Manufacturing procedures frequently change based on the unique features of each product variation. New features in Odoo 18 have made it feasible to easily and precisely route the manufacturing of distinct variations to several workcenters. This feature increases manufacturing processes' flexibility, particularly for companies that sell items that may be customised or configured. Today, businesses can create customised processes tailored to the specific needs of each version, rather than relying on a single, static routing for all. This guarantees better production scheduling, better resource allocation, and fewer shop floor bottlenecks. We'll look more closely at how variant-based routing is enabled by Odoo 18 and how to set it up in this blog.

We'll also look at real-world applications and the advantages this offers in intricate production settings. By the end, you'll know how to use this robust Odoo 18 feature to optimize your manufacturing process.

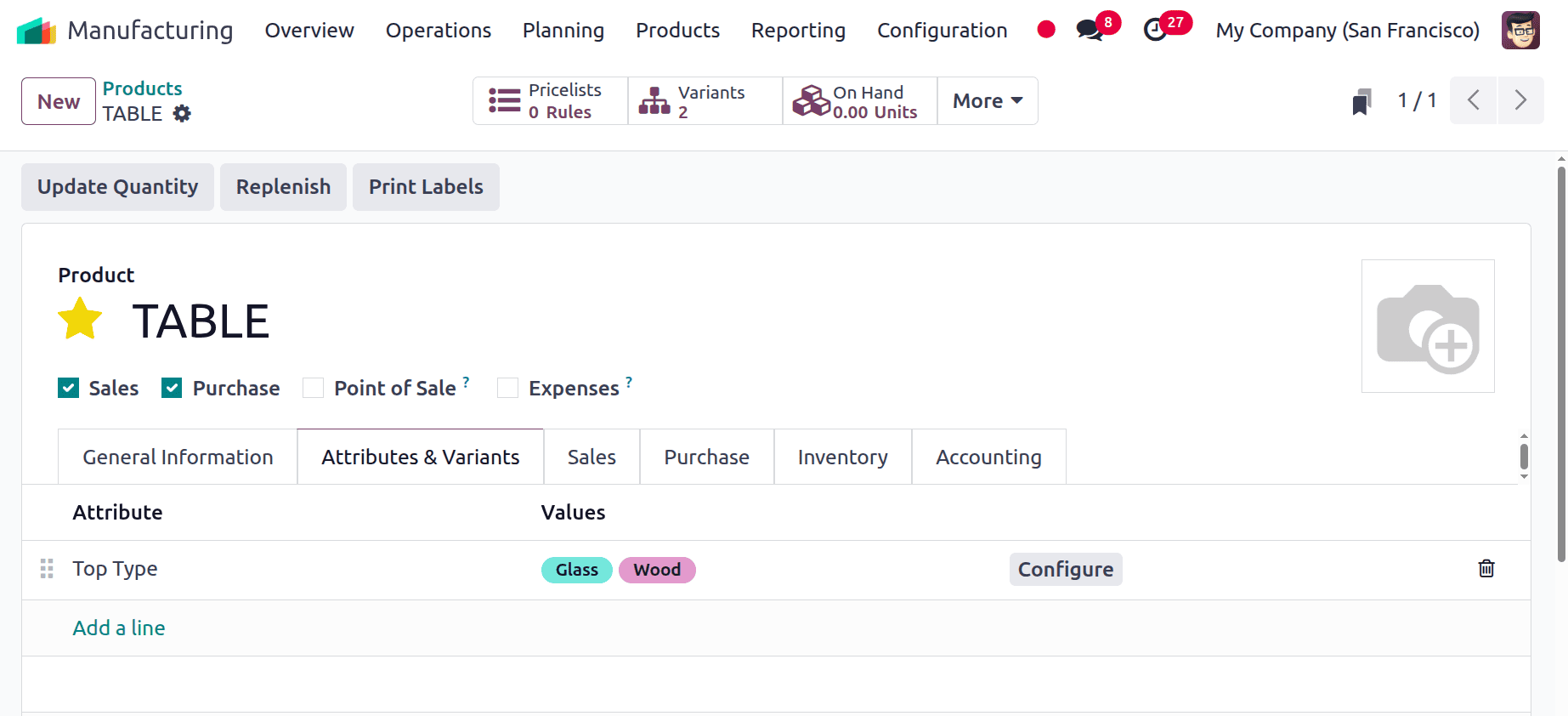

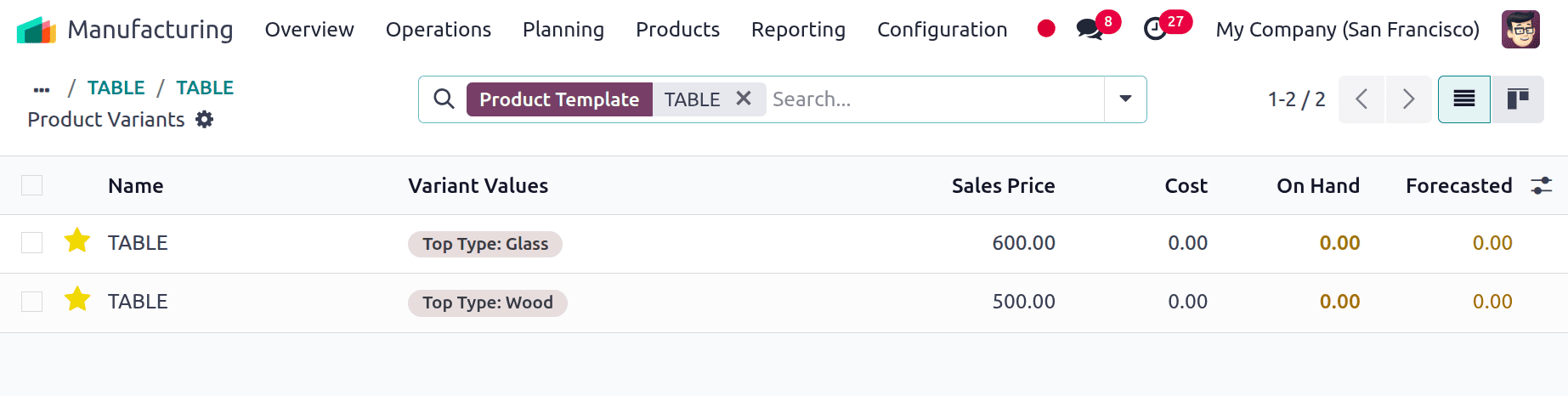

Let's take a very basic example, which is the production of a Table. Here, two variants of the table are sold in the company. The first one is a Glass top table, and the second type is a Wood top table.

So the manufacturing raw materials for the product TABLE are Table Top, Table Leg, Bolts, and Screw. But there is a difference between manufacturing Glass top Table and a Wood top Table. For manufacturing the Glass top Table, the raw materials are Glass Top, Table Leg, Bolts, and Screw, and for manufacturing the Wood top Table, the raw materials are Wood Top, Table Leg, Bolts, and Screw.

For manufacturing a TABLE, there are three operations needed. Cutting, Assembling, and Packing are the operations. But for the Glass top Table, the first operation should be Glass Cutting, and for the Wood top Table, the first operation should be Wood Cutting.

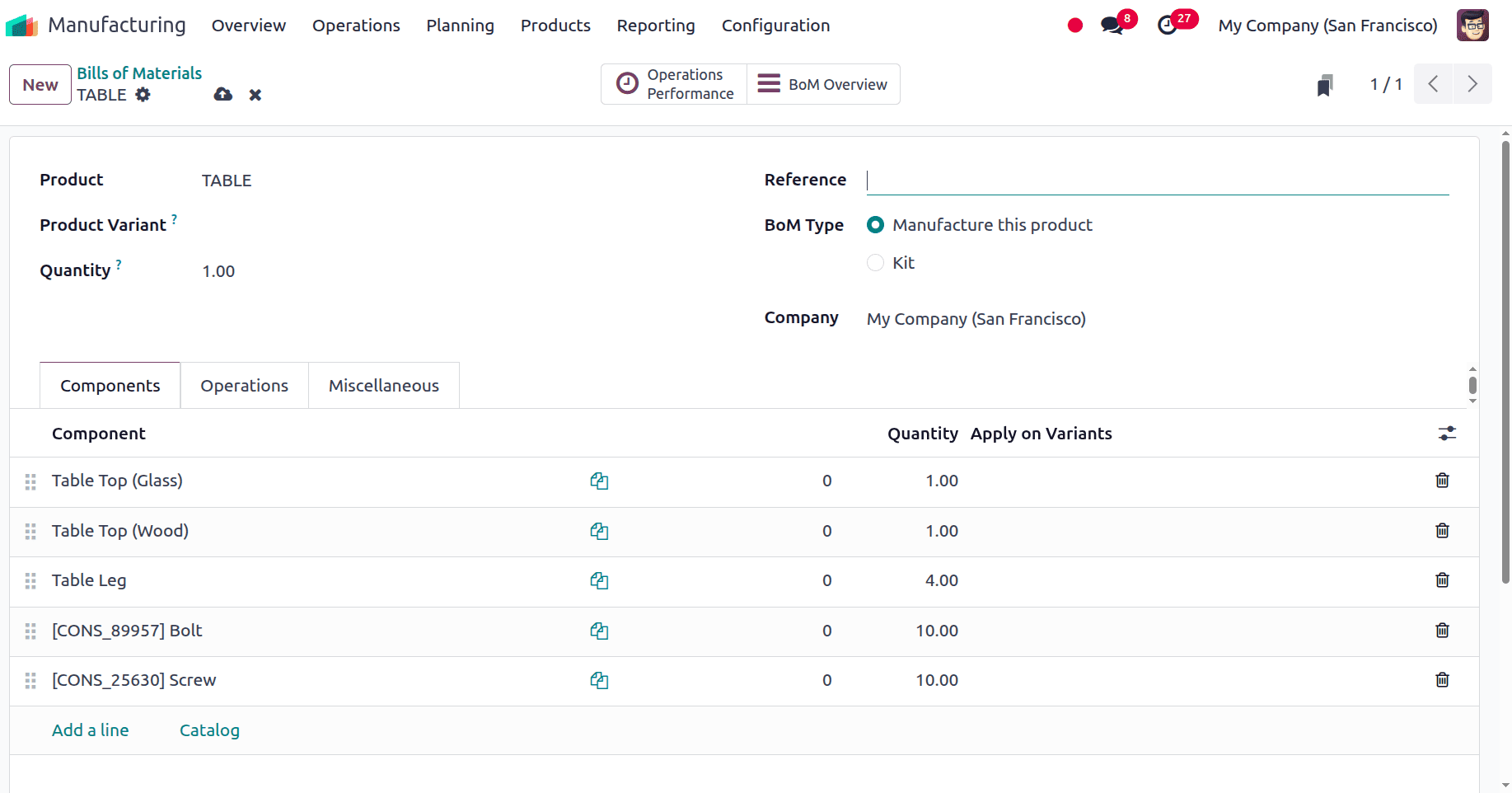

So let's create a new Bill of Materials for the TABLE. Here, the user creates only one bill of material, which is used for both the tables, Table with Glass top and Table with Wood top.

: Products > Bill of Materials> New

Add the product name first. No variant is chosen because the bill of materials is created for both variants, and the mentioned quantity is one here. BoM Type should be Manufacture this product. Under the components tab, add the components Table Top (Glass), Table Top (Wood), Table Leg, Bolts, and Screws.

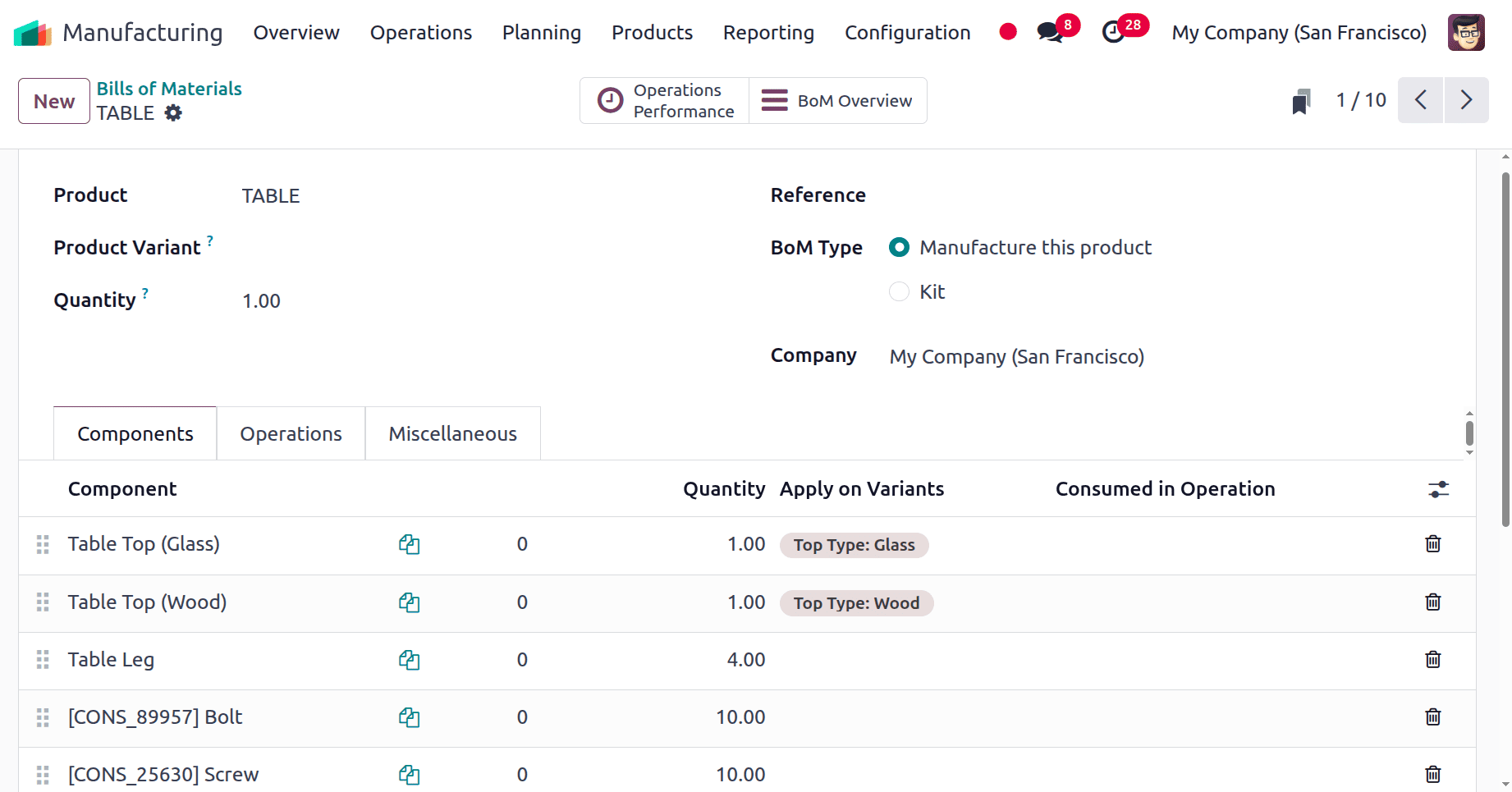

But here the Table Top (Glass) is only used to manufacture the Glass Top Table, and Table Top (Wood) is used for the production of Wood Top Table. So the user should mention that inside the bill of materials. So there is a field named Apply on Variants, mentioning the table variant, which the components used there, as shown in the screenshot below.

