In modern manufacturing, equipment utilization plays a crucial role in enhancing productivity, minimizing downtime, and ensuring product quality. Odoo 18 builds on this principle with an enhanced Maintenance and Manufacturing (MRP) integration, making it easier than ever to track, schedule, and monitor equipment usage directly from your production workflows.

Let’s explore how equipment is used in production within Odoo 18, step by step.

Step 1: Activate Maintenance and MRP Modules

To begin, install the following modules:

- Manufacturing (MRP)

- Maintenance

These apps are tightly integrated. The MRP module handles production orders and routings, while Maintenance ensures your machines are operational and scheduled for preventive and corrective maintenance.

Step 2: Define Equipment

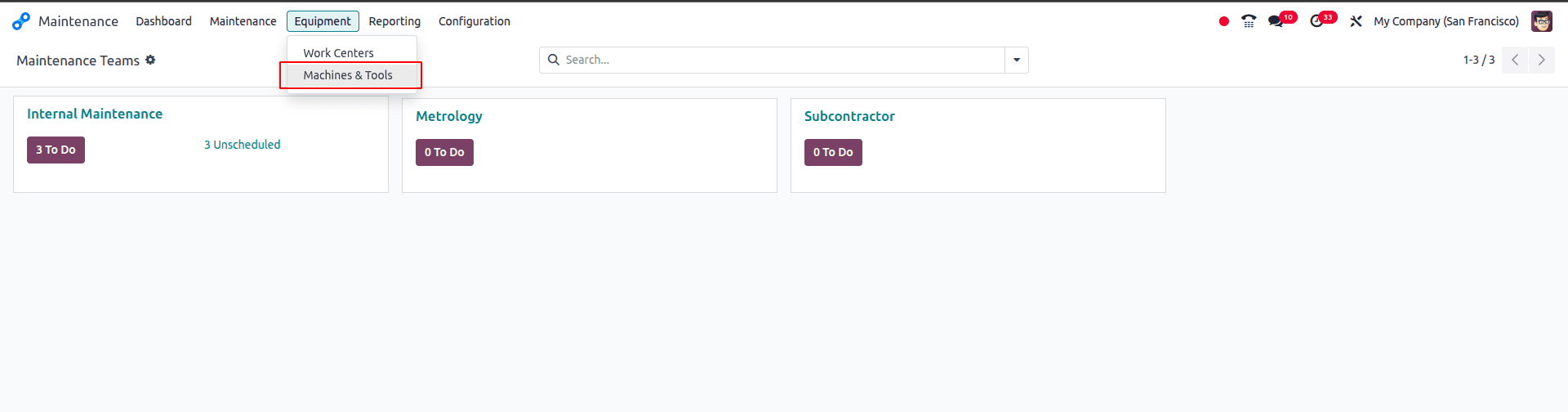

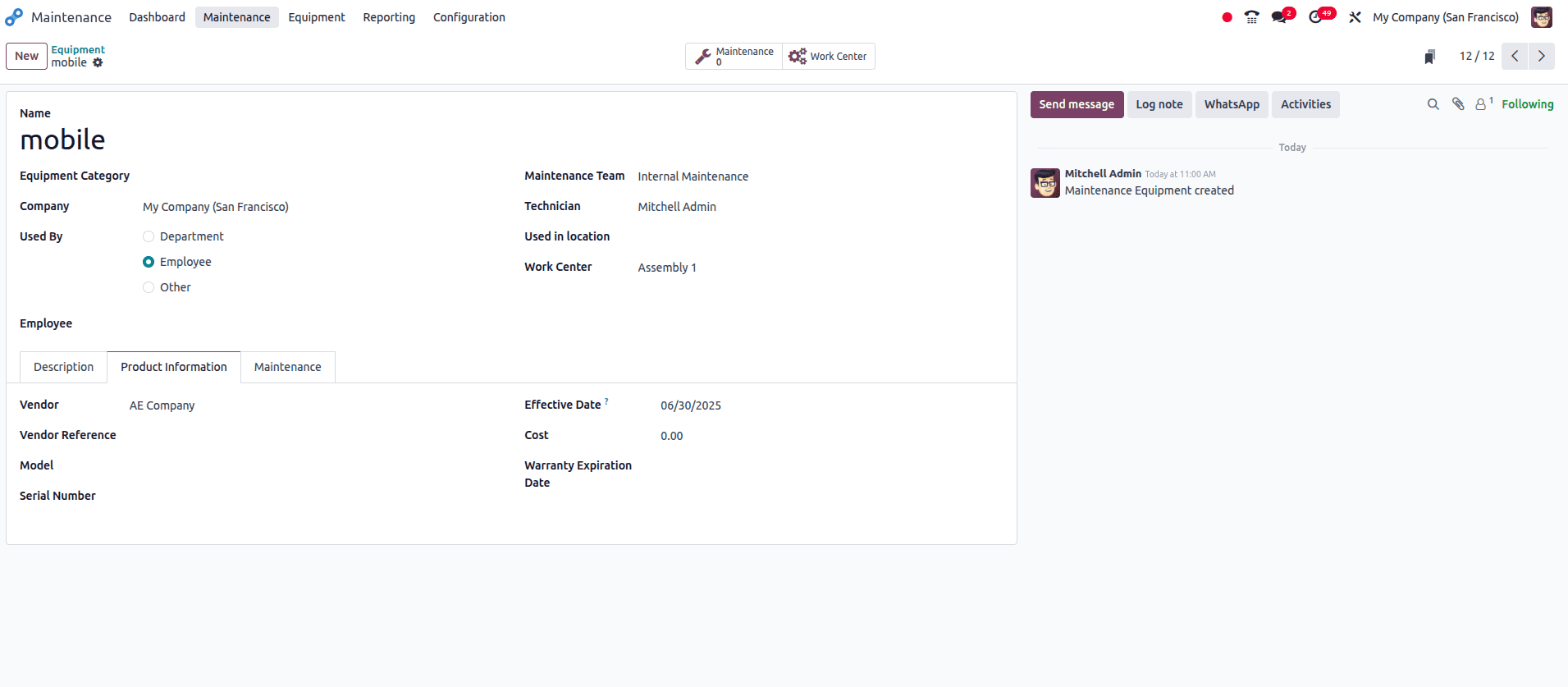

Go to Maintenance > Equipment and create a new equipment record.

Important fields:

- Equipment Name: e.g., "Mobile"

- Category: Group similar equipment (e.g., Lathes, Assembly Machines).

- Used By: Select “Employee”

- Workcenter: Assign it to the specific work center where this equipment is physically installed.

You can also define a maintenance team, set technicians, and track serial numbers, warranty dates, and vendor info.

