Businesses can schedule, monitor, and manage maintenance chores for their machinery and equipment with the help of Odoo 18's Maintenance module. It helps prioritise work according to equipment importance or urgency and enables real-time tracking of maintenance requests. Unexpected breakdowns can be decreased by automating preventive maintenance routines. Thorough maintenance history records facilitate improved decision-making and adherence to safety regulations. All things considered, it enhances operational continuity, equipment dependability, and resource allocation.

Two different kinds of maintenance procedures are available in the Odoo18 maintenance module. Corrective and preventive maintenance tasks are separated in Odoo 18. While preventive maintenance is scheduled regularly to keep equipment operating properly, corrective maintenance deals with problems when equipment fails, guaranteeing speedy repairs. Both proactive and reactive maintenance techniques are supported by this dual strategy.

Preventive maintenance in Odoo 18 refers to scheduled maintenance tasks carried out regularly to keep equipment from breaking down. It is scheduled according to consumption (such as operating hours or cycle count) or time (calendar dates). When the specified circumstances are satisfied, the system automatically creates maintenance requests. This ensures constant productivity, prolongs the life of equipment, and lowers unplanned breakdowns.

Preventive maintenance's advantages include

- Minimises Equipment Downtime: Unexpected malfunctions are reduced by routine maintenance.

- Increases Asset Lifespan: Maintains equipment in optimal condition, postponing replacements.

- Enhances Safety: Potential dangers are found and fixed before incidents happen.

- Boosts Efficiency: Assures that machines run as efficiently as possible.

- Lowers Long-Term Costs: Avoids significant malfunctions that necessitate costly fixes.

- Reduces Production Interruptions: Planned maintenance helps to prevent unplanned halts.

- Enhances Planning and Budgeting: With known expenses, maintenance may be scheduled ahead of time.

- Assures adherence to regulations: Complies with operational and safety regulations to ensure regulatory compliance.

- Increases Reliability: Equipment operates reliably and without unforeseen problems.

- Reduces Energy Consumption: Machines that receive regular maintenance use energy more effectively.

In this blog, we'll go into great depth on how the Odoo 18 Maintenance module's preventive maintenance is set up and operates. To prevent equipment failures, preventive maintenance is planned ahead of time according to usage metrics or time intervals. We'll go over how to create preventative rules, schedule maintenance, and automate the creation of maintenance requests in this blog. You will learn how Odoo 18 makes preventive maintenance easier to keep equipment operating efficiently.

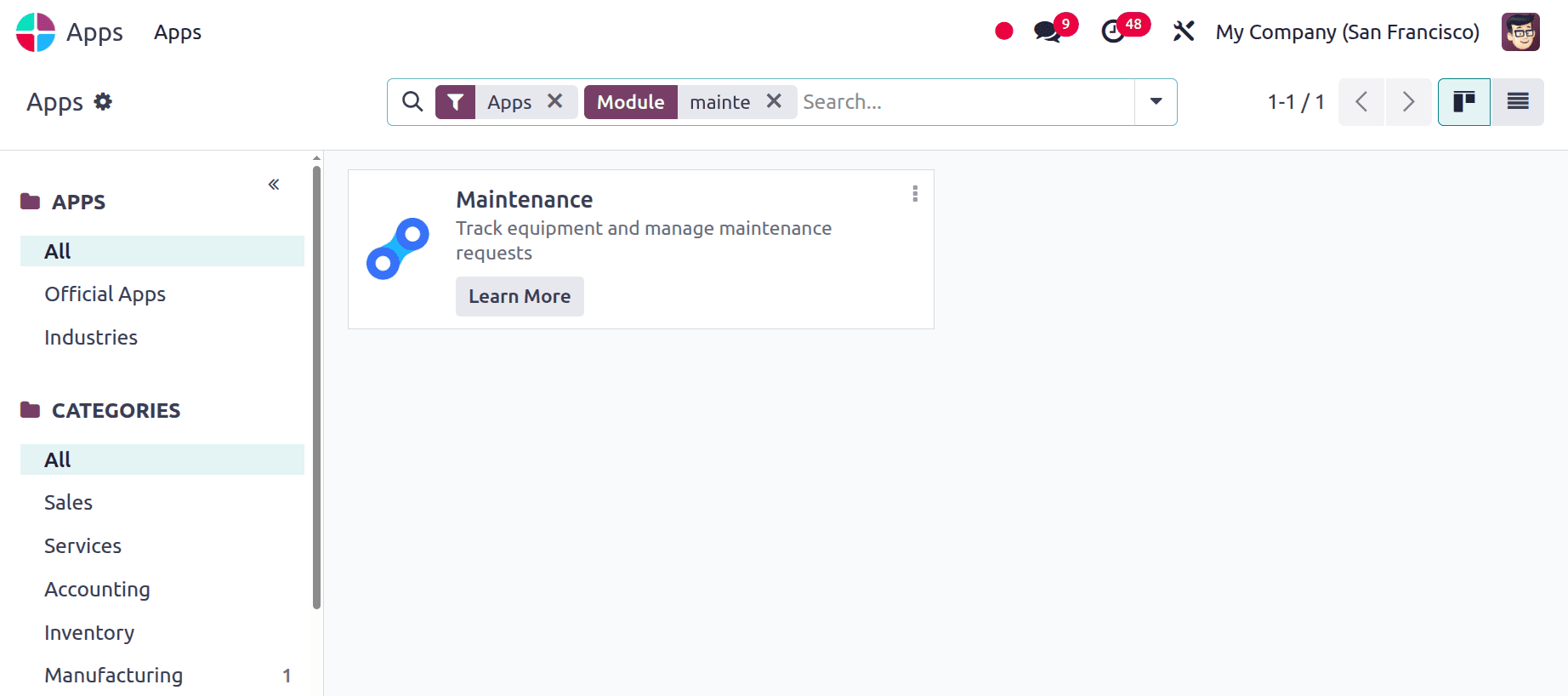

Make sure the Maintenance module is installed before doing any maintenance jobs in Odoo 18. Go to the Apps area, look for "Maintenance," and click to install it. Tools for planning both preventive and corrective maintenance are accessible through this module.

Preventive maintenance for equipment

Let's create new equipment. In daily operations, maintenance, or production, equipment is utilised to carry out particular activities or processes. It increases efficiency, accuracy, and productivity by providing the necessary tools or equipment. Equipment that is used and maintained properly guarantees efficient processes and minimises downtime.

