Both preventive and remedial maintenance tasks are planned and carried out using Odoo 18's Maintenance module. It assists businesses in maintaining their equipment to lower malfunctions and boost output. Maintenance requests can be created automatically or manually based on consumption or time data. The relevant technicians are assigned duties by the system, which also tracks their work. This prolongs the life of vital assets and guarantees effective maintenance procedures.

Preventive and corrective maintenance are the two primary maintenance options available in Odoo 18. Corrective maintenance is carried out following a breakdown, whereas preventive maintenance is planned ahead of time to prevent equipment breakdowns. These choices assist companies in minimising downtime and managing the condition of their equipment.

Corrective maintenance, as used in Odoo 18, is unscheduled maintenance carried out after equipment has malfunctioned or failed. To fix or get the equipment back in working order, a maintenance request must be created. Usually, when a problem is identified, users or technicians initiate these requests. Corrective maintenance reduces downtime and restores regular operations by swiftly resolving unforeseen problems.

Corrective maintenance's (CM) advantages include:

- Reduced Initial Costs: Regular checks and upfront preparation are not necessary.

- Fast Restoration: Restores operations by resolving problems as soon as they arise.

- Easy to handle: action is only necessary when an issue arises.

- Perfect for Non-Critical Equipment: cost-effective for items that don't significantly affect operations.

- Optimises Equipment Use: Equipment is utilised until it breaks, perhaps releasing its full potential.

- Reduced Resources Required Until Dismantling: Reduced Resources Required Up to Failure. No requirement for regular scheduling or inspections.

- Immediate Problem Identification: Errors highlight problems that require attention.

- No Over-Maintenance: Reduces the likelihood of unnecessary interventions.

In this blog, we'll delve into the Odoo 18 Maintenance module's corrective maintenance setup and operation in great detail. When a piece of equipment malfunctions or exhibits a flaw, a maintenance request is created, and corrective maintenance is started. We'll go over how to record these requests, allocate them to the appropriate personnel, and monitor their progress until they are finished. This blog will guide you through the Odoo 18 corrective maintenance setup, utilization, and optimization process.

