3. Configuration

Warehouse

Management

Warehouse management is one of

the unbiased activities of

the inventory operations of a

firm. For proper running of

the stock operations and

transfers, the warehouses of

a firm must be properly

managed and supervised. Odoo,

as a great inventory

management helper can provide

you with dedicated platforms

for proper management of the

company's warehouses. The

Odoo tools can assist you in

handling multiple warehouses

at a time. The number of

warehouses a company

possesses will vary depending

on the business they conduct.

Regardless of the size and

number of warehouses a

company has, Odoo will always

ensure to simplify the

workflow.

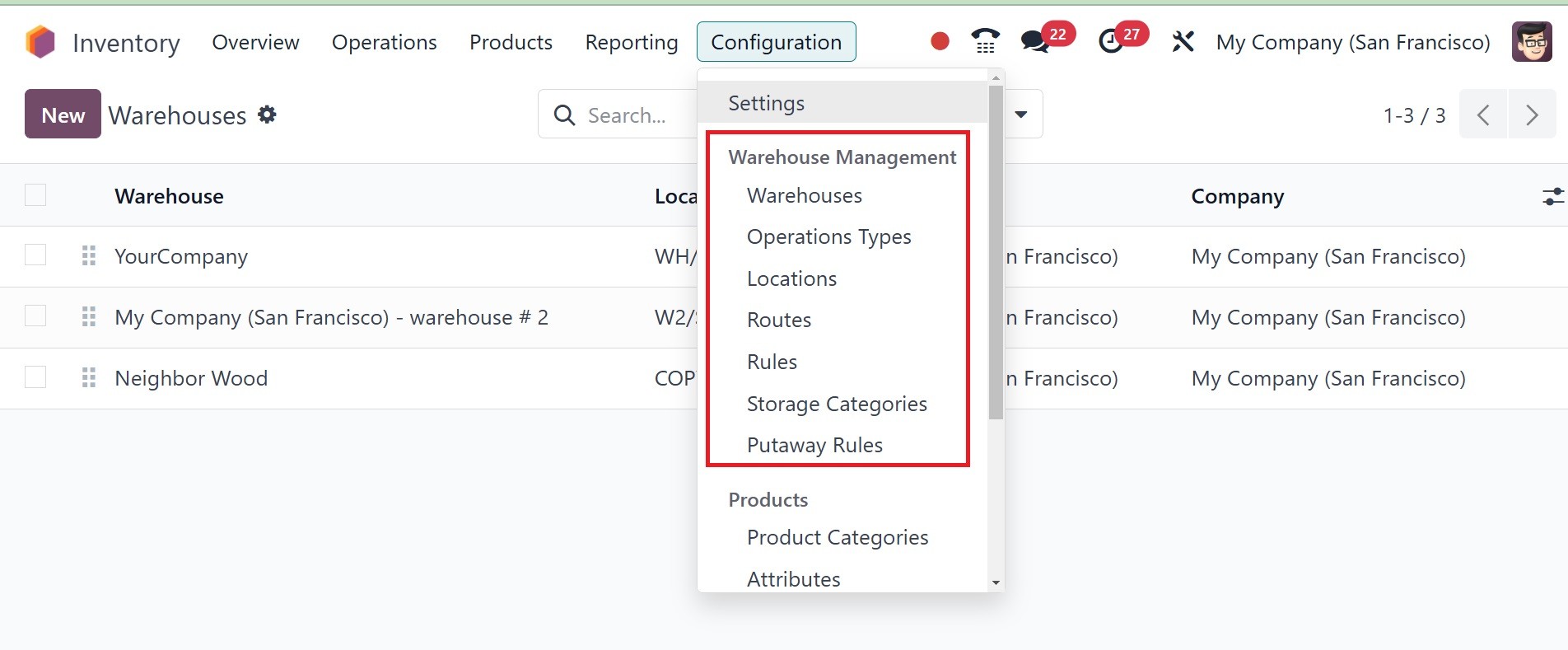

Advanced features like Warehouse,

Locations, Routes, Rules,

Operation Types, Storage

Categories and Putaway Rules

on the Warehouse Management

tab are available in the

Configuration menu of the

Odoo Inventory module.

4.1 Warehouse

These are the options that will

help you execute various

warehouse operations. First,

we need to discuss how to

configure warehouses in the

Odoo 18 Inventory module. To

do this, you can choose the

Warehouses option under the

Configuration menu.

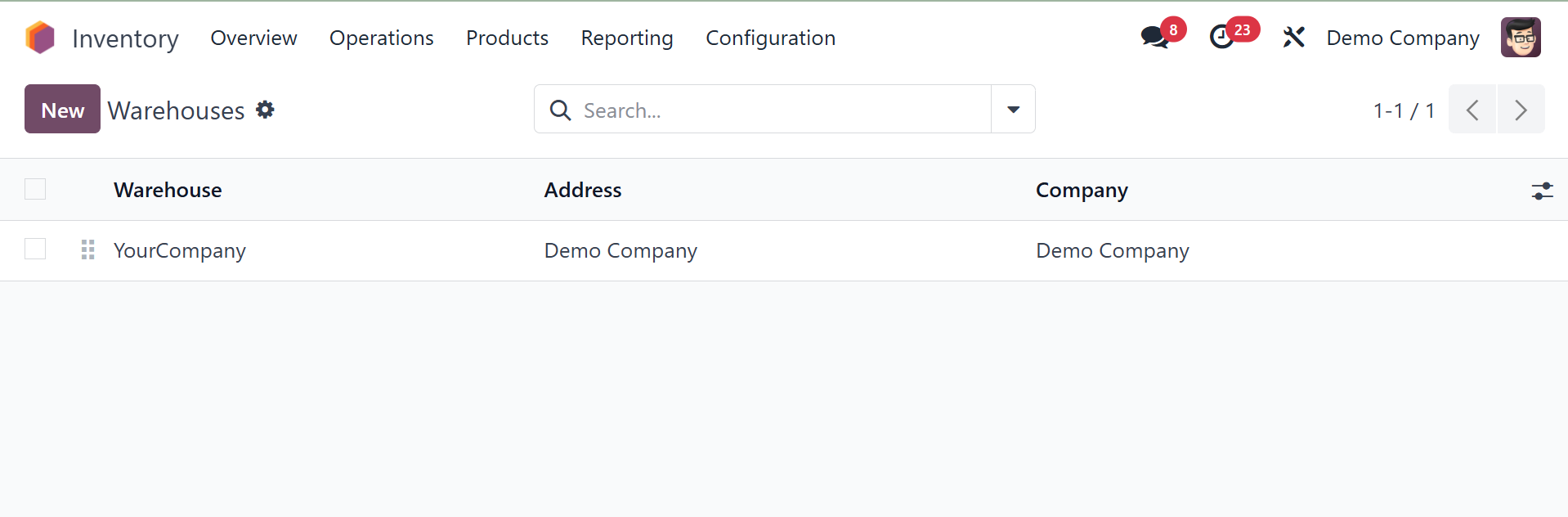

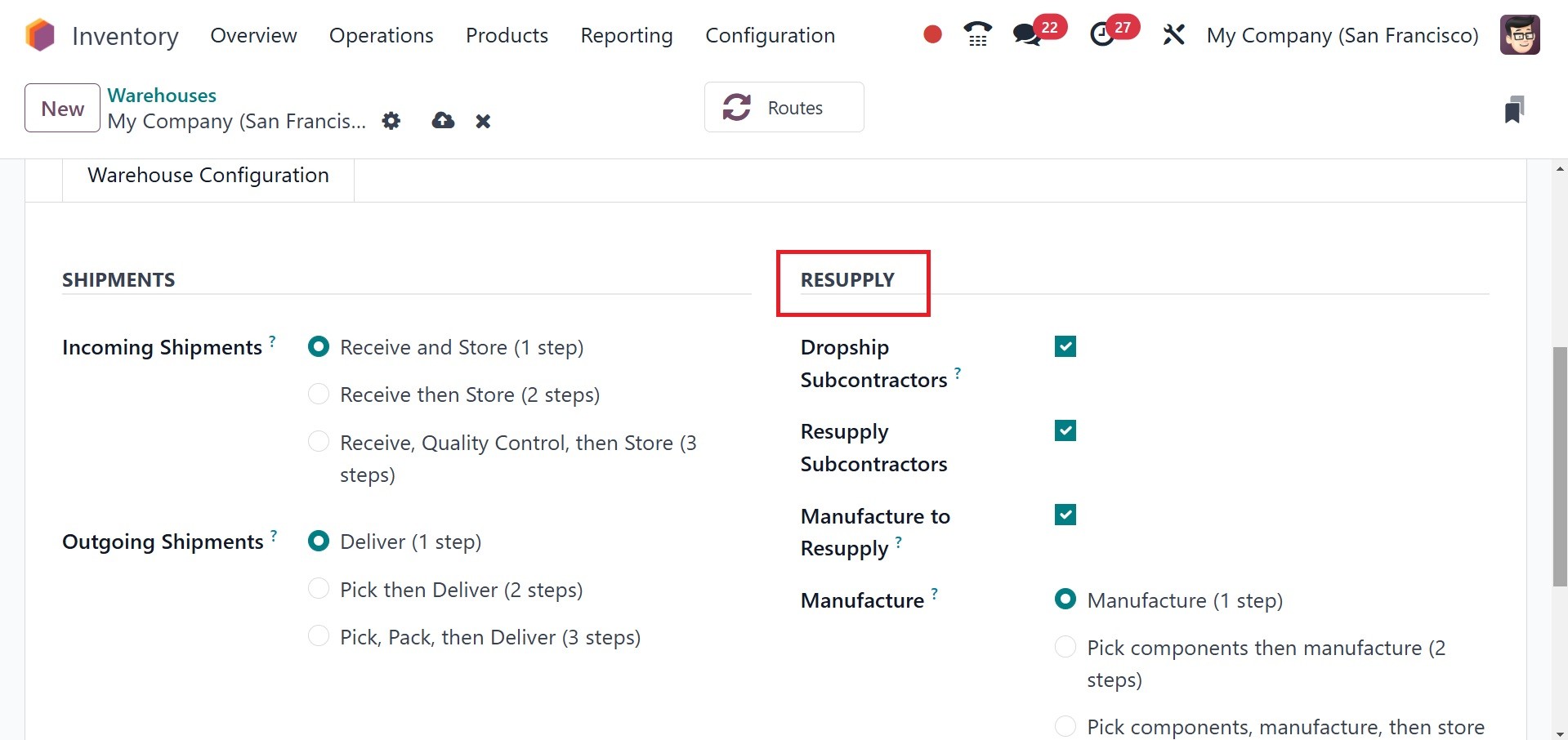

The above illustrated screenshot

is the list view of warehouse

platform. You will receive

the Warehouse, Address, and

Company information from this

view. Utilizing the New

button let's set the details

of a new warehouse to the

Odoo Inventory module.

