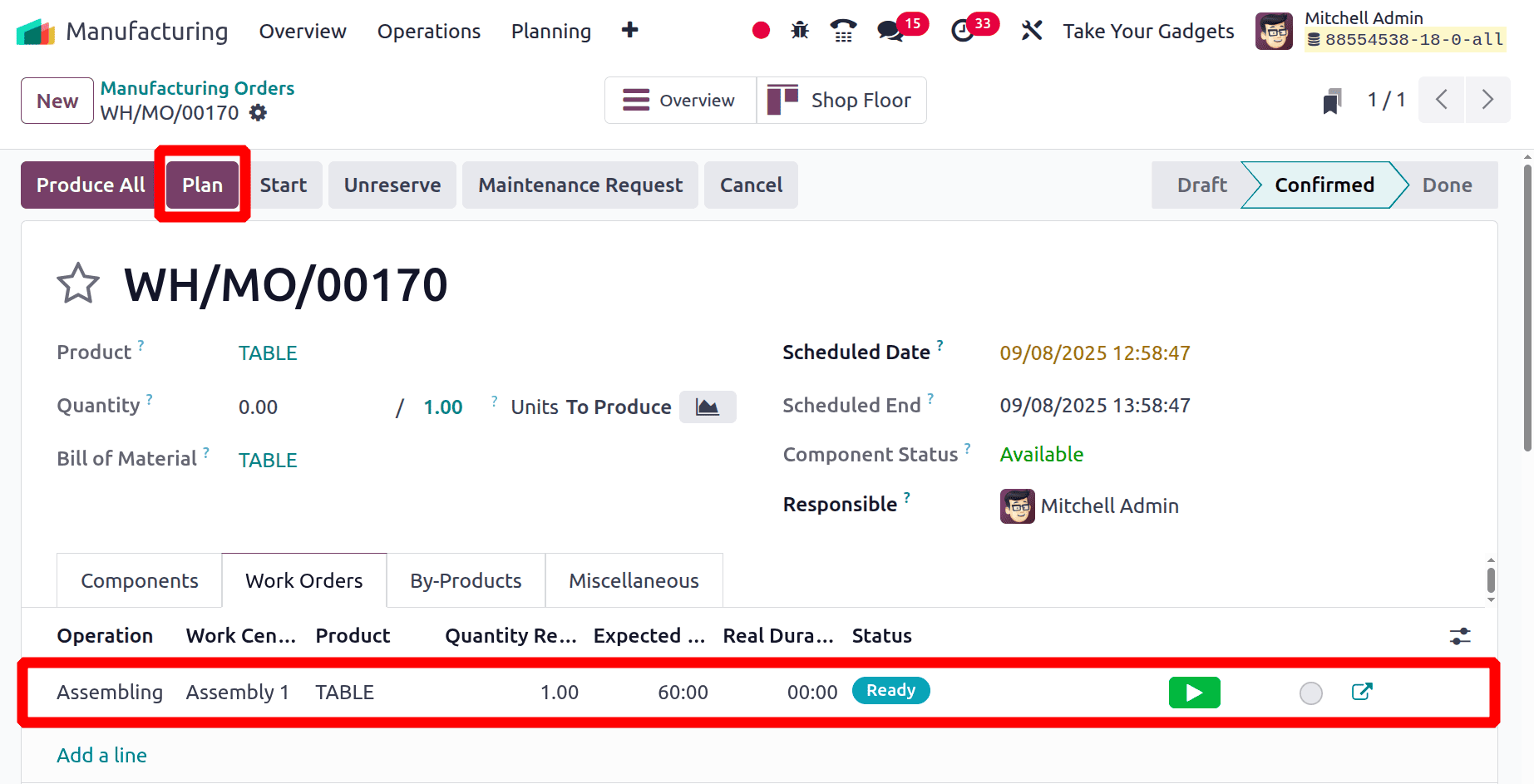

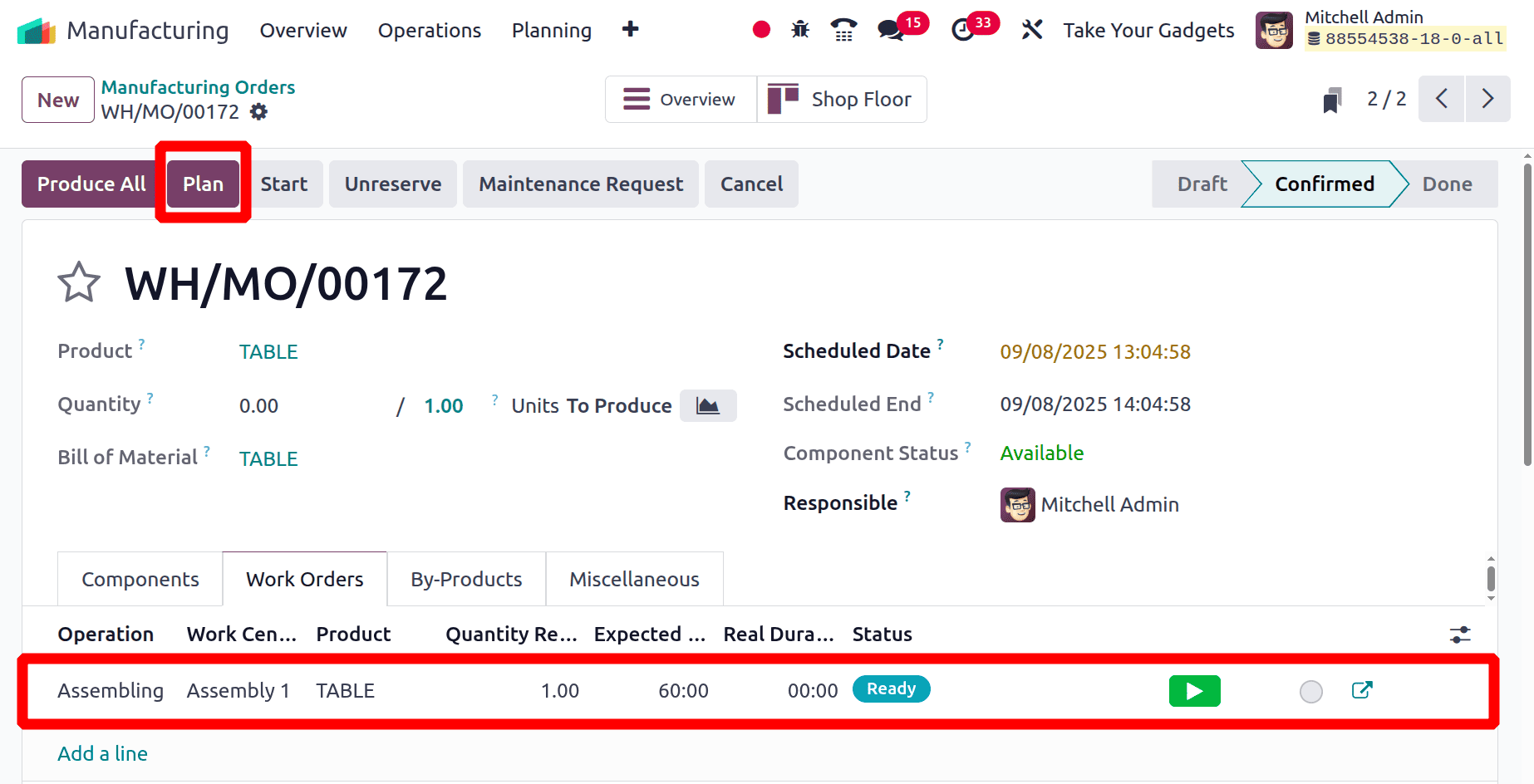

In the manufacturing order, choose the product table and the designated bill of materials. After that, this is where the things and processes mentioned in the bill of materials are automatically put. Click the Plan button, then select the work order tab to begin the process.