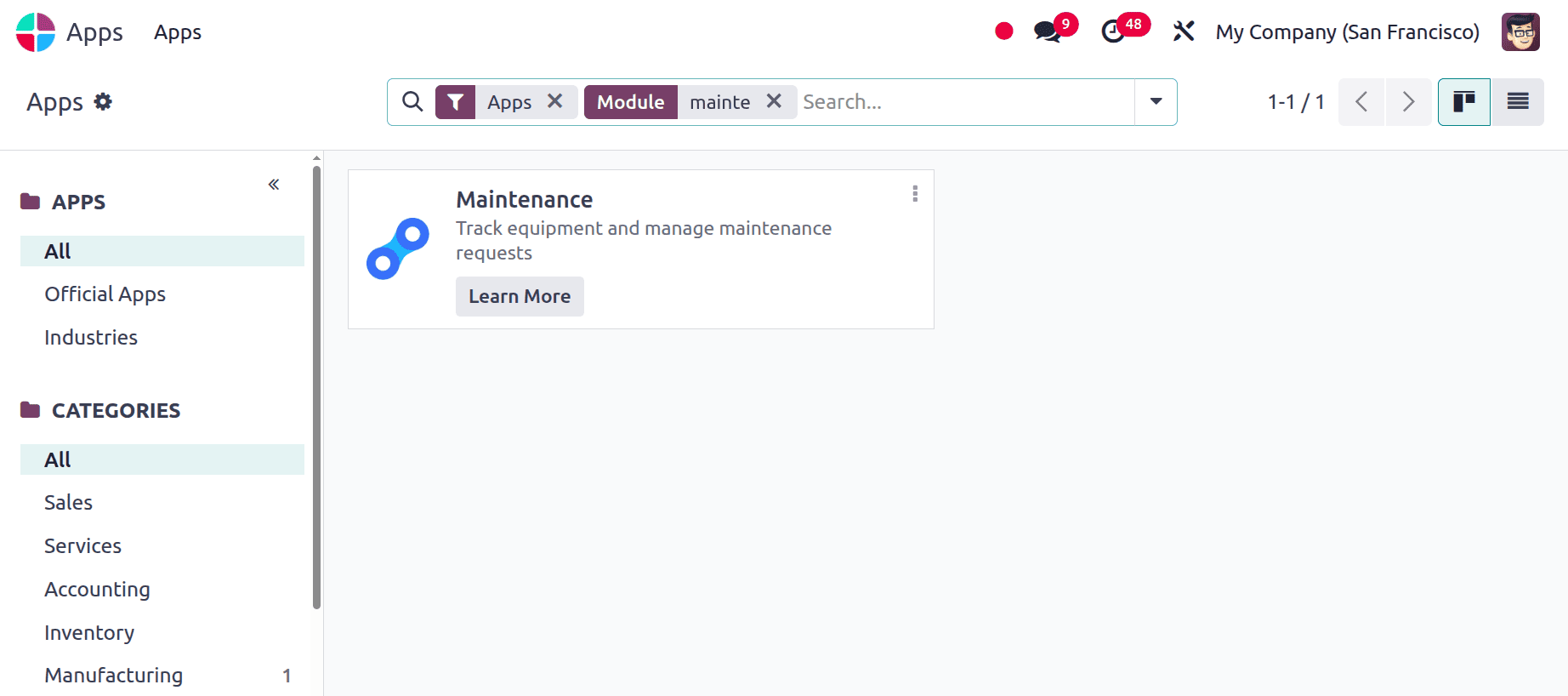

Installing the Maintenance module is a must for scheduling or monitoring maintenance tasks in Odoo 18. Navigate to the Apps menu, type "Maintenance," and select Install. After installation, you can begin making schedules and requests for maintenance.

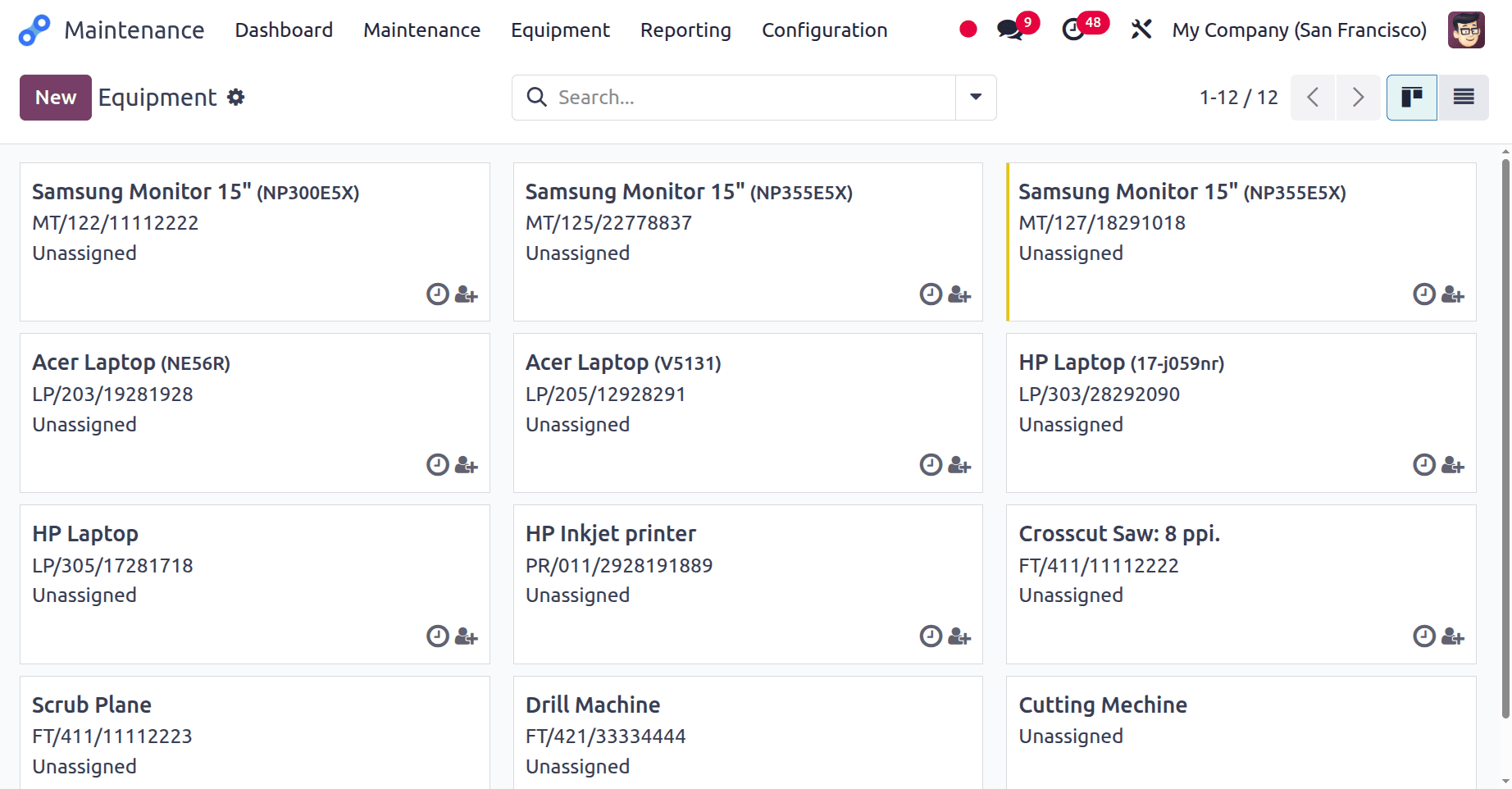

Let's develop new equipment to test the effectiveness of corrective maintenance. Equipment is a vital resource that helps a firm with a variety of operational tasks. They enable tasks that are either inefficient or impossible to complete by hand. Proper management of equipment usage maximises performance and prolongs its lifespan.