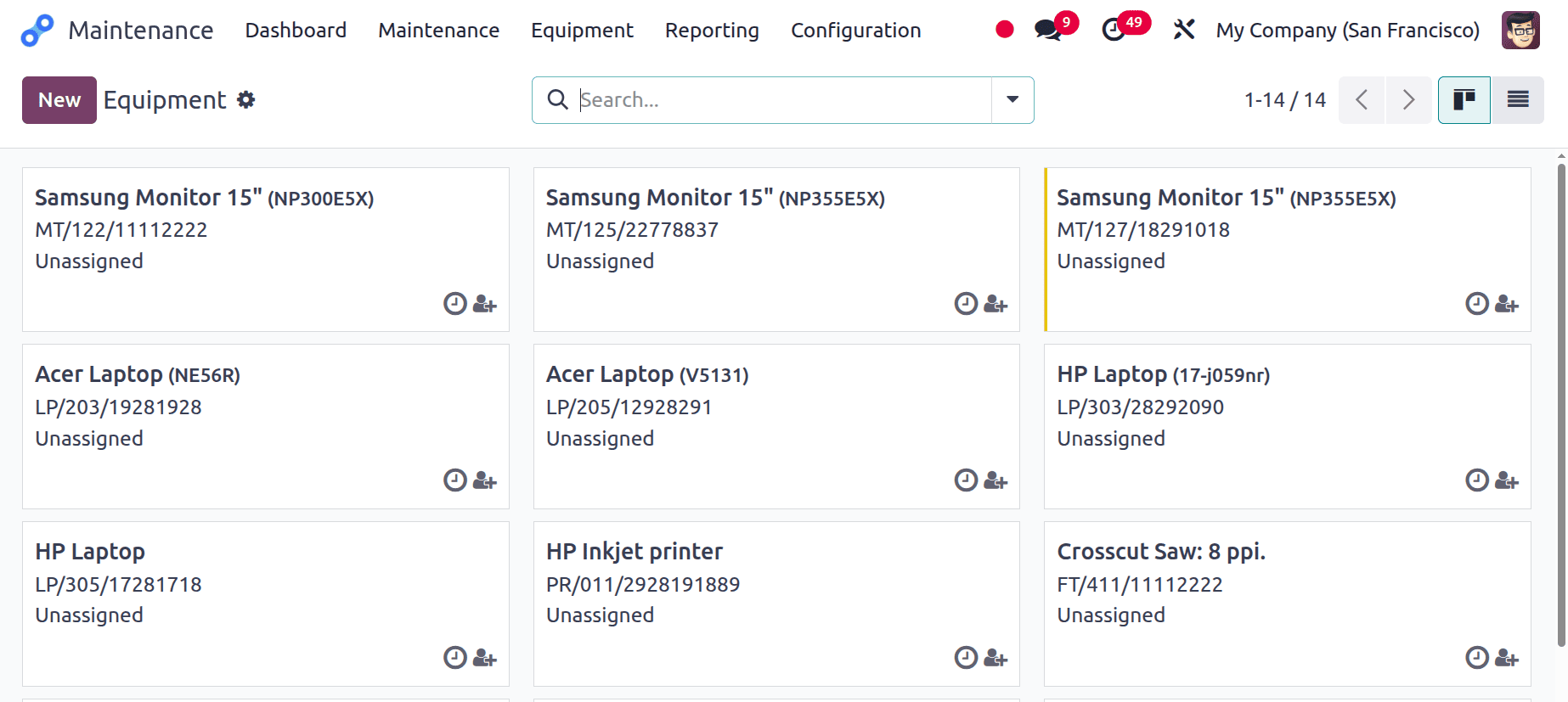

From the Equipment menu, select Machines & Tools. Then the kanban shows all the equipment that is visible. Open any one of the equipment.

