Manufacturing Orders (MOs) act as the central framework for managing the production cycle. They outline the raw materials, resources, and specific operations needed to transform components into finished products. Serving as the operational backbone of manufacturing, MOs guide teams through each stage of production to maintain efficiency, quality, and consistency. However, any disruption, whether in scheduling, material availability, or execution, can cause delays, raise costs, and impact customer satisfaction. To overcome these challenges, many manufacturers are turning to fully integrated systems that unify production control with real-time data capture.

With Odoo 18, this approach reaches a new level through its enhanced Barcode Application. The platform now enables the creation and management of Manufacturing Orders directly from barcode scans, allowing faster processing, reducing manual errors, and improving traceability. By encoding product and process details into scannable barcodes, and integrating them seamlessly with Odoo 18, manufacturers can move beyond traditional data entry toward an automated, accurate, and highly efficient workflow.

In modern production environments, this combination of barcode technology and Odoo 18 transforms how manufacturing teams operate. Workers can instantly scan materials, track semi-finished goods, and update production stages, without breaking the pace of their workflow, resulting in a smoother, smarter manufacturing process from start to finish.

Benefits of Processing Manufacturing Orders from the Barcode Application in Odoo 18

- Faster, Error-Free Data Entry

Eliminate tedious manual input by scanning barcodes directly on raw materials, components, and finished goods. This not only speeds up the process but also reduces the risk of costly data entry mistakes.

- Real-Time Inventory Updates

In Odoo 18, every scan instantly updates your stock levels, ensuring your inventory records remain accurate and up to date. This live visibility enables smarter forecasting and more precise production planning.

- Improved Material Traceability

Barcode integration allows you to track each material’s journey through every stage of production. This enhanced traceability simplifies compliance, strengthens quality control, and provides clear audit trails.

- Optimized Shop Floor Operations

Equip your shop floor teams with barcode scanners to handle production tasks efficiently. They can instantly check material availability, record progress on manufacturing orders, and trigger quality inspections—without leaving their workstation.

The Barcode application in Odoo 18 enables real-time execution of manufacturing orders, receipts, deliveries, and other operational tasks using a barcode scanner or the Odoo mobile app. Before starting with the manufacturing workflow, make sure your system is upgraded to Odoo 18 and that the Barcode module is properly installed and configured.

Activating the Barcode App for Processing Transfers in Odoo 18

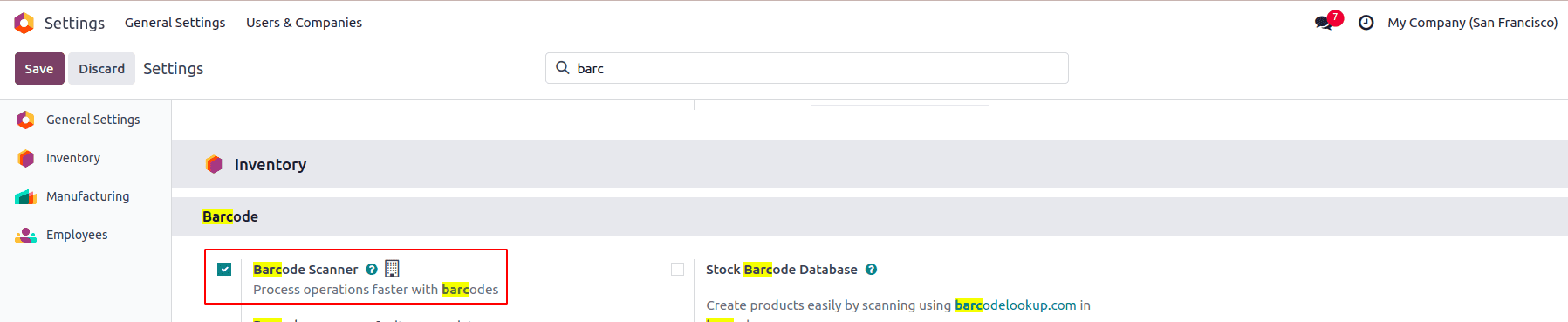

- Go to the Inventory module from your Odoo dashboard.

- Open Configuration > Settings.

- Locate the Barcode section.

- Enable the option for Barcode Scanner by checking the box.

- Click Save at the top to apply your changes.