To add equipment, go to the Equipmet menu and from the list choose either Workcenters or Equipment. For example, here let's choose the equipment. The kanban view shows all the equipment. Click the New button to add a new one.

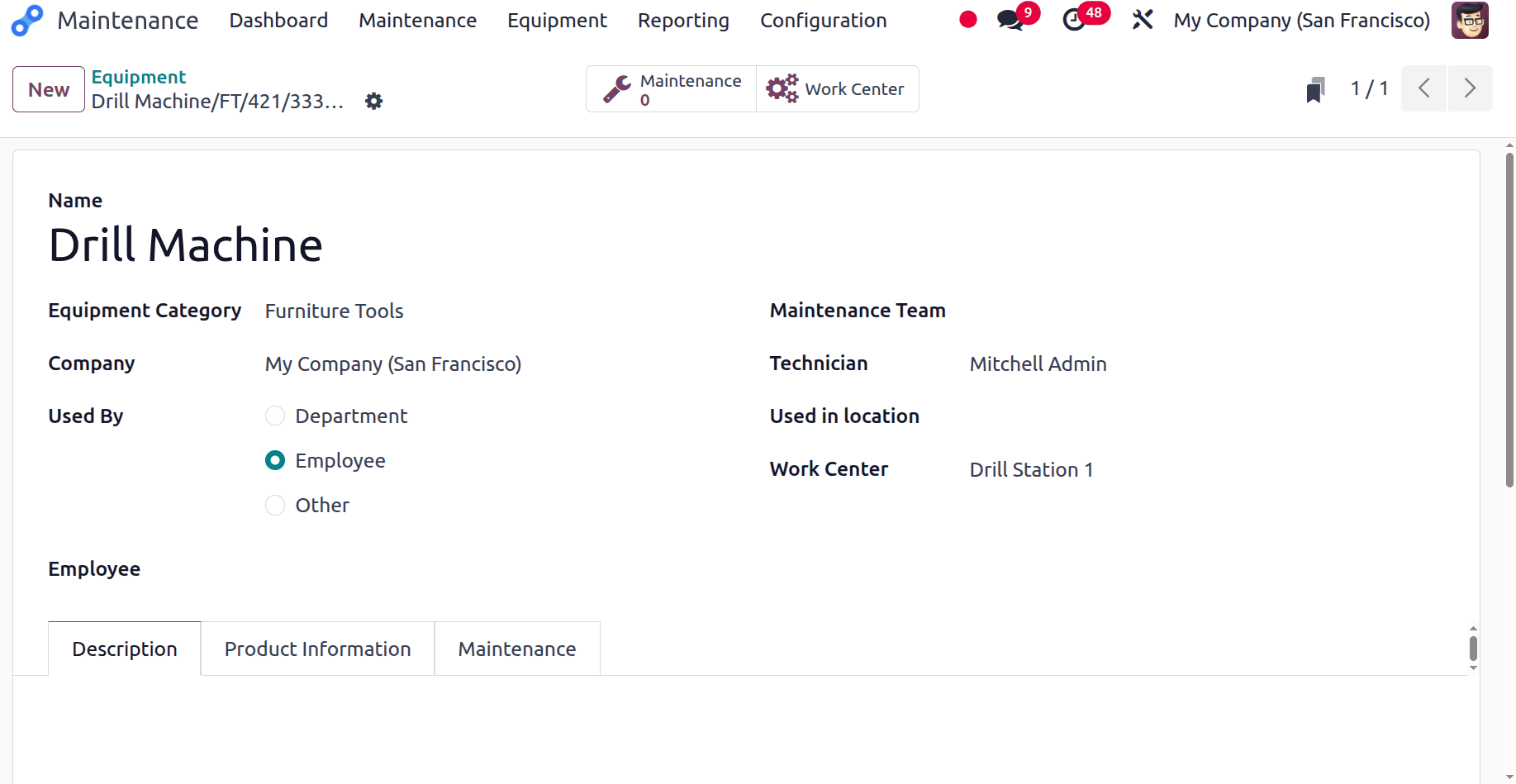

Here, the equipment is named as Drill Machine, which is included under the category Furniture Tools. Used by can be set as Department, Employee, or Others. Users can assign the Maintenance team, Technician, Used in location, and workcenter.