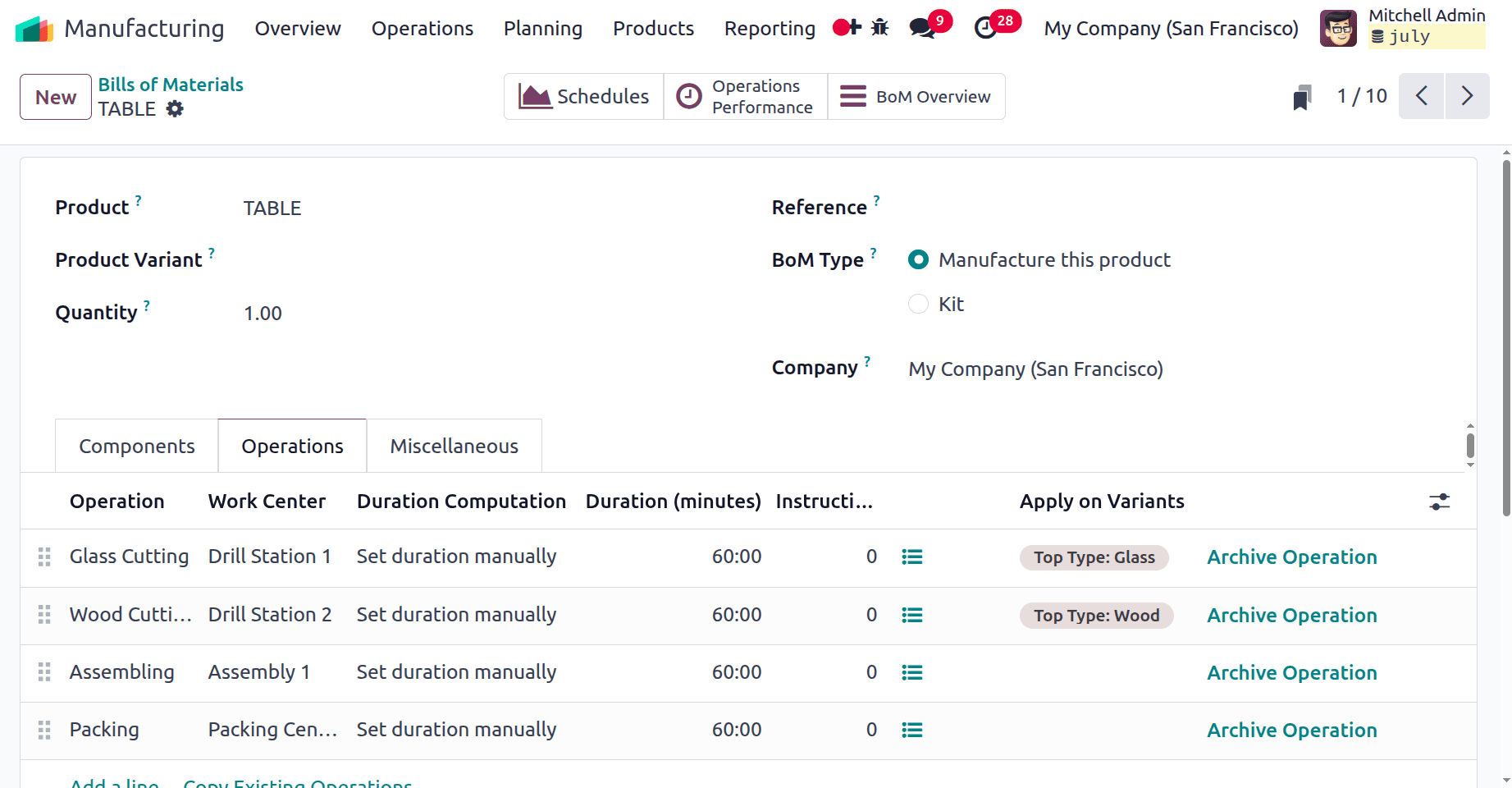

The next tab, named Operations, is used to mention the procedures needed for the production of the TABLE. So mention the operations like Glass Cutting for Glass top Table and Wood Cutting for Wood top Table.

Here, the Glass cutting occurs inside the workcenter named as Drill Station 1, and the Wood Cutting occurs inside the workcenter named as Drill Station 2. Then the other two operations are Assembling and Packing, and these two operations are common for both types. Save the bill of materials.

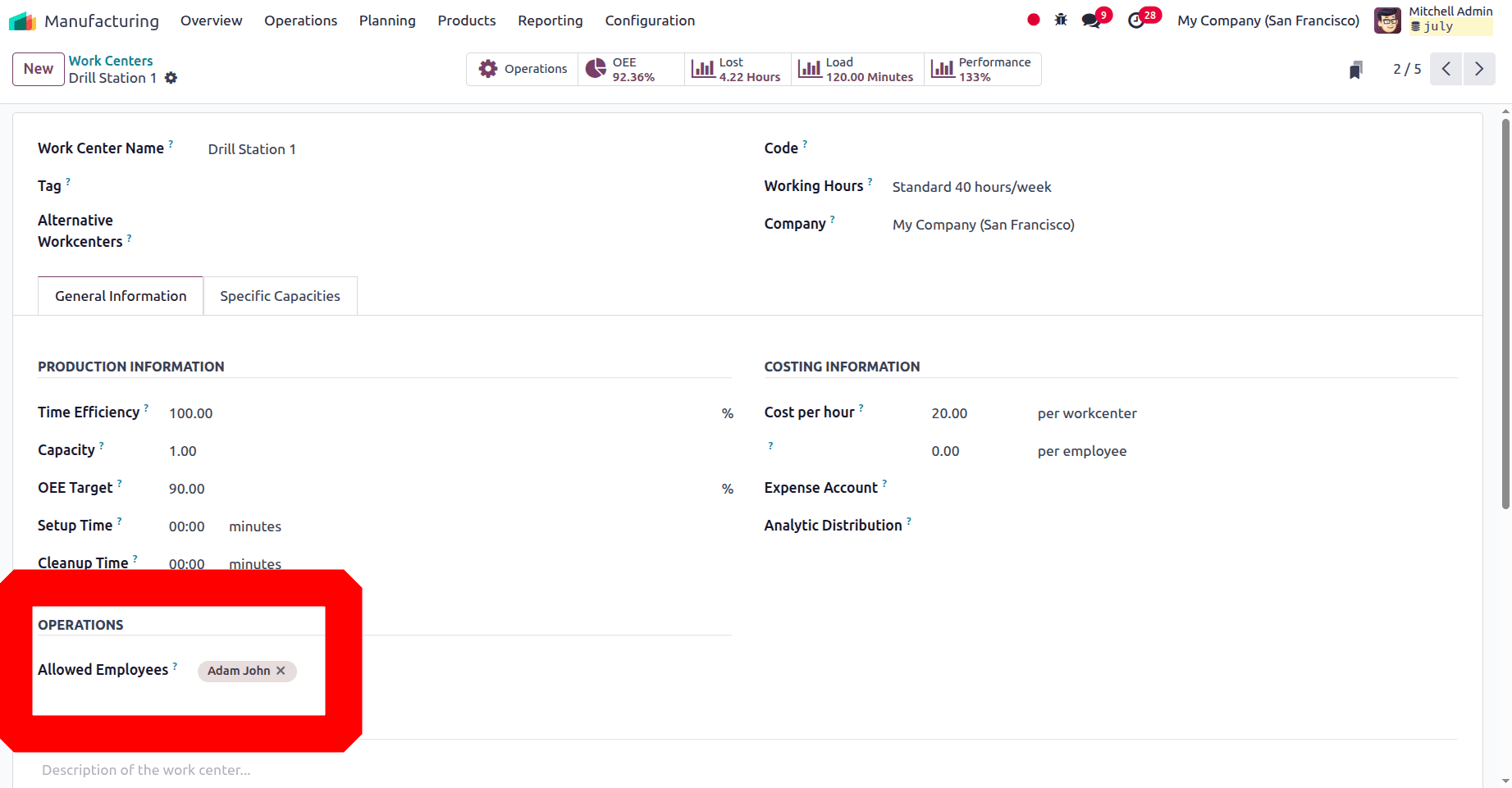

As per the bill of materials, the operation Glass Cutting will occur inside the Drill Station 1. Let's check the configuration of the workcenter. The allowed employee is Adam John, and he is the one who completes the operation.

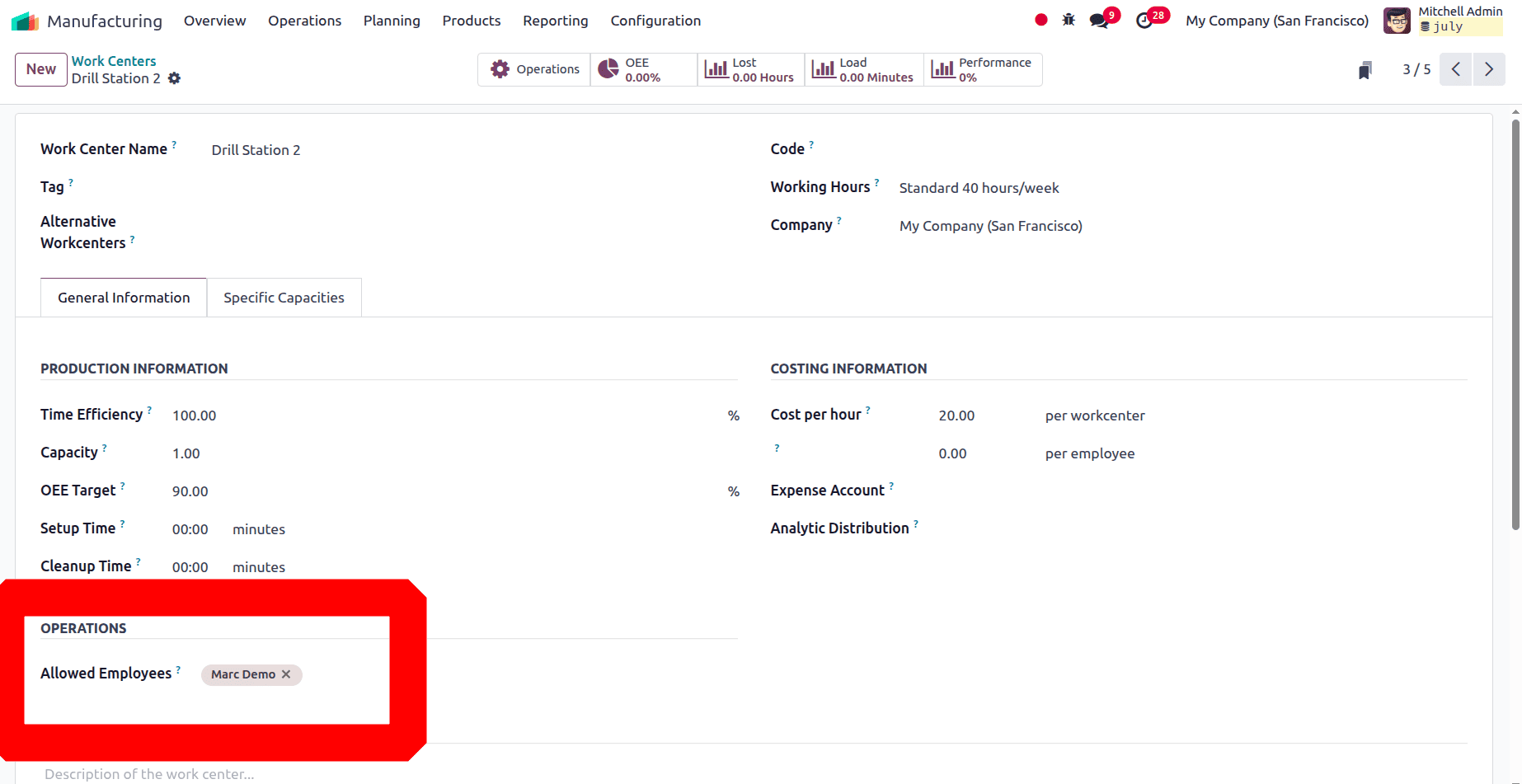

Then the Cutting operation for the second variant, which means for the Wood top Table, is named as Wood Cutting. Wood cutting works inside the work center, Drill Station 2. So, Marc Demo is set as the allowed employee in Drill Station 2. Which means he is responsible for the operation.

Currently, the first operations of the two distinct product versions are carried out in two distinct work centres.

Now the configuration of the BoM is created. Then let's check the on-hand quantity of the tables. As shown in the screenshot below, both tables are currently out of stock.

So let's assume a scenario where, if the company gets a requirement from one of the clients for the product table, the user should manufacture it first. There are two types of tables here, Glass Top Table and Wood Top Table, and the manufacturing orders should be created for the requested table.