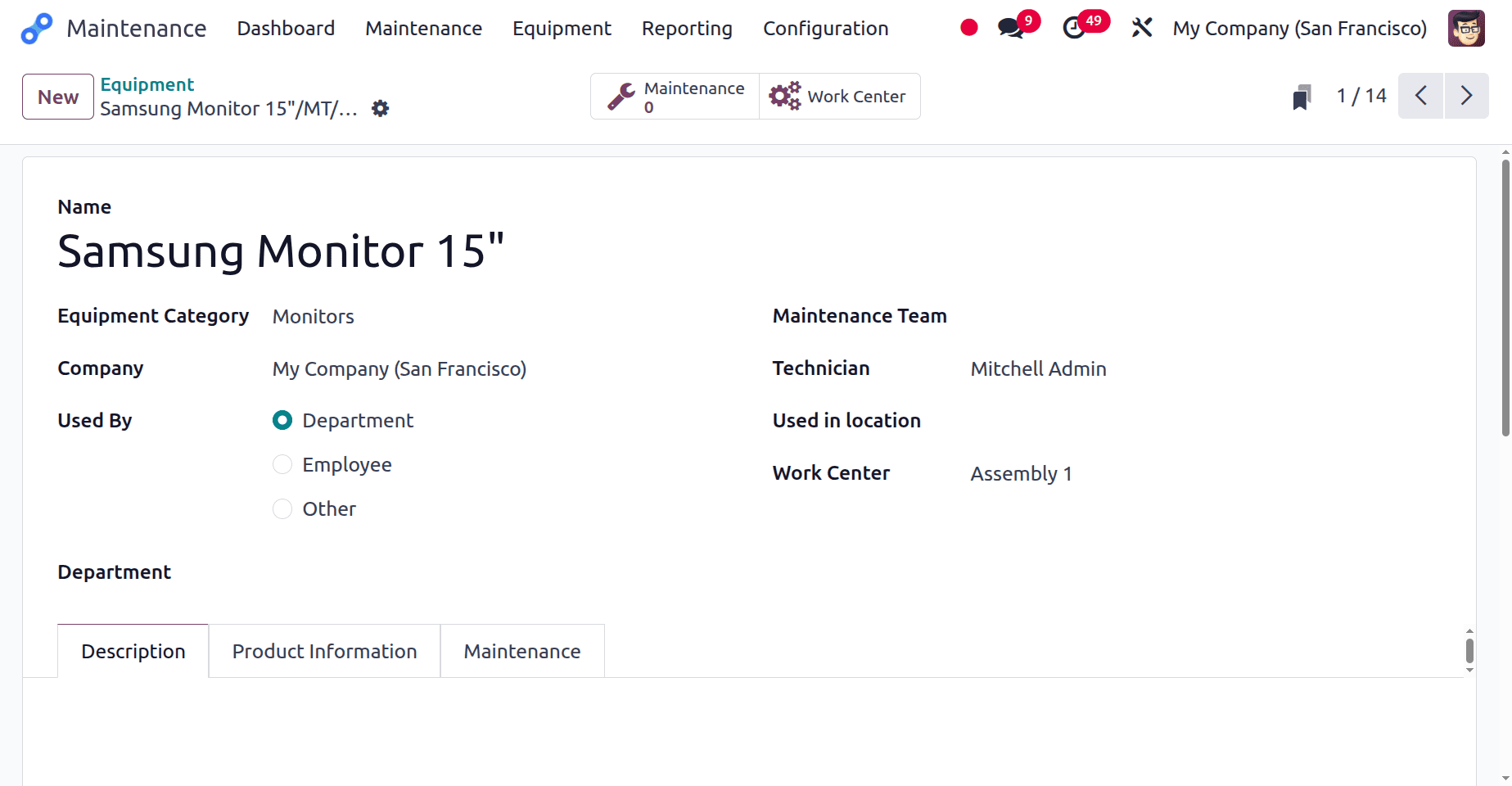

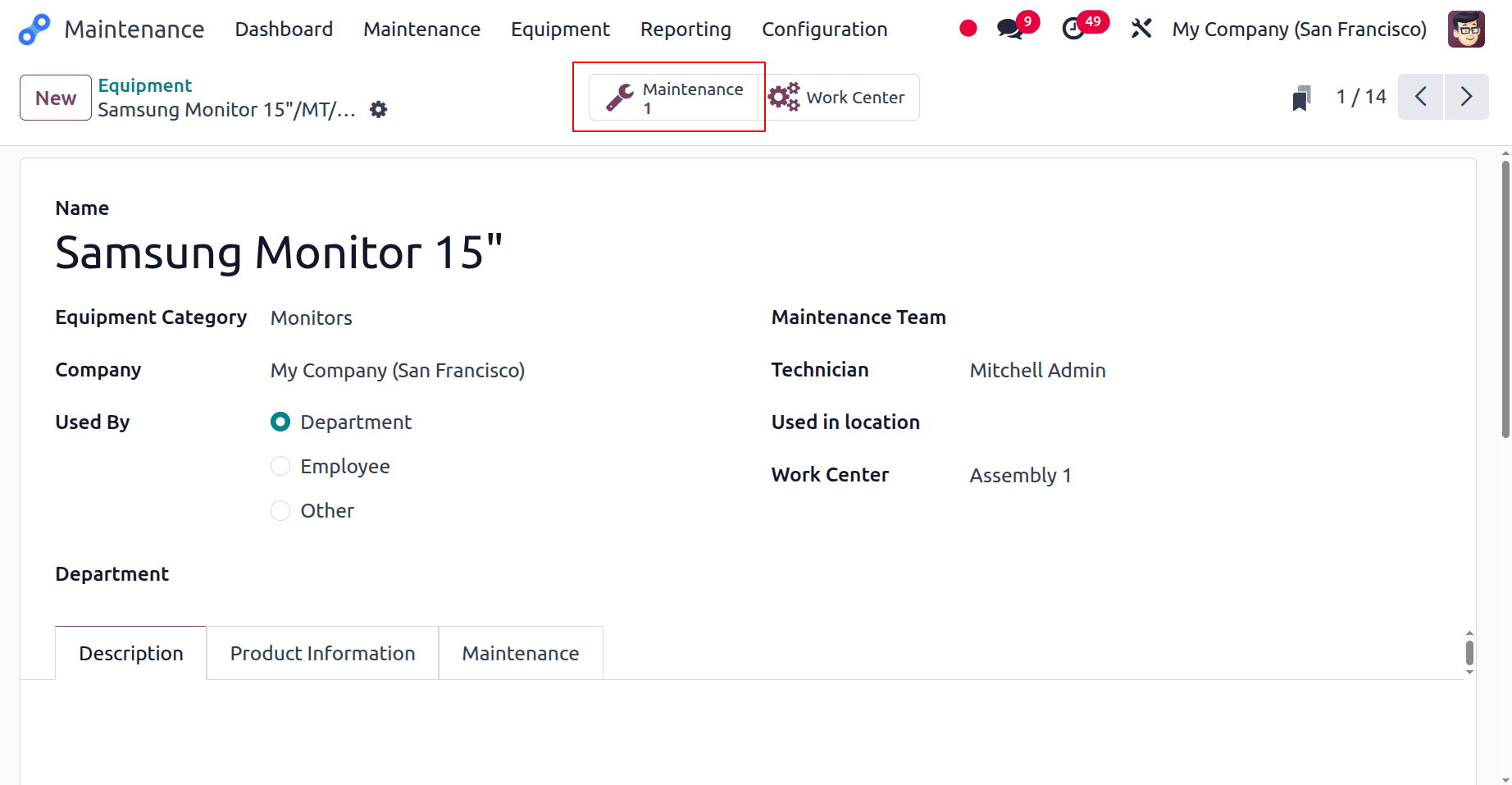

Here, the equipment is a Samsung Monitor 15”. The category is set as Monitors. Other details like company, maintenance team, technician, used in the location, and work center.

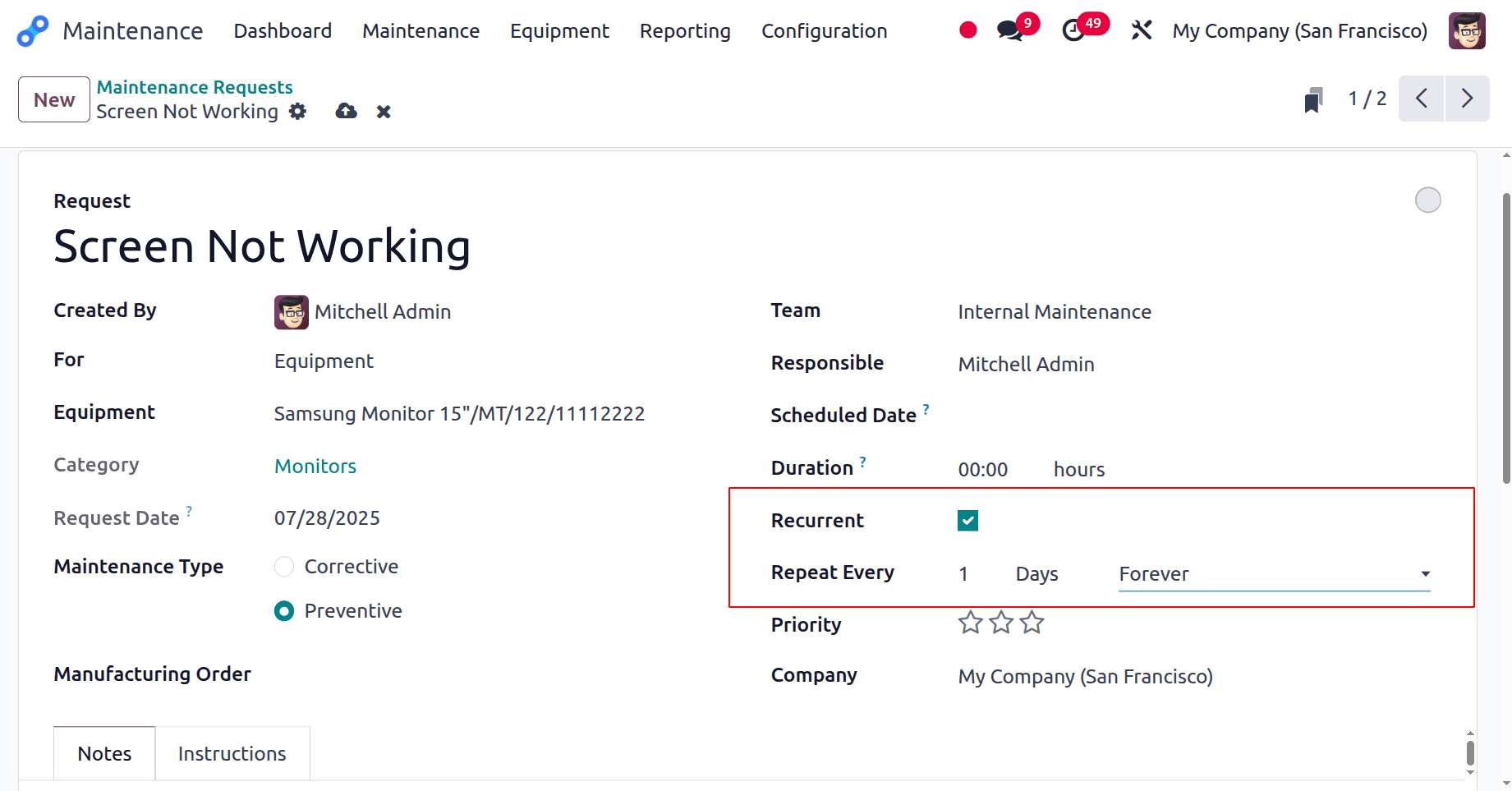

Then let's create a new preventive maintenance request for the equipment. Click on the Maintenance menu and choose the Maintenance Request. Add the description as “Screen Not Working“ and choose the same equipment.