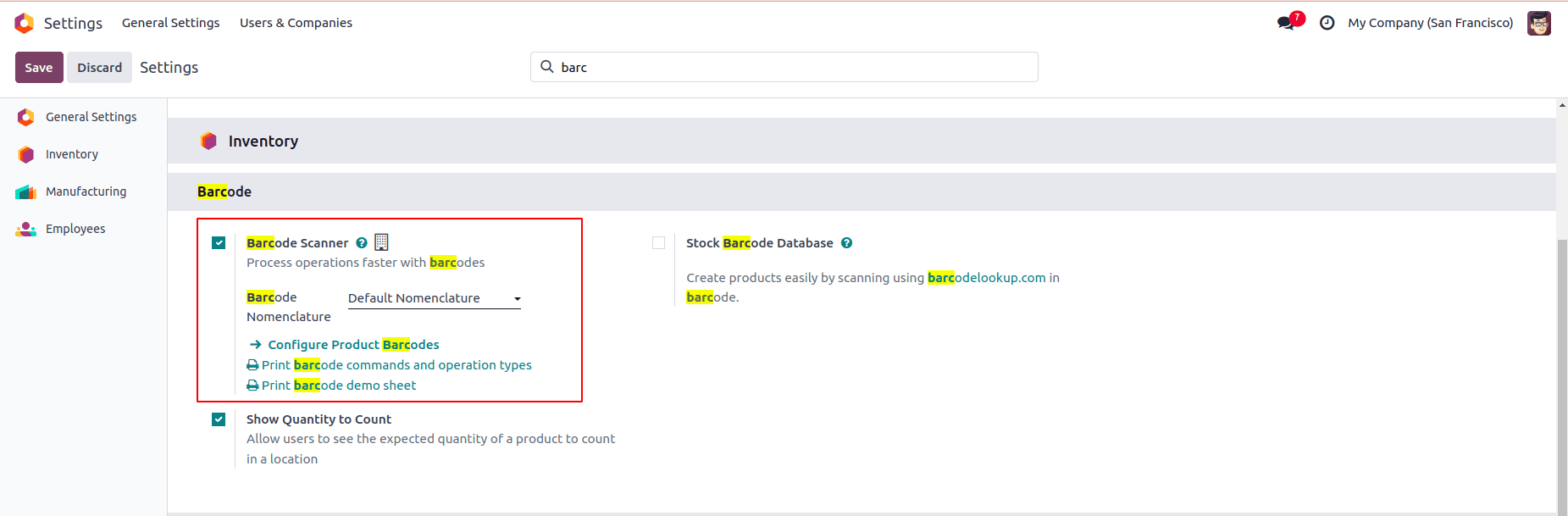

After saving your settings, you’ll see additional configuration options under the Barcode Scanner section:

- Barcode Nomenclature – Select either Default Nomenclature or Default GS1 Nomenclature from the drop-down list, depending on your preferred barcode format.

- Configure Product Barcodes – Click the internal link icon to set or edit barcodes for your products.

- Print Buttons – Use these buttons to print barcode commands or generate a barcode demo sheet for testing.

Once enabled, you can start using the Barcode application to process transfers and other operations directly through barcode scans.

To process a manufacturing order through the Barcode application, you must first create the order in Odoo.