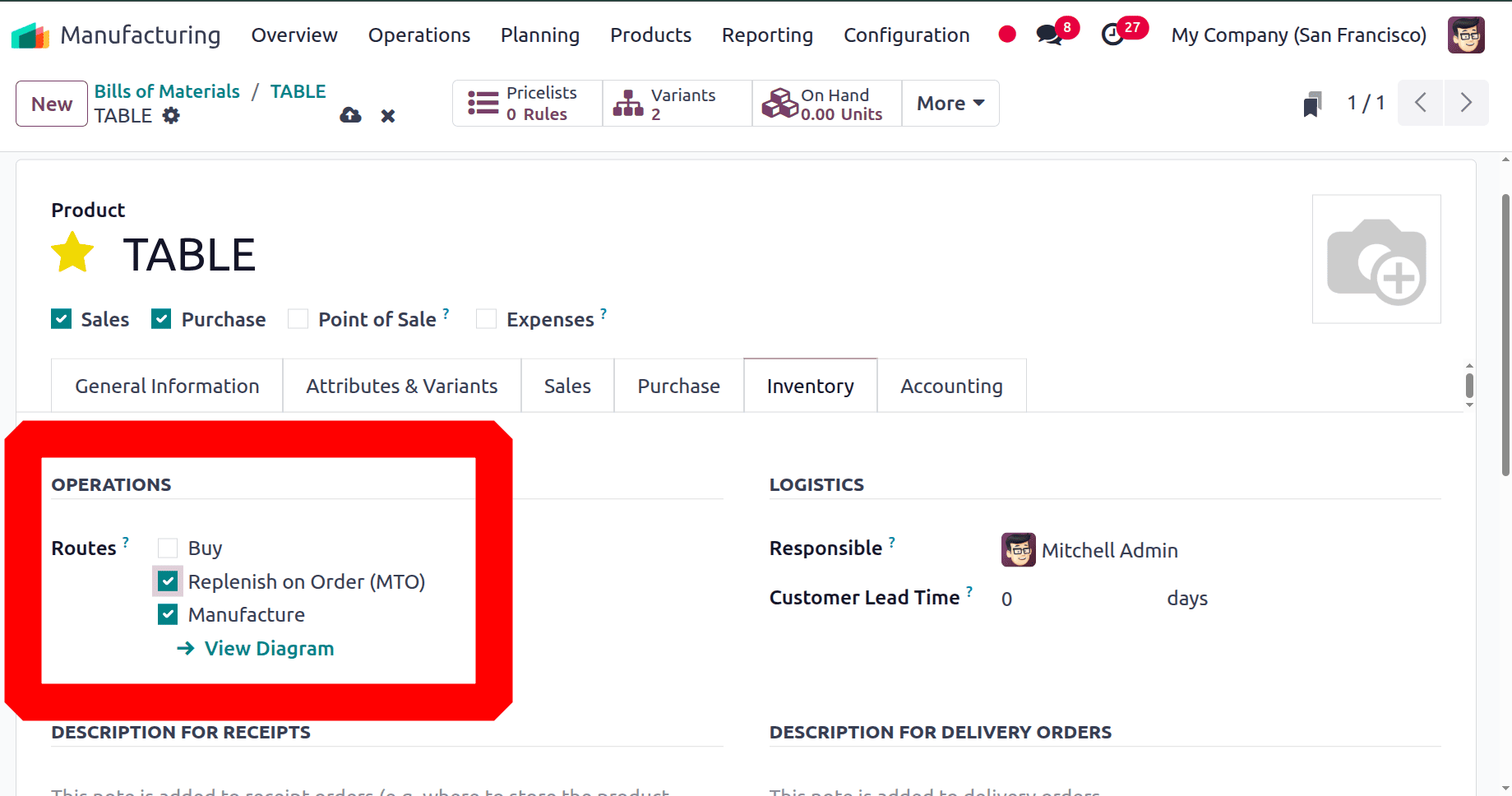

For that, the user should enable the routes Replenish on order (MTO) and Manufacture inside the inventory tab of the product.

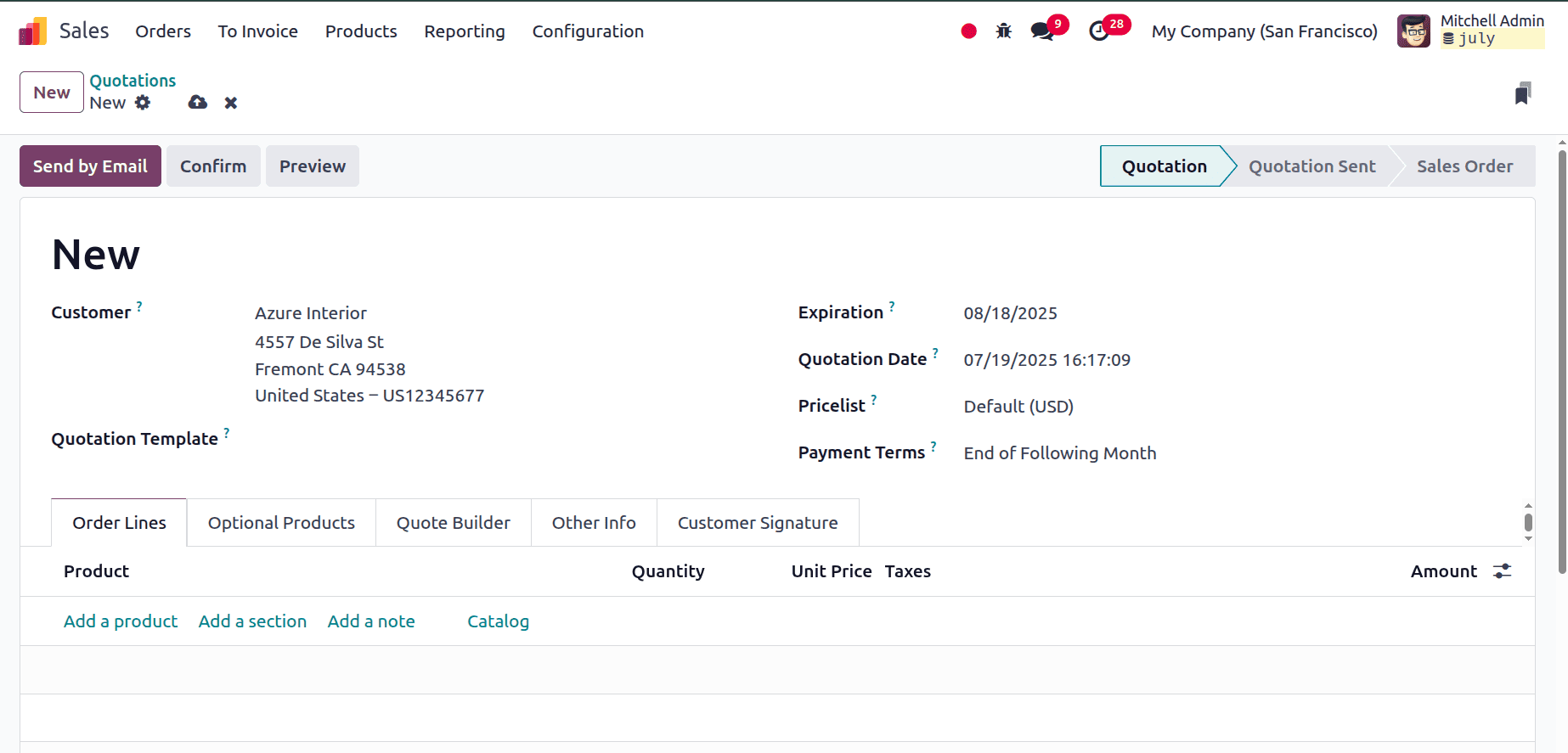

Consider there is a customer named Azure Interior who requested 1 quantity of Glass top Table. Create a new quotation for the customer. Then, to add the TABLE, click on the Add a Product button under the Orderline.

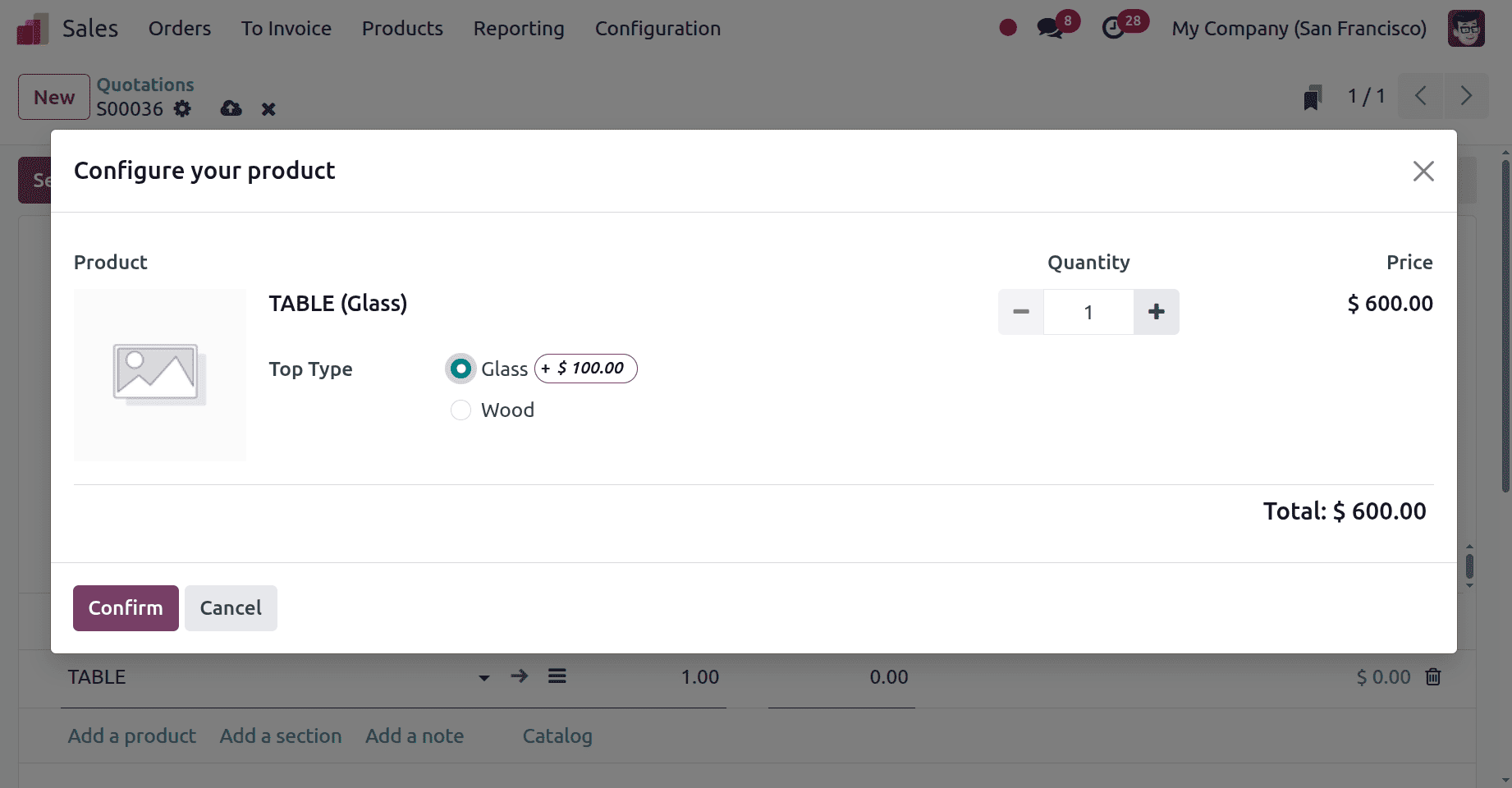

Then a new window will pop up as shown below, which is a Product Configurator window. Choose the product variant with quantity from there, and the sales price can be shown there. After choosing the product, click on the Confirm button.

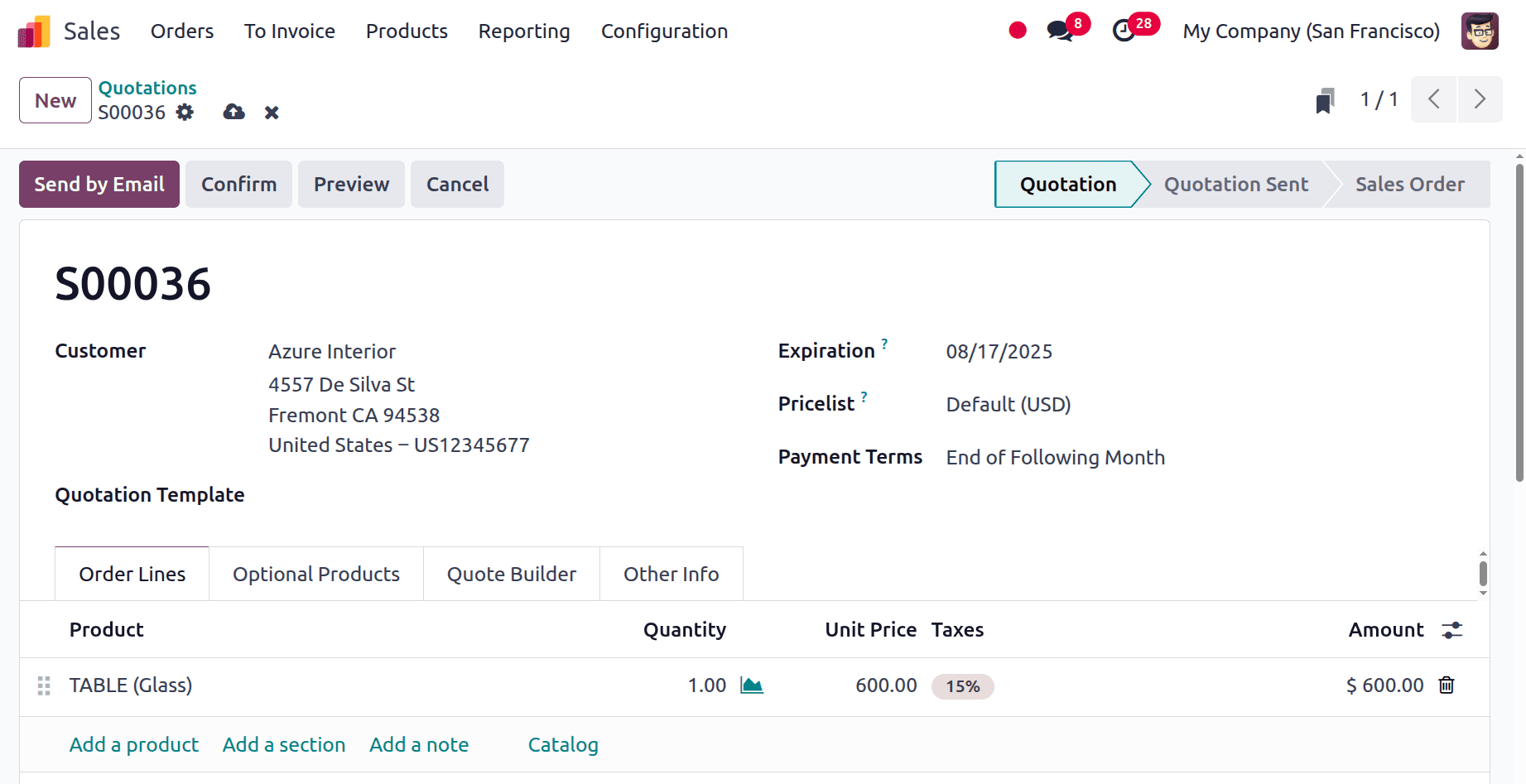

Then the product with quantity will be added to the order line as shown below. Here, the requested product is a Glass top Table, and the quantity is one. Confirm the order.