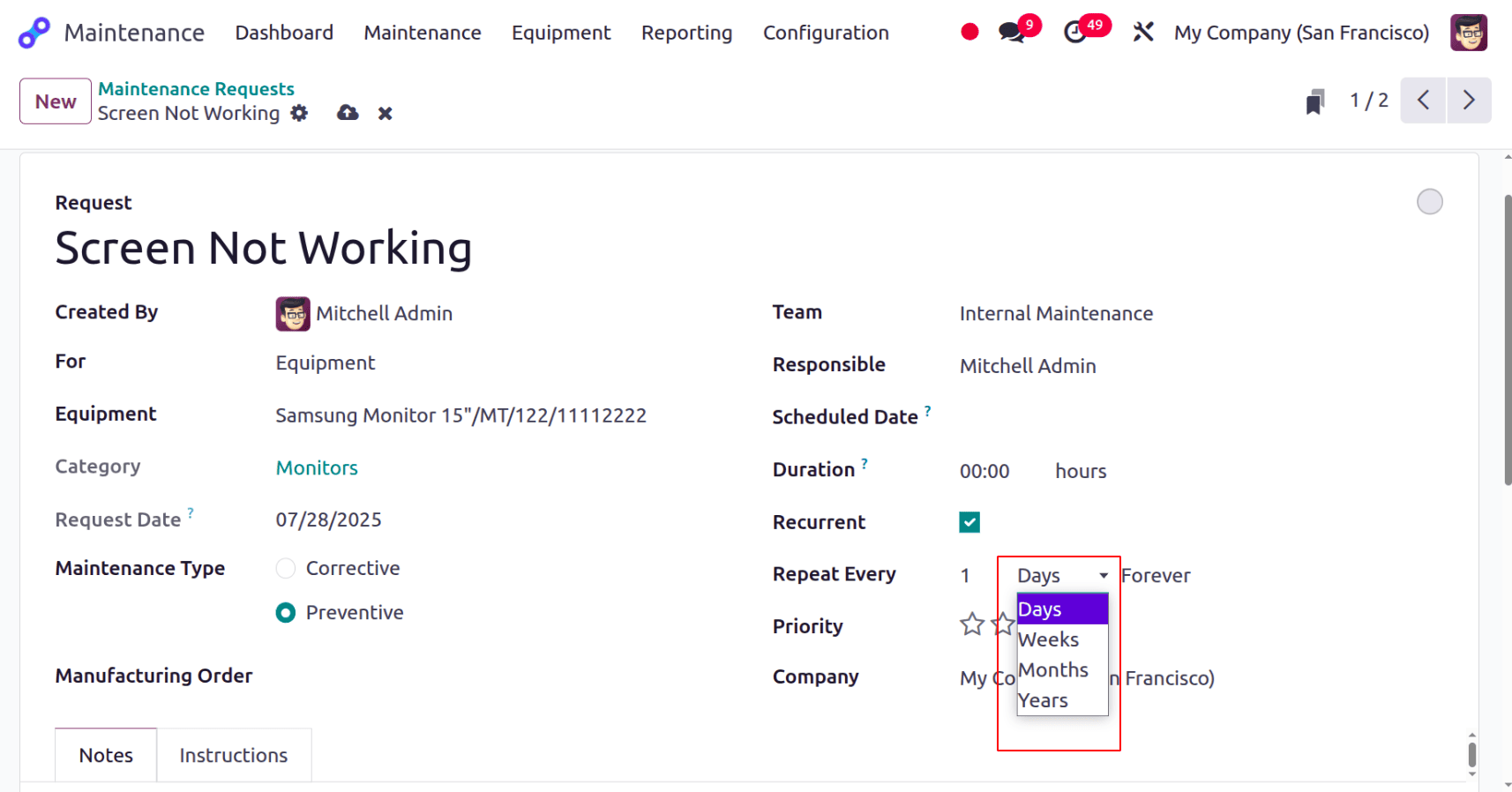

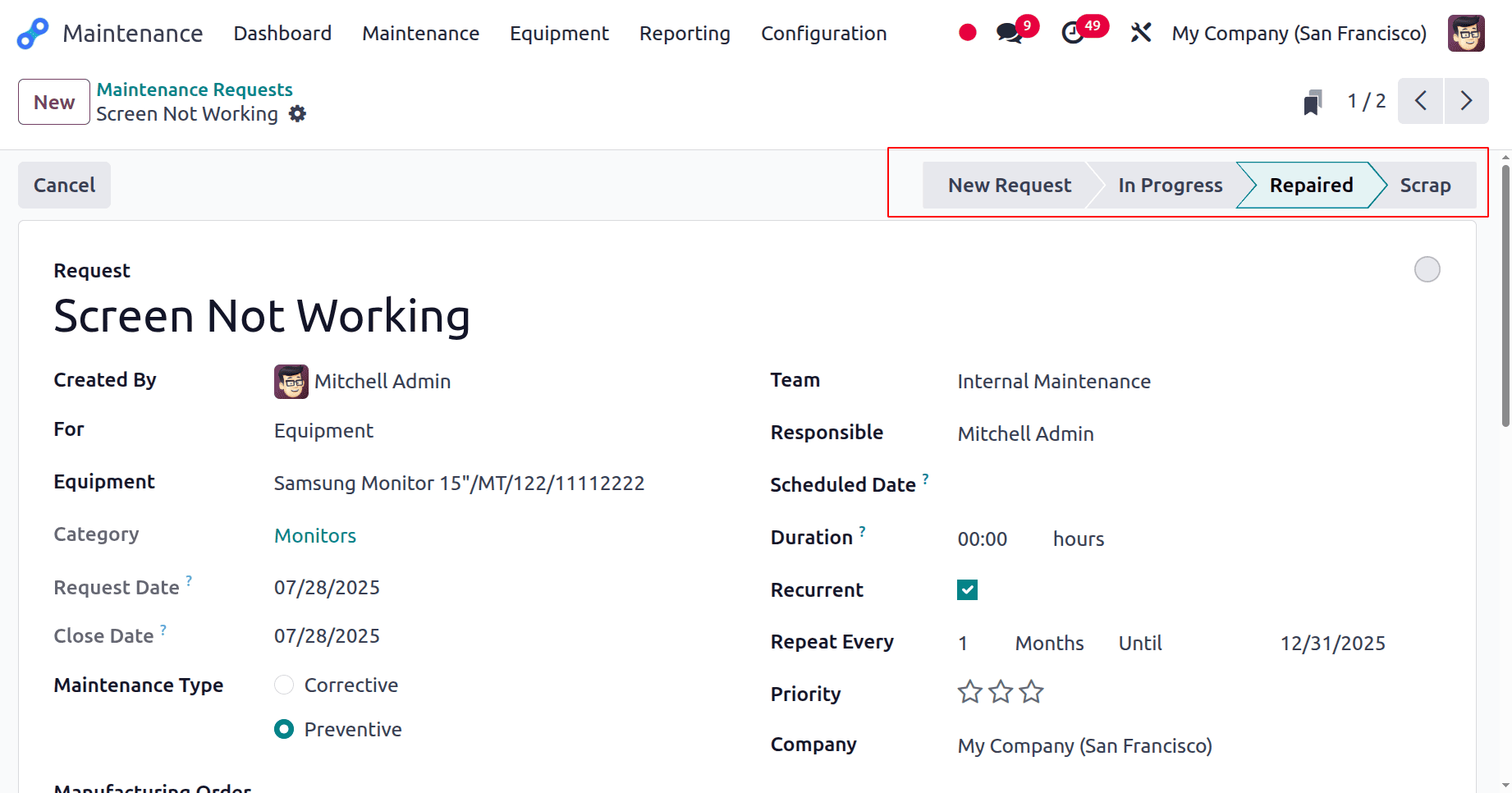

In this case, preventive maintenance is selected as the maintenance type. When preventive maintenance is chosen, another field shown there is named as Recurrent. As seen in the screenshot above, enable the check box and then repeat each field that is visible.