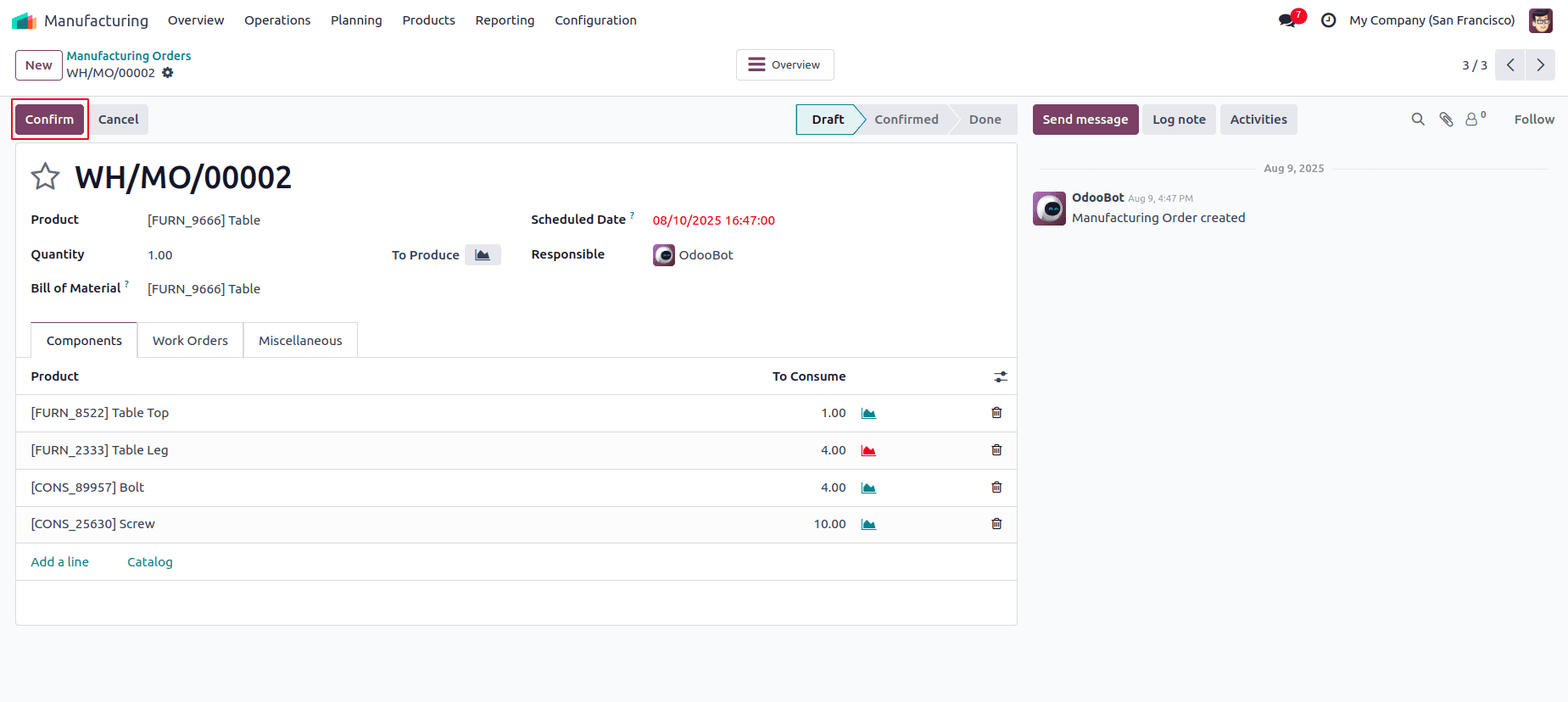

- Open the Manufacturing module and click New to start a new manufacturing order.

- Fill in the required details, including the product, quantity, and any additional information needed.

- Click Save at the top of the form to record the order.

- Once all details are correct, click Confirm Manufacturing Order to validate and move it forward in the workflow.

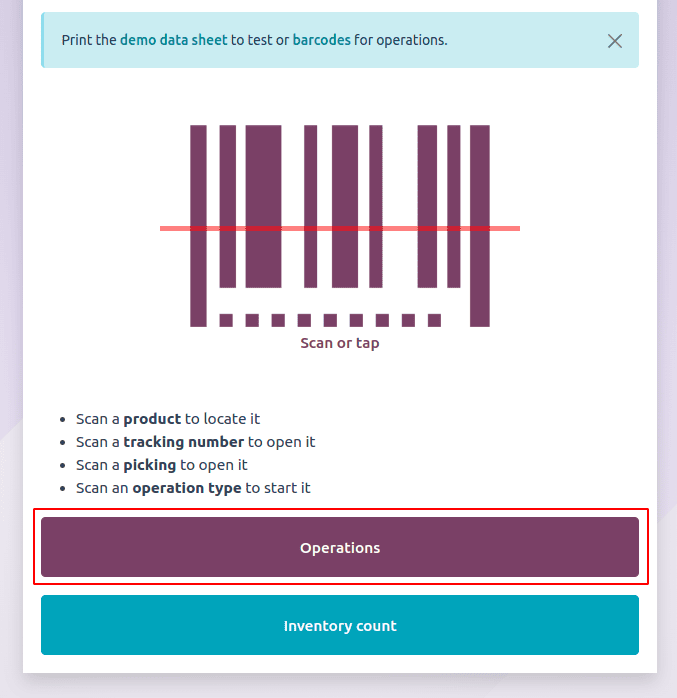

To begin barcode scanning for Manufacturing Orders, open the Barcode application.

Once inside, you’ll be directed to the scanning interface, where different options related to manufacturing operations are available.

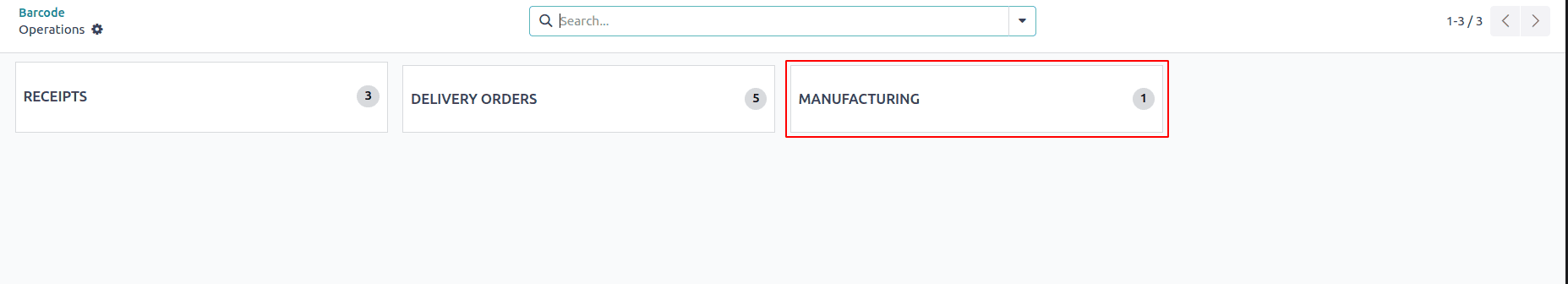

To manage Manufacturing Orders, tap the Operations button at the bottom of the screen. You will then be redirected to the Operations overview page.

On the Operations overview page, locate the Manufacturing card and click the # To Process button to view all pending Manufacturing Orders. Alternatively, you can scan the Manufacturing barcode with a scanner, which will take you directly to the order’s component list.