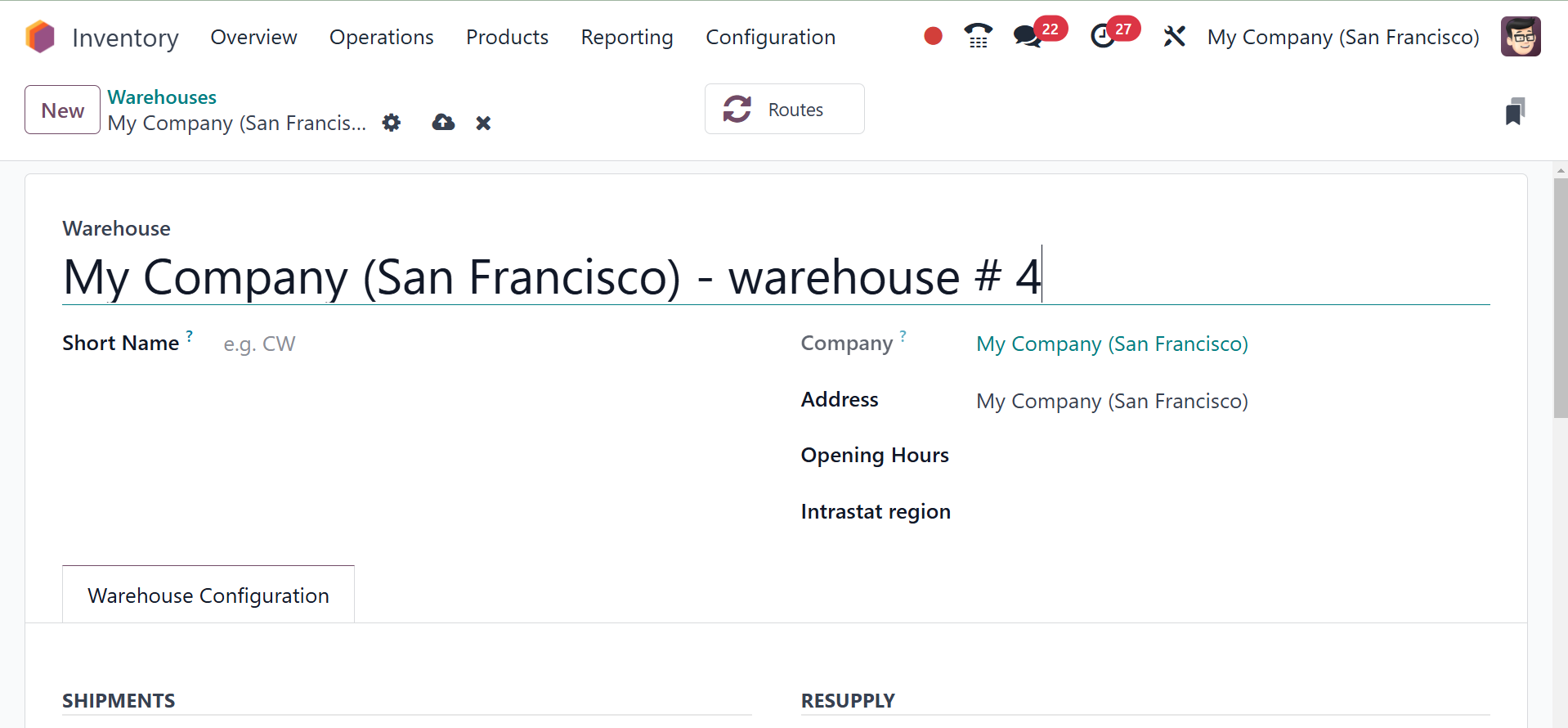

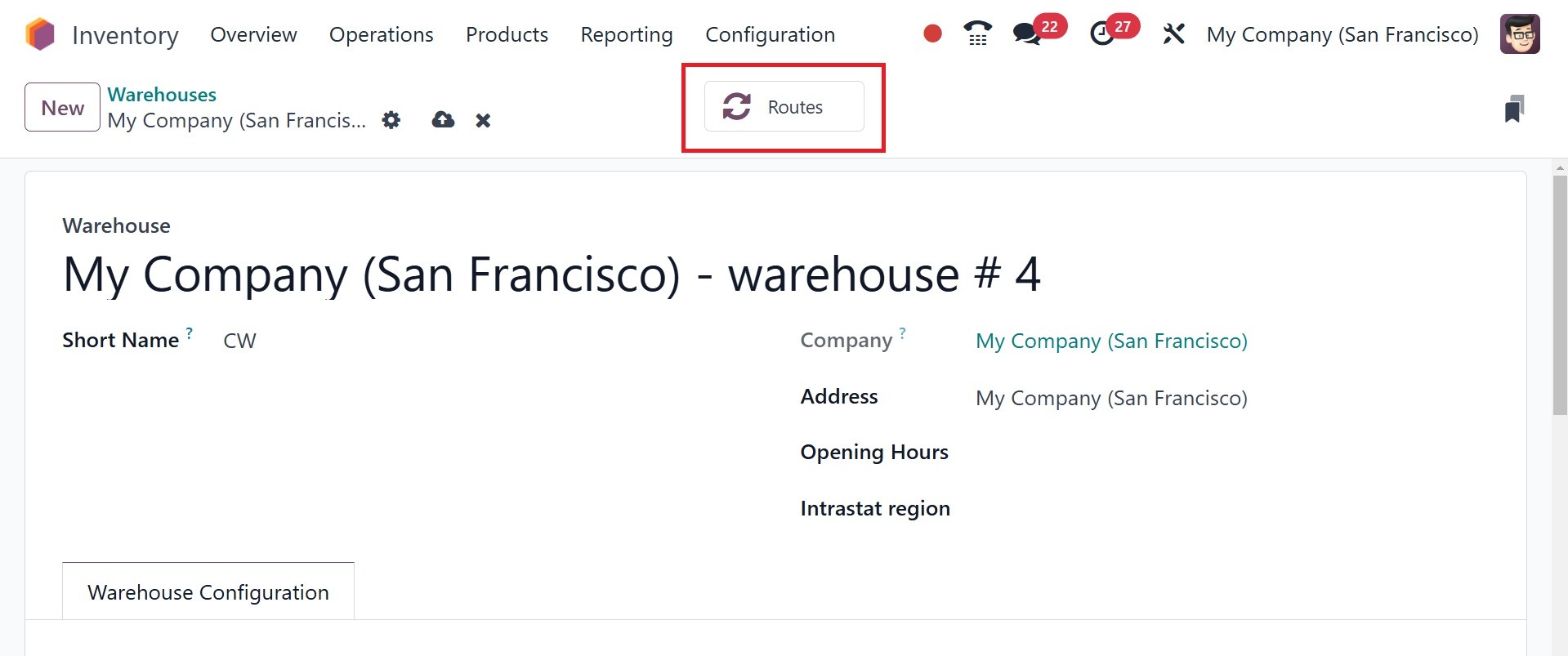

Here, you can enter the

Warehouse, Short Name of the

warehouse, Company, Address,

opening hours, and Intrastat

Region that the warehouse is

part of in the respective

fields. Under the Warehouse

Configuration section, you

are asked to specify the

Shipments and Resupply

information.

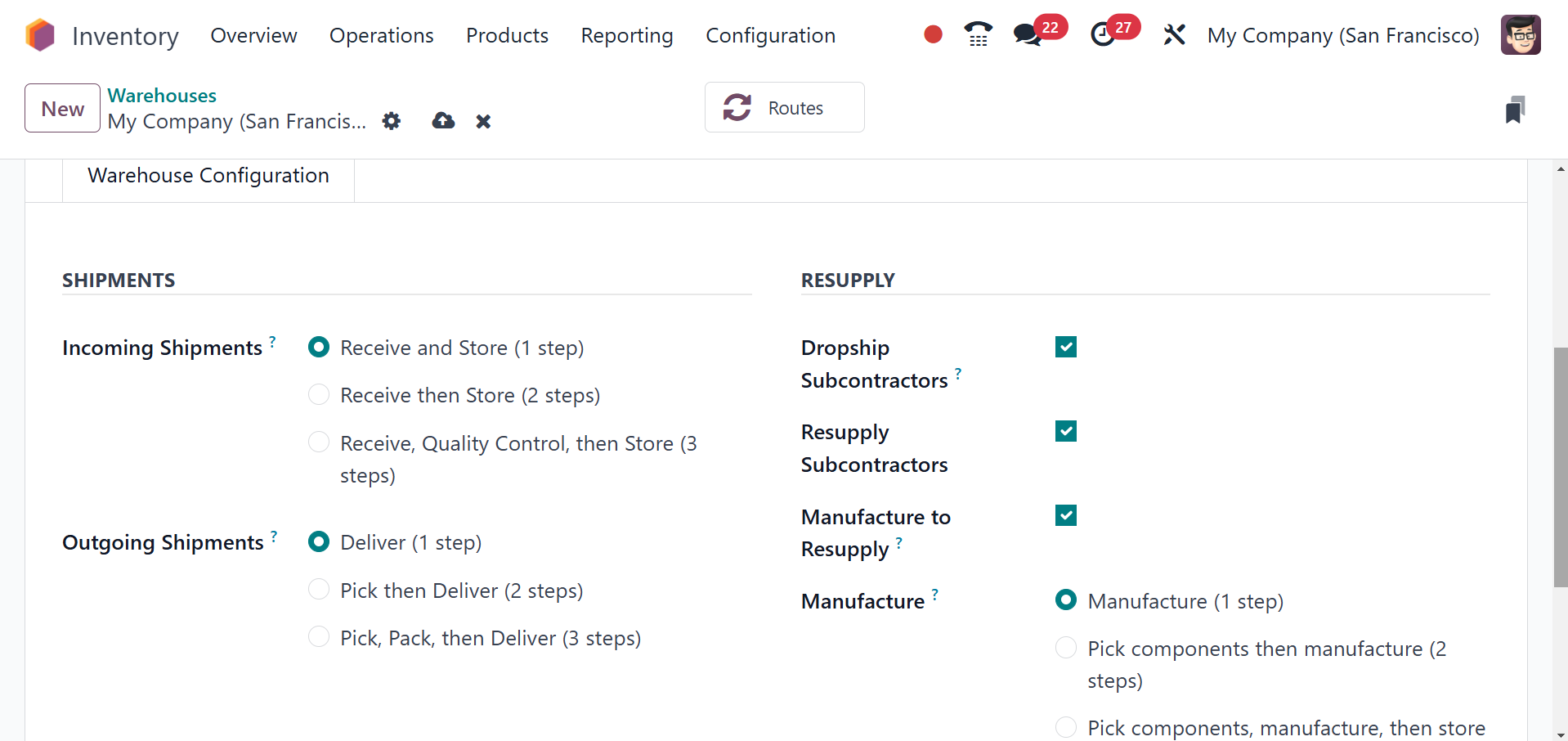

In the Incoming Shipment, you

have the option of how to

handle the incoming shipment

of the products. If you

choose the Receive goods

directly option, you can

receive products directly

into the warehouse. In the

Receive goods in input and

then stock method, the

incoming shipment has

two-step. In this two-step

method, the products will be

received first and then

transferred to the stock.