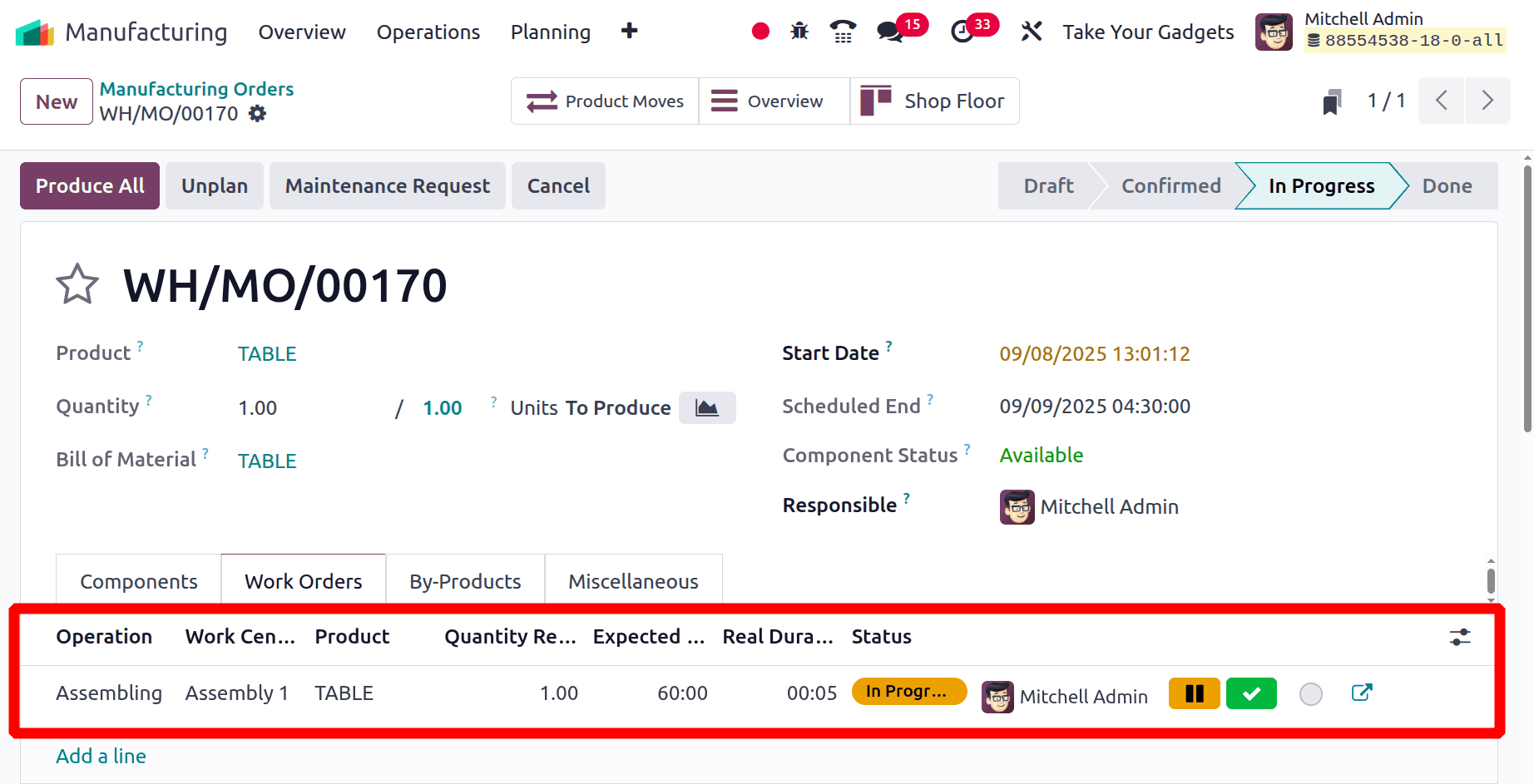

Once the process has started, changing its state to "In Progress" starts a countdown.

The first workcenter Assembly 1 is now in the "In Progress" stage, according to the overview.

However, there are currently no orders scheduled for the second workstation, which is located in Assembly 2.

Using the same bill of materials, let's place another production order for the product table. Verify that the operation is planned for the Assembly 1 workstation by looking at the Work Order page. Next, click the Plan button right before the operation is carried out.