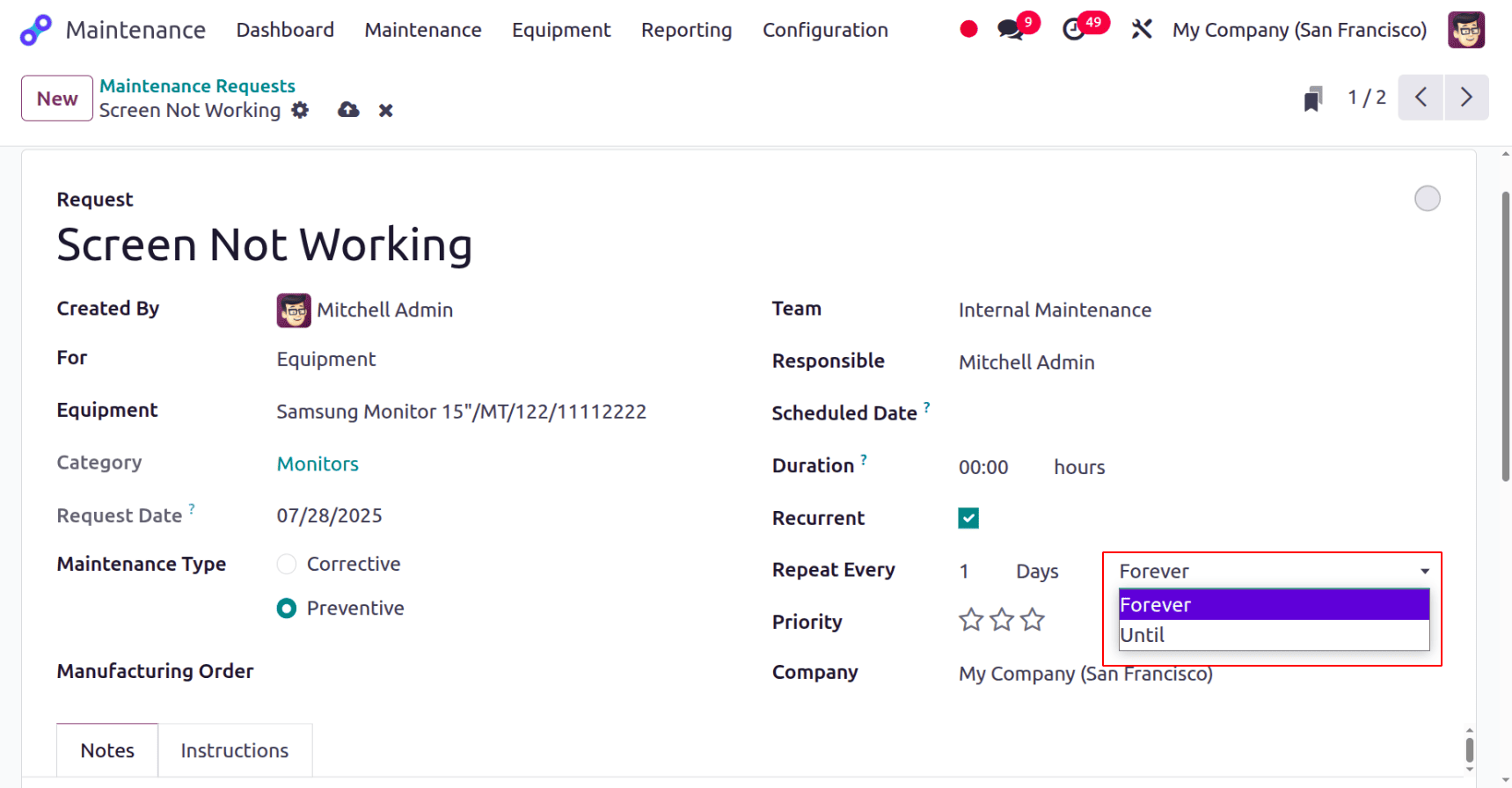

Users can add the maintenance recurrence by enabling the Recurrent option. Depending on the day, week, month, and year, the maintenance request may recur. There are two options, like Forever and Until.

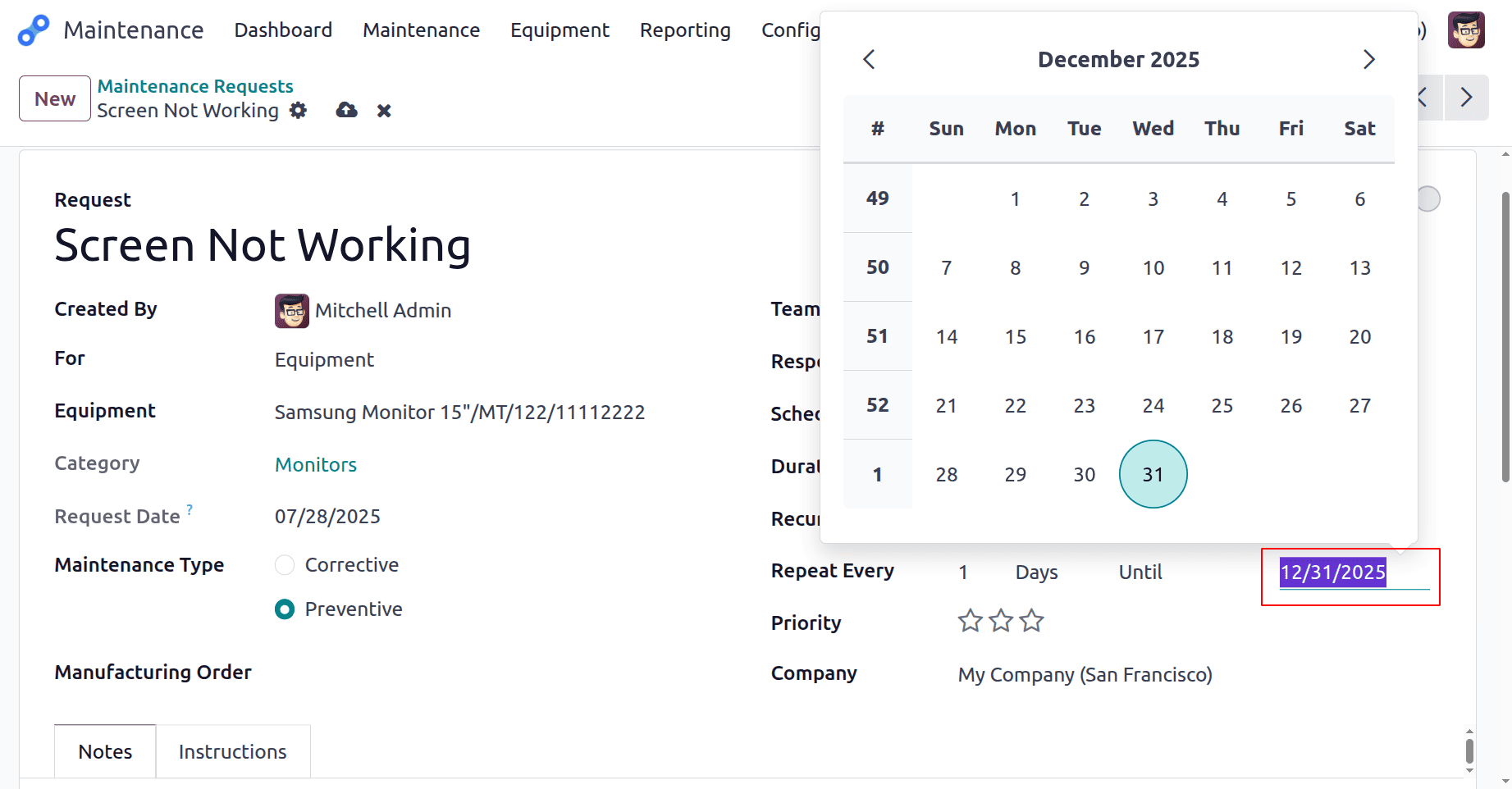

If Forever is selected, then there is no end date for the maintenance. If Until is selected, then add an end date from the calendar as shown below.