Once you have taken delivery

of the goods, you can conduct

quality checks on the same

before you stock them via the

Receive goods in input, then

quality, and then stock

method of the incoming

shipment. The same kinds of

options shall be there for

the Outgoing Shipment too and

you shall be able to choose

the appropriate one for this

warehouse's shipment

operations.

With the Resupply tab, you shall

have upgraded features to

switch on.

Enabling the Dropship

Subcontractors feature will

enable you to dropship

subcontractors with

components. The Resupply

Subcontractors can be

employed to resupply

subcontractors with the

components. This will assist

the manufacturer to supply

materials to the

subcontractors when needed.

If the company possesses

numerous warehouses, you can

resupply components from one

warehouse to another with

these features.

You can easily resupply raw

materials in warehouses when

they are demanded. When the

products go out of stock, you

can produce them in the

warehouse to resupply by

enabling the Manufacture to

Resupply option. You will

receive three ways to set

manufacturing procedures. By

choosing the Manufacture

option, you can transfer the

components directly to the

production area and initiate

the manufacturing procedures.

Under the Pick components and

then manufacture method, you

have to go through two steps.

First, you need to unload the

components from the stock to

the input location and then

proceed to the production

location for manufacturing.

Once you have picked the

components and manufactured

the products, you can store

them in the warehouse by

using the Pick components,

manufacture, and then store

products option. Activating

the Buy to Resupply feature,

Odoo enables you to purchase

raw materials to resupply and

stock them in this warehouse.

Clicking the Save button will

save the information of the

newly set warehouse.

The routes management window for

this warehouse's operations

can be accessed by clicking

the Routes smart button in

the upper right corner of the

display.

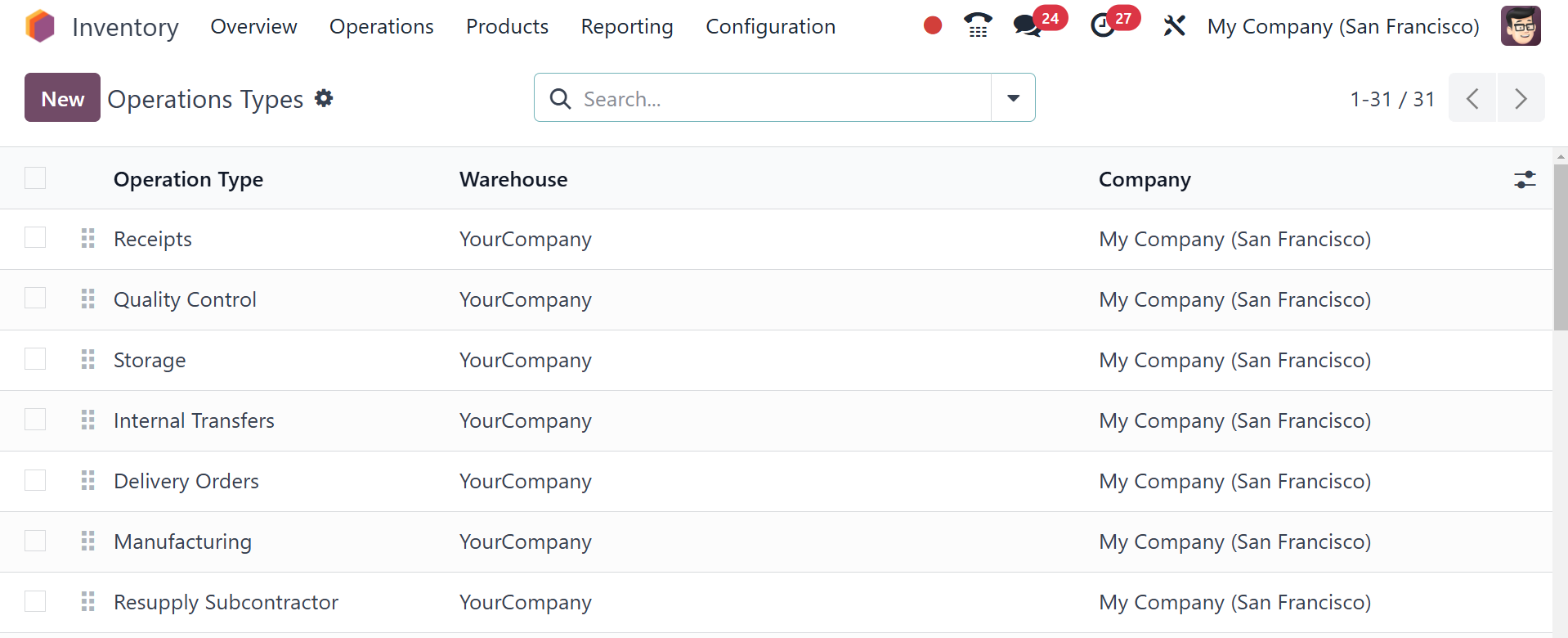

4.2 Operation Types

You may quickly create new

operation types in the Odoo

18 Inventory module with the

help of the specific tools

that are offered in the

module. The Operation Types

menu can be accessed from the

Configuration menu, as seen

below.

When this choice is made, a new

window with details regarding

the operation currently set

up is opened. You can change

the kinds of operations

available by selecting them

from the given list. In this

case, we are going to create

a brand-new Operation Type.

Hence, click the New button.