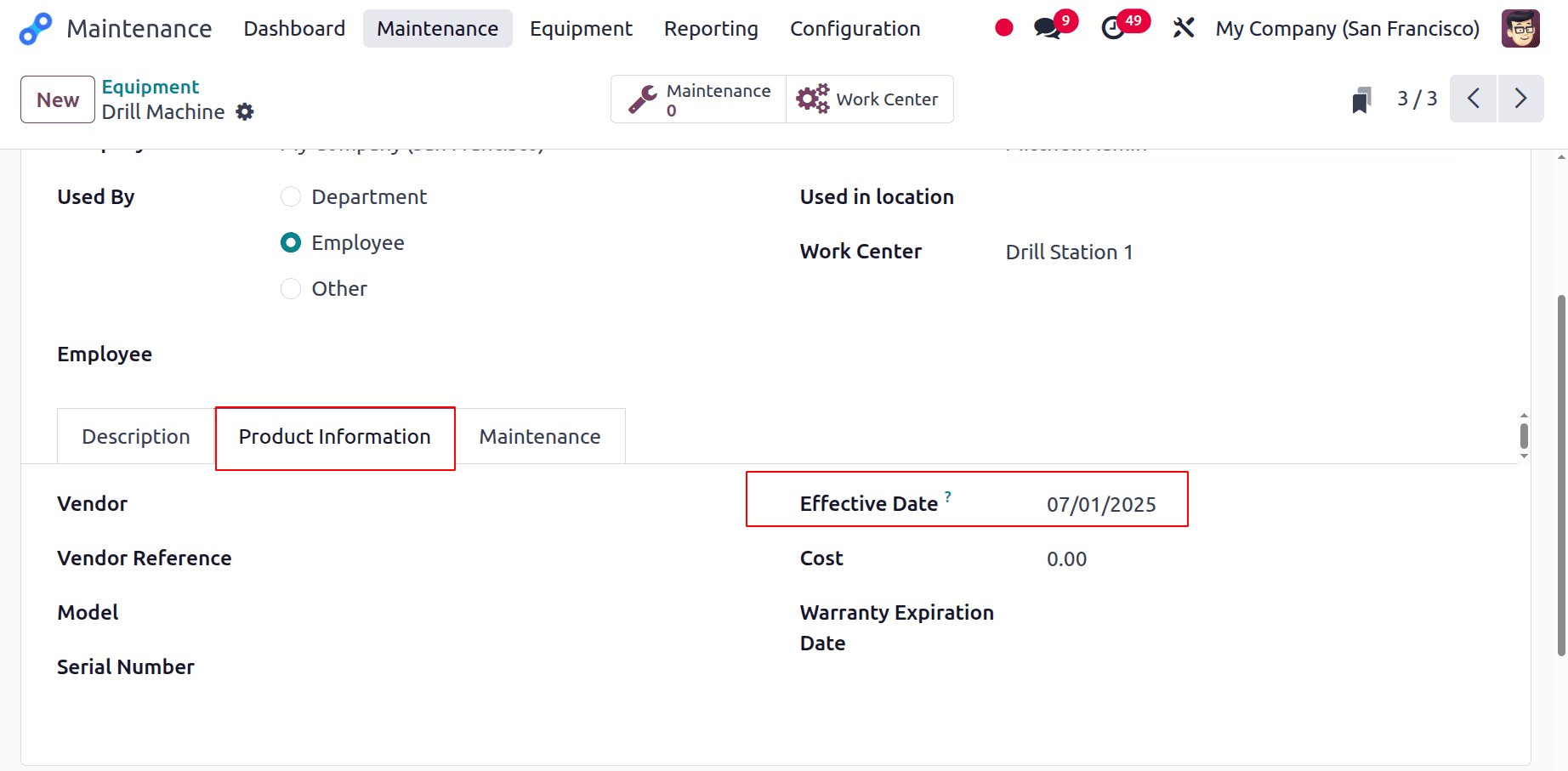

Under the Product Information tab. Users can add information like Vendor Name, Vendor Reference, Model, and Serial Number. Then add the dates, such as the Effective date and Warranty expiration date. Here, the Effective date is the date at which the equipment becomes effective, and the warranty expiration date is the date by which the product warranty ends. Then update the product cost.

