Manufacturing a product is a crucial process that involves multiple stages. Consequently, another essential task is making appropriate use of these manufactured goods. Maintaining efficient customer service requires allocating these manufactured commodities to various customers while taking priority concerns into account. Make sure that resources are used as efficiently as possible and that the proper consumers receive their purchases on time. This requires careful planning and wise decision-making, which improves customer satisfaction.

Since a corporation has numerous clients, each one is important. If several customers placed orders for a product that wasn't available, what would happen? In these situations, the company is forced to either manufacture or purchase these items.

In some cases, if the numbers requested are large, it is allowed to acquire many large quantities at once. It may be difficult to manufacture a product in huge quantities at once since the workstation has some capacity. It is therefore impossible to provide the goods to every customer who requests them at once in such situations. The user's only choice in this situation is to split the amounts of the produced goods among the numerous deliveries. Correctly allocating the manufactured goods to customers' deliveries minimises user labour and expedites delivery timeframes.

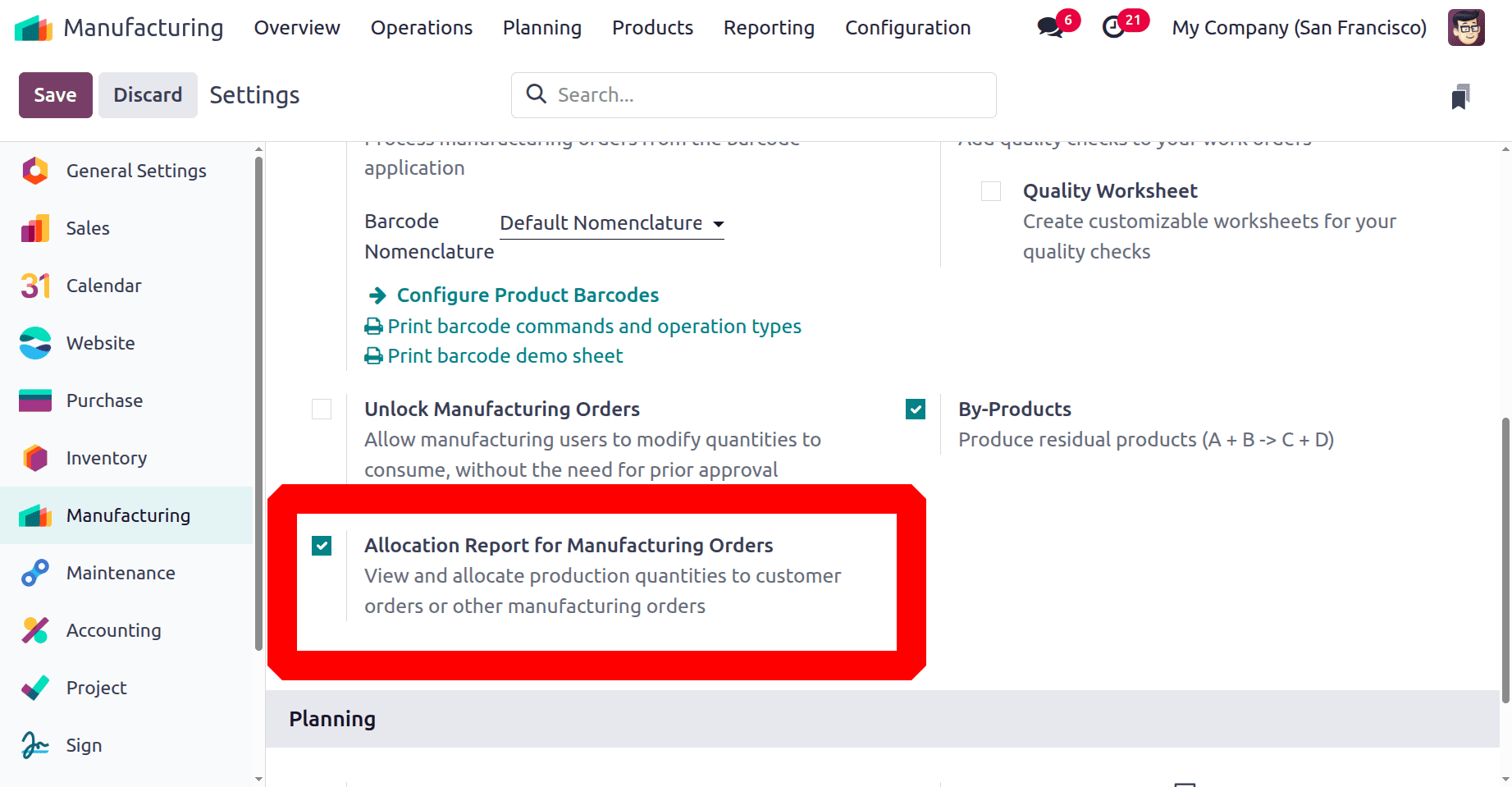

The Allocation of Products feature, which was included in Odoo 18, aids users in completing this process. Therefore, users can enable the Allocation Report for option from the Configuration settings tab. Save the updated configuration after turning on this option.

If the user chooses this option, after the manufacturing process is finished, an Allocation Report is shown. A list of deliveries is part of an allocation report for the manufactured items. Some deliveries are in the waiting stage because of the organization's inventory shortage. From that moment on, the user can effortlessly allocate the merchandise to every delivery.

A company receives a lot of product deliveries. When a product is refilled, it could be quite difficult for a salesperson to look through the delivery orders for that particular product. The user can utilise this allocation report to find all manufactured goods shipments and properly complete orders.