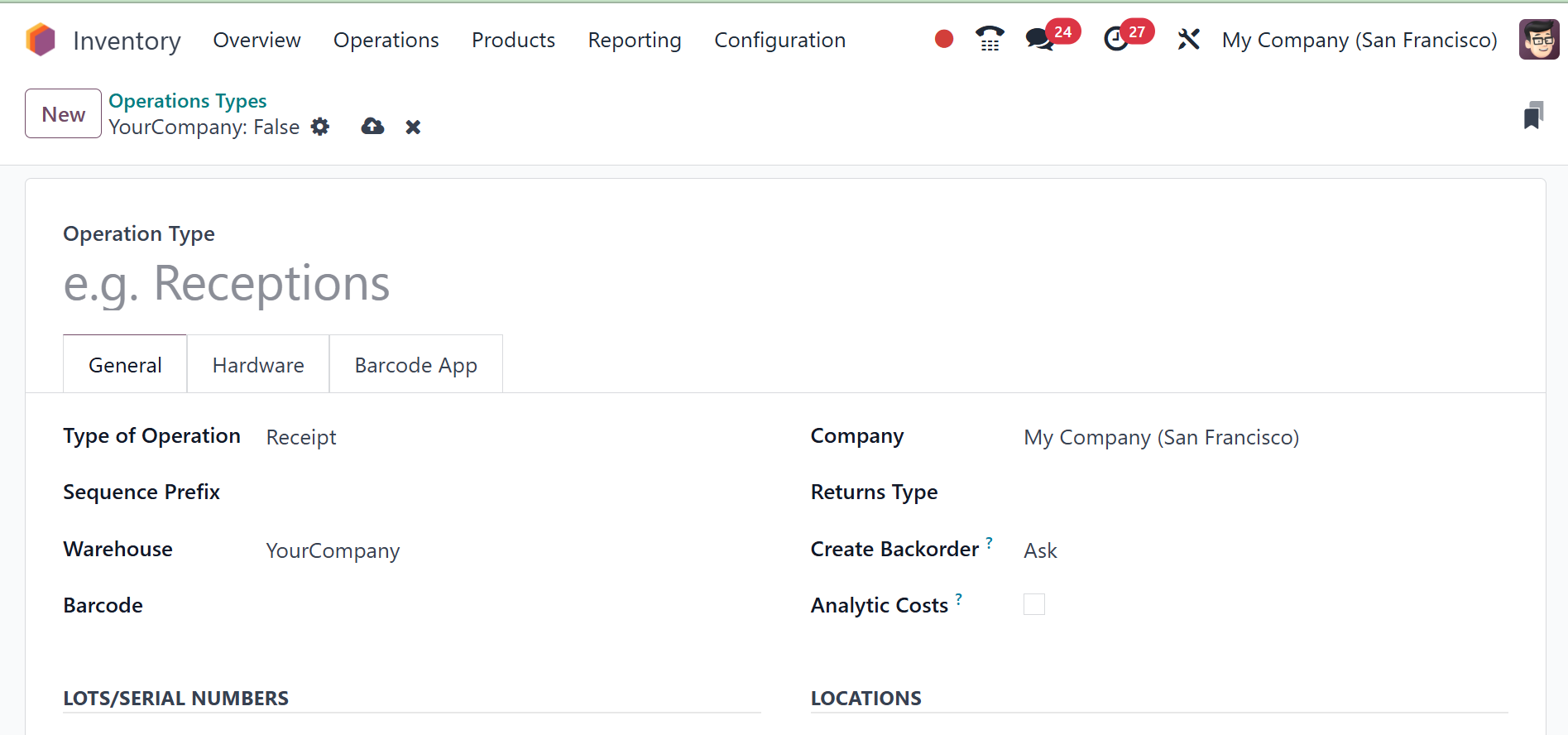

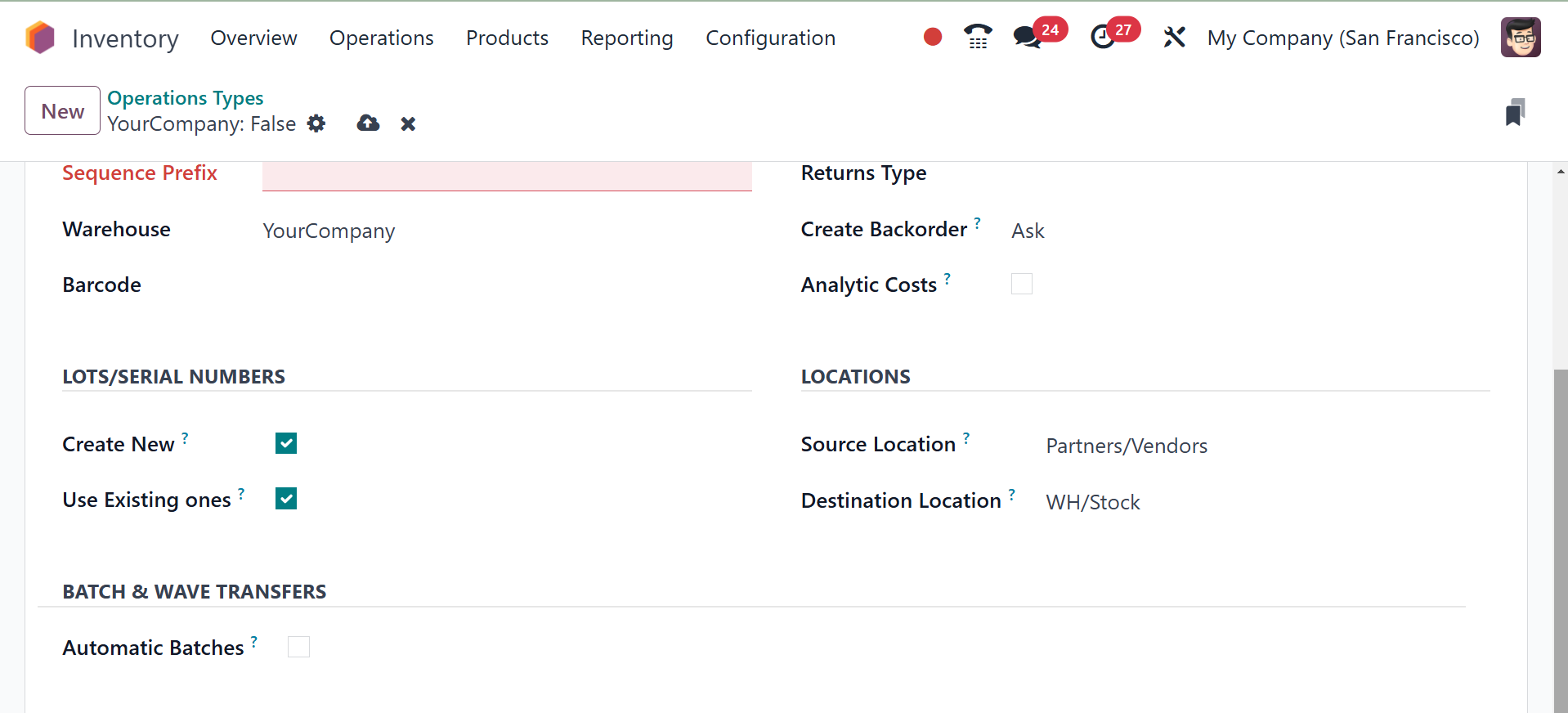

In this window, you can create a

new type of operation. In the

appropriate field, you can

define the operation type. In

the relevant fields, put in

the Sequence prefix,

reservation method, Barcode,

return type, create

backorder, analytic costs,

and Company.

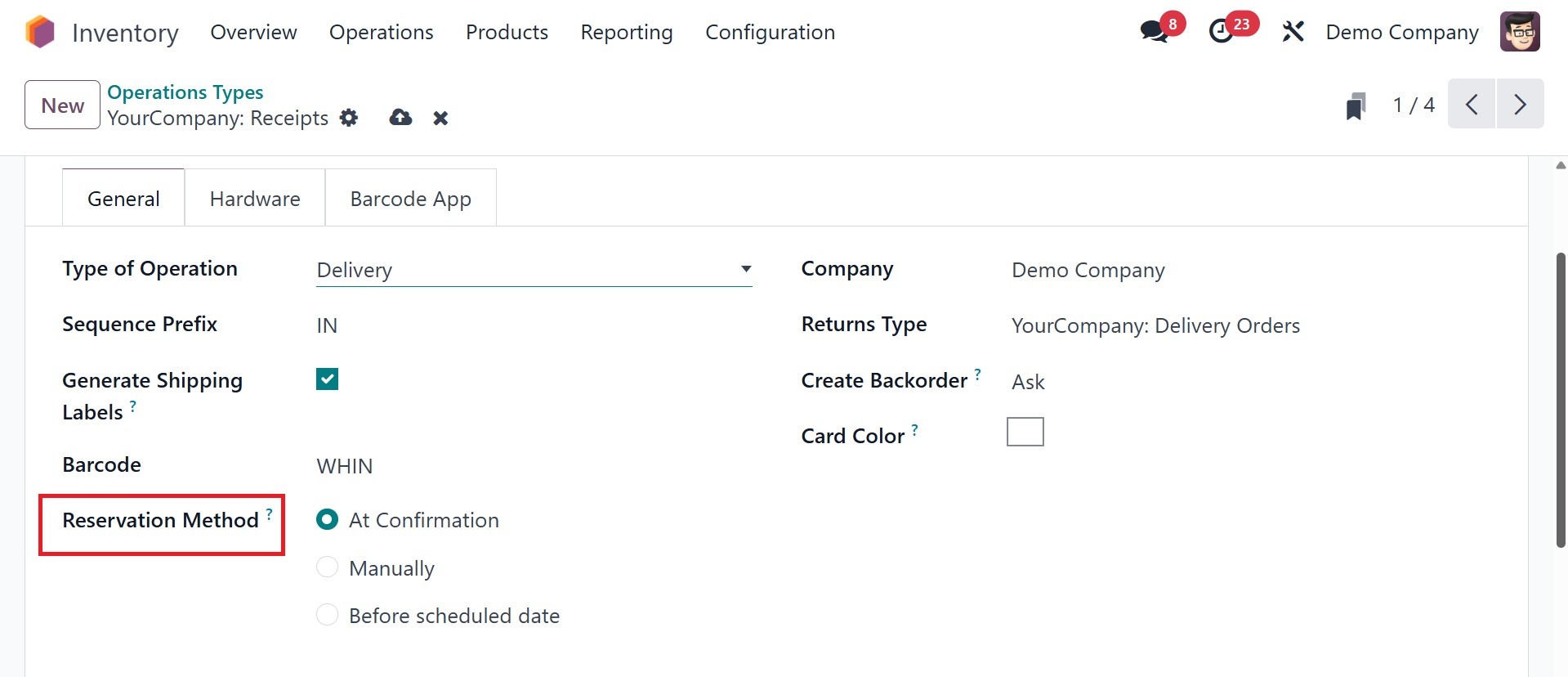

The Reservation Method will

decide the method through

which goods in this kind of

transfers ought to be

preserved.

There, you have the sub options,

like at confirmation,

manually, and before

scheduled date, as in the

above image. That is, It is

possible manually, at

confirmation time, or even

before the reserved date. To

select the 'Ask' choice in

the Create Backorder area

while you confirm a transfer

and ask your clients to

choose if they desire a

backorder on the selected

items. Odoo18 will create a

backorder of the remaining

products automatically if the

'Always' option is selected.

The remaining products will

be canceled if the 'Never'

option is selected. Select

the Show Detailed Operation

option if you want to show a

complete stock operation on

the picking lines.

The related fields on the

Locations tab enable you to

define the Default Source

Location and Default

Destination Location of the

transfers of this operation

type.

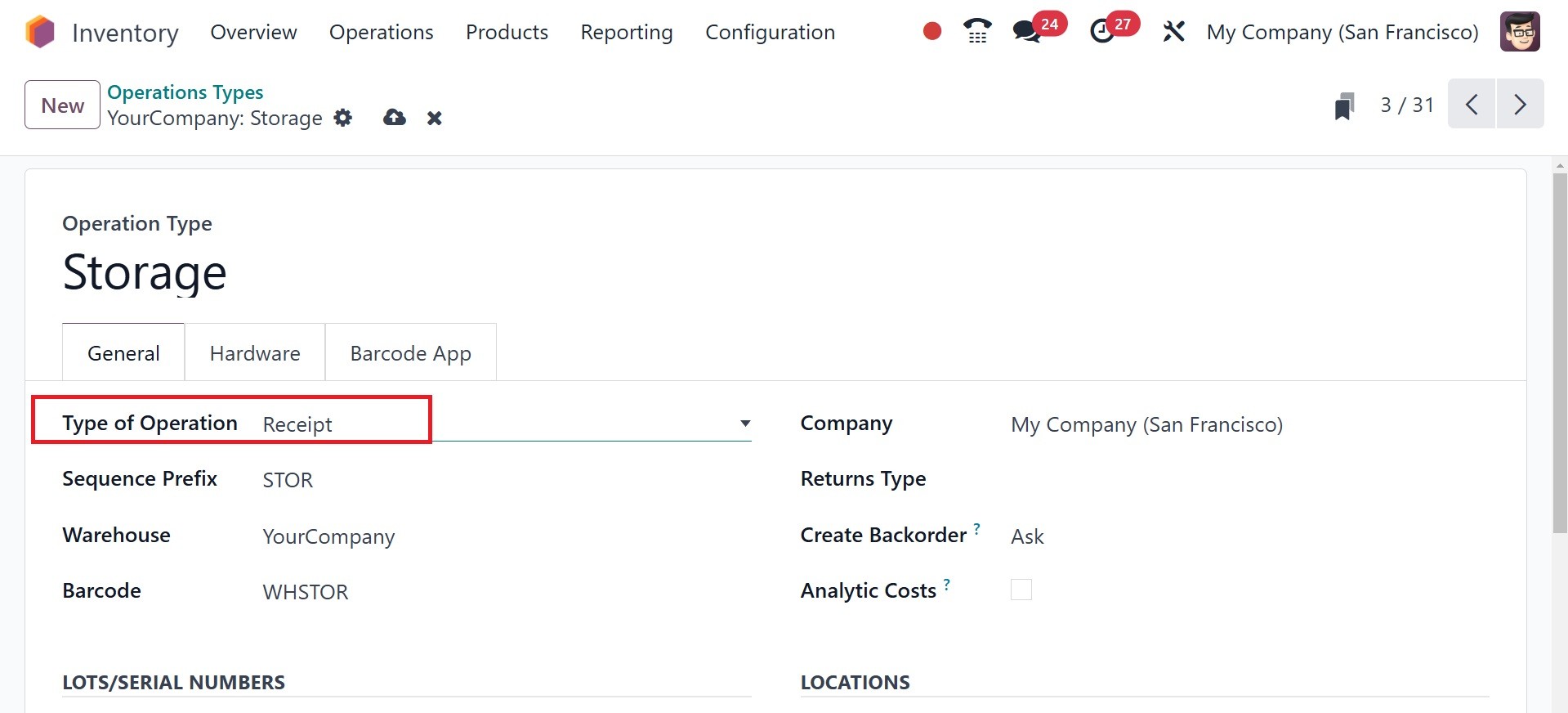

The operation type would be

internal transfer,

manufacturing, delivery, or

receipt. All the other fields

will change by a small

percentage based on which

Type of Operation you select.

There are setup options for

every type of Operation. The

added fields that will appear

on-screen, such as if you

decide to have the type of

operation as receipt, are

mentioned below.

You have the freedom to select

the most appropriate type of

operation in product return

through its insertion into

the Operation Type for

Returns field. The specific

goods, locations, and

lot/serial numbers of

relevance shall automatically

be completed in detailed

operations by Odoo18.

4.3 Locations

There, storage location helps you

to track product location in

your warehouse.You can define

the locations in your

warehouses where the products

are stored using the platform

to set up and control

different locations available

in the Odoo18 Inventory

module. You can control

numerous stock locations

within one warehouse. You

might activate the Storage

Location feature, which will

assist you in monitoring

product location in your

warehouse, from the Inventory

module's Settings menu.