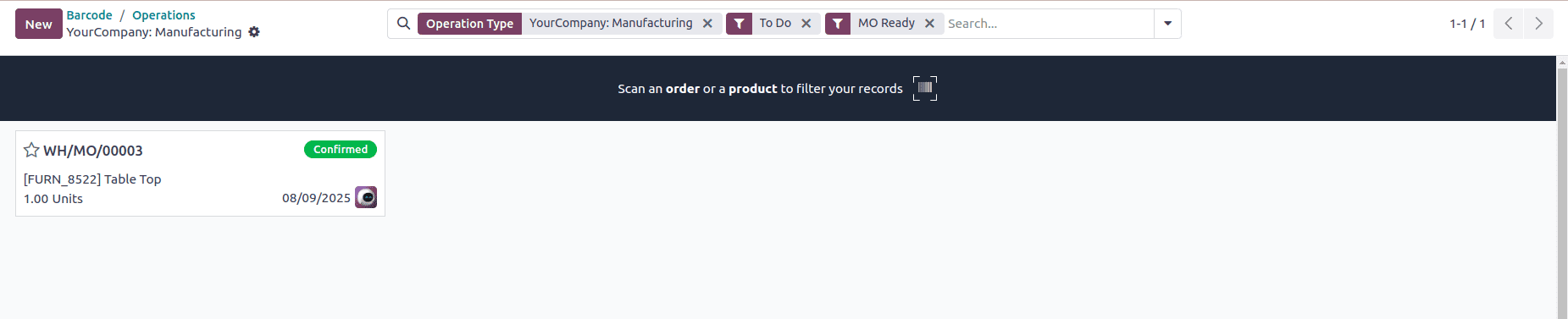

From this list, select the Manufacturing Order you want to process. Once chosen, you’ll be taken to the barcode transfer screen to continue with the next steps.