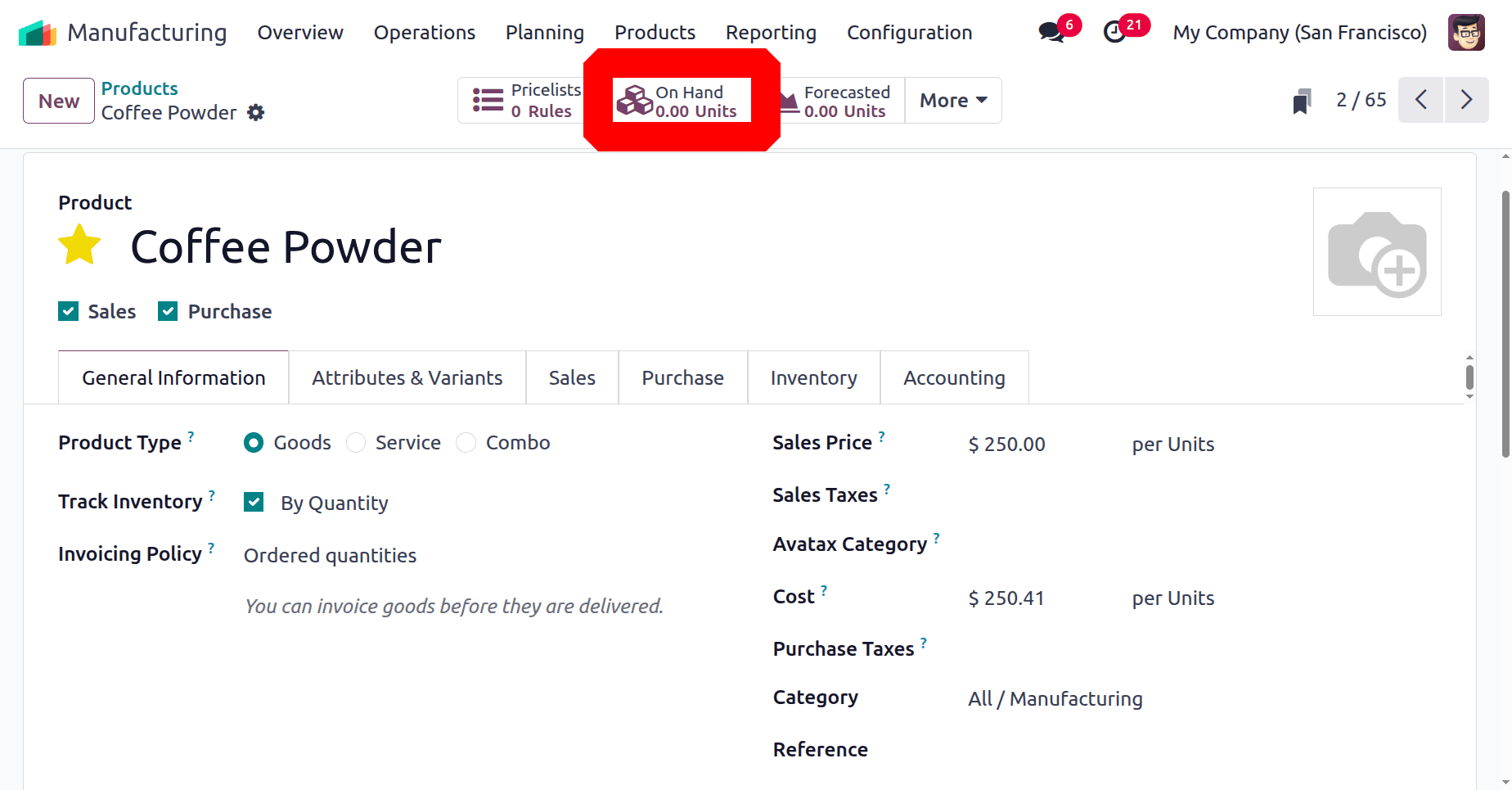

Let's start by outlining the operation of this allocation. This product, Coffee Powder, shows the items that are available in zero quantities. In this case, three customers request the goods. In order to restock the product, the user wants to make it. To complete the order, let's examine how easy it is for the user to find the deliveries and assign the product to the delivery.

Think of a product called Coffee Powder that is storable. But the product is unavailable in the inventory. Route manufacturing is enabled on the Inventory tab.