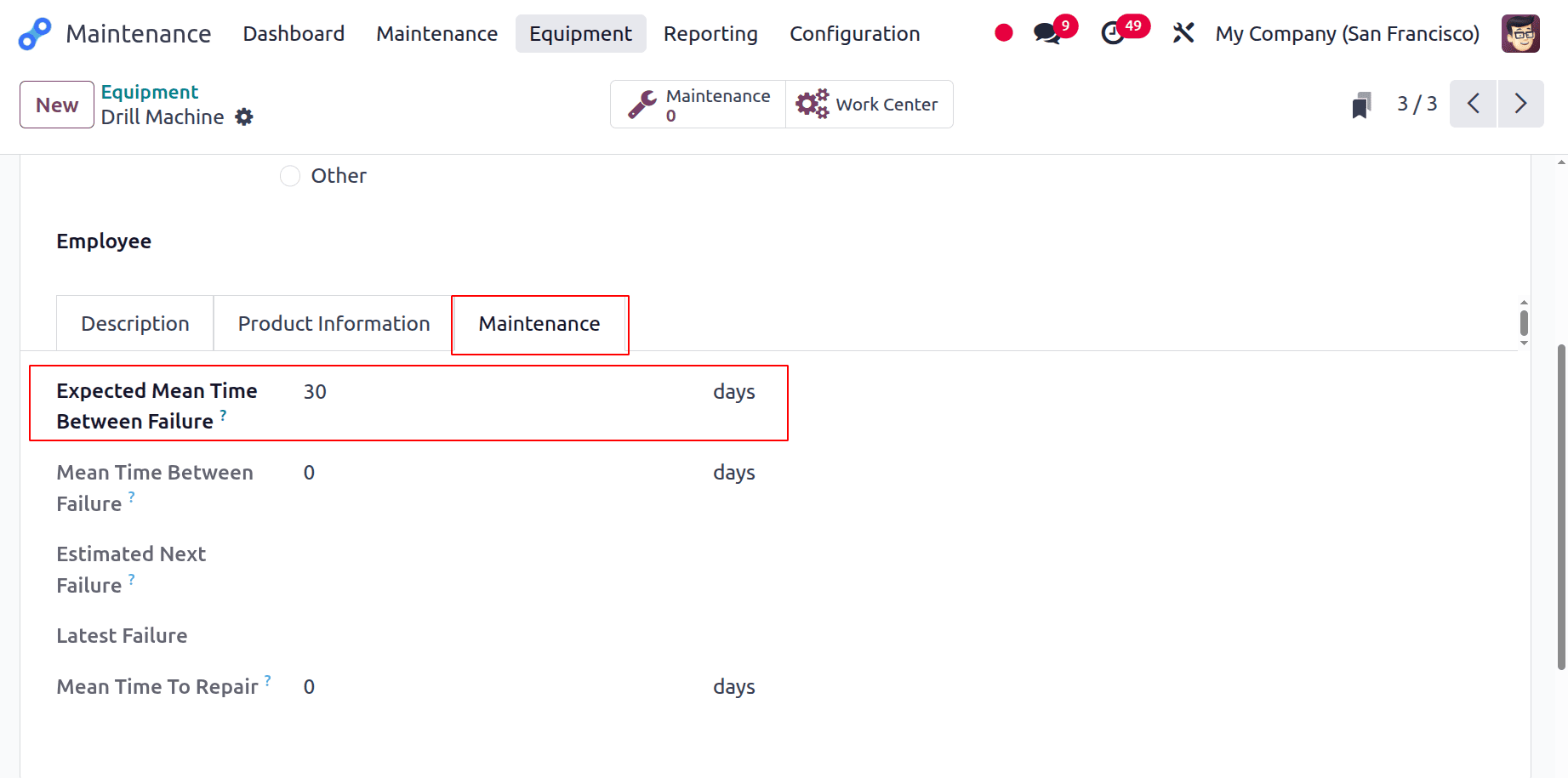

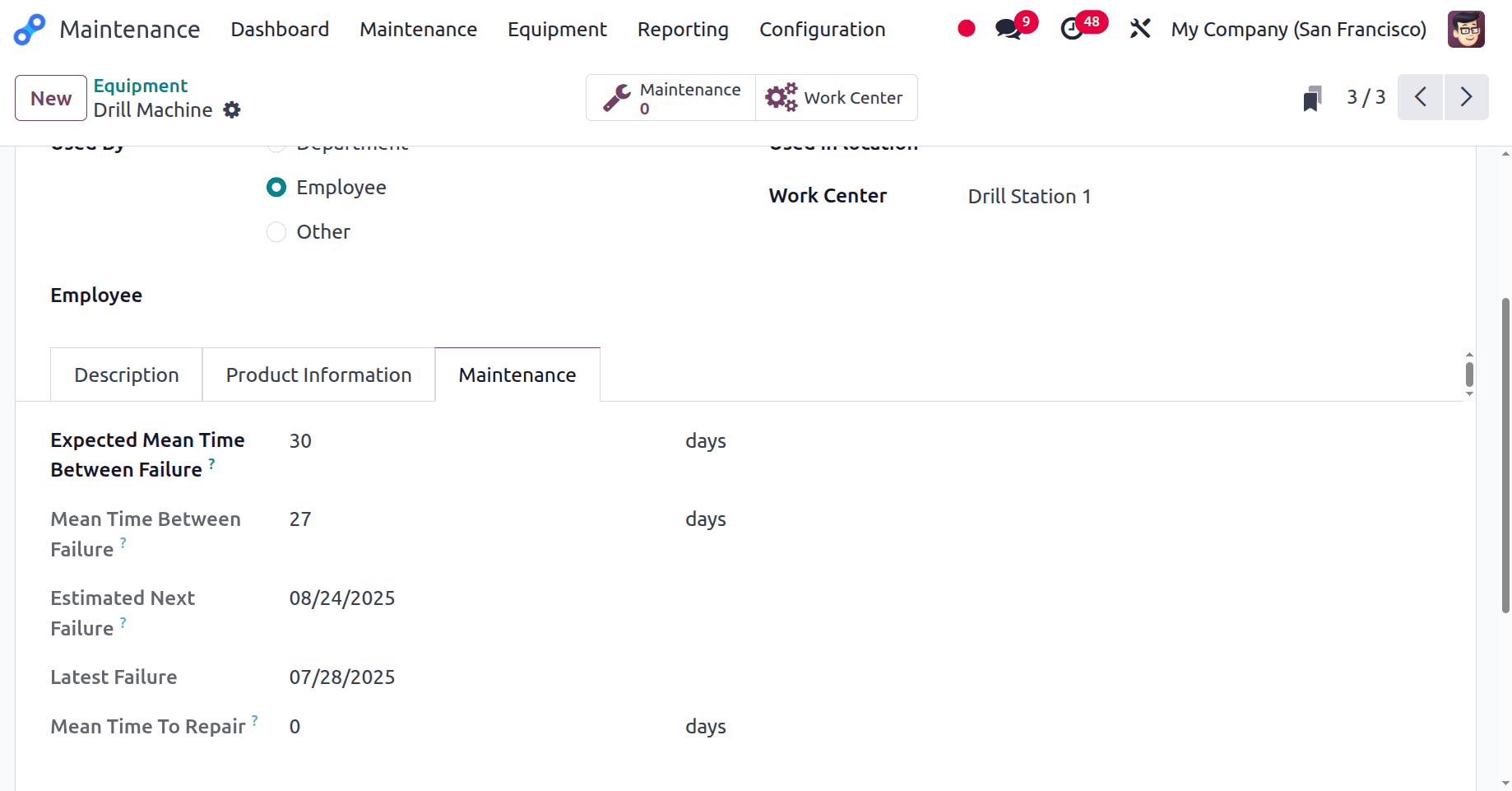

The next tab is the Maintenance tab. Users can view the Mean Time Between Failures, Estimated Next Failure, Latest Failure, and Mean Time to Repair after adding the Expected Mean Time Between Failures.

The Mean Time Between Failures is calculated based on the corrective maintenance. The Estimated Next Failure is the sum of the Latest Failure and the Mean Time Between Failures.