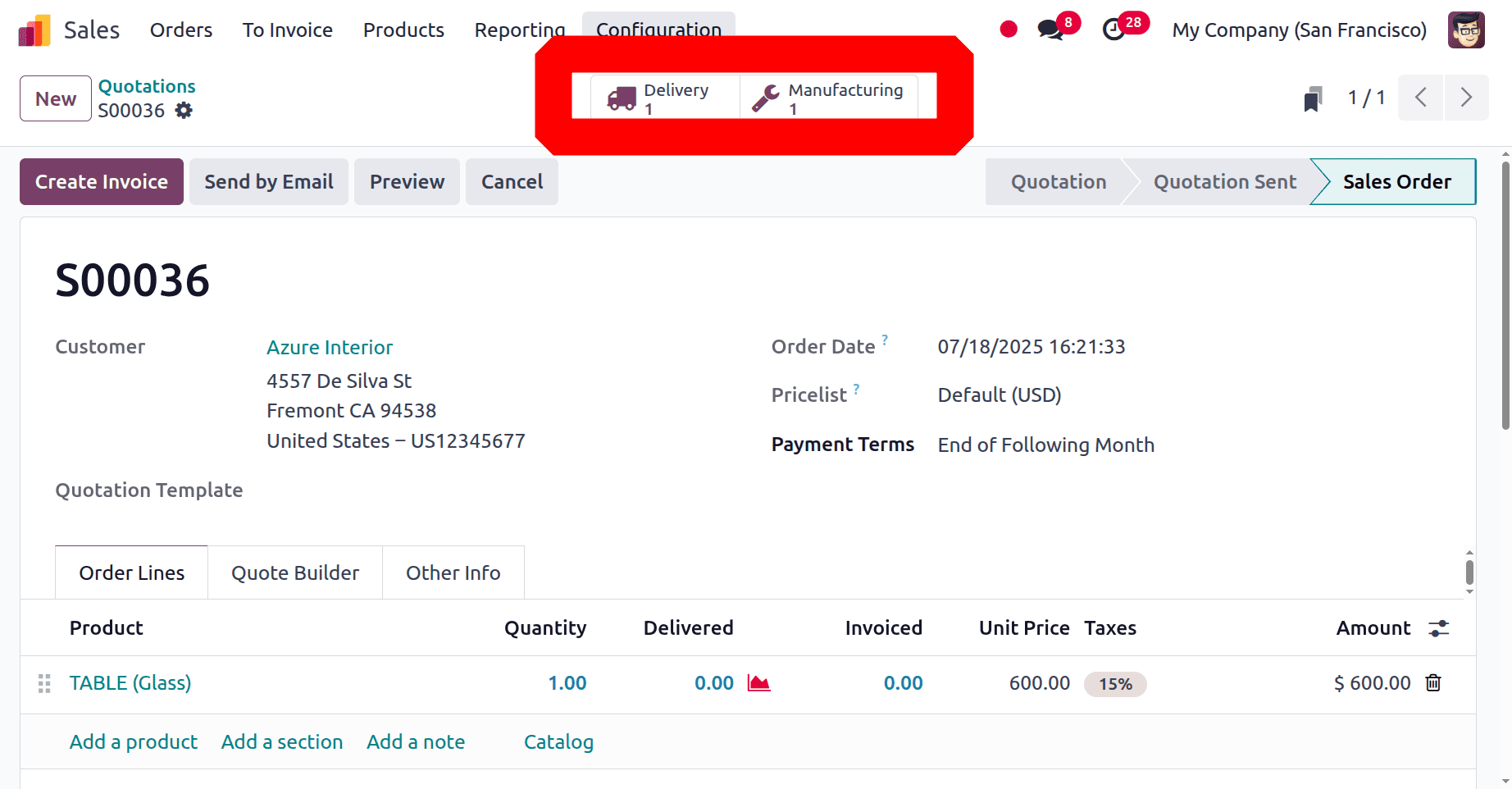

Two smart tabs appeared there, one is Delivery and the other is Manufacturing. The product is currently being manufactured first.

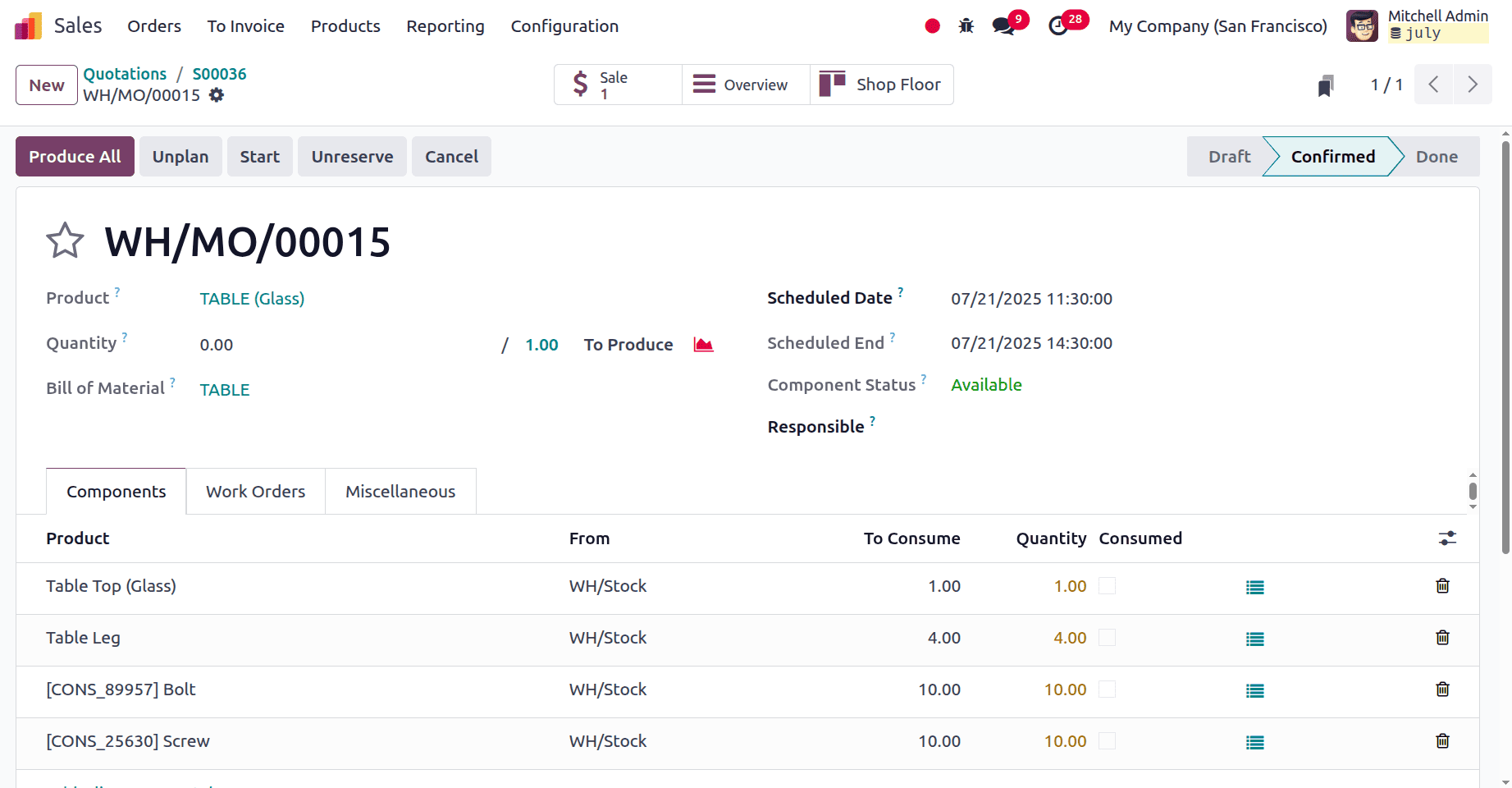

Open the Smart Tab Manufacturing first. This is the same bill of material that is configured, but the components and operations are chosen based on the requested product variant.

Here, the product name is TABLE (Glass). While checking the components, the listed components are Table Top (Glass), Table Leg, Bolts, and Screws.