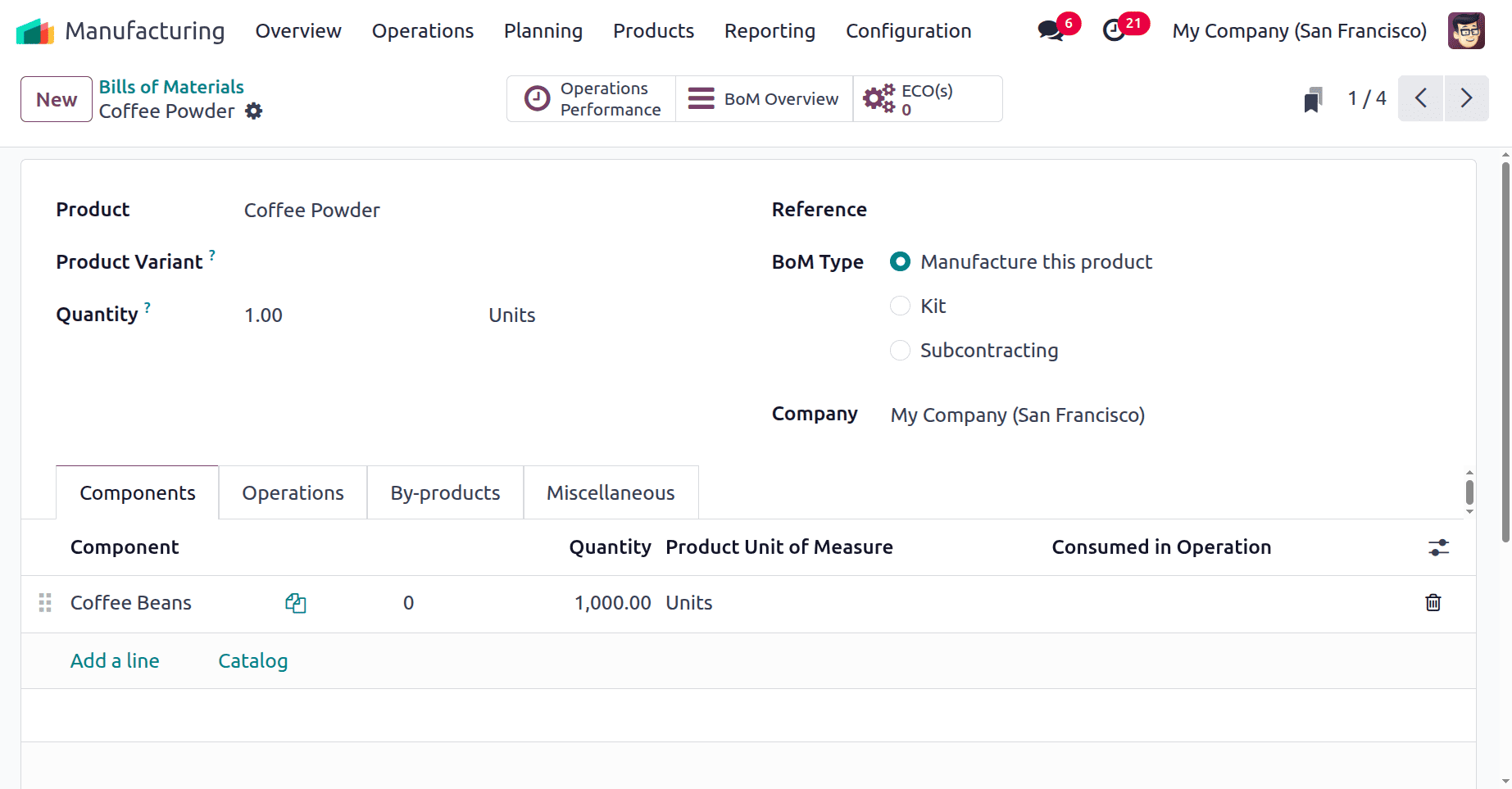

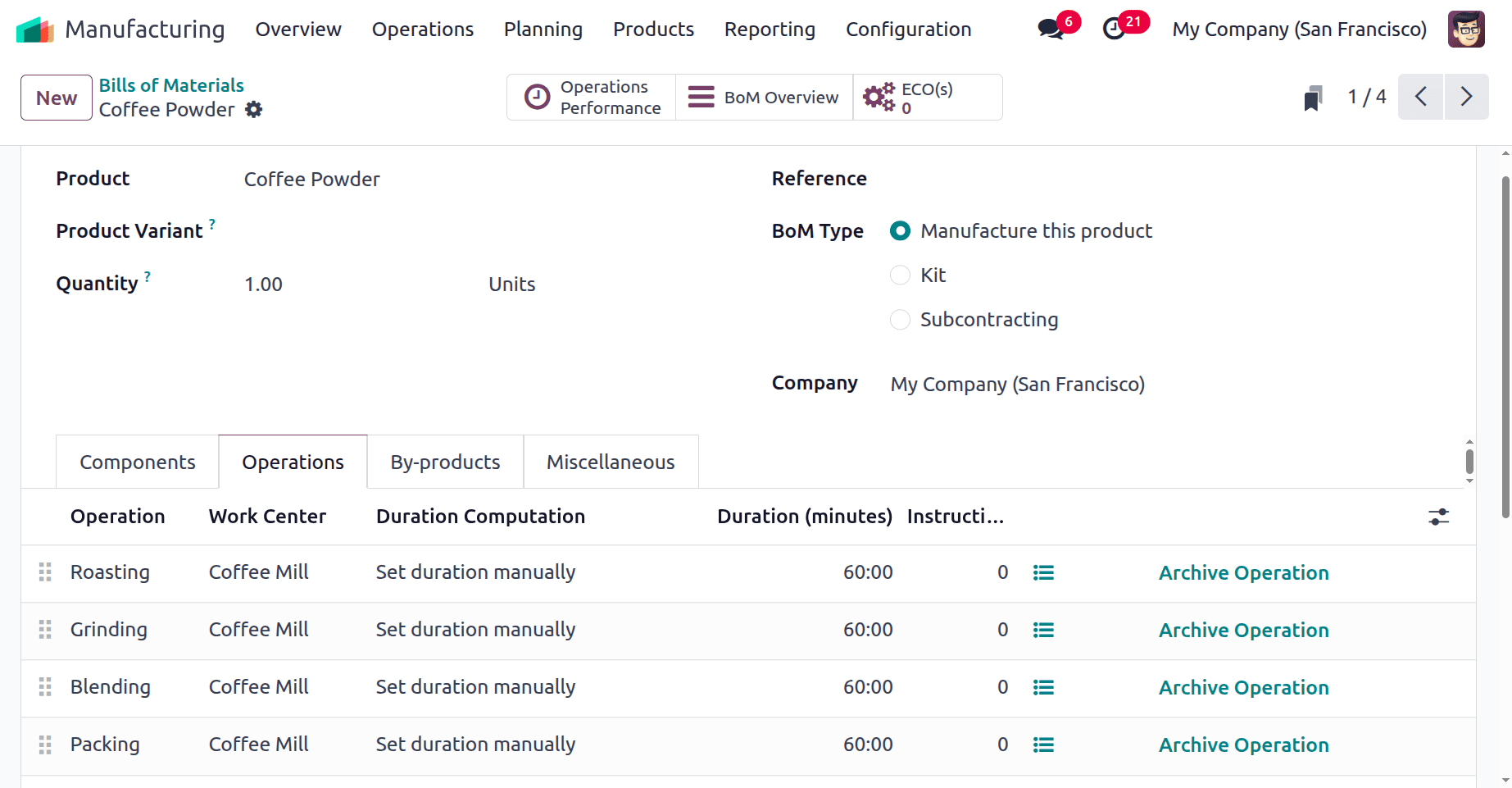

Select the Bill of Materials from the Product menu. The generated bill of materials is shown on this page. Open the BoM that was made for the coffee powder product. Production makes use of this bill of materials. The components stated here are utilised as raw materials for manufacturing, and the operations indicated in this bill of materials are performed during manufacturing to produce the final product. There are currently enough ingredients to make multiple types of coffee powder.

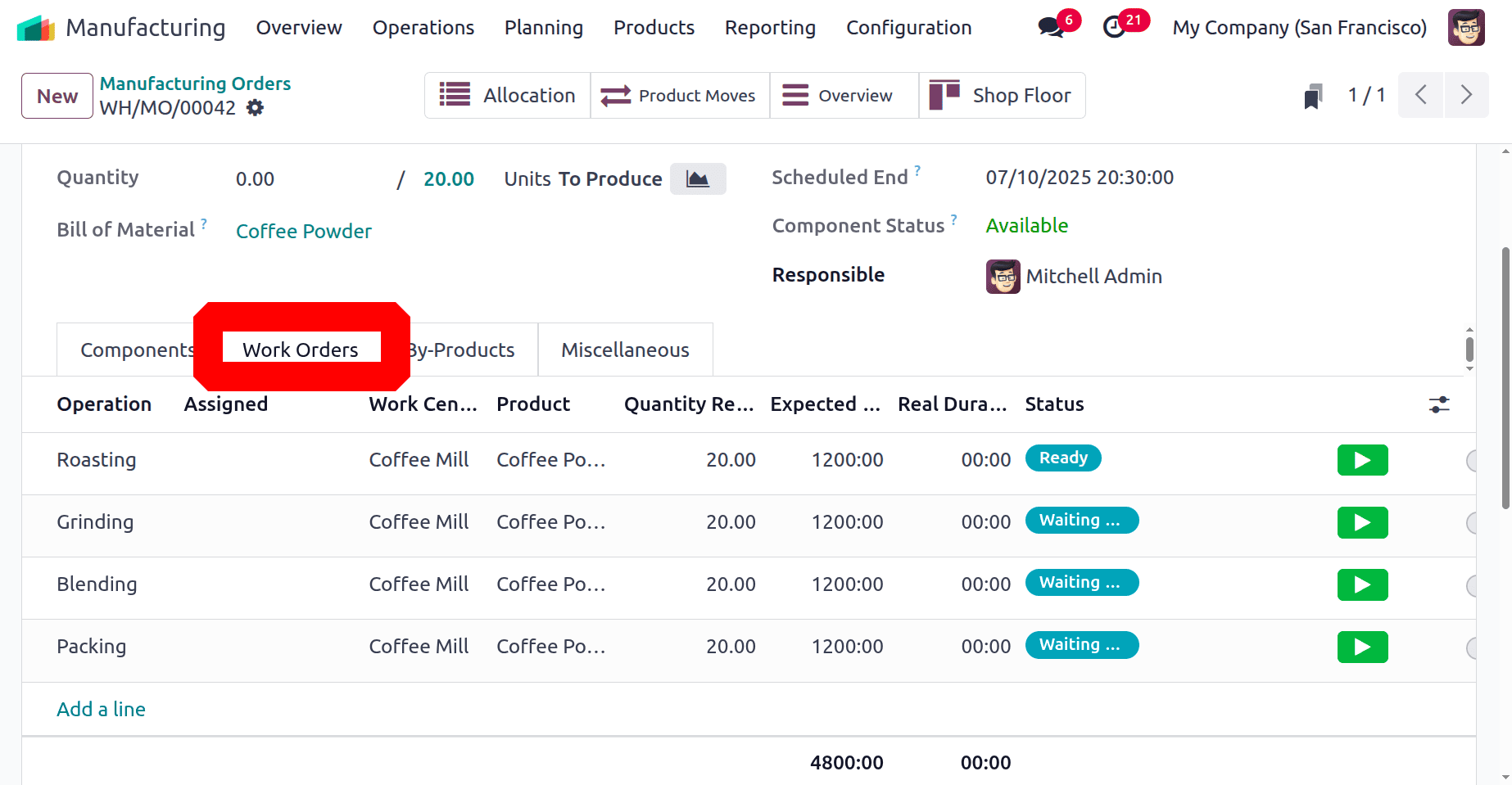

Roasting, grinding, blending, and packing are the processes carried out throughout manufacture. This was conducted at the Coffee Mill workplace.