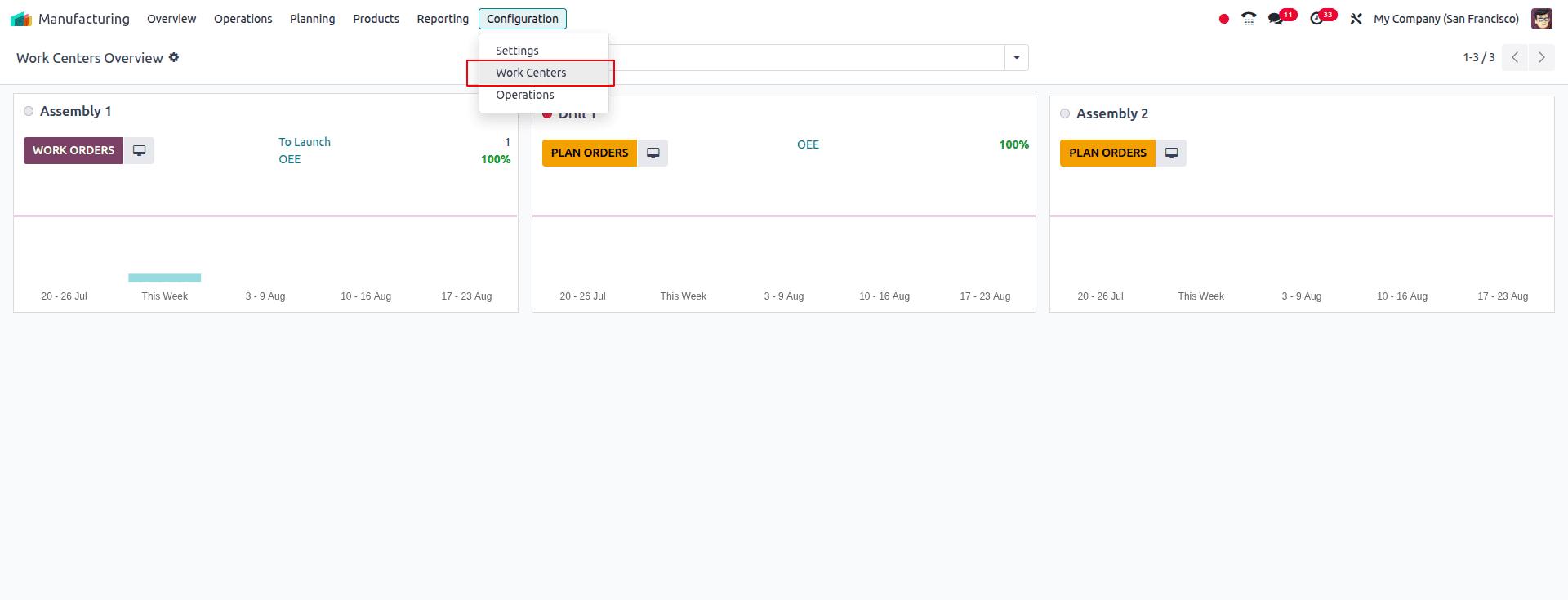

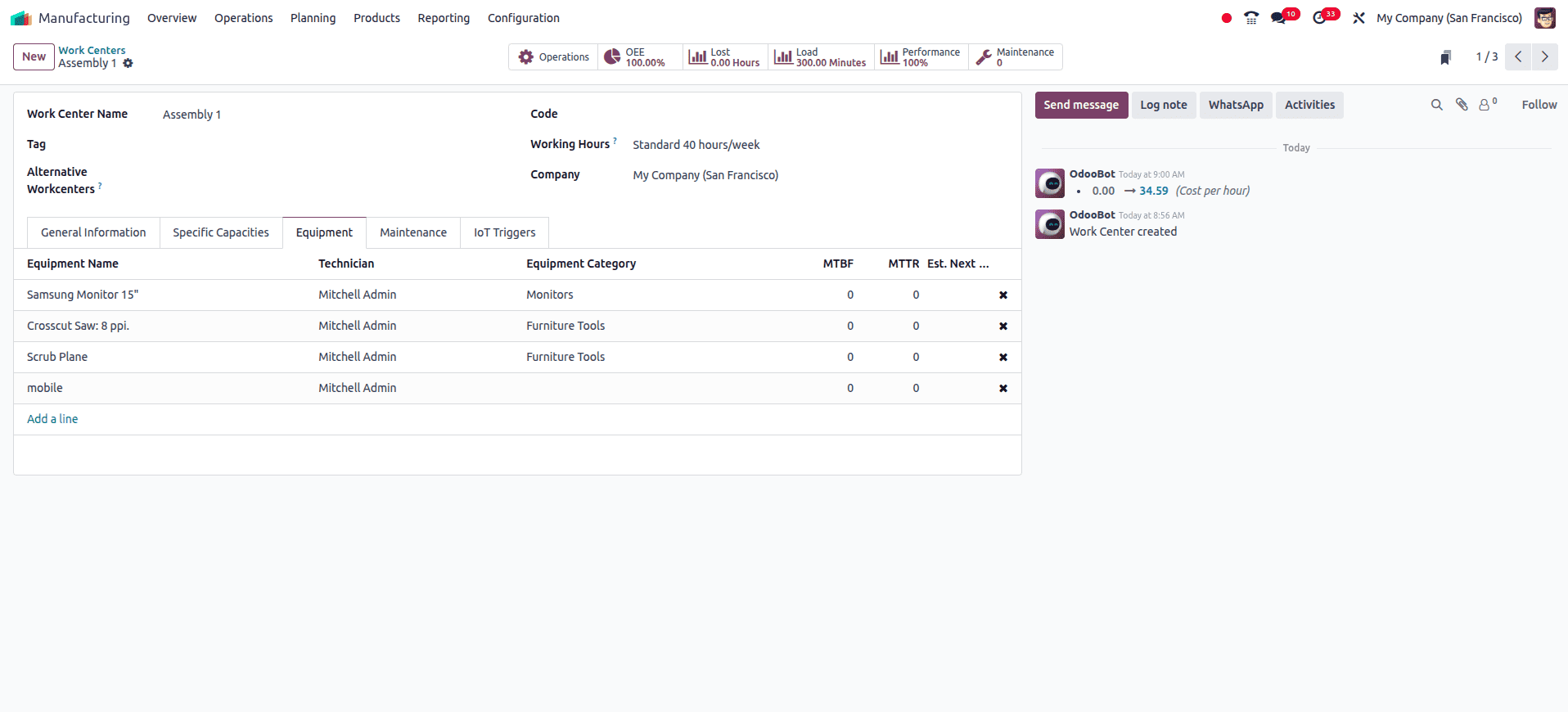

Step 3: Set Up Work Centers

Navigate to Manufacturing > Configuration > Work Centers.

Create a work center like:

- Work Center Name: ‘Assembly 1"

- Equipment: Link the earlier-created equipment here.

- OEE Target: Set efficiency expectations.

- Working Hours: Define shift schedules to reflect realistic capacity planning.

This relationship is key; equipment is linked to work centers, and work centers are assigned to routing operations in your Bill of Materials.