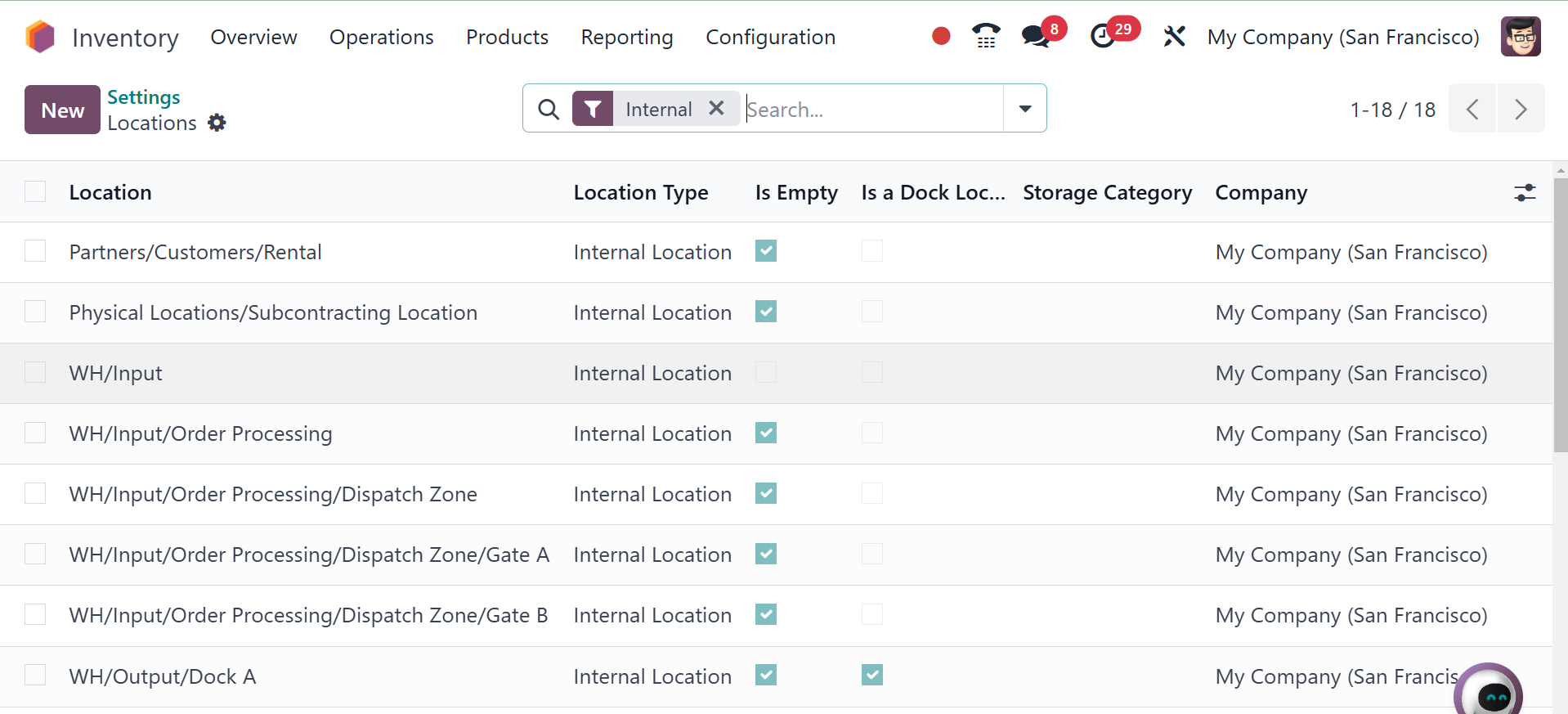

On selecting the location options

there, you will be directed

to the given page.

Information regarding the

Locations, Location Type, Is

empty, Is a dock location,

Storage Category, and Company

is given in this platform's

list view. When discussing

how to create a new location

in Odoo 18, we will consider

each of these options in

further detail. You can

accomplish this by choosing

the New button.

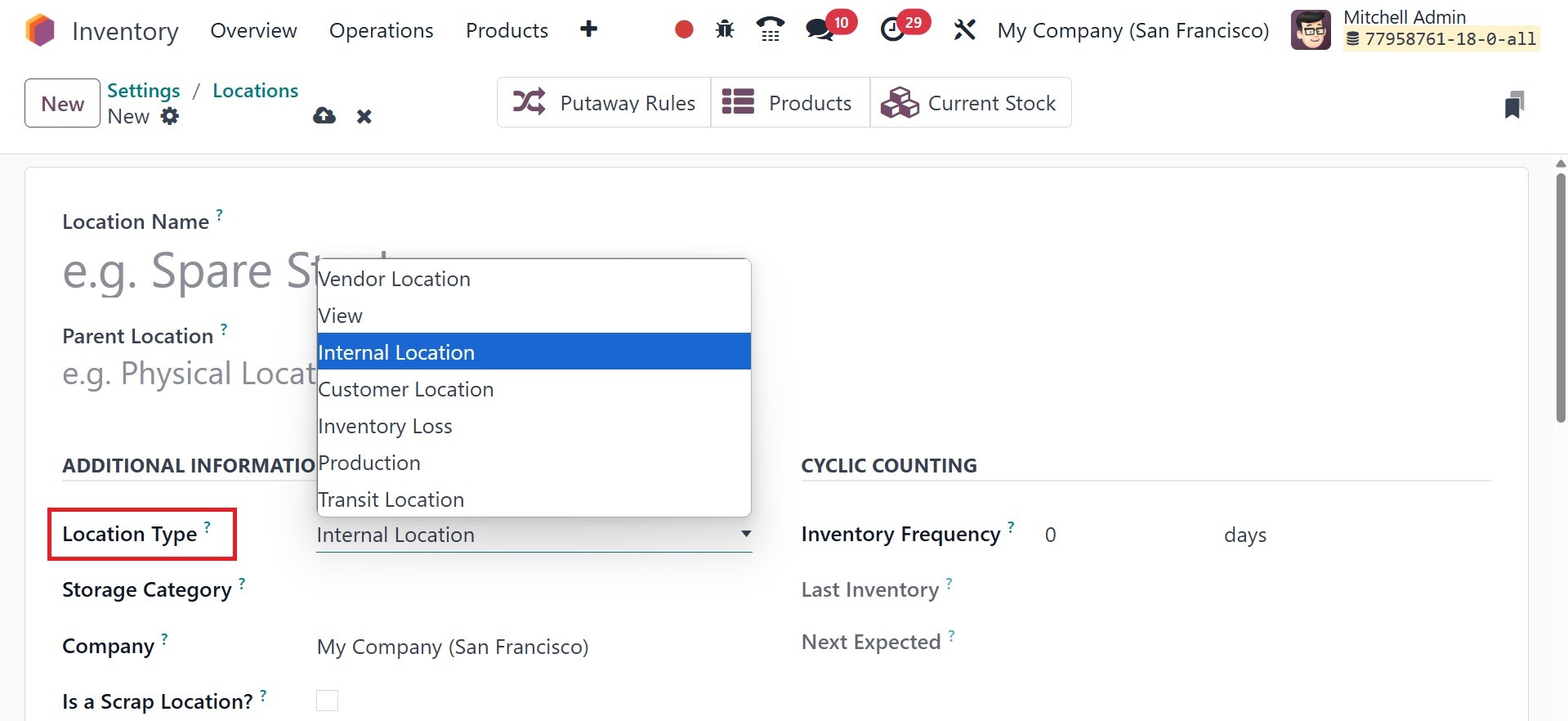

The window to create a new

location is shown above. You

can provide the location name

in the field given here. The

Parent Location option

enables you to enter the

parent location that has this

location. You can select the

parent location from the

drop-down menu. You can

configure the tabs for

Additional information,

Logistics, and Cyclic

Counting. The products stored

at this location will have

the inventory count

automatically set at the

given frequency if it is not

equal to zero. You can select

Location Type for the new one

from the options. The

location types include vendor

location, view, internal

location, customer location,

inventory loss, production,

and transit location.

Vendor location: Represents the

location where goods come

from when you purchase

something.

Internal Location: Represents

your own warehouses or

storage areas.

Customer Location: Represents

where goods go when you

deliver to a customer.

Inventory Loss: Used for stock

adjustments when products are

missing or gained.

Production: Used during

Manufacturing operations.

Transit: Used for dropshipping or

multi-step delivery

View: Not a real location—used as

a parent or container for

other locations.

You can indicate the storage

grouping that is being used

in this location by filling

out the Storage Category

section. If multiple

companies share this

location, you can leave the

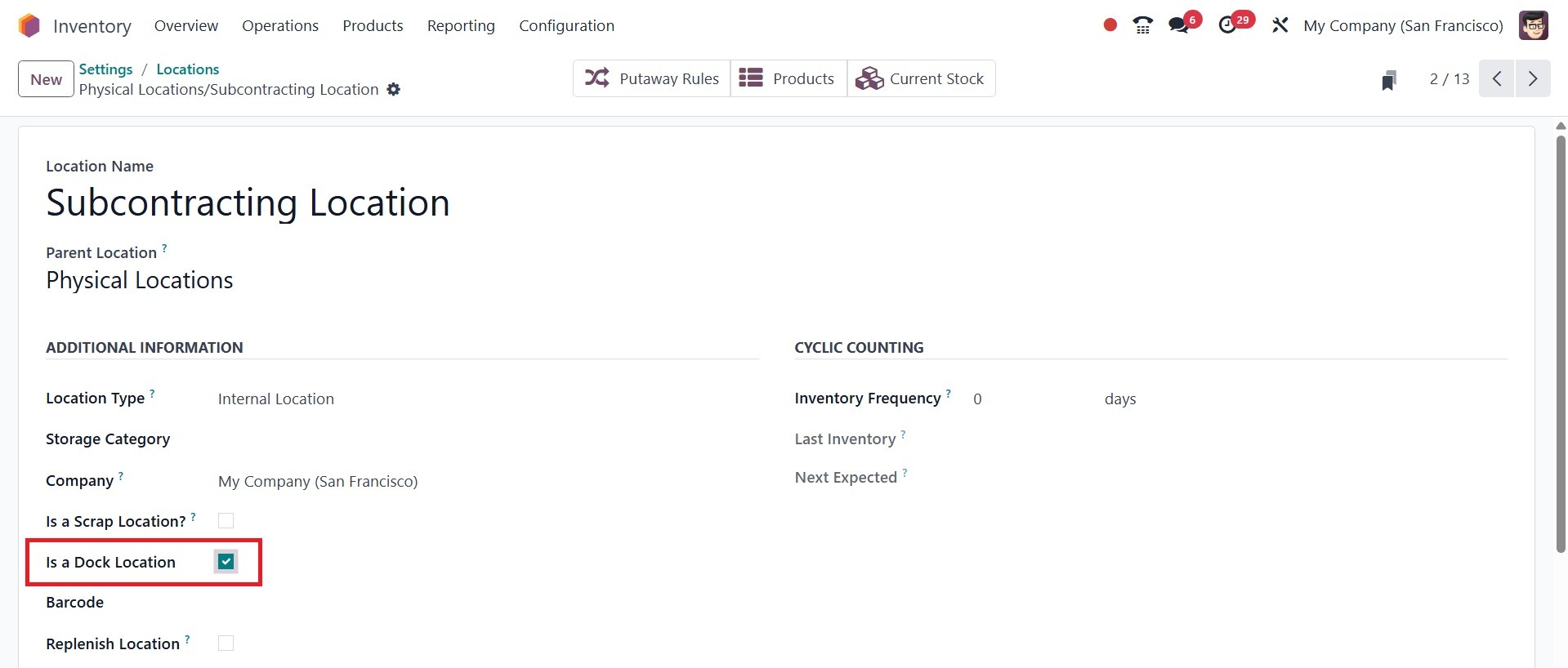

Company box blank. By turning

on the Is a Scrap Location?

option, you can approve the

placement of scrap and

damaged products here. You

can designate a location as a

dock location by checking a

boolean field in the Location

form. This checkbox, located

in the "Additional

Information" section, allows

you to define specific areas

within your warehouse as

loading/unloading docks.