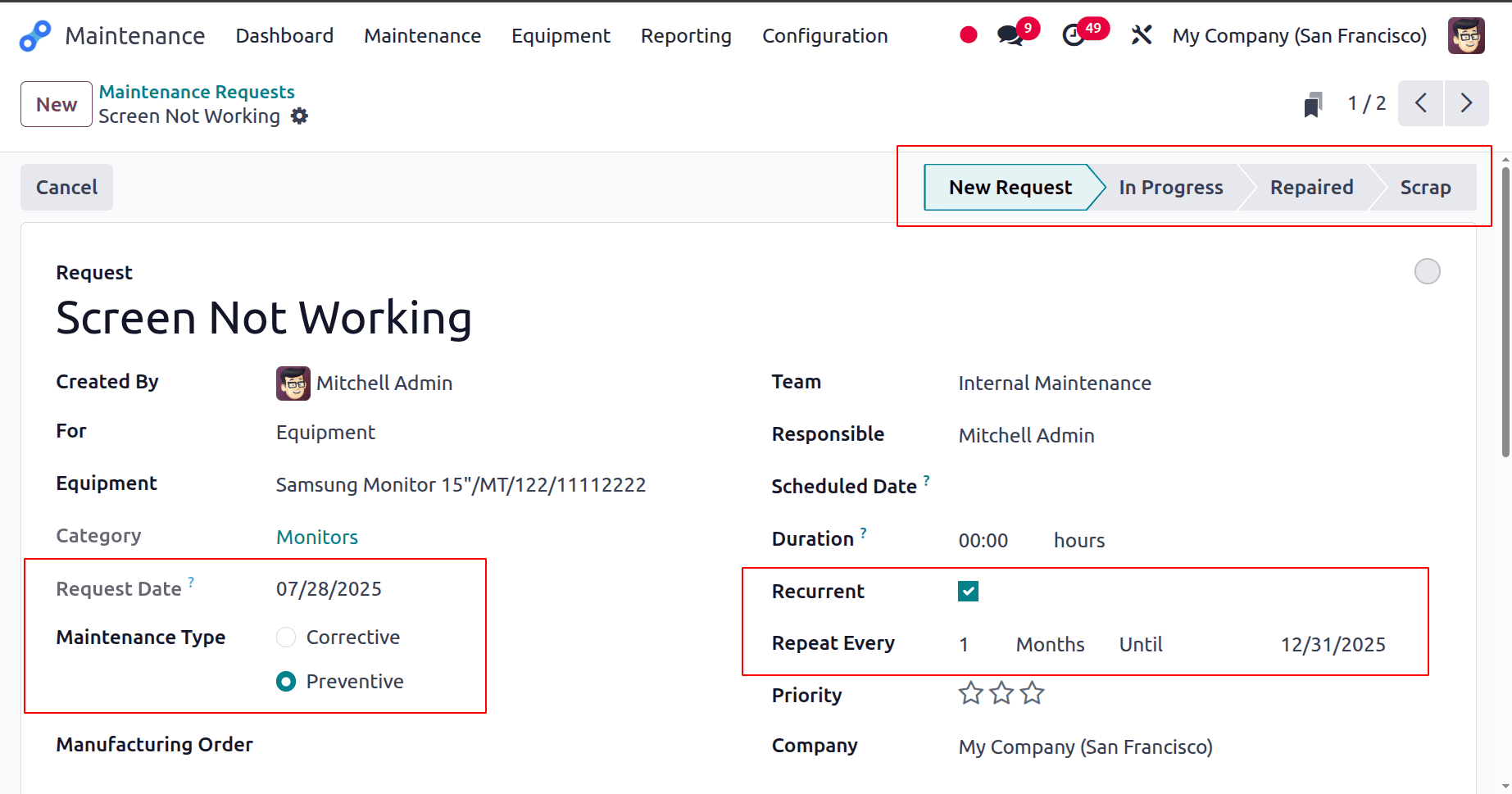

Here, the preventive maintenance request is created for the equipment. The request date is updated as the current date, and this request will relate every month until 12/31/2025.

Currently, the request is in the New Request stage. If the maintenance starts, change the request to the In progress stage, and after completion, change the stage to Repaired.

Then move back to the Equipment and open the same Samsung Monitor 15”. There, the user can view a smart tab named Maintenance, and a request is created there.