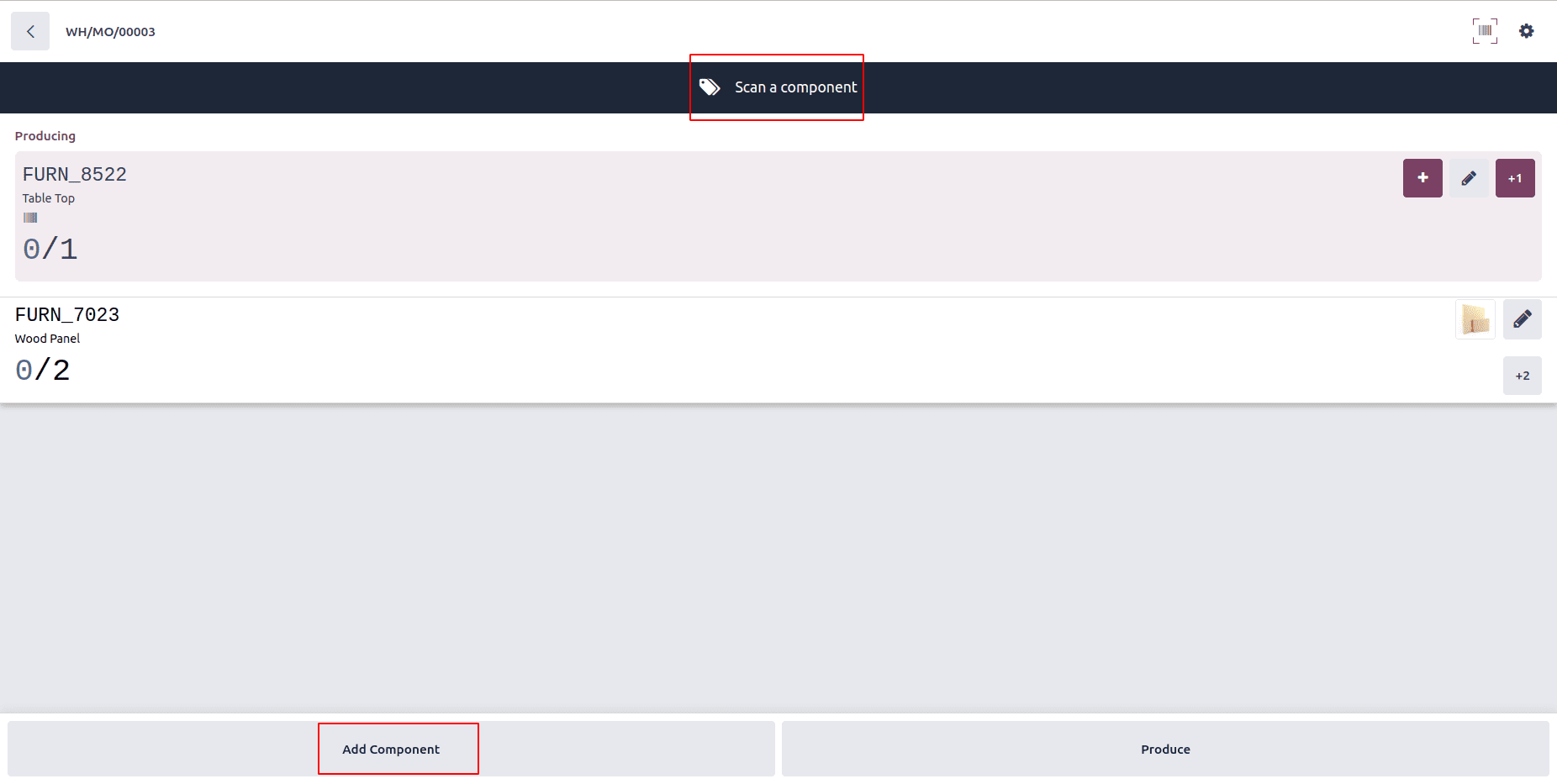

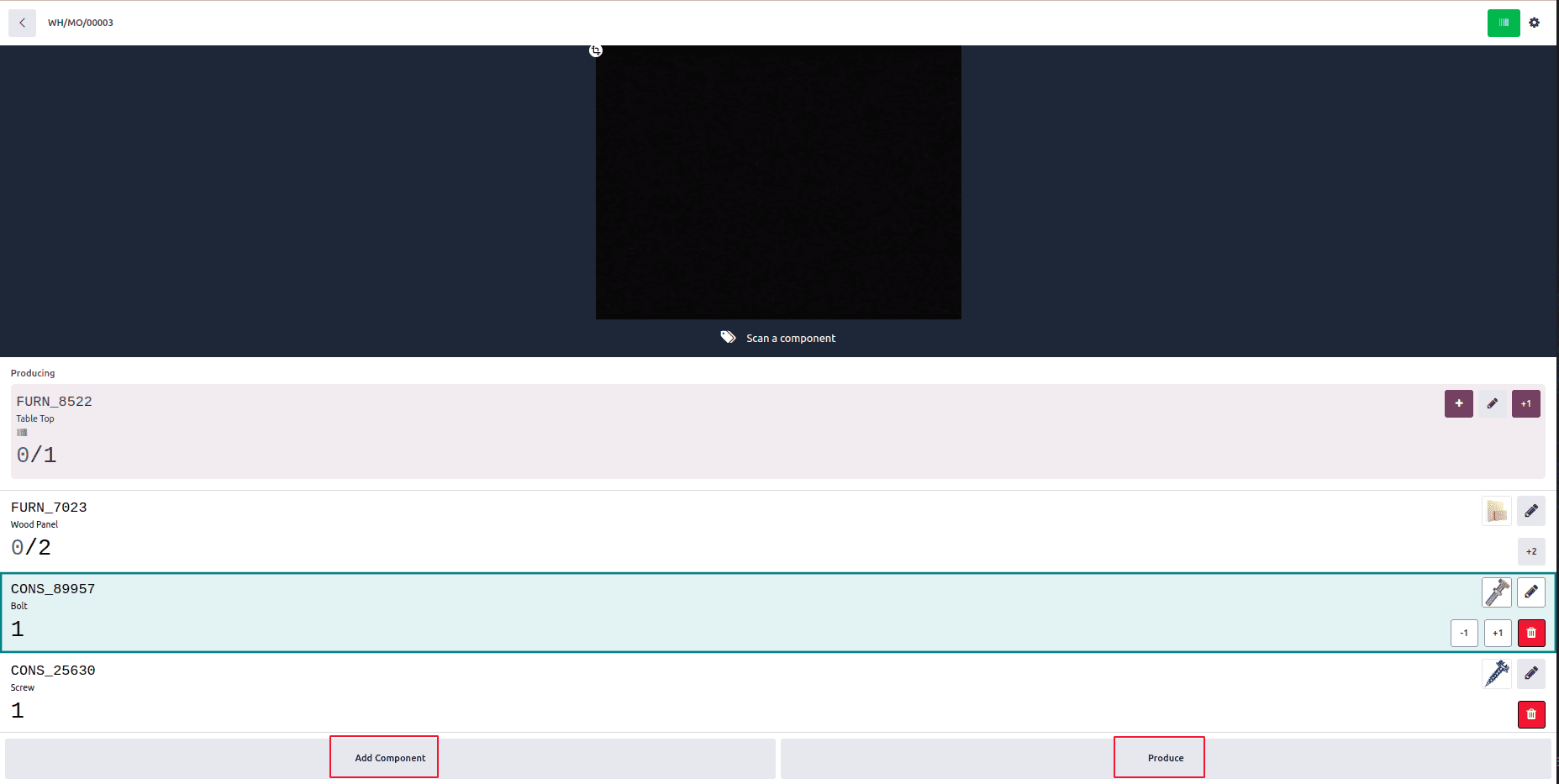

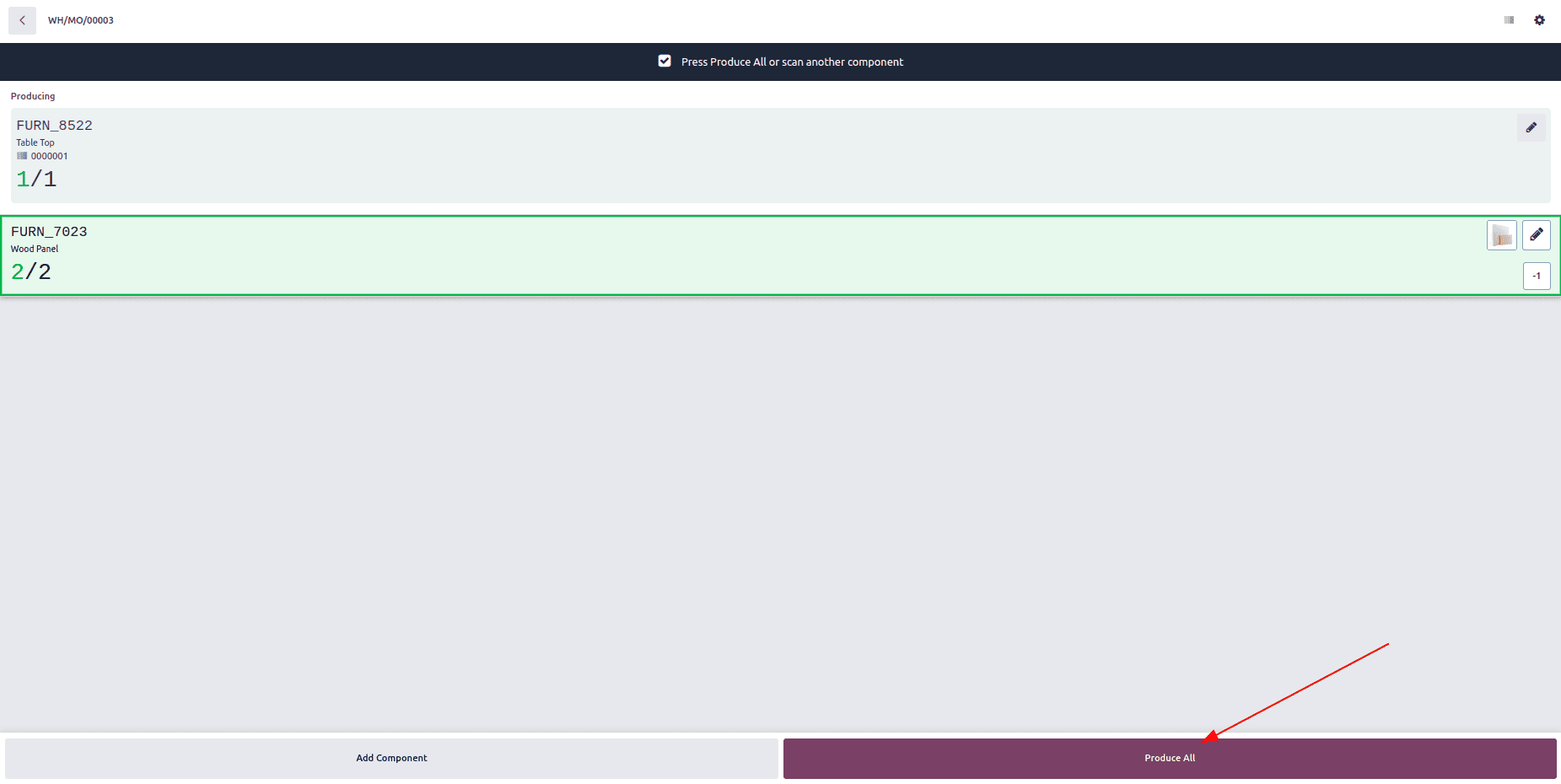

On the barcode transfer screen, you’ll find a detailed summary of all components that still need to be processed for the Manufacturing Order (e.g., WH/MO/00003). From here, you can use the Scan a Component button to scan and register each listed component.