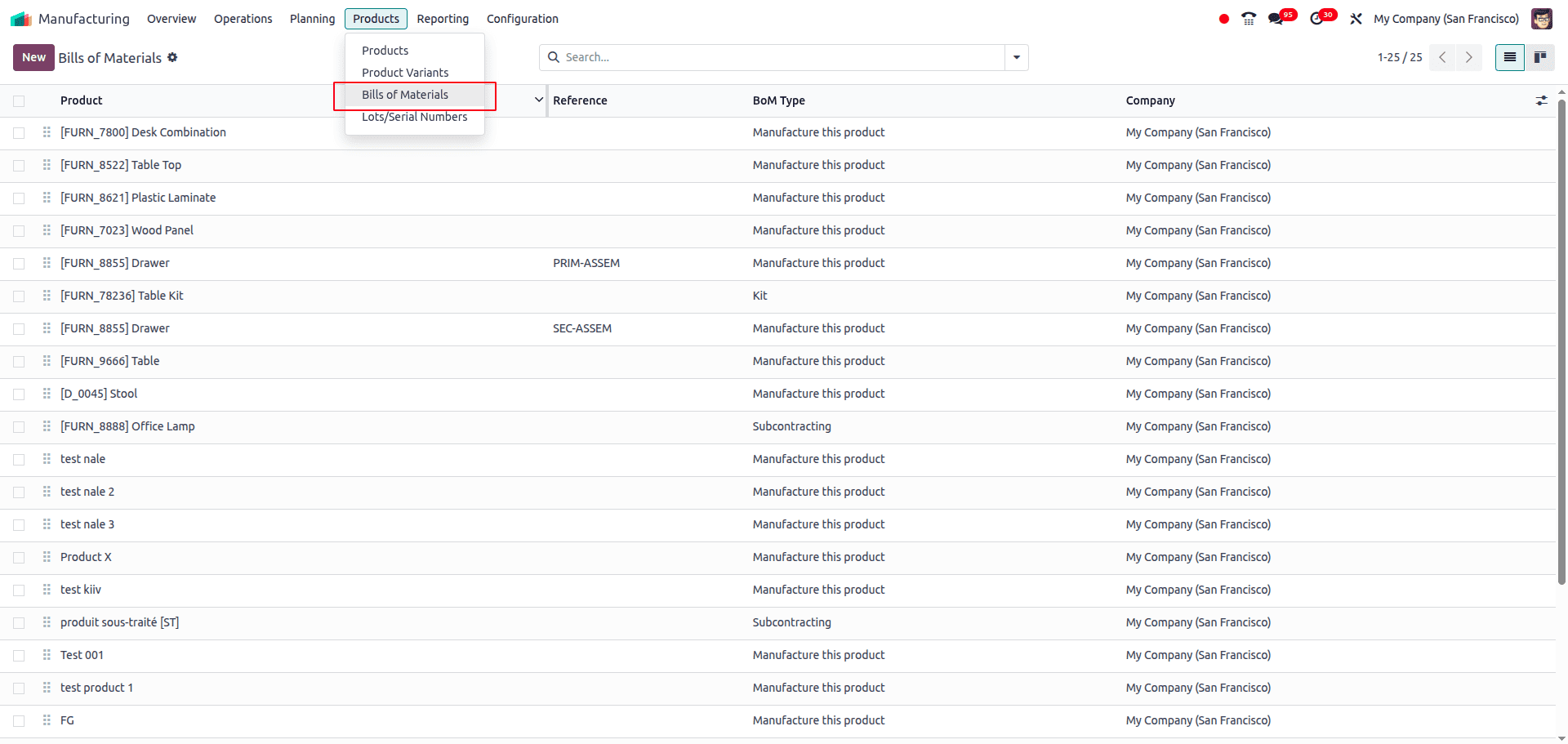

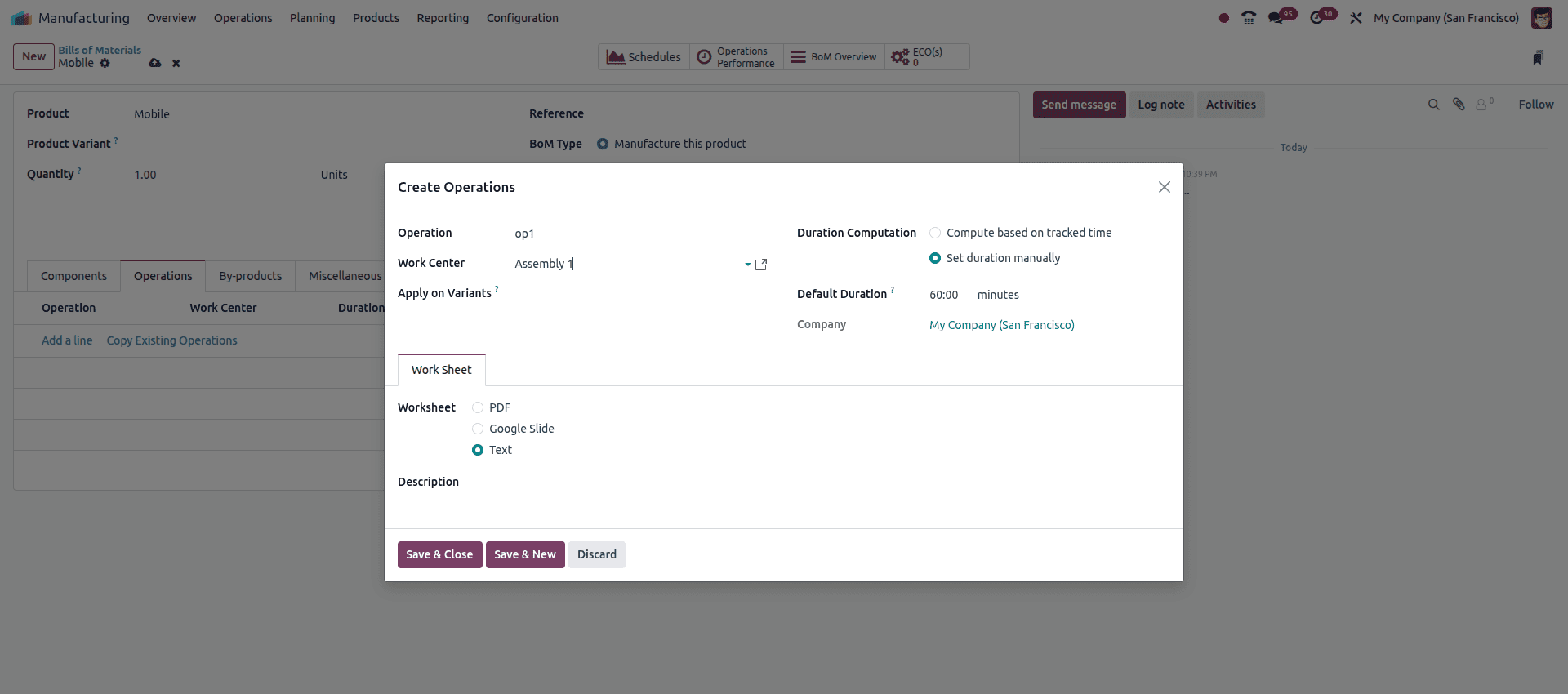

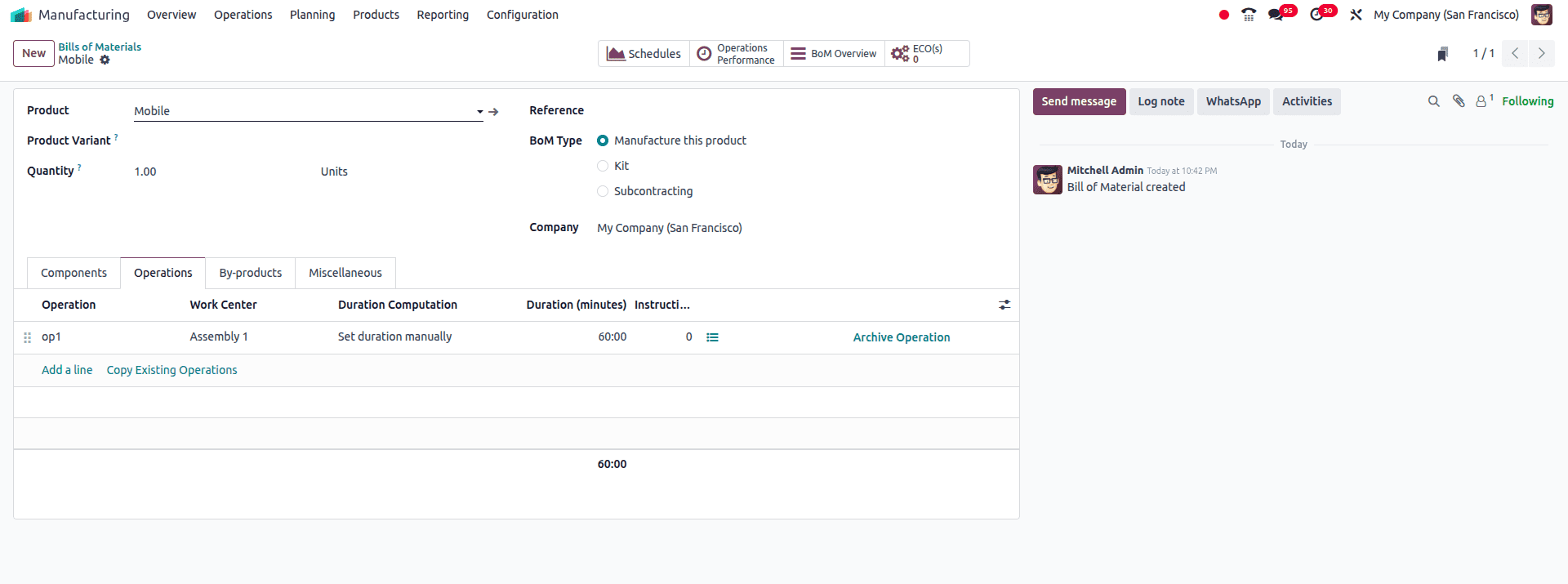

Step 4: Configure Routing and BOM

To associate equipment usage in production:

- Create a Bill of Materials (BOM) for a product.