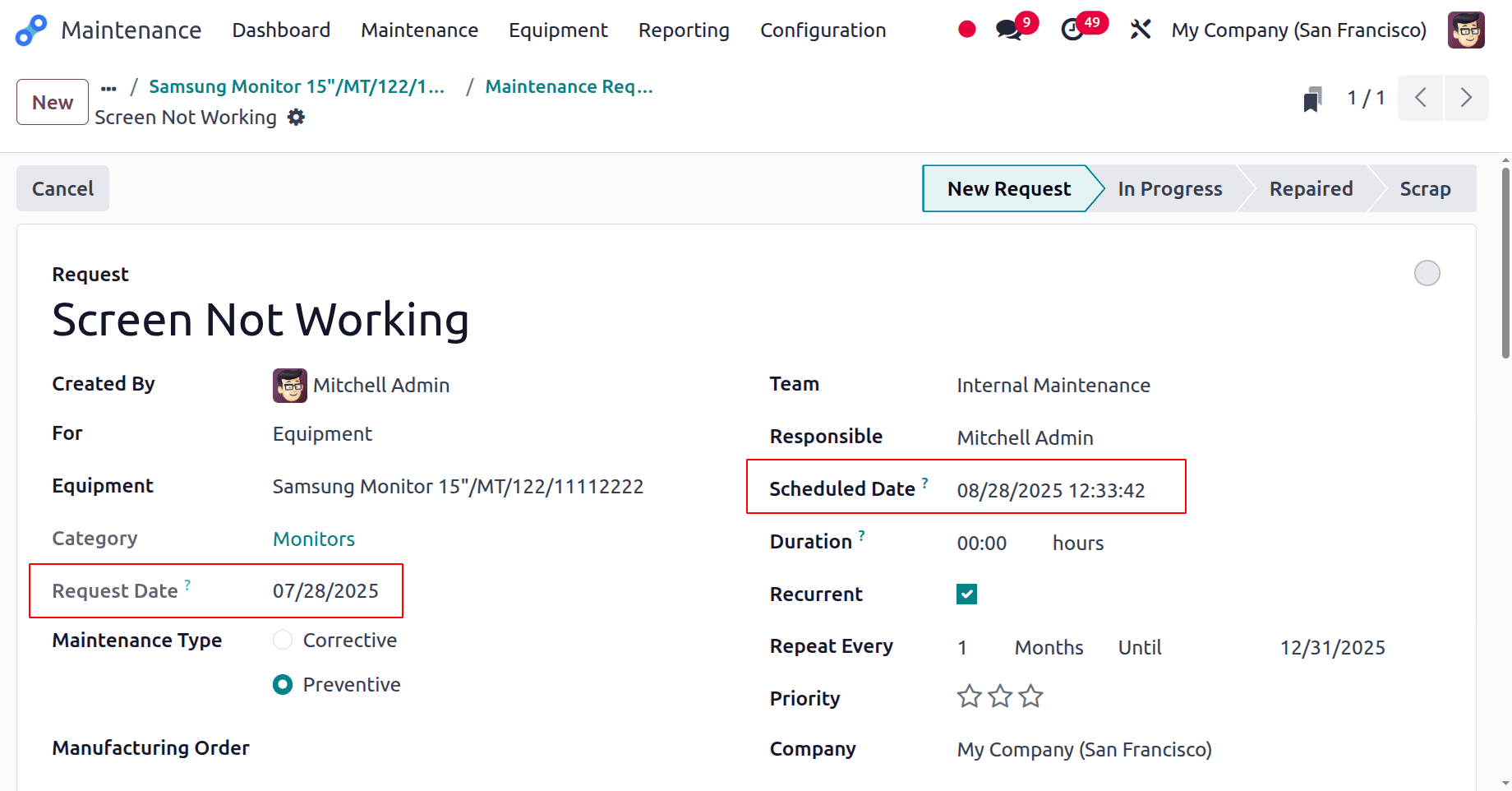

Click on the smart tab to open. Then the maintenance request is created automatically. Check the request date and the scheduled date of the request.

Here, the request date is the current date, but the maintenance is scheduled for next month. Here, the Request date is 07/28/202,5 and the Scheduled Date is 08/28/2025. If the request changes to the Repaired stage, the next maintenance request will automatically generate there with the scheduled date of 09/28/2025.

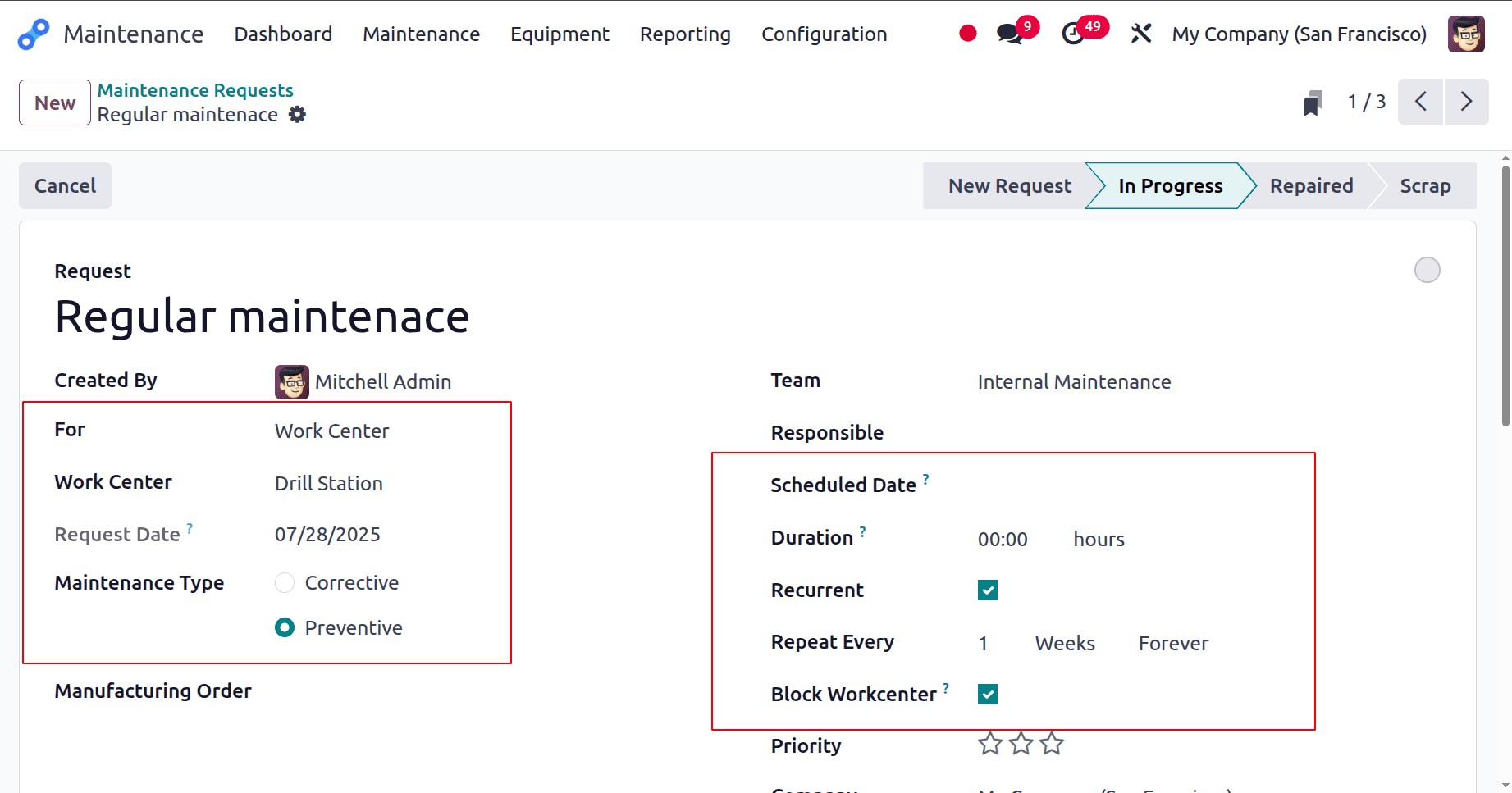

Similarly, it's possible to add Preventive Maintenance requests for the Work centers too. In Odoo 18, a workcenter is a real place, equipment, or resource used for industrial activities. Managing particular jobs or phases in a manufacturing process contributes significantly to the production process. Meeting deadlines and preserving production efficiency depend on workcenter management done right. Because it helps prevent unplanned work center breakdowns that could stop output, preventive maintenance is particularly crucial for work centers. Businesses can guarantee uninterrupted and seamless workcenter operations by planning routine maintenance according to usage or time. This prolongs the life of vital machinery, lowers repair costs, and increases output.