The item isn't available right now. Suppose buyers had questions regarding this product. Let's see what happens under these conditions. Let's come up with some quotes for the item. Users of the sales module can create quotations. Alternatively, users can create a Delivery directly from Inventory Operations.

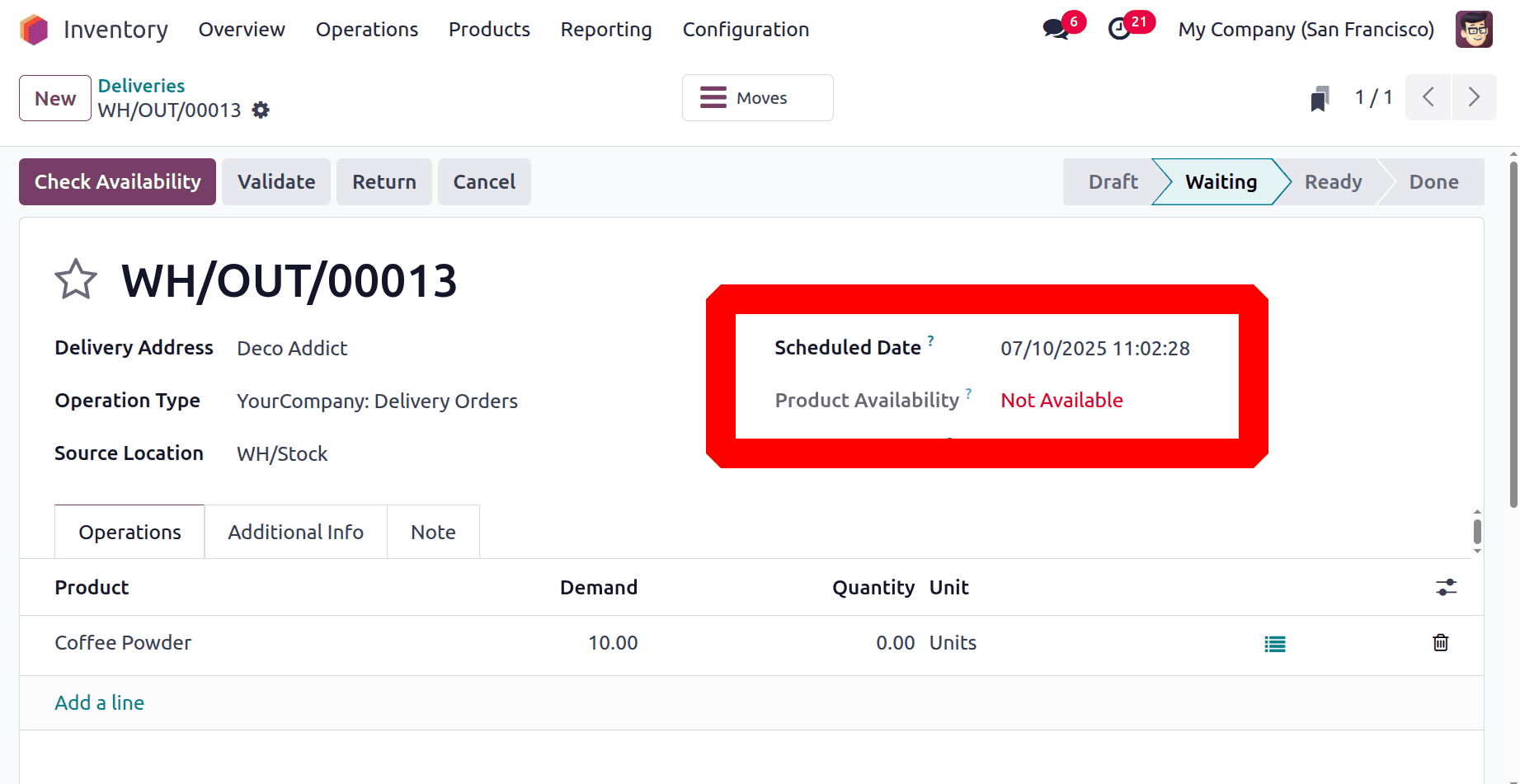

This is the Delivery Order that was made for Deco Addict's client. He asked for ten quantities of coffee powder. There is no stock even though the quantity is 10. The product is unavailable while the delivery is being checked. The delivery date is set for July 10th. Here, the delivery order is in the Waiting stage.