- Under Routing, define operations like "Cutting", "Drilling", etc.

- Assign the Work Center to each operation.

The added work center will be displayed on the line.

When a manufacturing order is triggered, these operations will be executed at the associated work centers, thereby involving the equipment automatically.

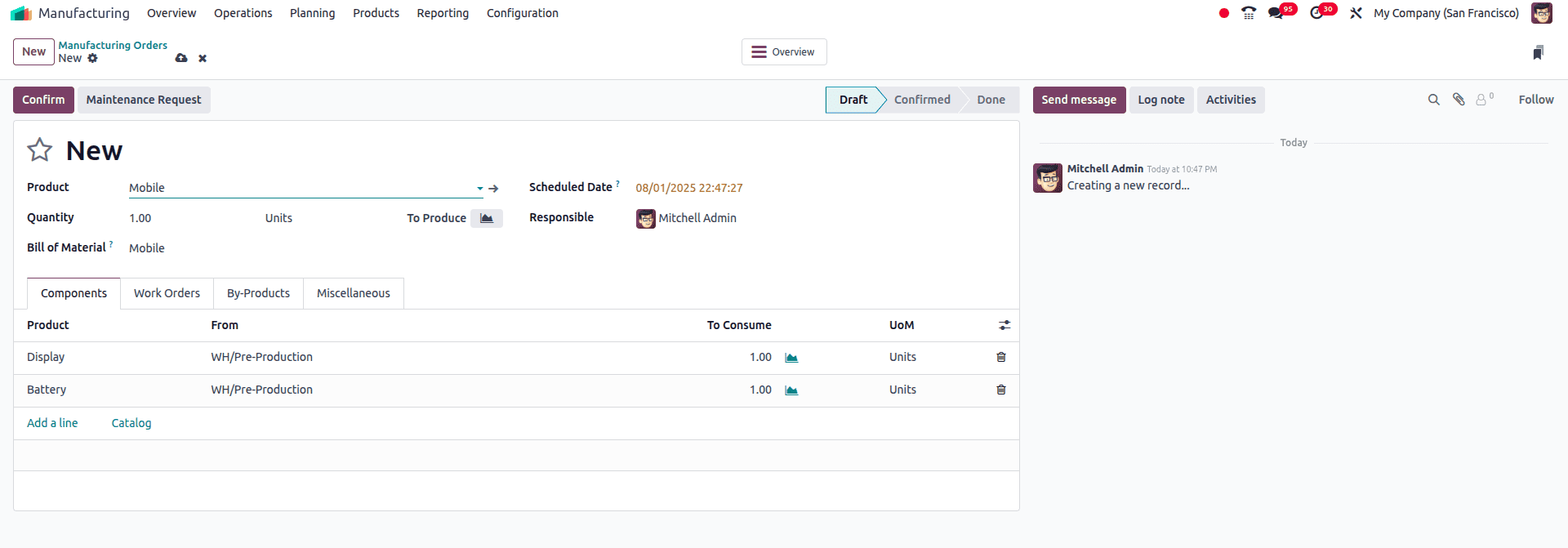

Step 5: Monitor Equipment Usage

Start the manufacturing.

Once production starts:

- Equipment is logged for usage duration, load, and work time.

- You can analyze equipment performance from Maintenance or MRP reporting views.

- Equipment breakdowns or preventive maintenance can now block production, ensuring realistic lead times and safety.

Odoo also provides OEE (Overall Equipment Effectiveness) reports to track performance, availability, and quality, key indicators of how efficiently your machines are running.

With Odoo 18, equipment is no longer a passive asset. It becomes an integral part of your manufacturing flow, helping businesses improve throughput, reduce bottlenecks, and ensure high-quality output. If you’re serious about optimizing production, equipment management in Odoo is a game-changer worth adopting.

To read more about How to Manage Equipment Maintenance During Production in Odoo 17, refer to our blog How to Manage Equipment Maintenance During Production in Odoo 17