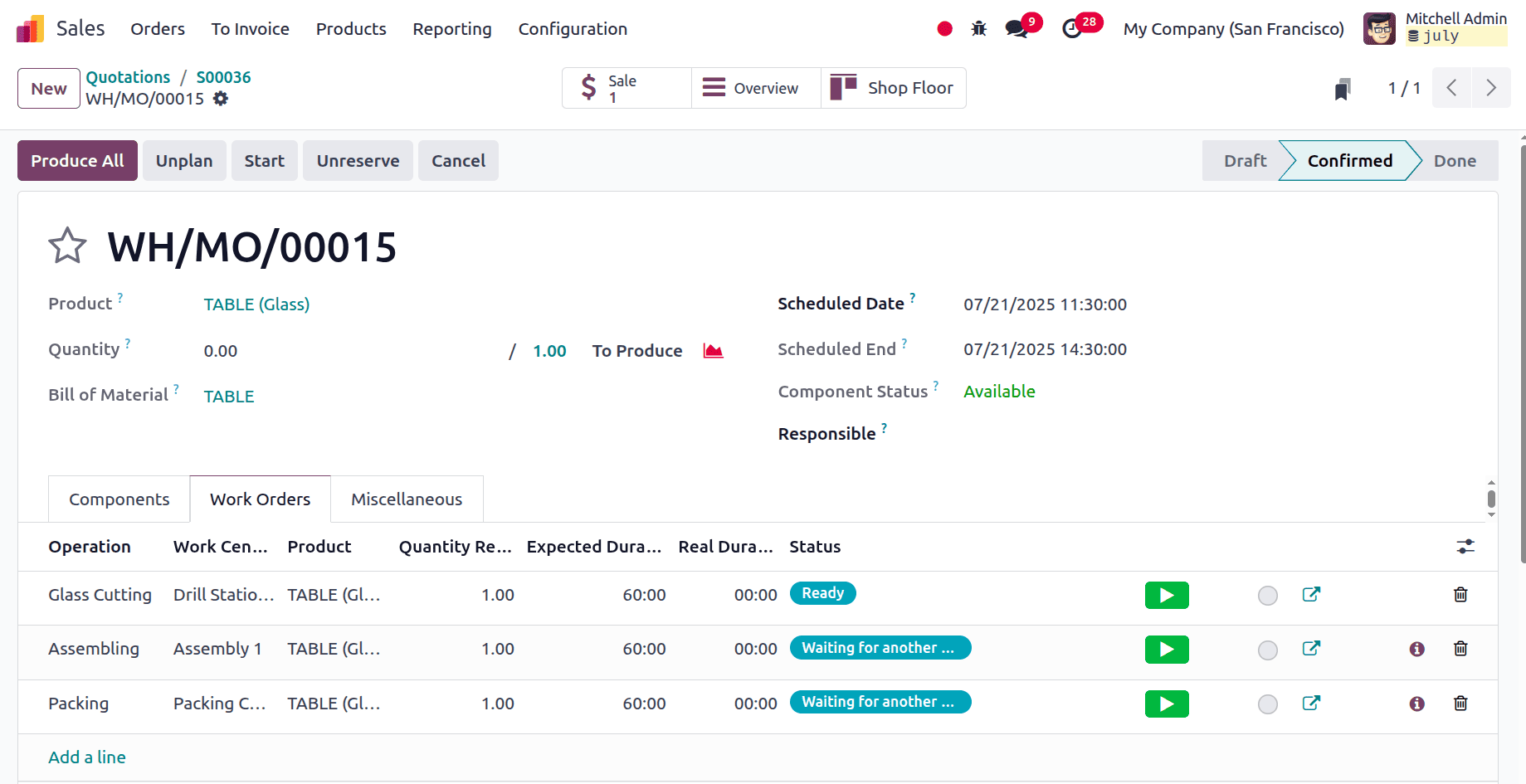

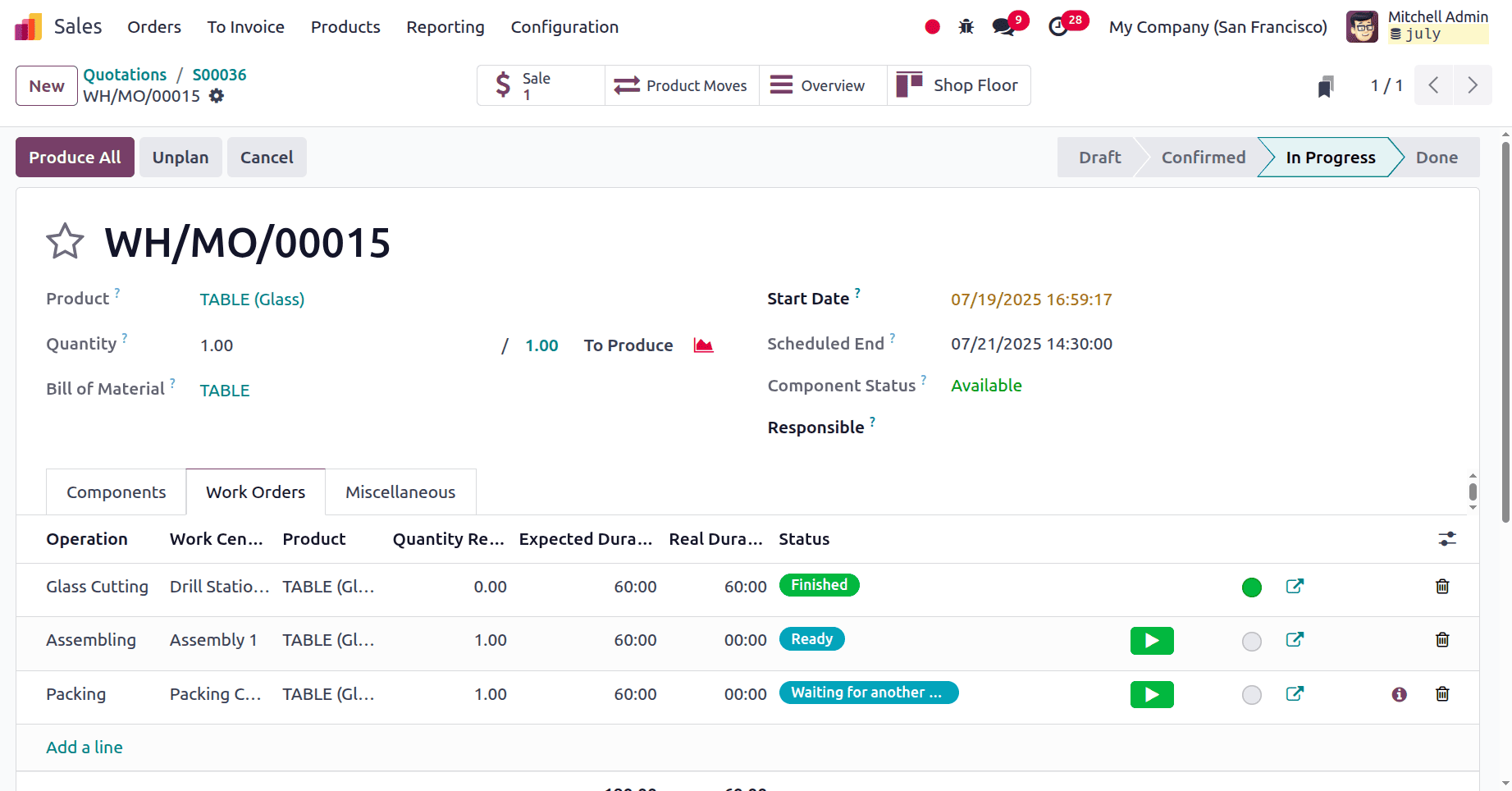

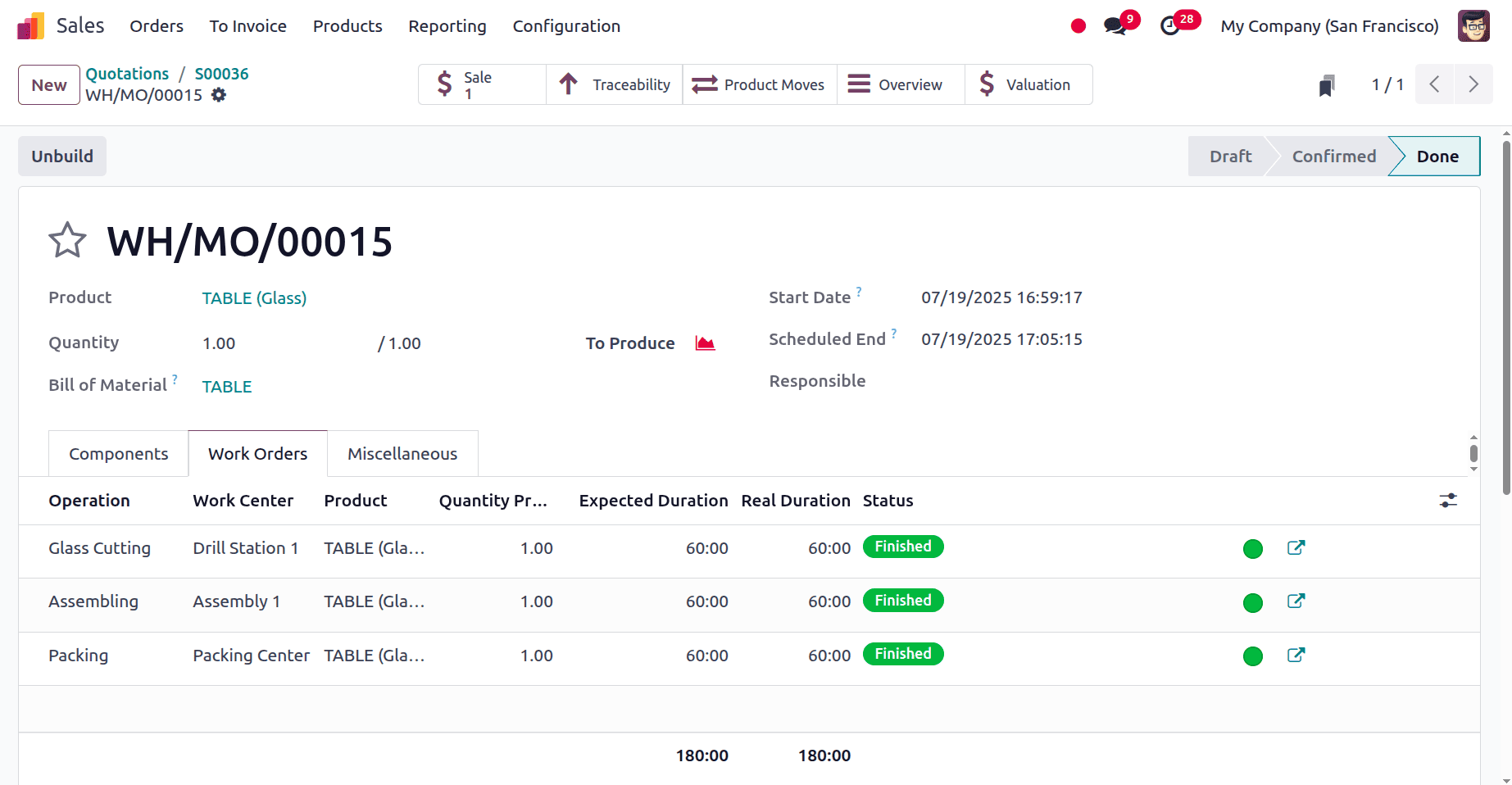

Click on the Plan button first, then the Work Orders tab, which contains the operations named Glass Cutting, Assembling, and Packing. Here, the 1st operation is Glass Cutting, and the workcenter is Drill Station 1.

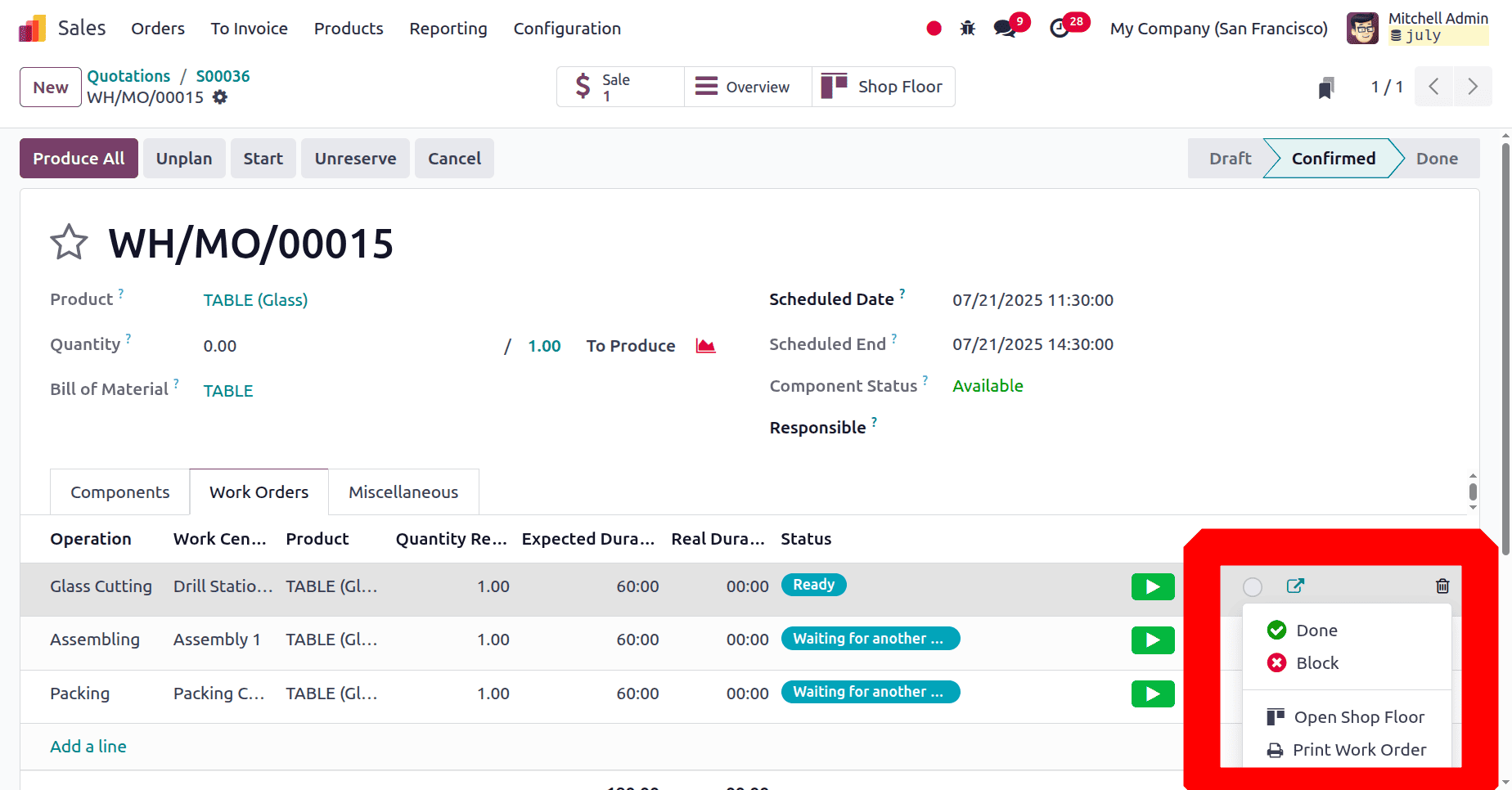

From the Work order tab, choose the Shop Floor app as shown below.