For the equipment, Drill Machine, the Effective Date is set as 07/01/2025, and the Expected Mean Time Between Failure is set as 30 days. Let's make a fresh request for the equipment's remedial maintenance.

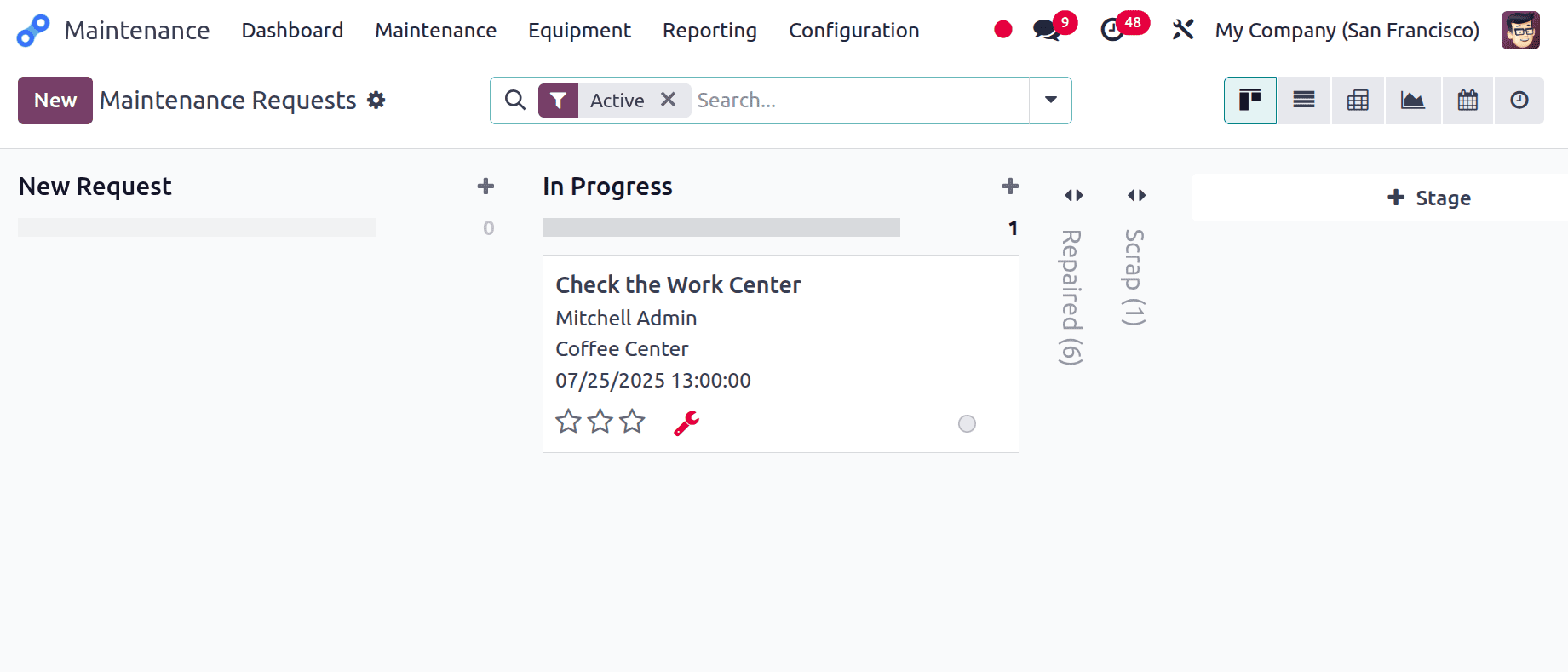

Click on the Maintenance request menu. Then the maintenance stages can be seen as shown below. To add a new request, click the New button.