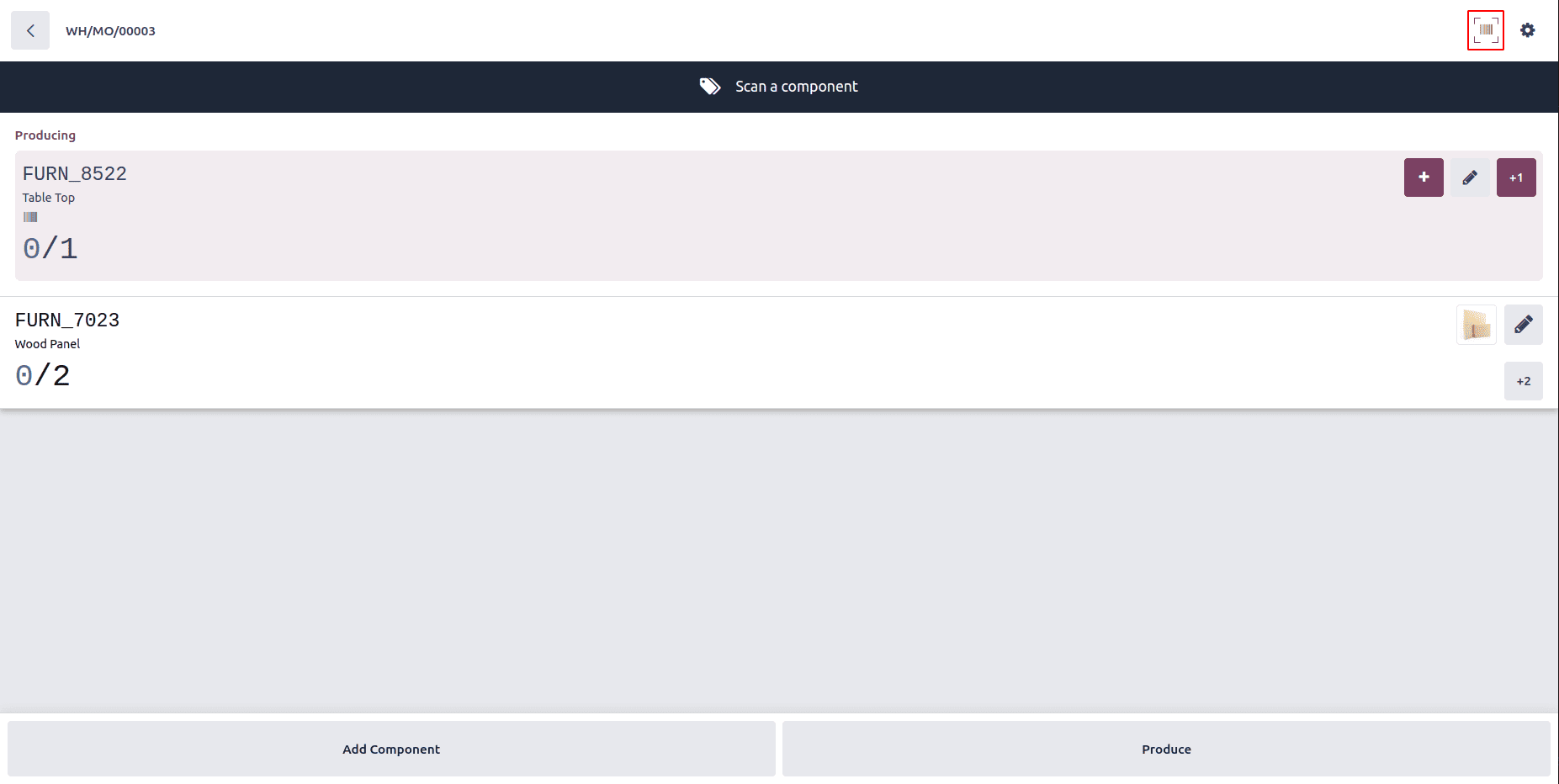

If the scanner fails to work, you can still enter the barcode manually by clicking the Barcode icon at the top-right of the screen. This option allows you to input the barcode manually whenever scanning is unavailable.

The list changes to green once all components are scanned, signaling that the products have been processed without issues.

At the bottom of the screen, two actions are available based on your needs:

- Add Components – Select this if extra products must be added to the operation.

- Produce – Choose this when the operation is ready to be finalized and the finished product can be produced.