The Barcode field allows you to

enter the barcode that is

used at this site. To have

all amounts replenished at

this place, use the Replenish

Location function.

Add a line to the Cyclic Counting

tab with the label "Inventory

Frequency" in days. The date

of the inventory count for

the items stored at this

location will be

automatically entered at the

designated frequency if the

difference is more than zero.

The date of the last

inventory at this location

will be shown in the Last

Effective Inventory column.

The Next Expected Inventory

field will then show the date

of the upcoming planned

inventory depending on a

cyclic schedule.

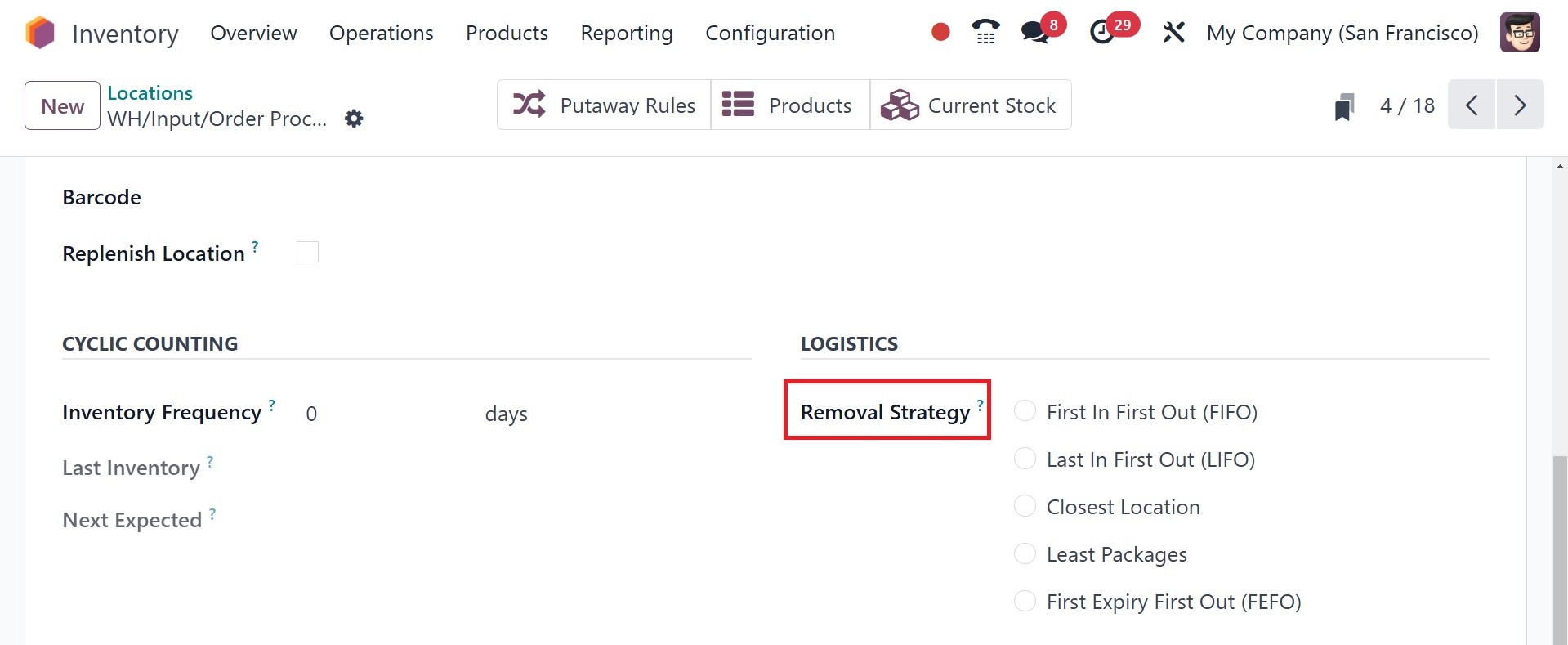

It provides the standard policy

to recommend the exact

location, the lot, etc.,

where the products will be

taken from for this site. In

the event of not being

provided here any parent

locations, there's a fallback

done to the level of the

product category where this

technique may be imposed.

Removal Strategies that can

be utilized here are,

FIFO: Products or lots initially

received will be taken out

first.

LIFO: The last stocked products

or lots will be emptied

first.

Closest Location: The lots or

products closest to the

destination location will be

shipped out first.

FEFO: The products/lots with the

earliest feasible removal

will be emptied first.

Least Packages: Products can be

packed into packages.

Therefore, the smaller

package will be emptied from

the inventory first.

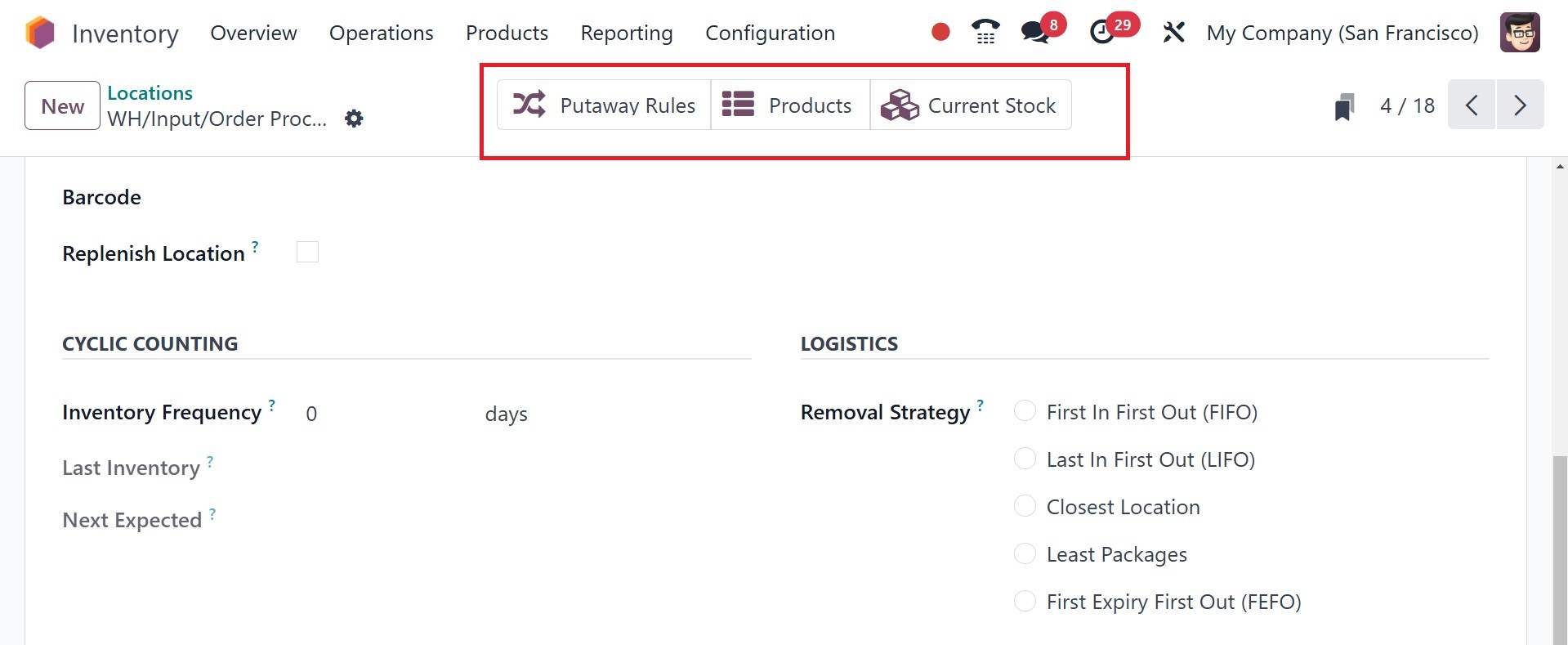

Further, in the window of

location, there are such

special smart buttons for

stocks and putaway rules. The

button of Putaway Rules will

come up with the window of

the instructions to take

products from a place to

another, and Current Stocks

button will give information

of the latest stocks of this

place.

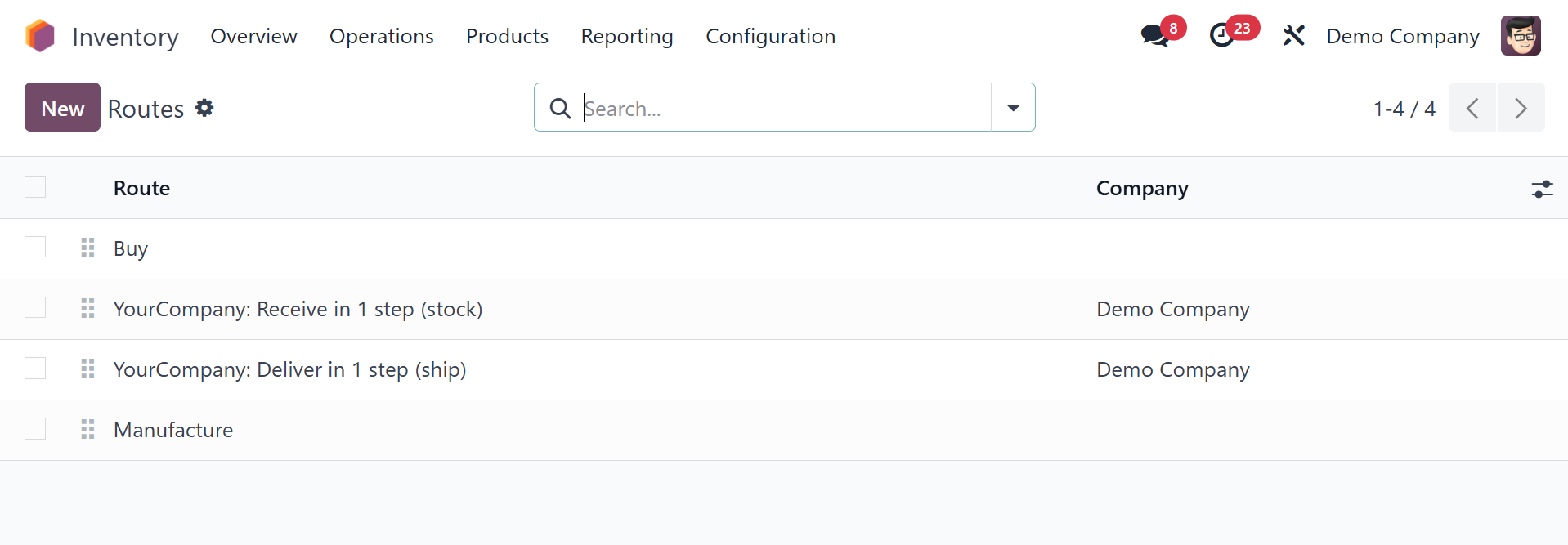

4.4 Routes

The interface for managing and

creating various operating

routes is available via the

Configuration menu of the

Warehouse Management tools in

the Odoo 18 Inventory module.