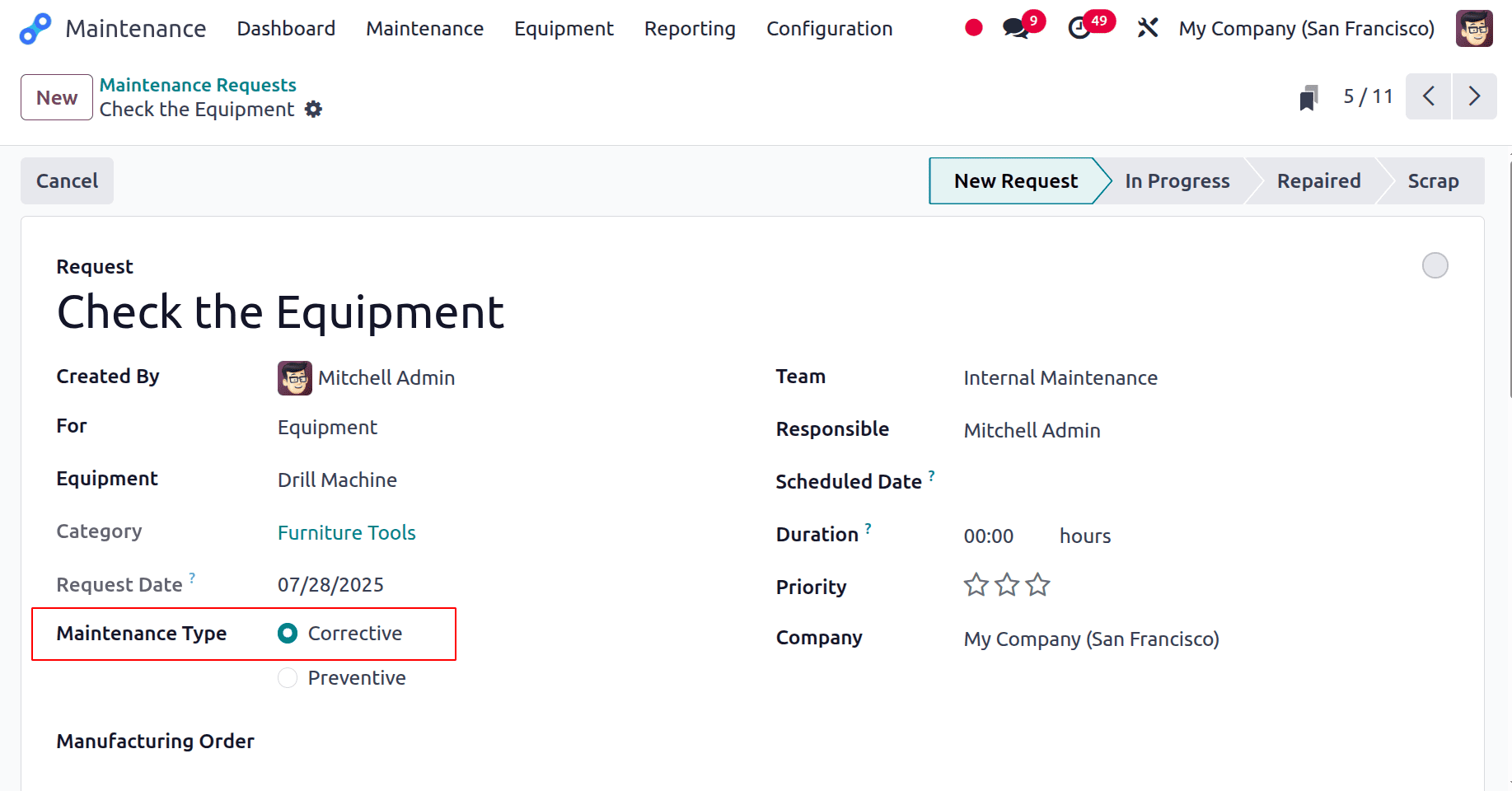

Here, the request description is added as “Check the Equipment”. Then, add the following details: Created By, For equipment, the equipment, requested date, team, responsible person, scheduled date, duration, priority, and company.