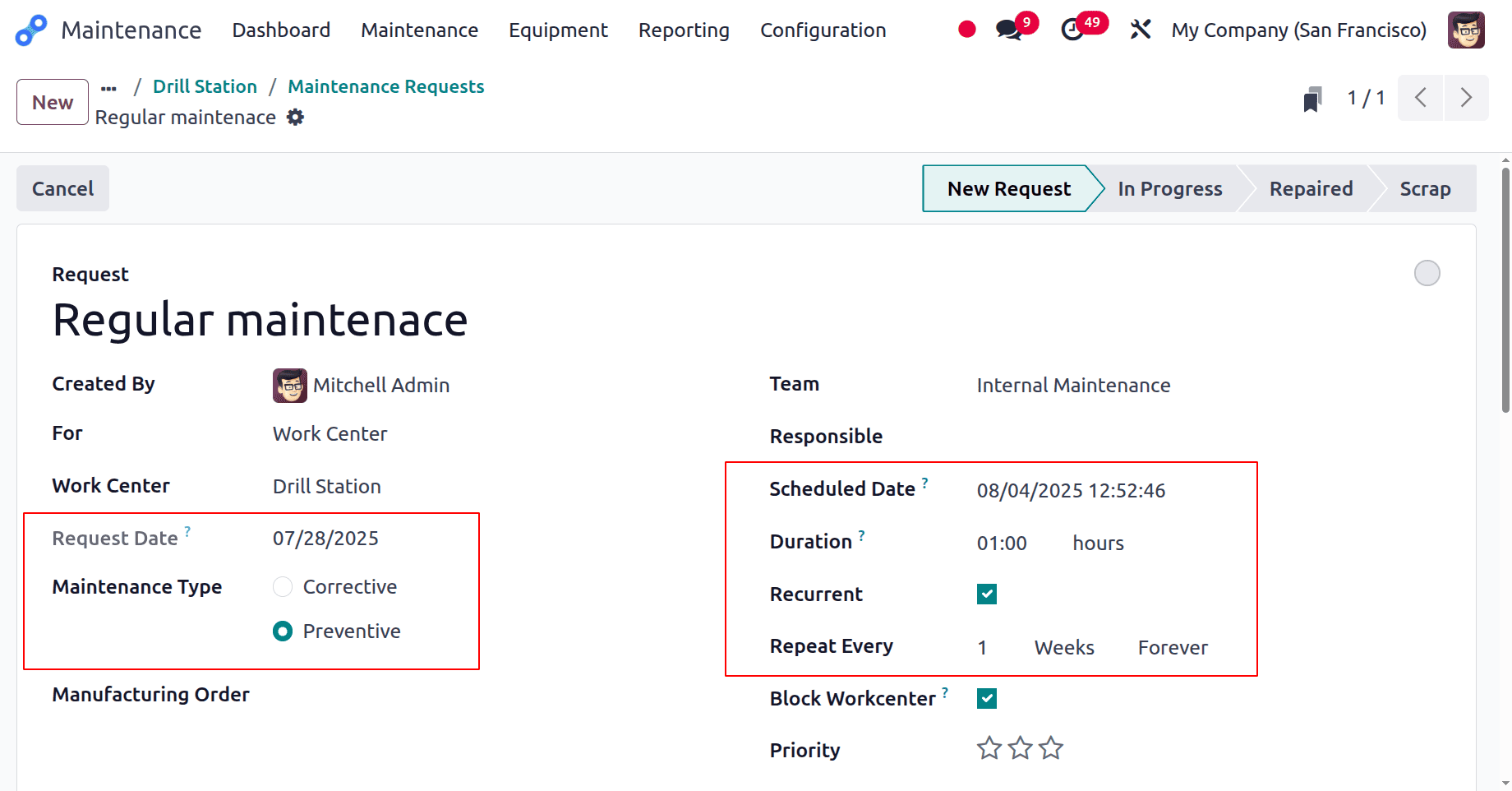

Here is the maintenance request created for the workcenter named Drill Station. In this instance, the work center is selected, and a request is made for it. Preventive maintenance is chosen. The request will repeat every week forever. Here is another checkbox named Block Workcenter. The workcenter cannot have work orders or other maintenance requests scheduled if it is enabled. Change the stage from New Request to In Progress, then to Repaired.

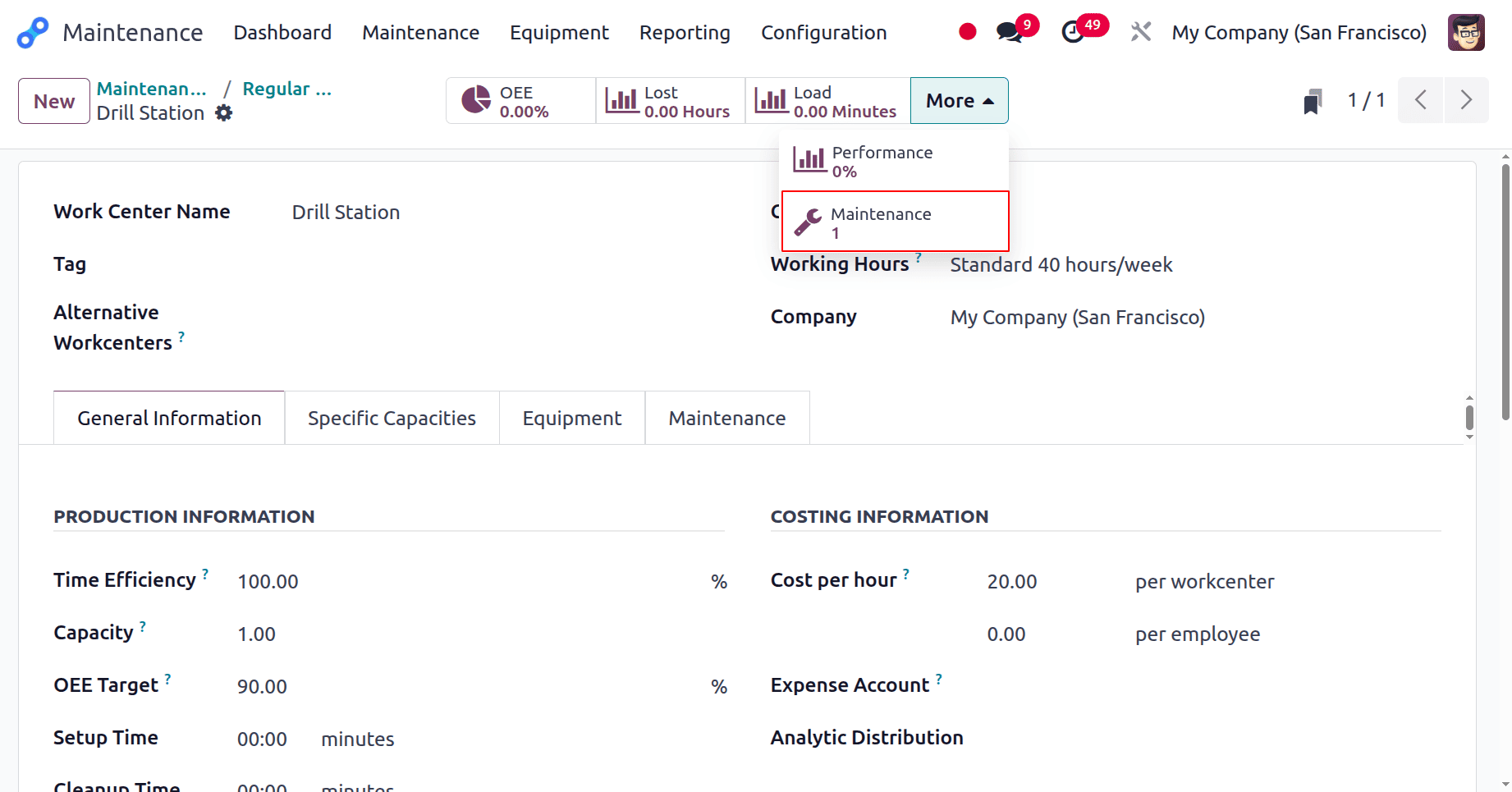

After that, go back to the work center, as mentioned above, a smart tab named Maintenance will show an automatically created maintenance request.

Open the maintenance request, then check the dates. Here, repeat every week is set. So the next maintenance request is scheduled for 08.04.2025 as shown below.

This is how preventive maintenance is added to the work center and equipment. To sum up, preventive maintenance in Odoo 18 enables companies to proactively maintain their machinery and steer clear of unplanned malfunctions. It guarantees that assets stay in top shape by planning maintenance according to usage or time. This not only extends the equipment's lifespan but also improves overall operational efficiency and dependability.

To read more about How to Manage Preventive & Corrective Maintenance in Odoo 17 Maintenance App, refer to our blog How to Manage Preventive & Corrective Maintenance in Odoo 17 Maintenance App.