Besides corporate data and

route names, the user can

navigate a preconfigured list

of routes here.

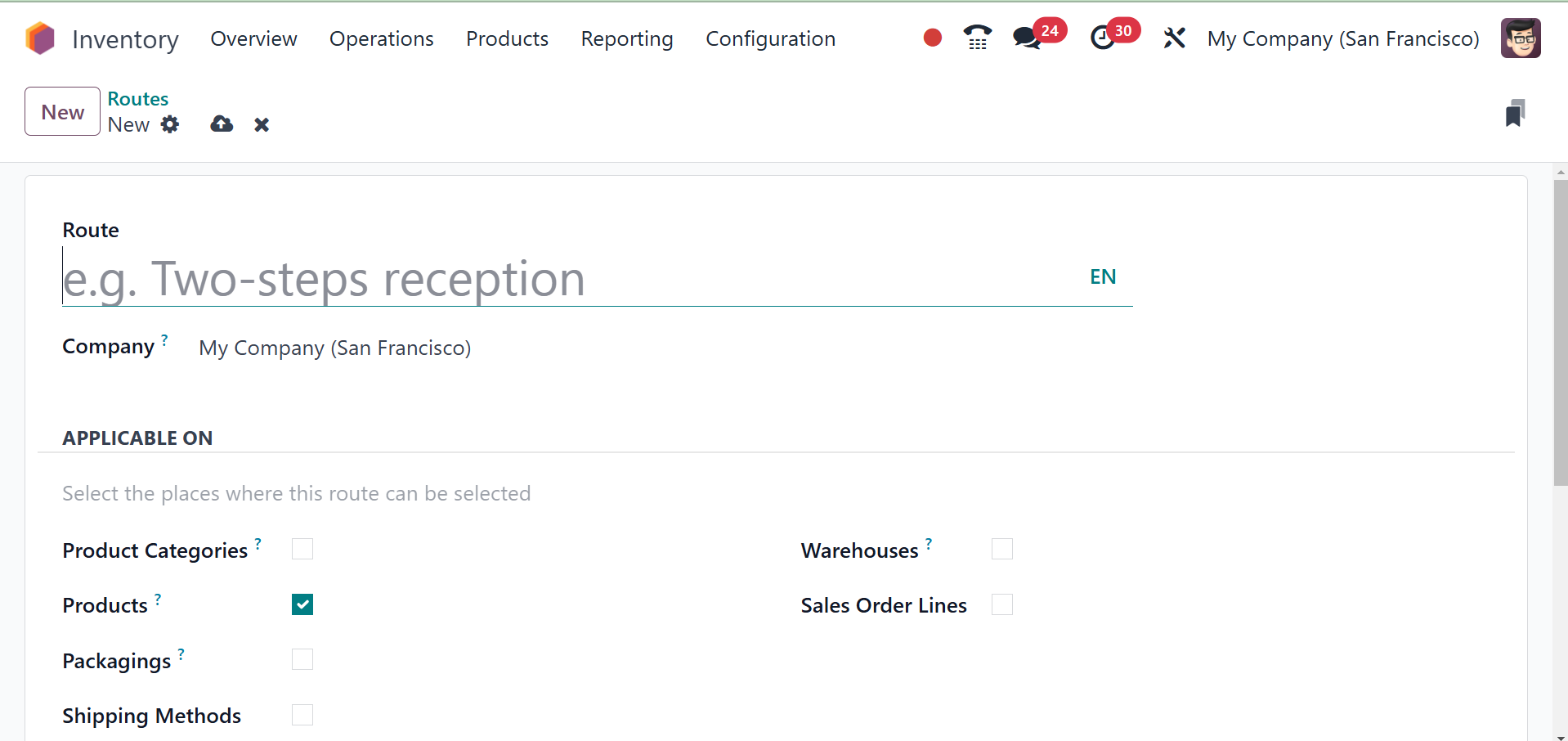

To create a new inventory move

route, select the New button.

You may input the name of the

route in the Route field. The

same fields can also indicate

the Sequence, Supplied

Warehouse, and Company. You

may not fill the Company

field if all companies in

your database utilize the

same route. In the section

Applicable On, you can choose

which areas this route may be

chosen. You may choose from

the Product Categories,

Products, Packaging, Shipping

methods, Warehouse, and Sales

Order Lines provided here in

line with the policies of

your company.

The Add a Line button on the

Rules tab enables you to add

a description of the rules

applied to this operation

path. The steps outlined

above can be utilized to

create new rules for this

route. Don't forget to save

the changes by clicking the

Save button at the end.

While configuring, you can define

a specific operation path for

every product in the Odoo

database. You can find a

particular field on the

Inventory tab of the products

management window, as

depicted below, and choose

the best path for a product's

inventory movement.

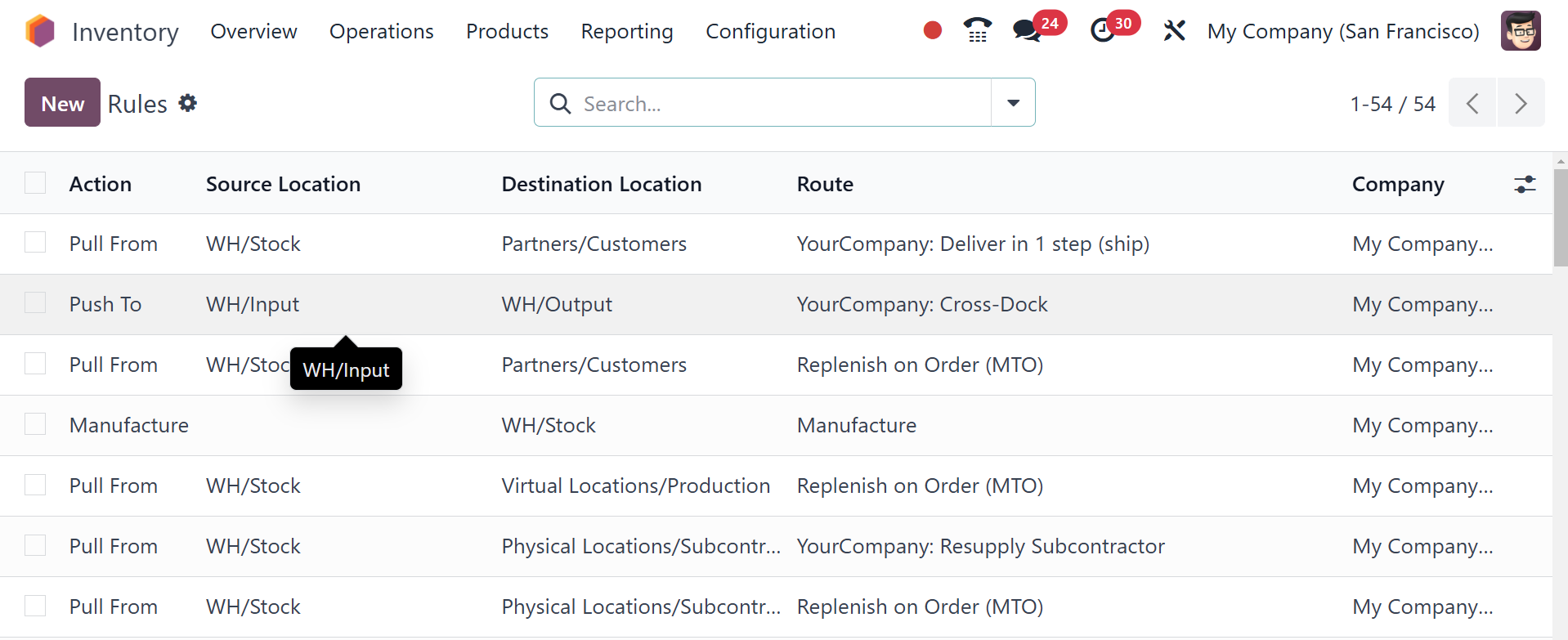

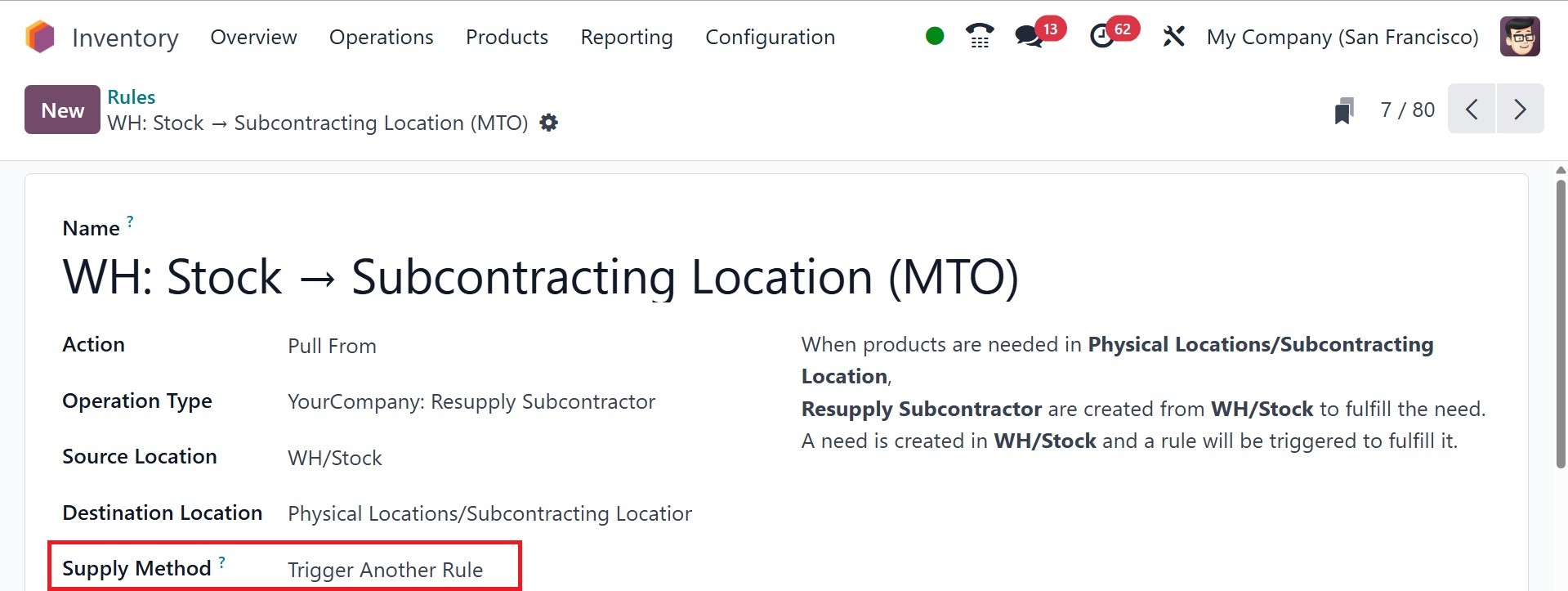

4.5 Rules

The user is able to add new rules

for inventory movements via

the Inventory module's

Configuration menu. By

selecting the Rules option

from the Warehouse Management

menu, as shown below, a new

window with the list view of

the already configured Rules

is opened.