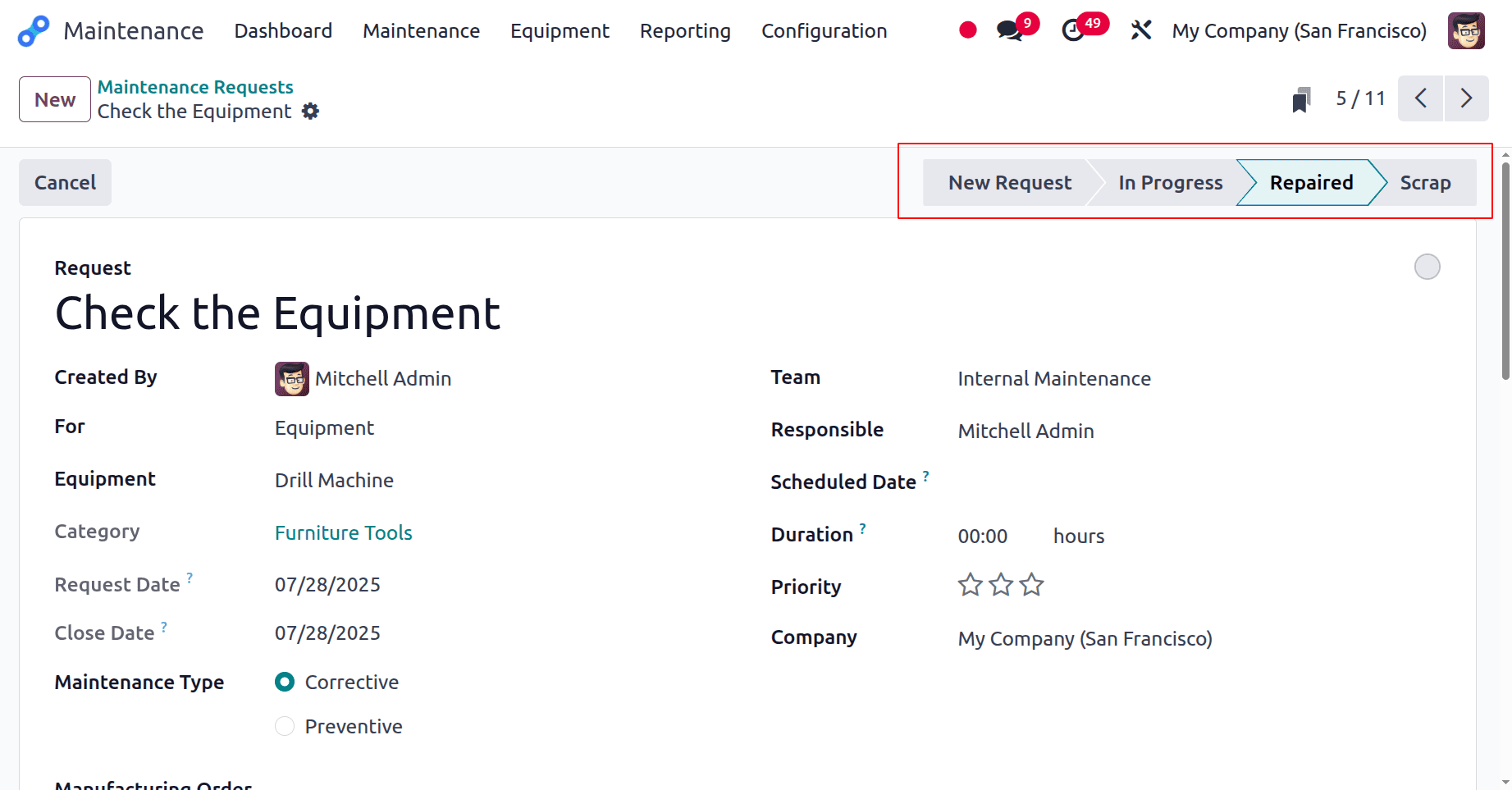

There are two types of Maintenance, so choose the type as Corrective. Here, the request is in the New Request stage. Users can change the stage to In Progress when the maintenance process starts, then, after completion, change the stage to Repaired.

This is how the corrective maintenance request was raised and completed in the Odoo 18 Maintenance module.

After completing the maintenance request, go back to the same equipment to check the updates. Check the Maintenance tab of the equipment. As indicated below, the Mean Time Between Failure, Estimated Next Failure, and Latest Failure fields have been modified.

For the equipment, the Drill Machine Effective Date is set as 07/01/2025, and the Expected Mean Time Between Failure is set as 30 days. The latest Failure date is updated to match the date the maintenance request was raised.

Mean Time Between Failure = [Number of days between the Effective date and the Latest failure date.]/number of failures

There are 27 days between 07/01/2025 and 07/28/2025, and one failure

Estimate Next failure = Latest Failure + Expected MTBF

= 07/28/2025 + 30 DAYS = 08/24/2025

This is how Corrective Maintenance was added in Odoo 18 maintenance. In conclusion, Odoo 18's corrective maintenance feature offers a practical solution for dealing with unforeseen equipment failures. It helps reduce downtime and quickly restore operations by enabling the rapid development, assignment, and tracking of maintenance requests. Odoo guarantees a quick and efficient maintenance procedure with its intuitive interface and connection with other modules.

To read more about How to Manage Maintenance Requests in Odoo 18, refer to our blog How to Manage Maintenance Requests in Odoo 18.