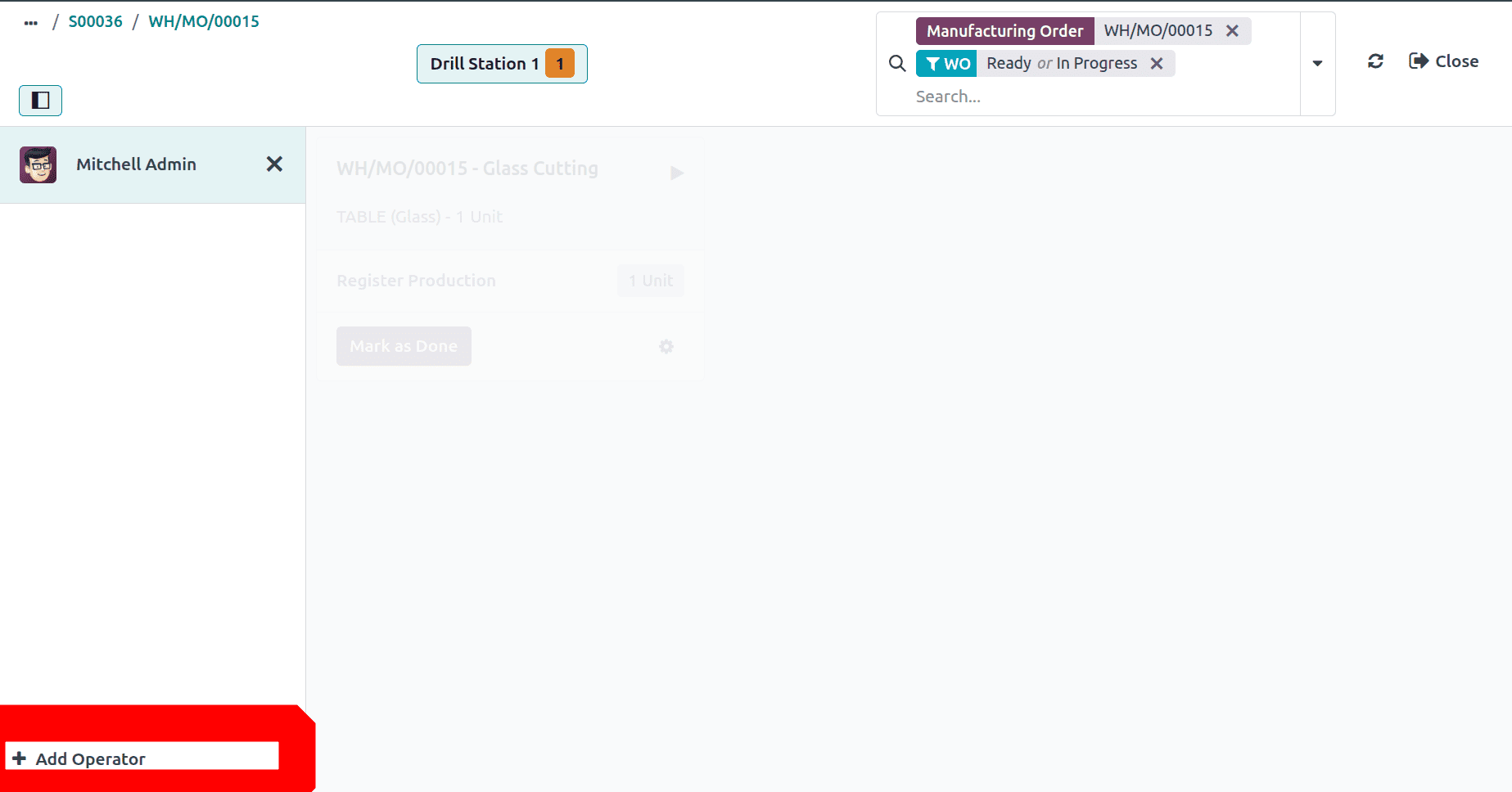

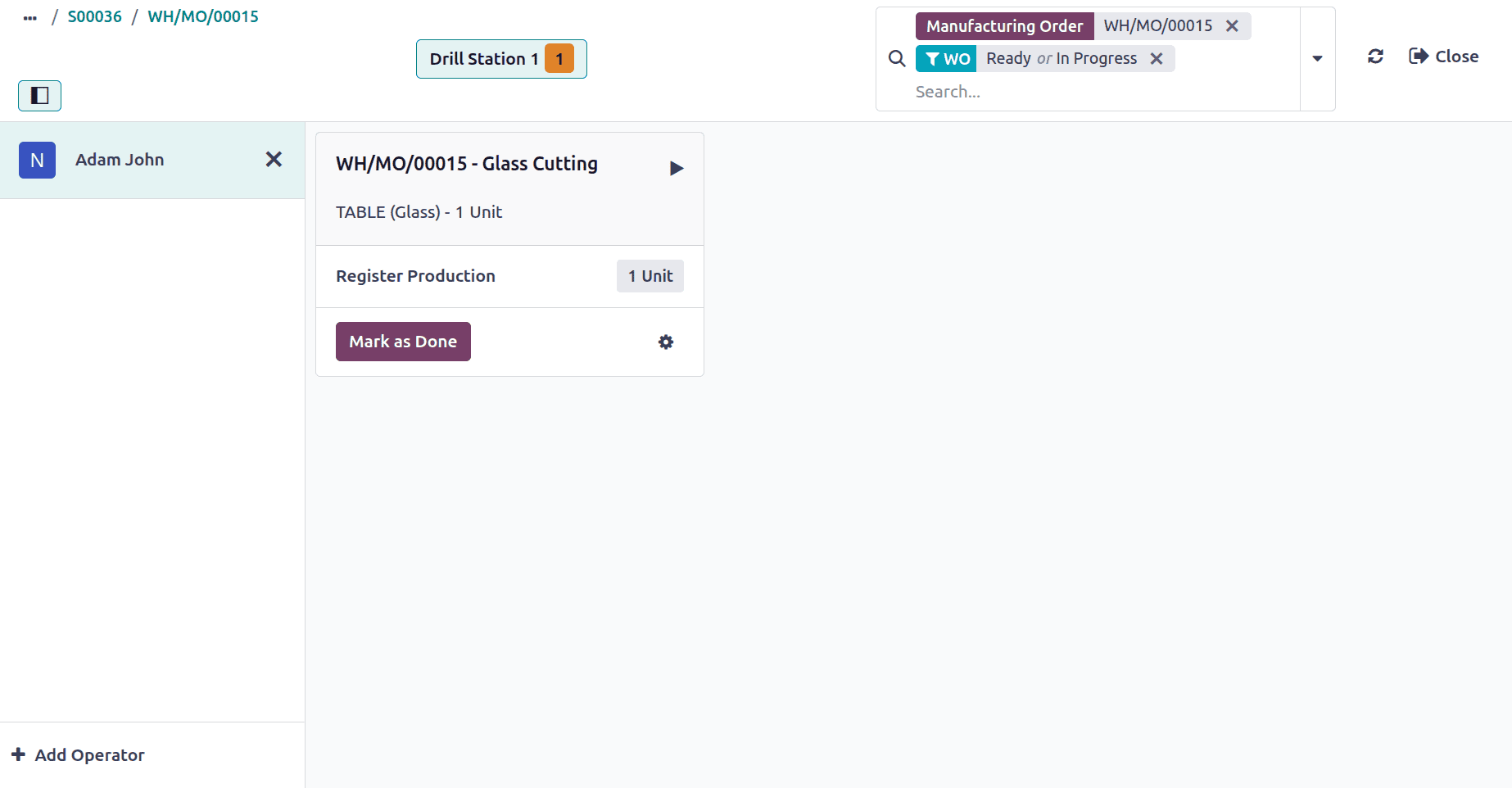

Now, the next window is the Shopfloor app. The operator for completing the Glass Cutting is Adam John. Click on the +Add Operator button placed at the bottom left corner.

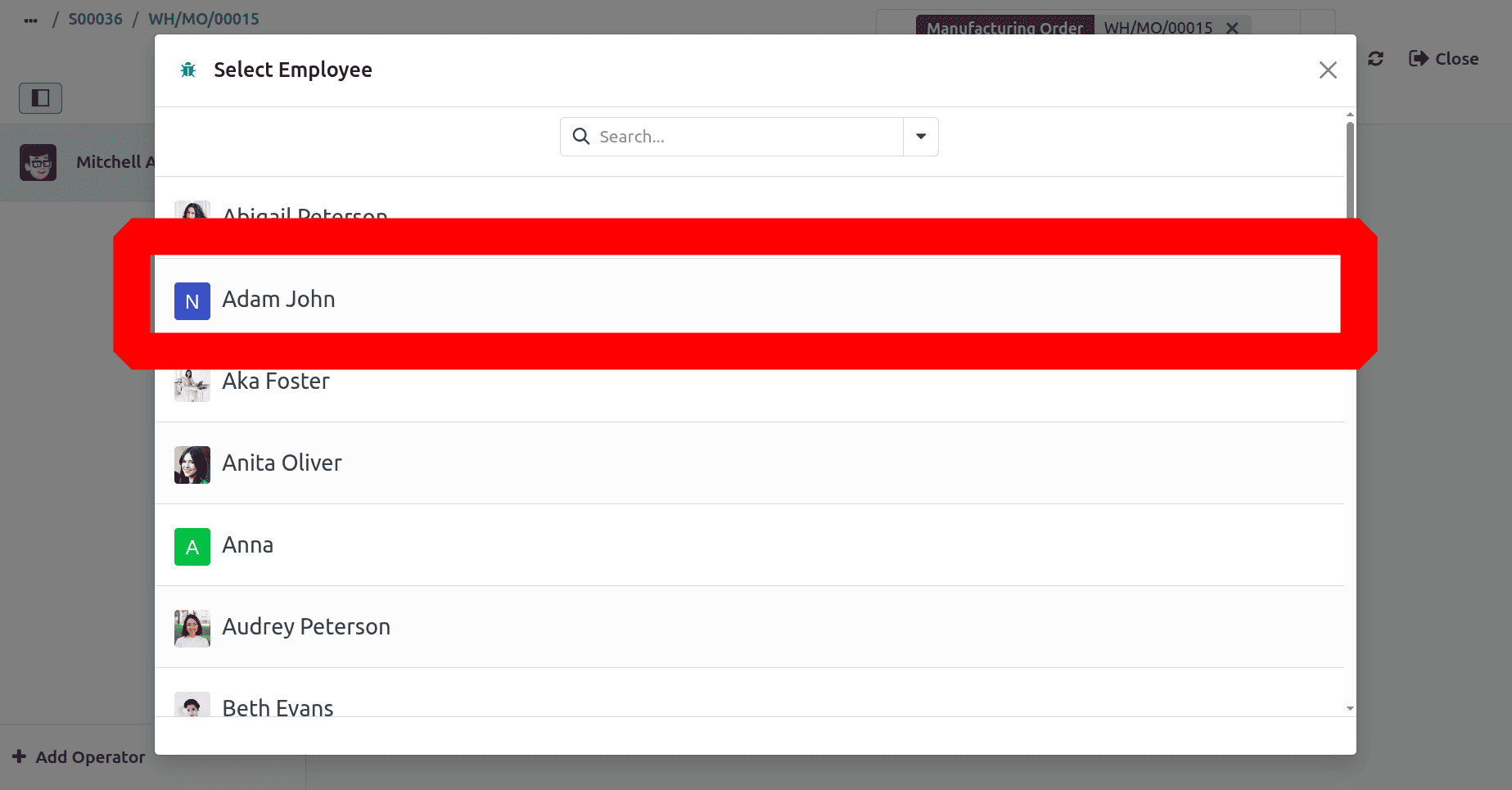

Then a list of employees will be displayed. Choose the employee Adam John from the list.

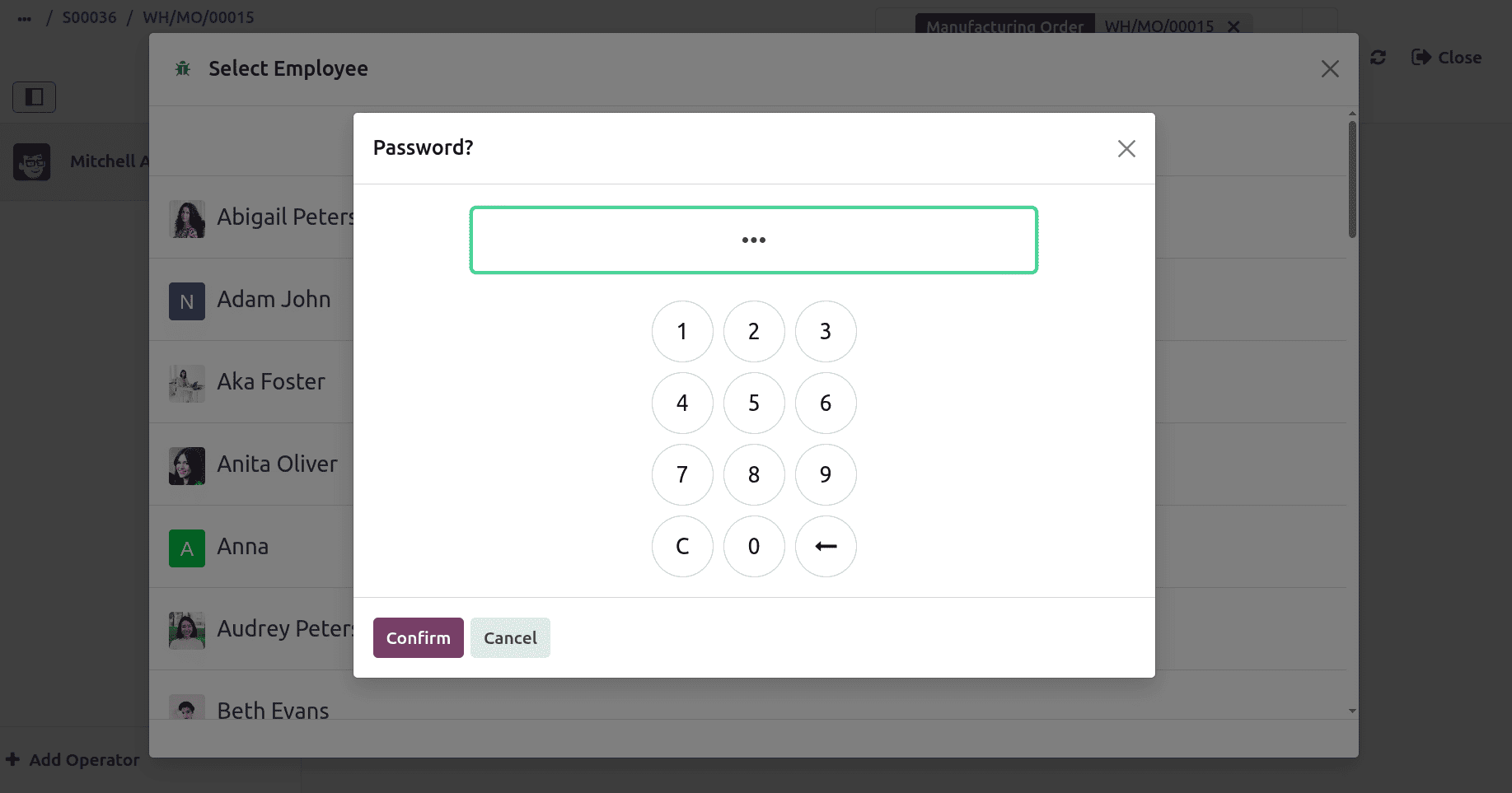

Then add the PIN to log in. Then click on the Confirm button.

Now, the Employee Adam John is logged in to the shop floor. And the operation Glass Cutting is shown there. Click on the arrow to start the operation. Then click on the Mark as Done button to complete the operation.

Now the first operation is completed. Then complete the other two operations. After that, click on the Plan All button.

Then complete the work orders. Then click on the Produce All.

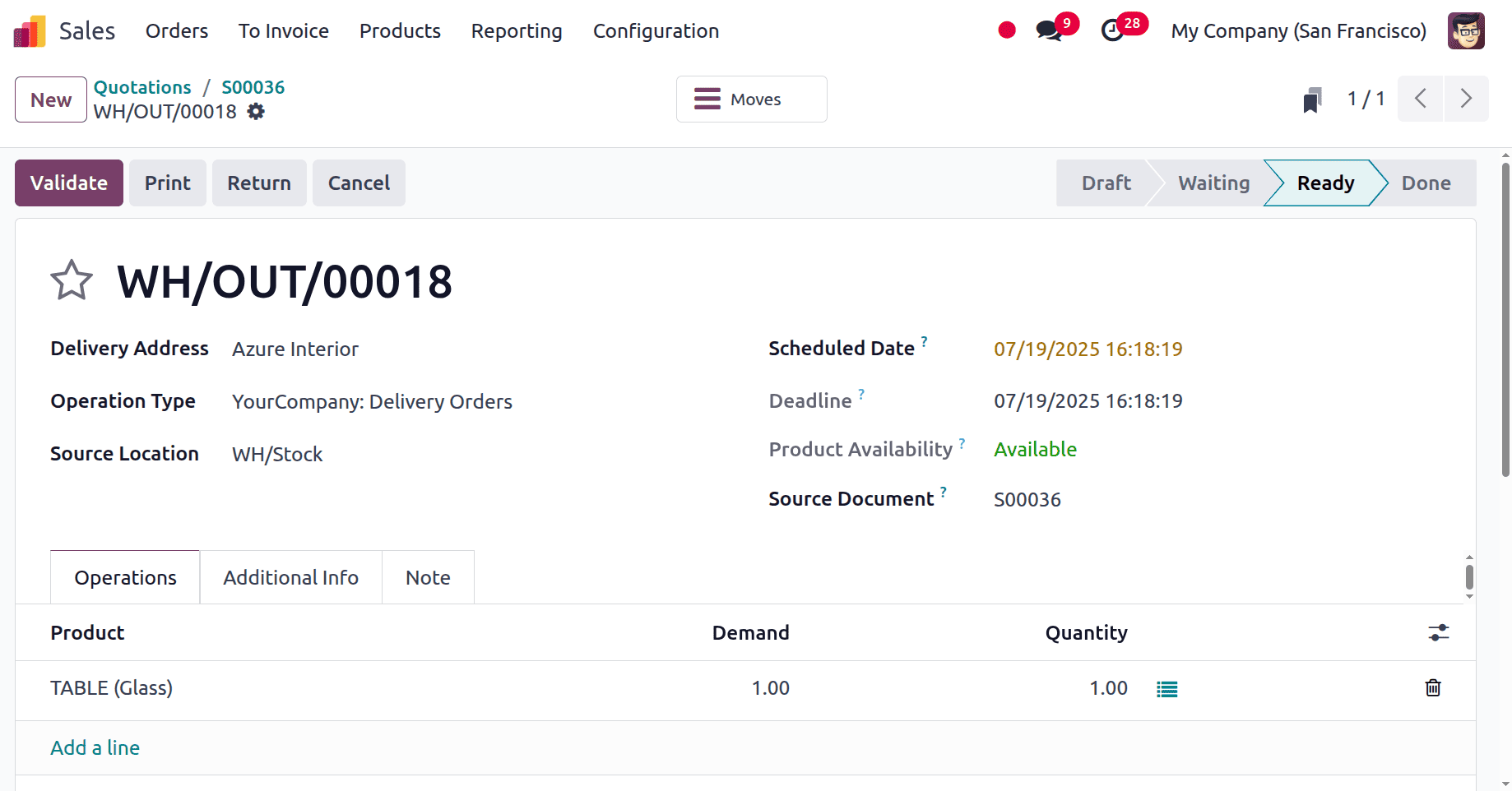

Now the product is manufactured and restocked in the inventory. Then the user can deliver the product. Choose the Smart tab Delivery.