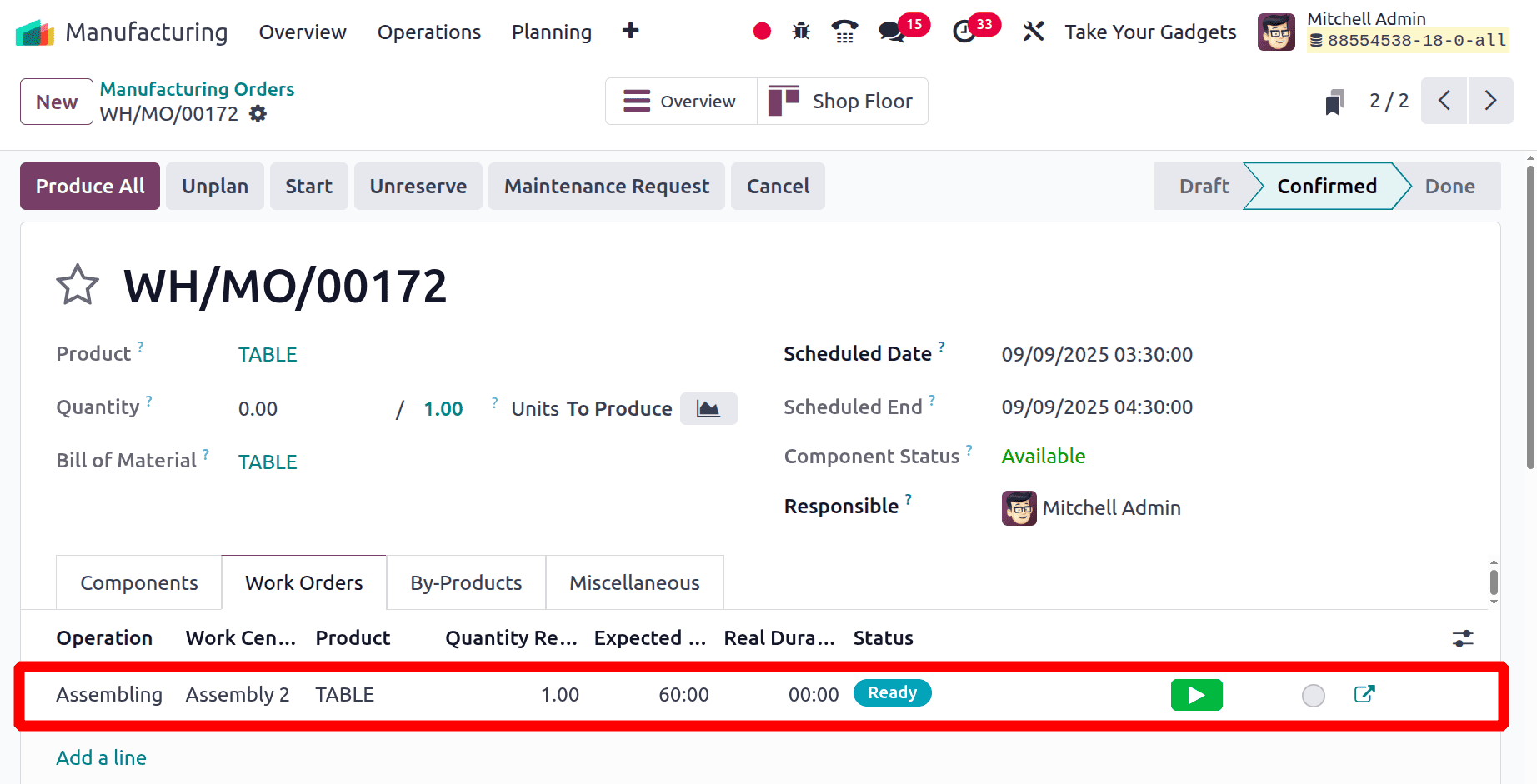

After clicking on the Plan button, the work order is immediately sent to Assembly 2, the second work centre. Next, look at the work order tab.