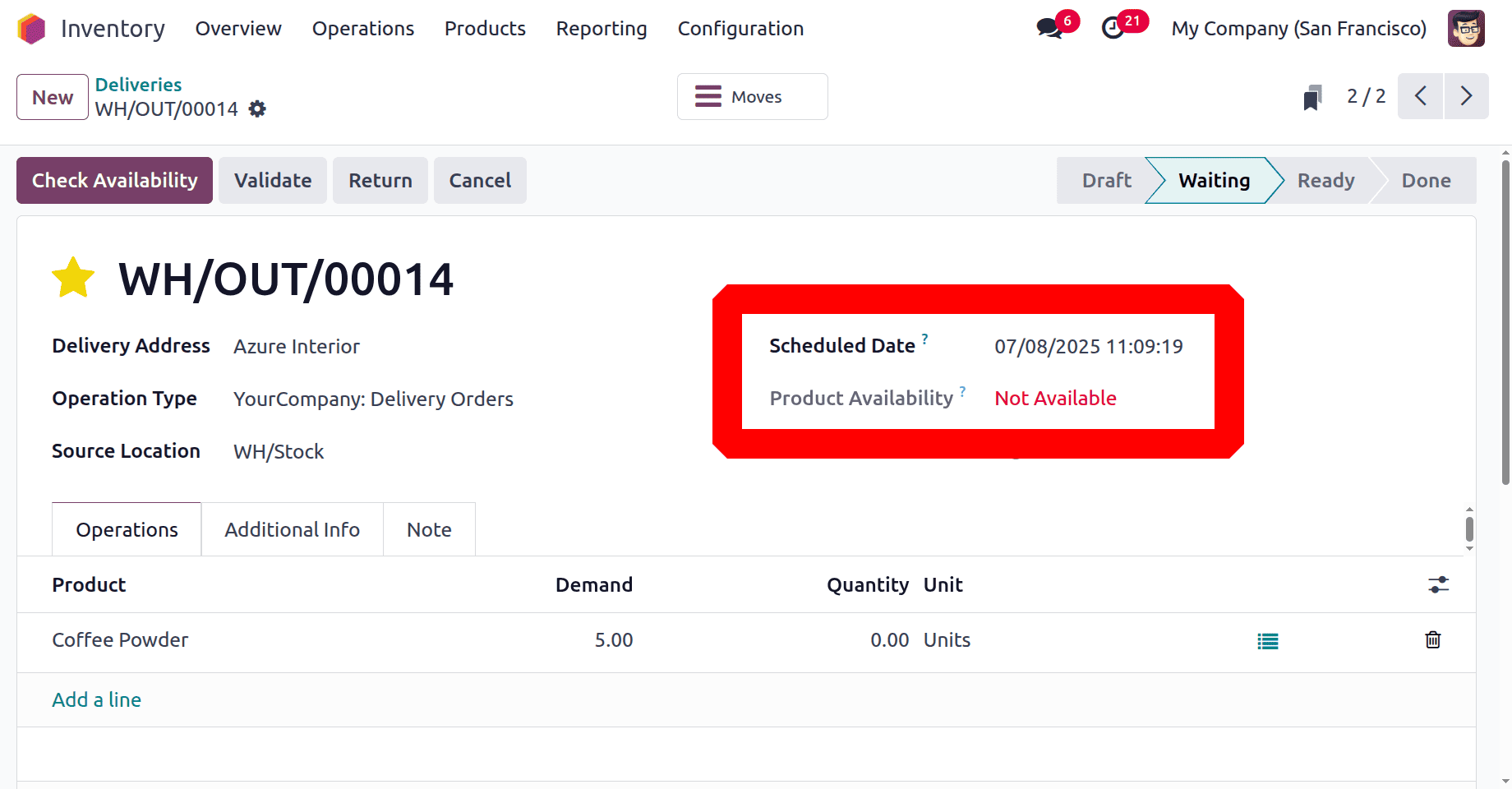

Azure Interior is the client for the second delivery. Here, the client asked for five different amounts of the coffee powder product. Verify the order. Because the goods need to be restocked, the delivery is being checked while it is also in the waiting stage. This delivery is expected to occur on July 8.