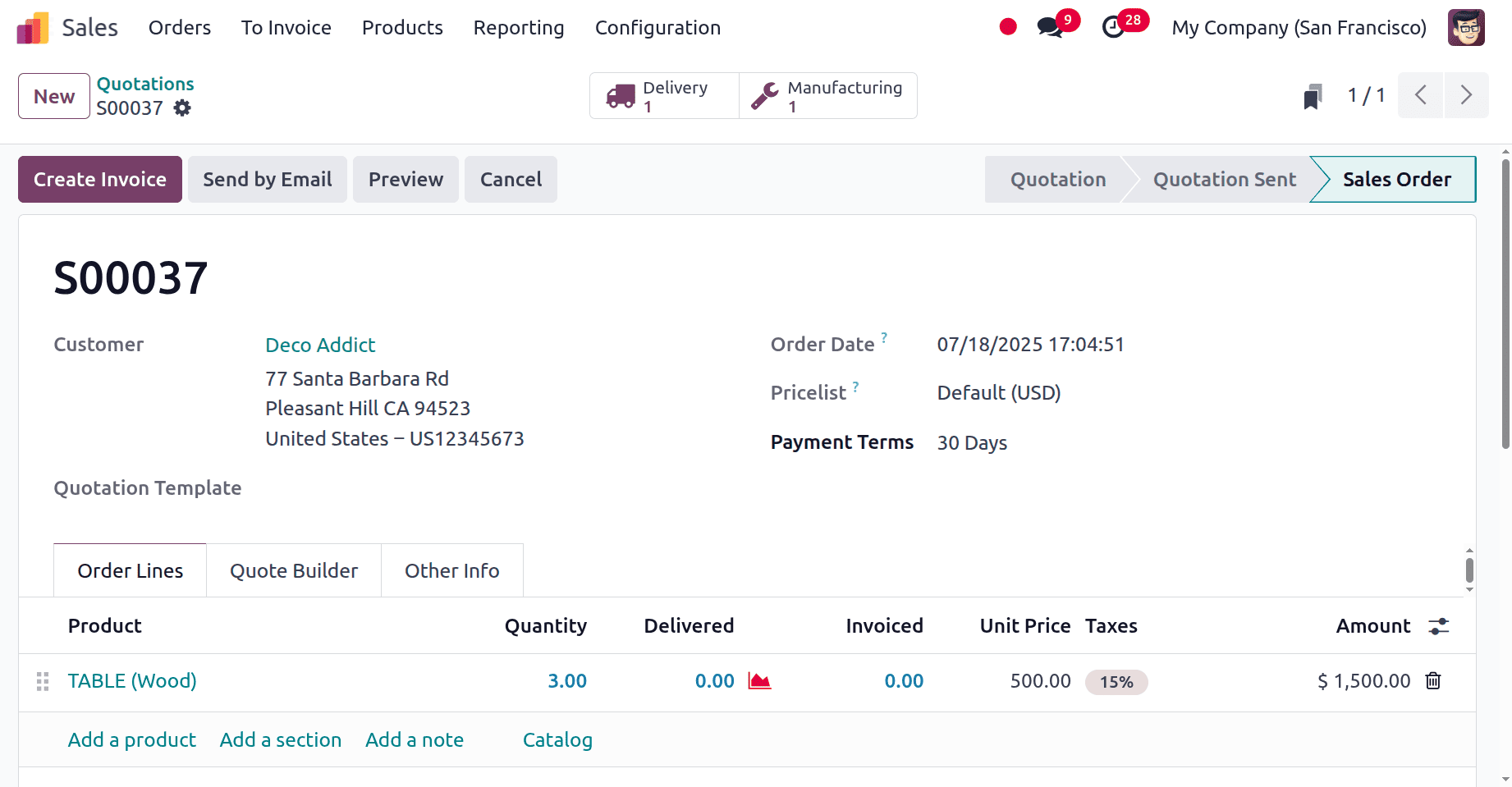

Here is the second customer named Deco Addicts, and the customer requested 2 quantities of Wood top Table. Quotation is created as shown below and confirms the order.

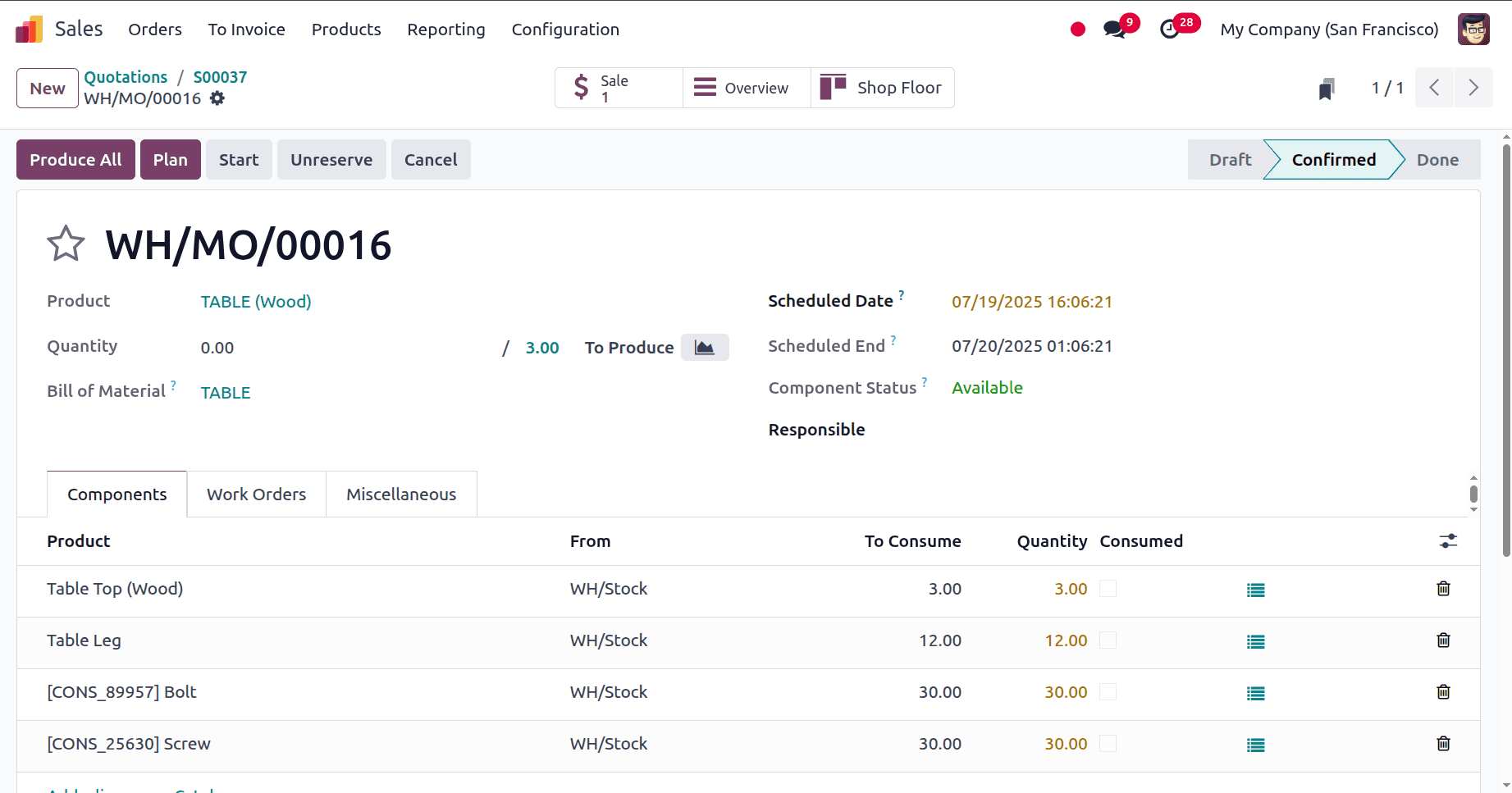

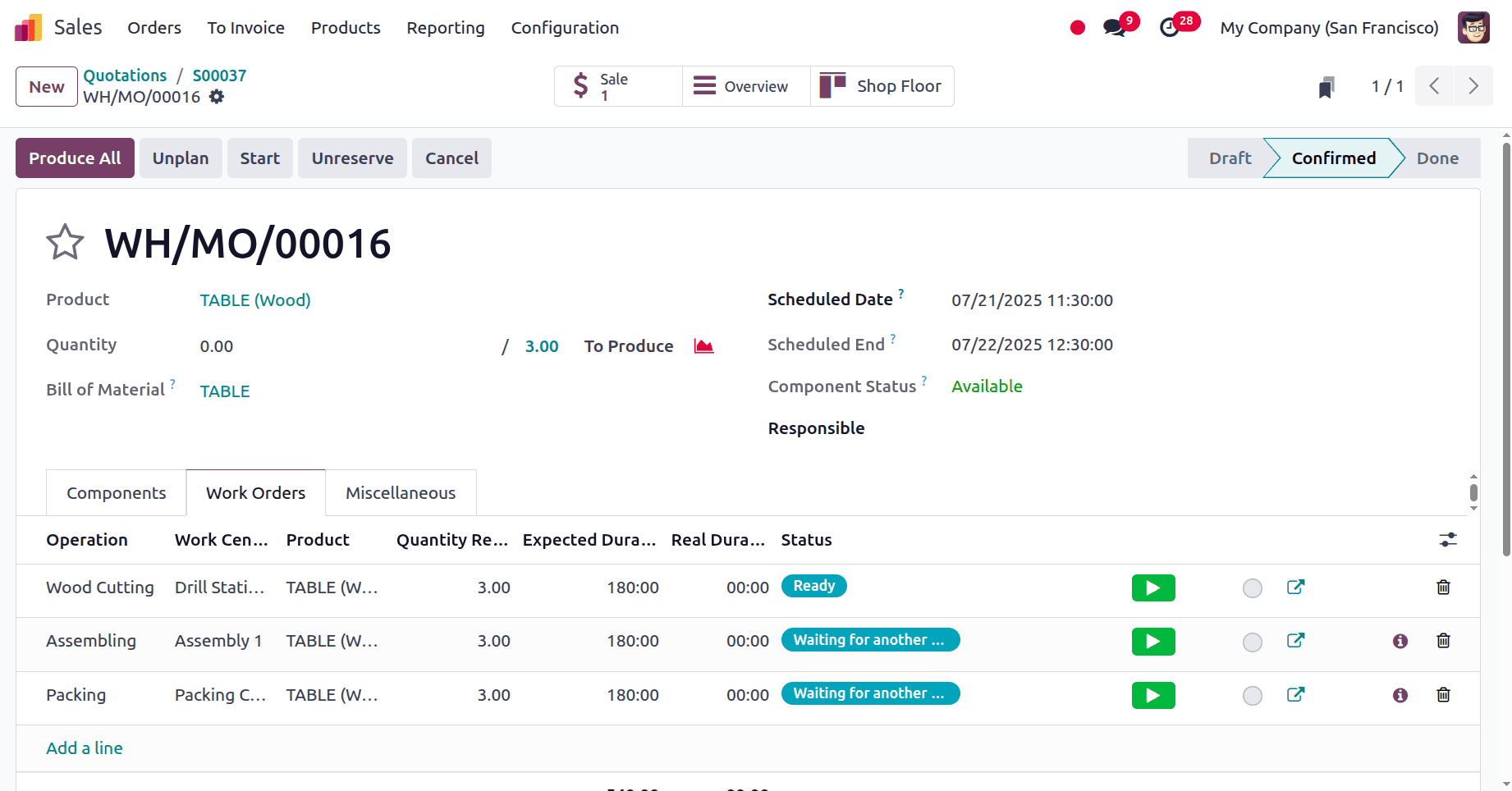

Here, the manufacturing order was created for TABLE (Wood). The components are Table Top (Wood), Table Leg, Bolts, and Screws. There are 3 quantities to produce. According to the quantity, the component quantity also increased.

Then inside the Work Orders, operations are Wood Cutting, Assembling, and Packing. As said before, complete the operations and close the manufacturing order.