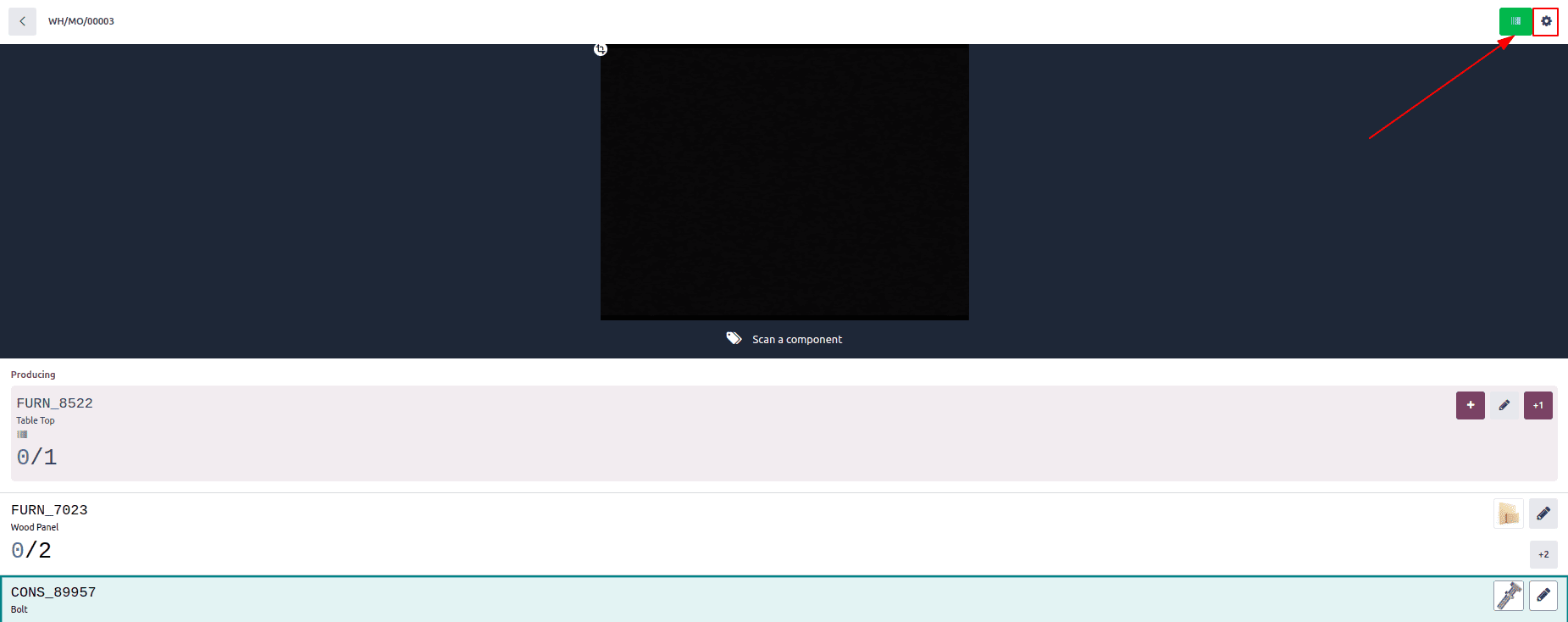

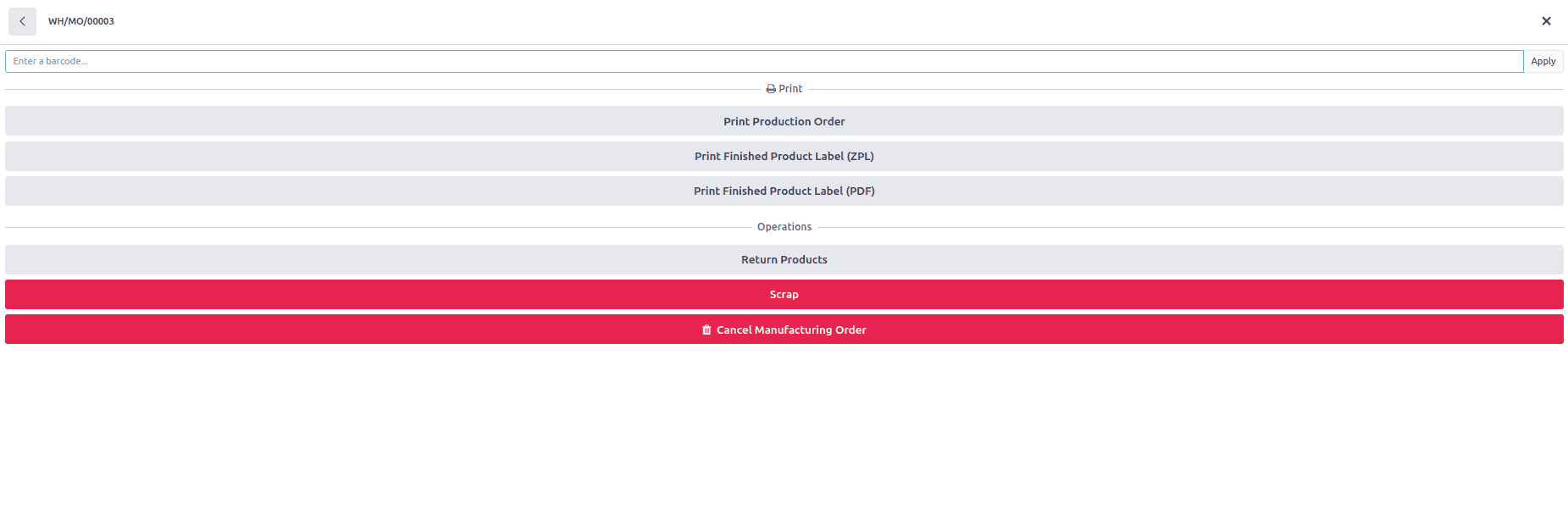

You can access extra actions for the manufacturing order by clicking the gear icon in the upper-right corner of the screen. This menu contains supplementary options related to the order.

The menu provides options such as Print Production Order, Print Finished Product Label (ZPL), Print Finished Product Label (PDF), Scrap, and Cancel Manufacturing Order.

When all components have been scanned, the Produce All button turns green, indicating that every required item is ready for production.

Clicking the Produce All button completes the manufacturing process.

All of these steps can also be managed using a barcode scanner. By scanning the barcode of the manufacturing order, the system opens a window displaying the list of required components. You can then scan each component’s barcode to confirm their availability automatically. Finally, scanning the barcode of the finished product finalizes and validates the manufacturing order.

Using the Barcode application in Odoo makes it possible to handle manufacturing operations more efficiently, ensuring greater accuracy and traceability across the entire process.

To read more about How to Process Manufacturing Orders From Barcode Application in Odoo 17, refer to our blog How to Process Manufacturing Orders From Barcode Application in Odoo 17.