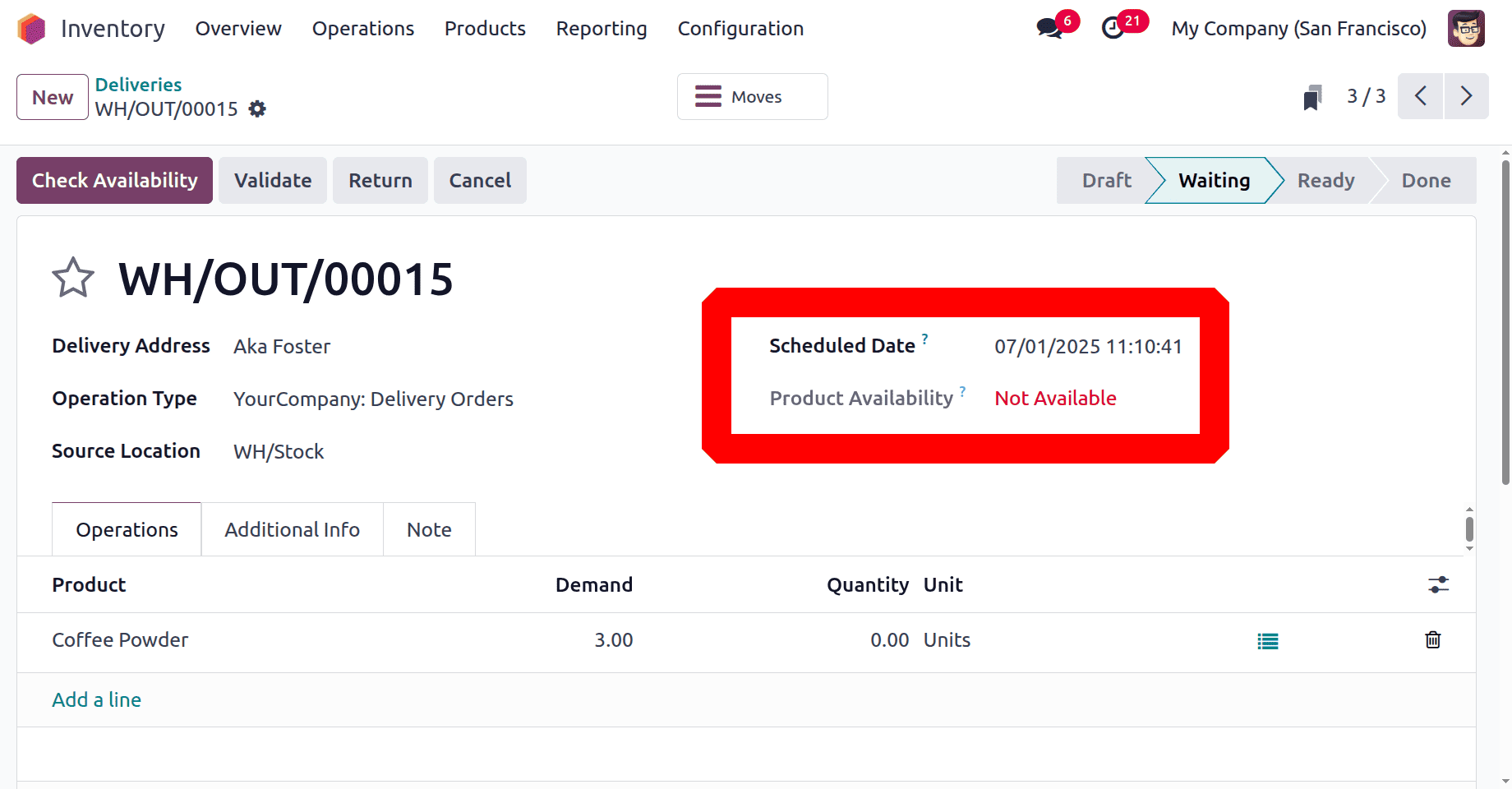

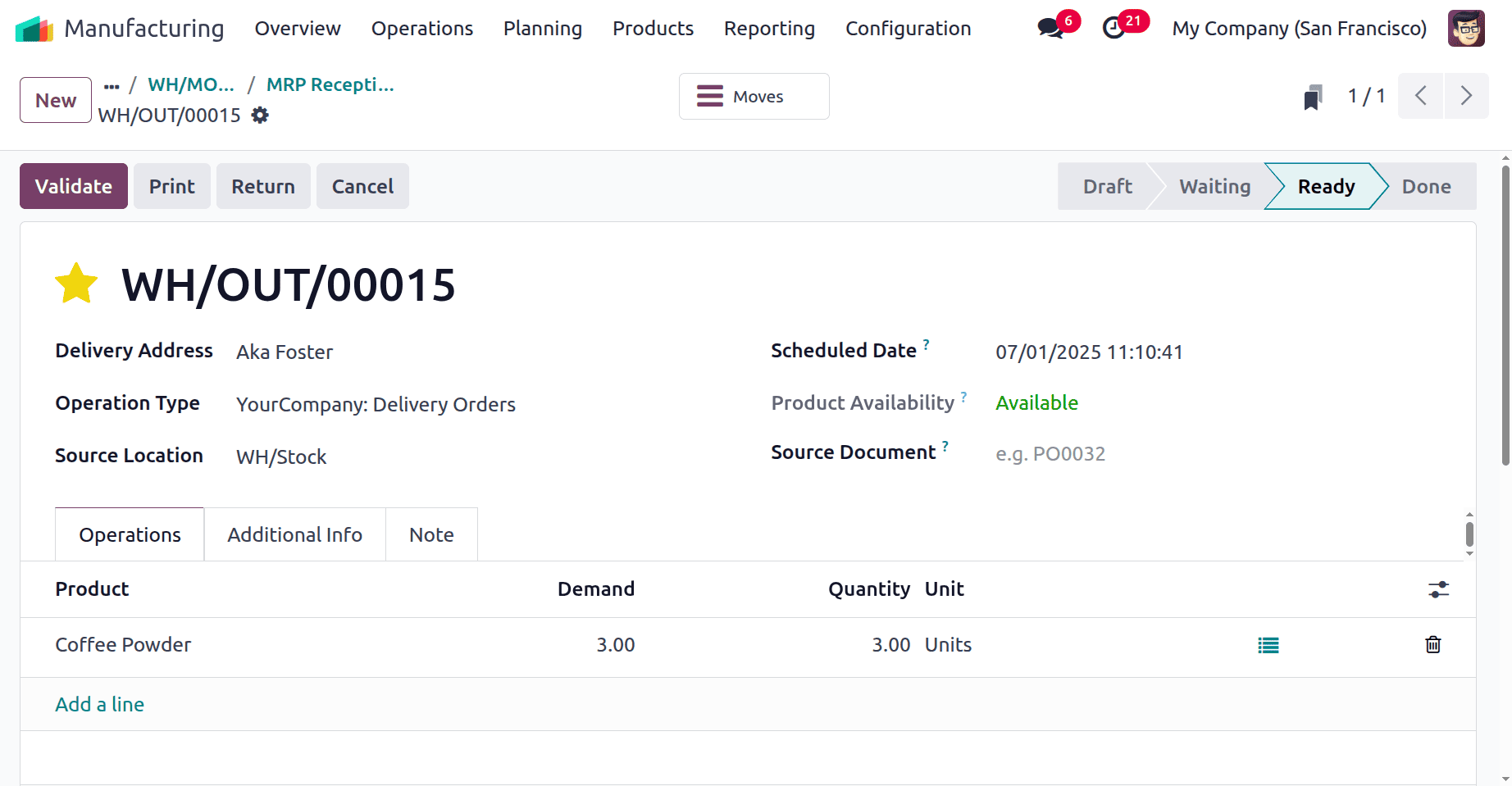

Aka Foster is the third customer. He requested three product quantities. Verify the order. The third delivery order has also been shifted to the waiting stage and is planned for July 1st.

In this case, three buyers each desired a different amount of the same item. The item is sold out, though. The company decided to manufacture the products as a result. Now, let us place a production order. To begin the production process, select the Manufacturing module. The manufacturing order can be chosen by users from the Operations tab.

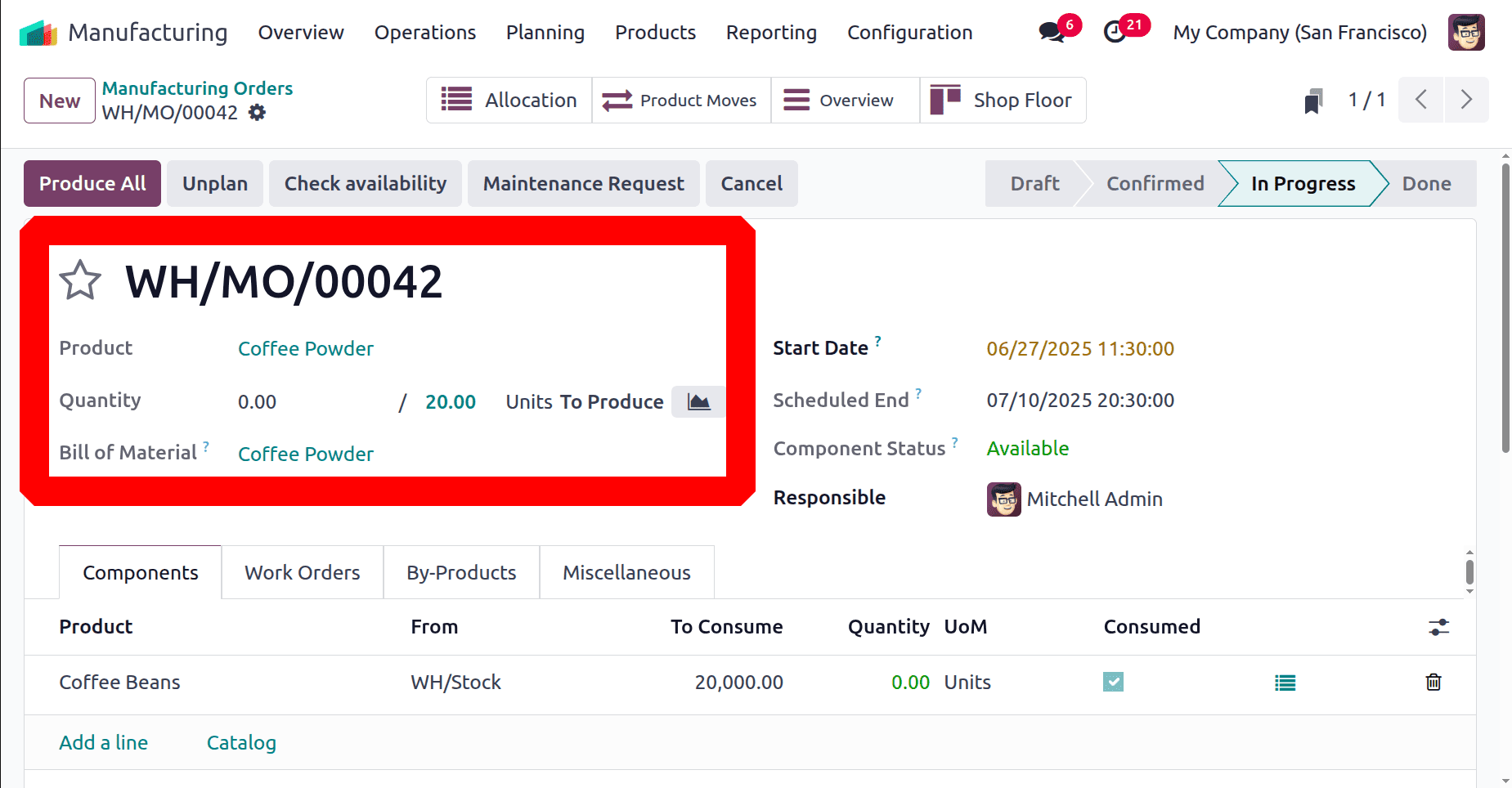

After that, a fresh production order was made for 20 amounts of the product coffee powder. The identical bill of materials that was previously displayed is used here. To finish the manufacturing, all the parts and procedures are replicated in the manufacturing order. Verify the order. Since three orders totalling eighteen quantities are pending delivery. The product coffee powder needs to be produced in twenty lots.

Once the order has been confirmed, the operation is in the Ready stage. To initiate the process, click the "Start" button. Then finish it correctly.