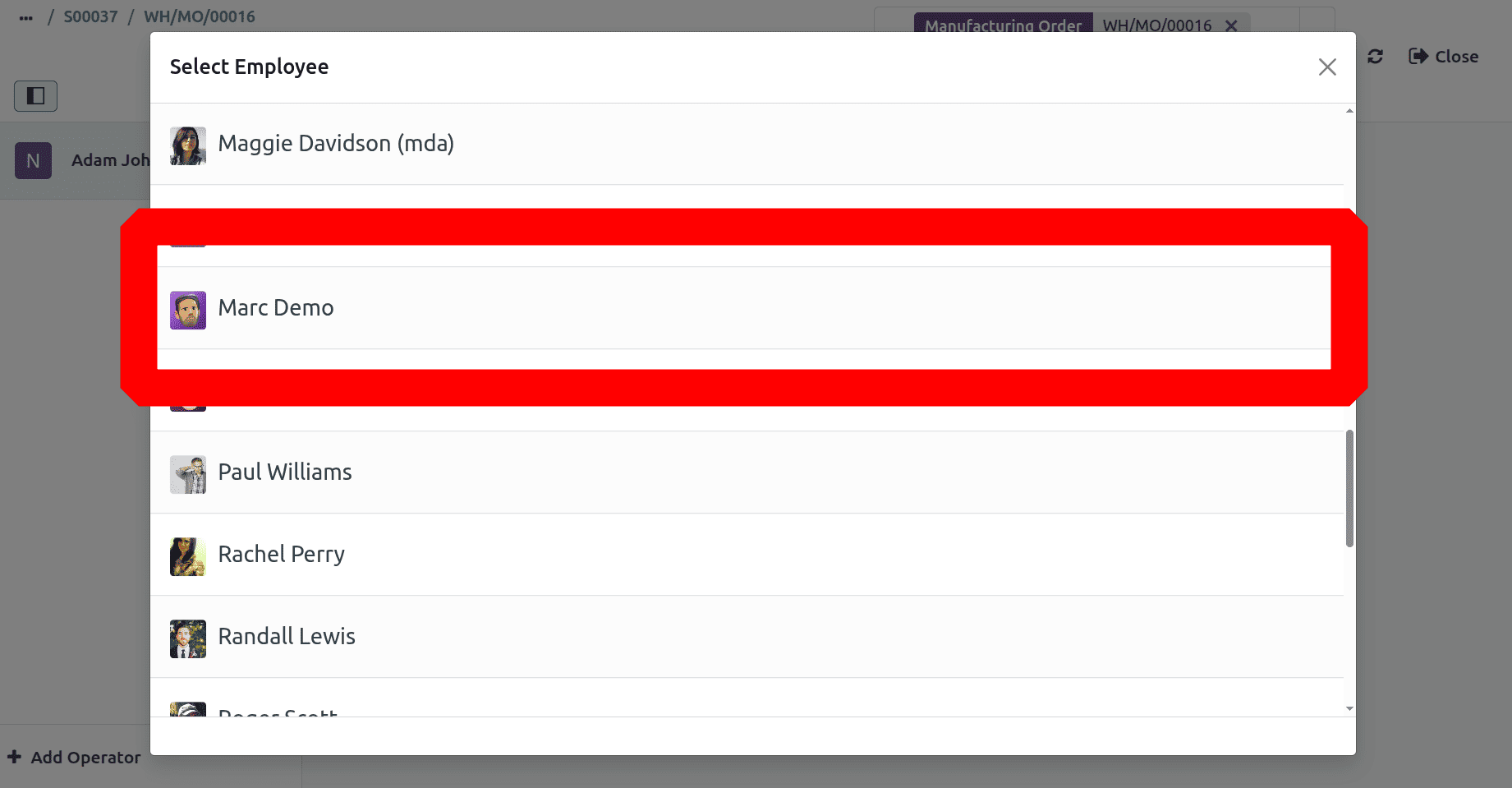

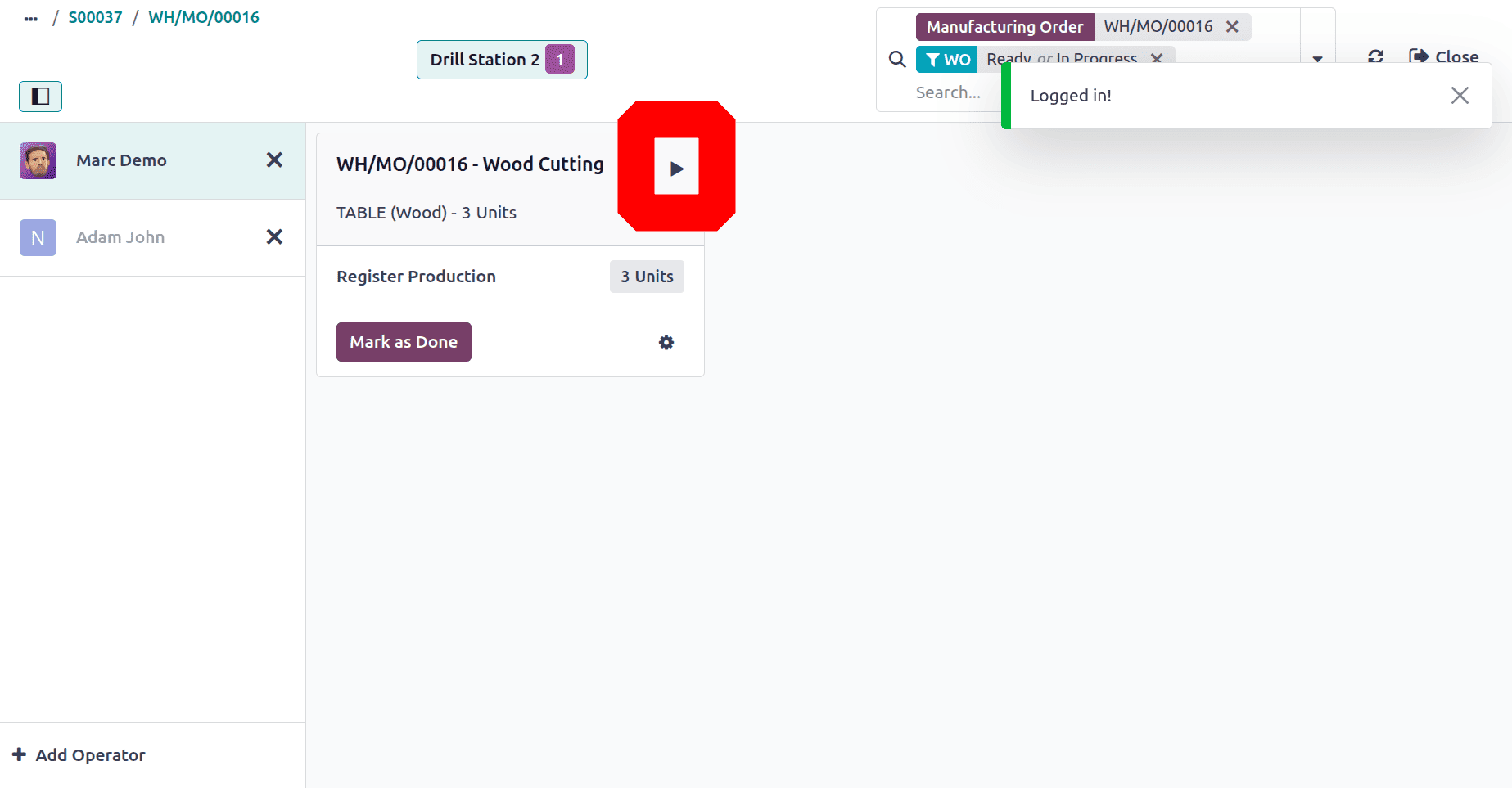

Here, the first operation is Wood Cutting, and the work center is Drill Station 2. The operator inside the work center is Marc Demo. Choose the employee and add the PIN, and log in to the work center.

Then complete the work order from there.

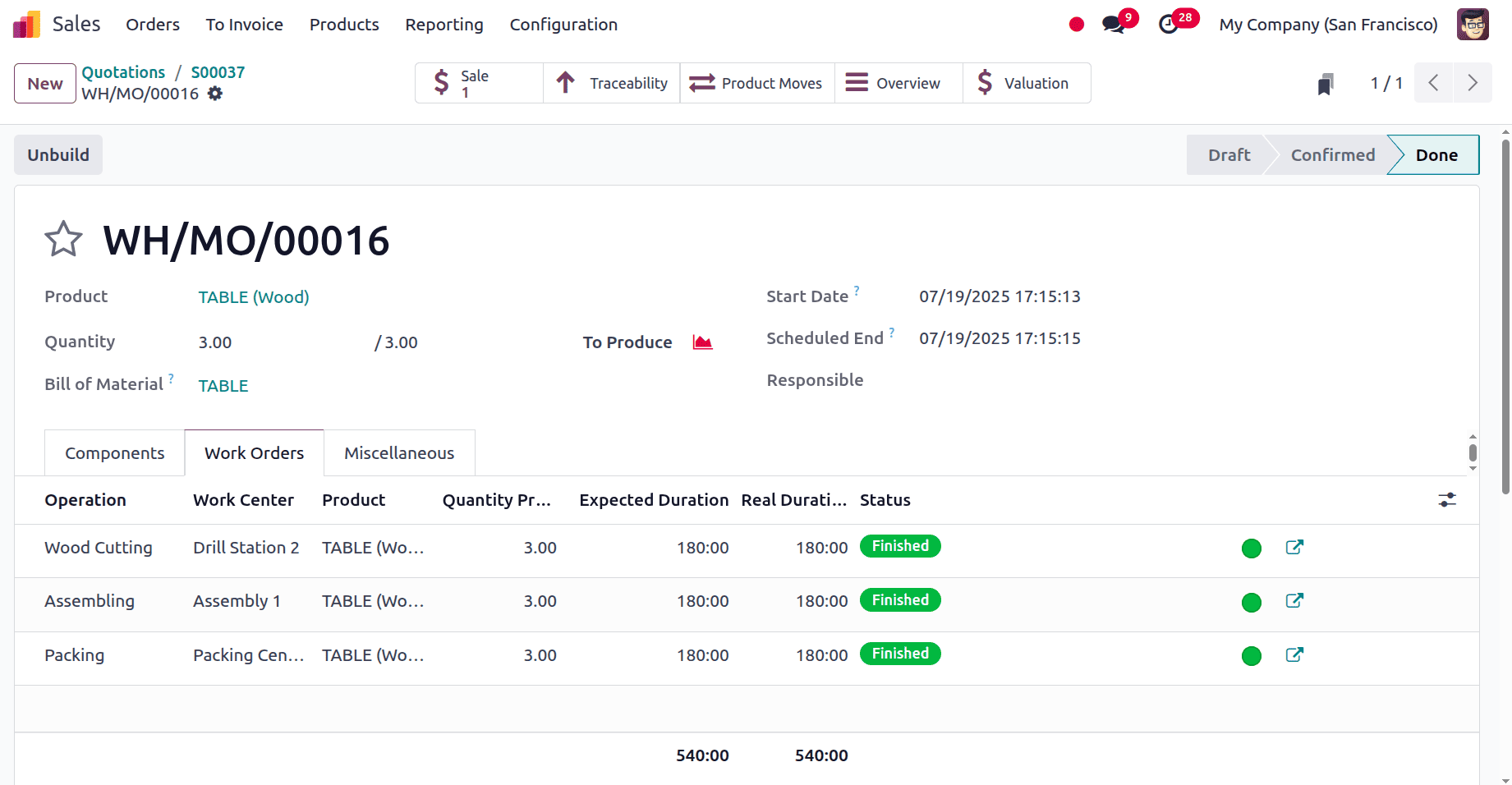

Then complete the other 2 operations. Then the production of 3 TABLE (Wood) is completed.

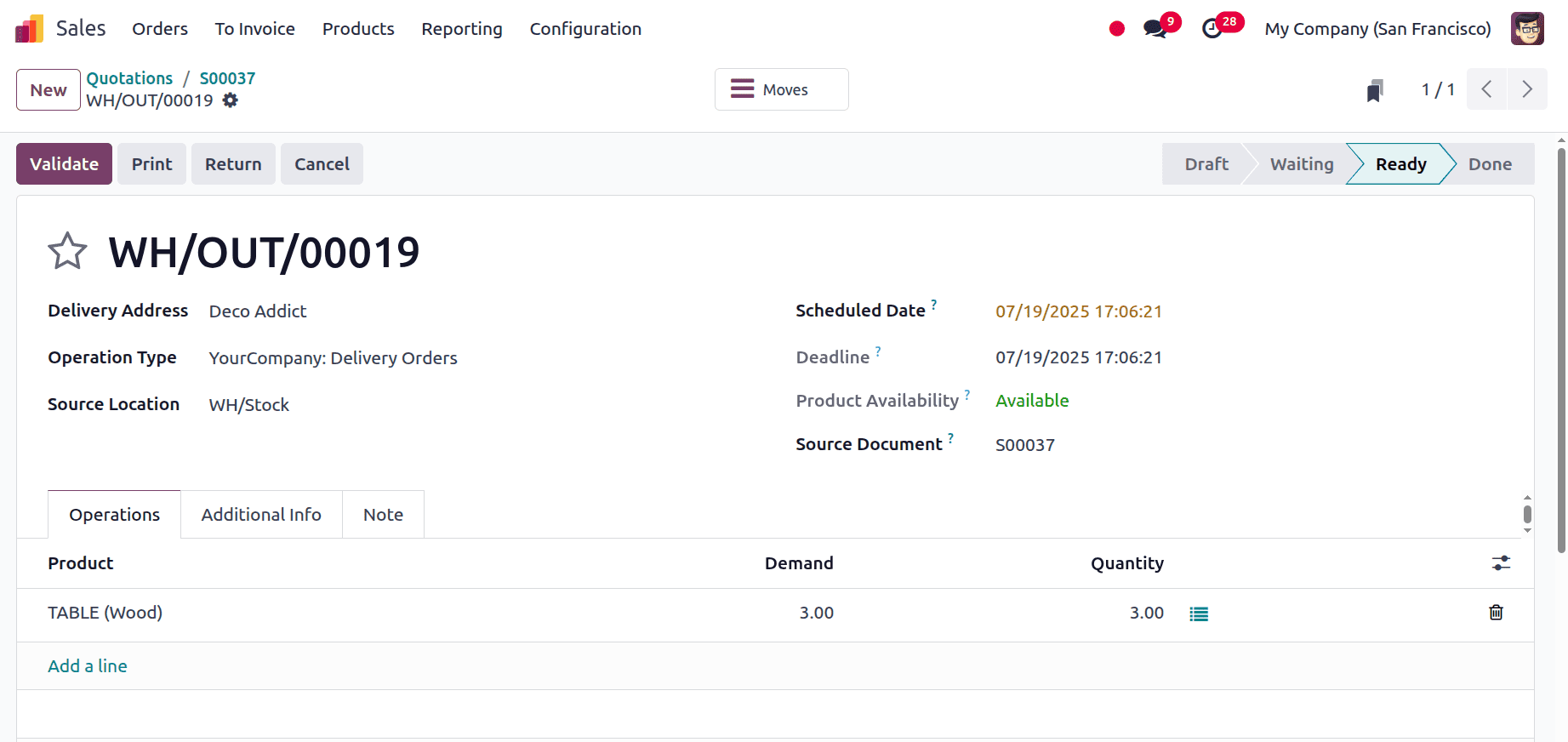

Now the product is restocked so that users can deliver it. Here are 3 quantities: TABLE (Wood) is ready to deliver. Confirm the delivery.

To sum up, Odoo 18 offers a versatile and effective method of allocating the manufacturing of any product variation across several workcenters in accordance with certain operational requirements. This guarantees efficient manufacturing processes catered to variant-specific requirements and optimal resource utilisation.

To read more about How to Manage Production of Variants in Different Workcenter in Odoo 17, refer to our blog How to Manage Production of Variants in Different Workcenter in Odoo 17.