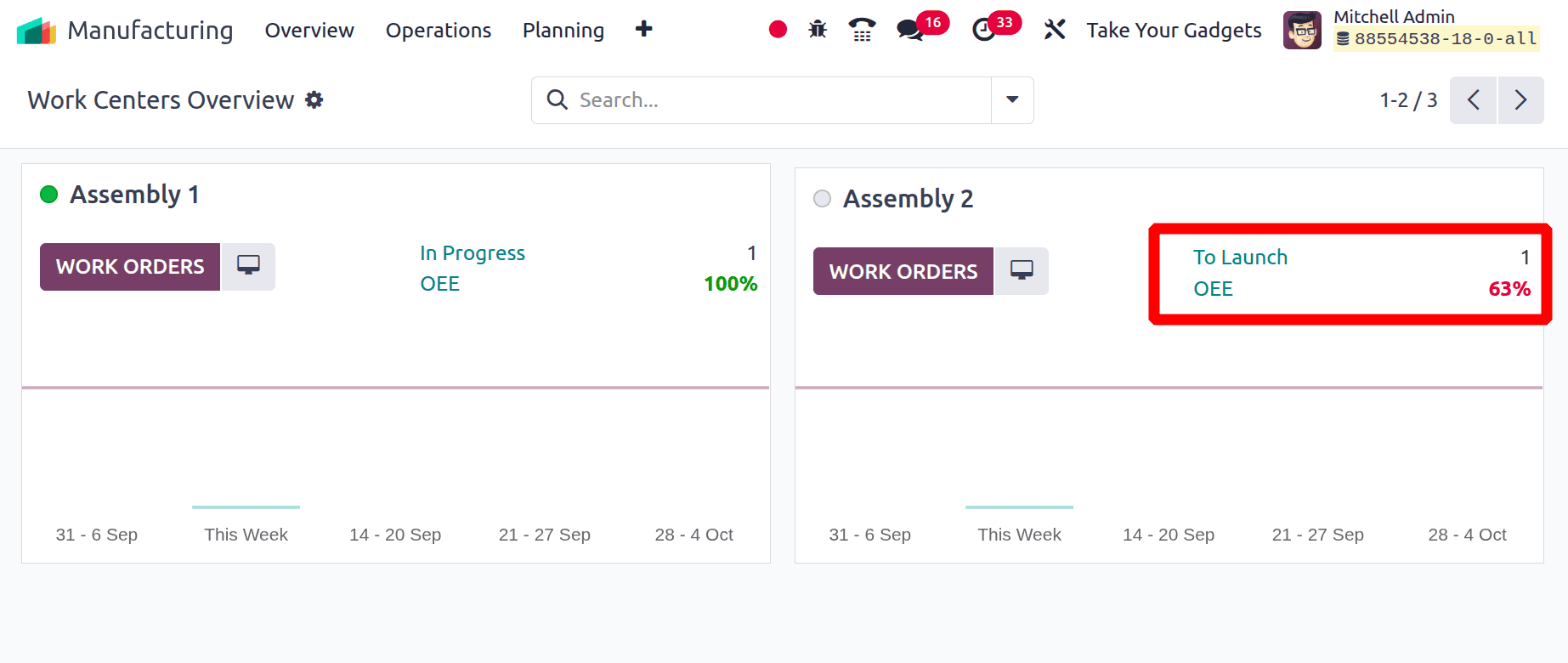

Then go over the overview again. Drill Station 1, the first workcenter, is currently under construction. But Assembly 2 is now in the To Launch stage, which changed to "In Progress" once the operation started.

Click the Validate button to finish the manufacturing order.

To sum up, alternate workcenters in Odoo 18 Manufacturing provide a workable way to manage resource limitations and maximize production efficiency. Businesses can reduce downtime and maintain smooth operations by allowing the usage of backup workcenters in the event that the primary ones are unavailable. This adaptability facilitates improved real-time decision-making and improves production planning. Alternative workcenters can create a manufacturing process that is more resilient and agile when configured properly. All things considered, Odoo 18 keeps giving manufacturers the tools they need to meet changing operational demands.

To read more about How to configure work centers in Odoo 18, refer to our blog How to configure work centers in Odoo 18