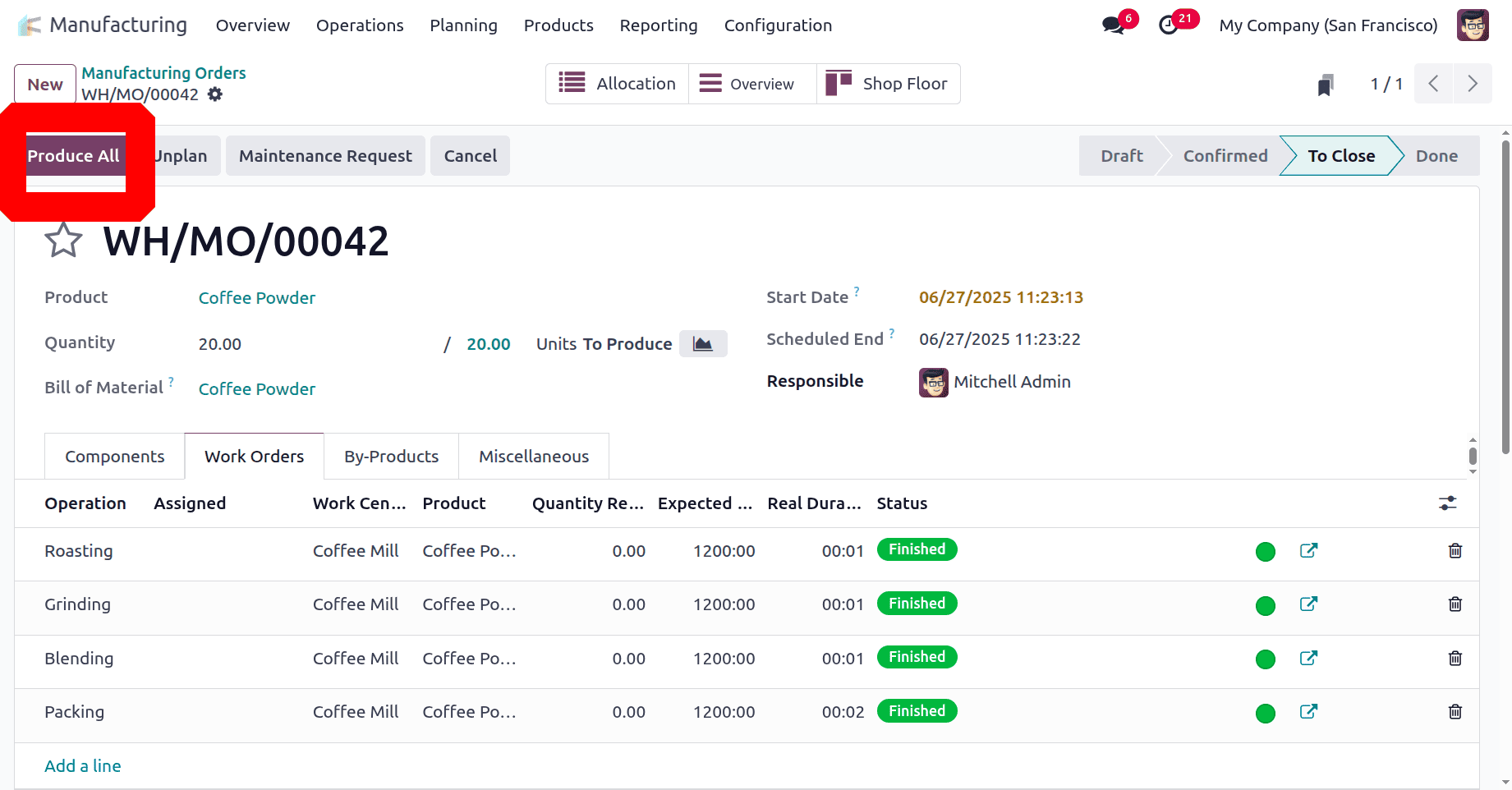

Click "Produce All" once the process is finished. Following the completion of the manufacturing order, the 20 product quantities will be placed into stock.

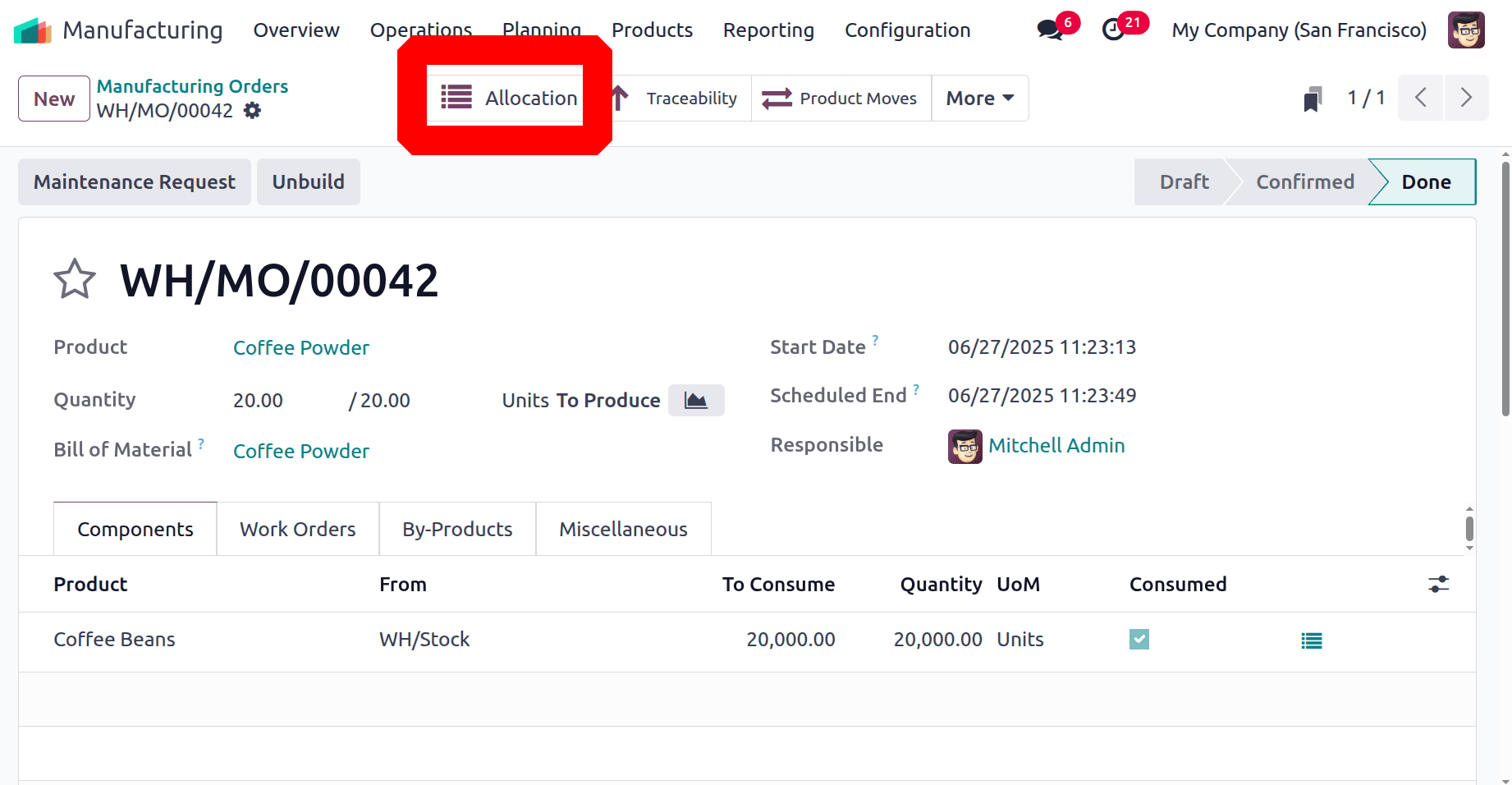

The production procedure is now finished. The finished production order includes a few of the smart tabs. Additionally, a tab for allocation will be displayed. To view the Allocation report, open it.

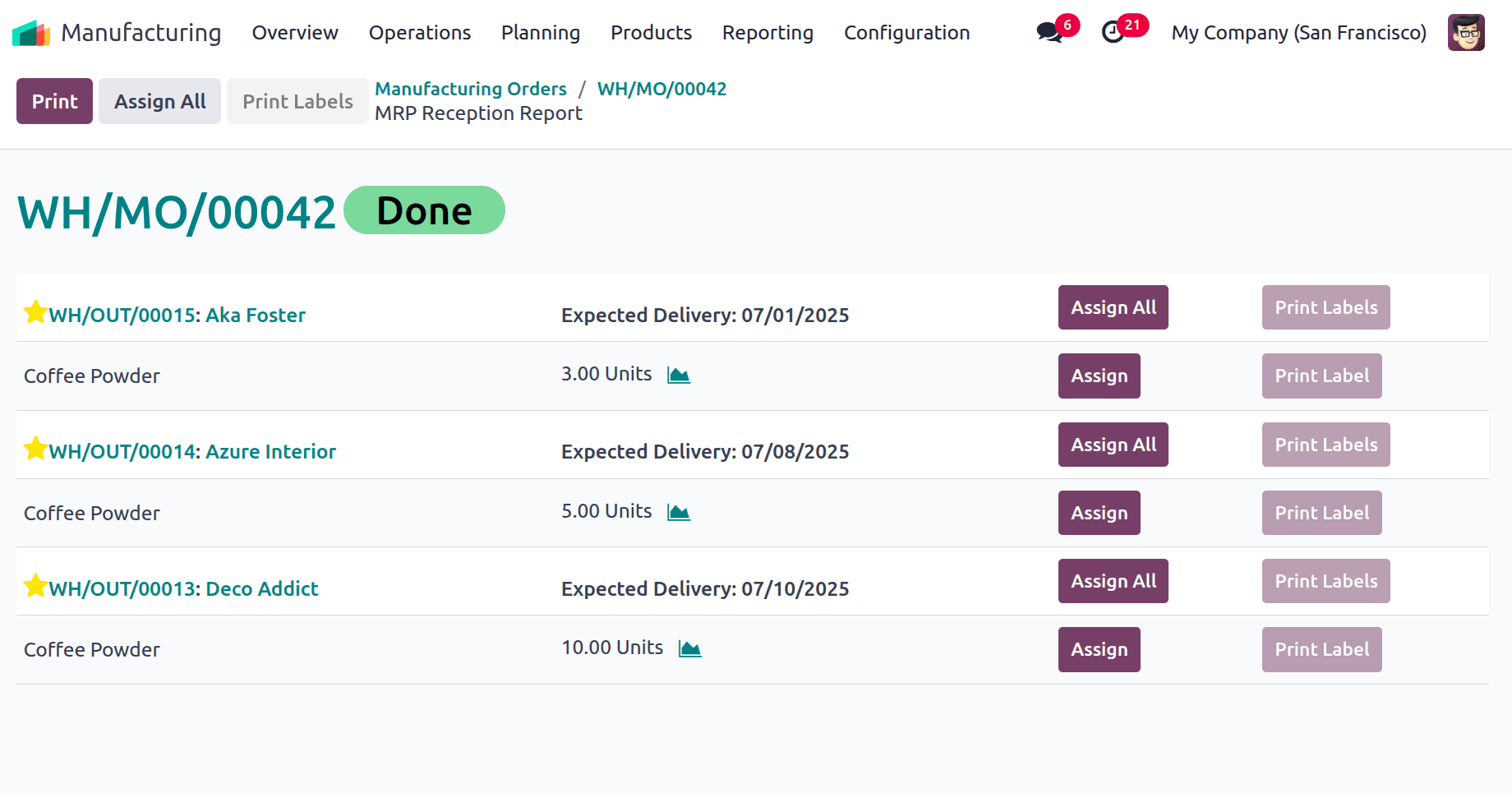

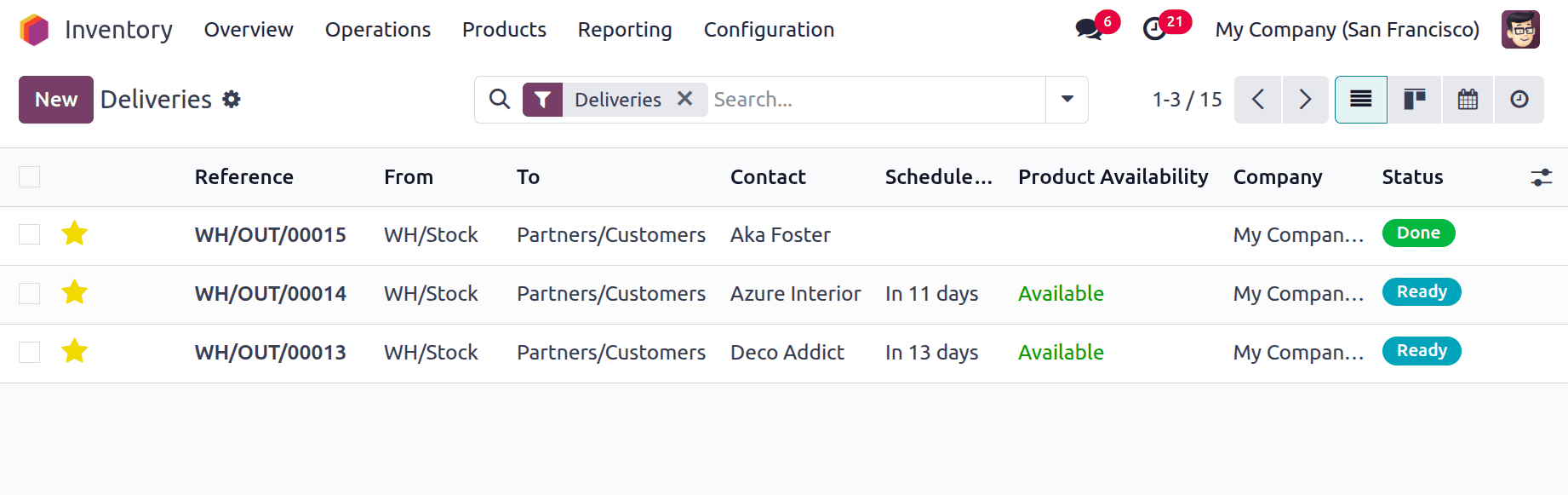

All of the previously made deliveries are included in the allocation reports. The Allocation request displays information such as the delivery order sequence number, the requested customer's name, and the desired quantity. They are all anticipating the coffee powder product.

Products can be assigned to delivery orders using the Assign button. To allocate every product, click the Assign All button. Once the product has been assigned to the delivery, open the delivery. Click on the delivery sequence number here to see the delivery order.

In this case, the designated goods are held for delivery. The product will be moved from stock to the customer's location once the user clicks the Validate button to finish the delivery.

Products can be attached to each delivery in the same manner by the user. The main advantage of the report is that it allows the user to assign products on time. The user can select which product is assigned to which delivery order if there isn't enough inventory to complete every delivery. The most urgent delivery can thus be completed promptly.

Time delays can be reduced and customer satisfaction increases when manufactured goods are appropriately assigned to delivery orders. The complicated procedure is simplified to a one-touch method in Odoo 18.

To read more about How to Handle Manufacturing with One-Step Warehouse Configuration in Odoo 18, refer to our blog How to Handle Manufacturing with One-Step Warehouse Configuration in Odoo 18