This preview shows the Action,

Source Location, Destination

Location, Route, and Company

information for each Rule.

Similar to other platforms,

Odoo makes sure that the core

and flexible GroupBy and

Filters capabilities are

available to enable

searching. You can go ahead

and click the New button

right away to see how to

create a new rule in Odoo 18.

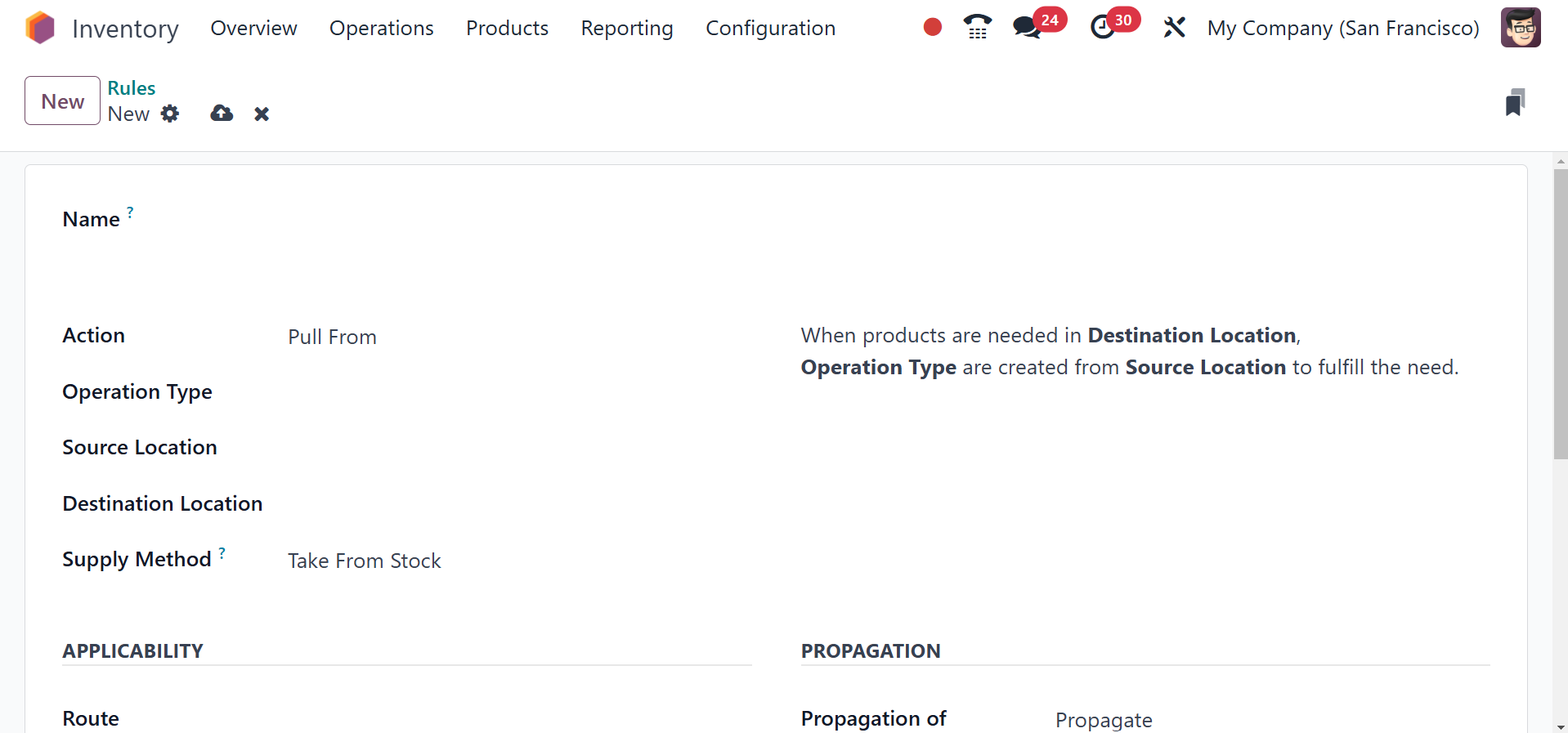

In the Name field, you can enter

an appropriate title for the

new rule. The second step is

to specify the Action for the

new rule. There will be a

drop-down menu where you can

choose the appropriate action

to perform.

Pull From: This action can be set

when goods are required in

the desired location. It may

be from a manufacturing order

or a sales order. In case

there is a requirement for a

product at the destination

point, Odoo will create a

picking operation type from

the source point to fulfill

the need.

Push To: Using this rule, you can

move a product. When the

items have arrived at the

beginning point, you can

transport them to another

location using this action.

Odoo will create a pickup

operation type to ship them

to the destination in this

instance.

Push and Pull: This is an

activity that can be applied

in the above-stated

situations. A pick is taken

from the source location when

products are required at the

destination point.

Specifications of products

are thus needed at the origin

area. After the source point

has met the requirements,

products are pushed to the

destination point to respond

to the needs of the

destination point.

Manufacture: Users can directly

create manufacturing orders

to fulfill the requirements

of the source location with

the assistance of this task.

Buy: When the product is required

at the destination place,

Odoo will utilize this action

to fetch a quote for the

purchase of the product.

The fields below enable you to

select the operation type,

source location, and

destination location. In the

Applicability tab, you can

specify what Route,

Warehouse, Company, and

Sequence this rule is applied

to. The supply method option

determines how a product is

sourced to fulfill a demand,

especially when using

push/pull rules. It dictates

whether the product is taken

from existing stock or if

another rule is triggered to

resupply.

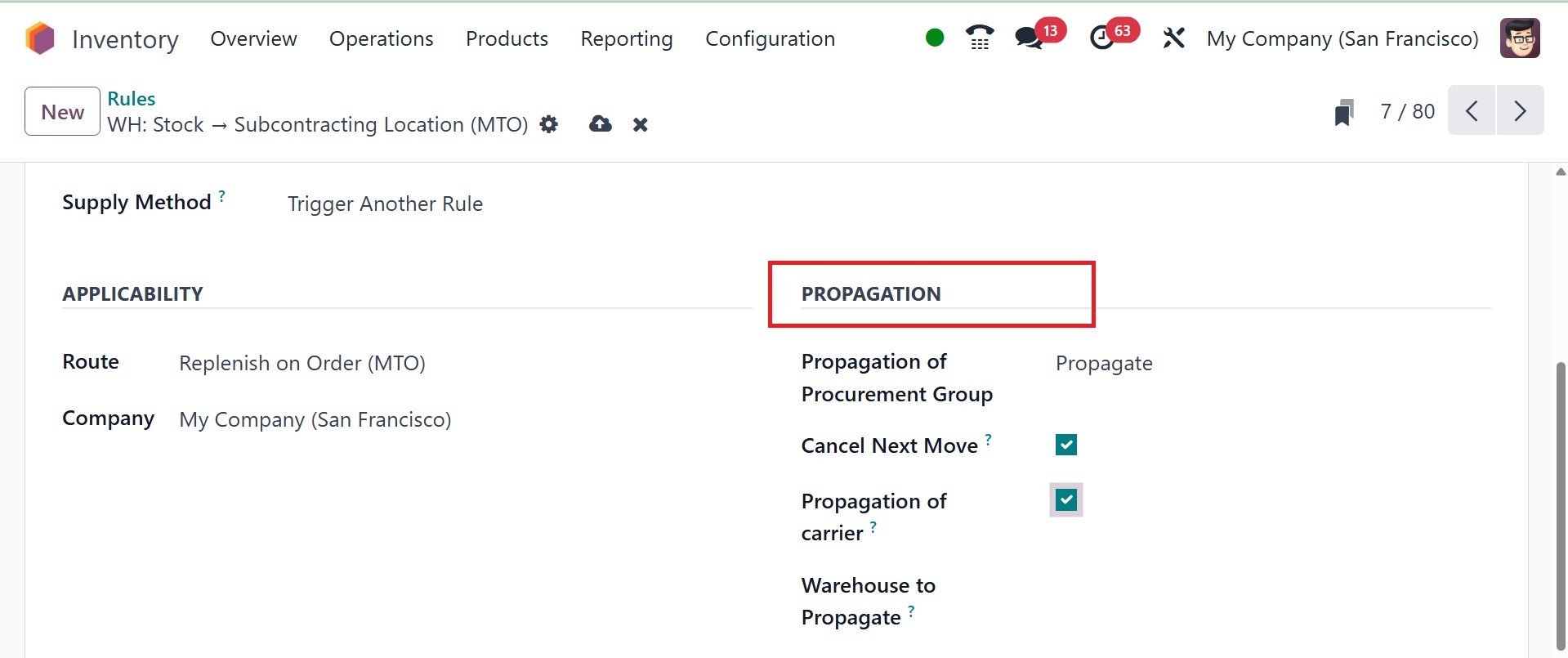

The "Propagation" tab within a

rule defines how the

procurement group associated

with a move or procurement is

handled. It allows you to

choose how related transfers

are linked and determines

whether a specific

procurement group is applied

to all transfers. In the

Propagation tab, you can

select Empty, Fixed, or

Propagate for the propagation

of the Procurement Group.

If the Cancel Next Move is set,

the move that this rule

created will be canceled and

so will the next move. When

the carrier propagation is

turned on, the cargo carrier

will propagate. For a new

move or procurement, you can

specify another warehouse in

the Warehouse to Propagate

field than the one for this

rule.

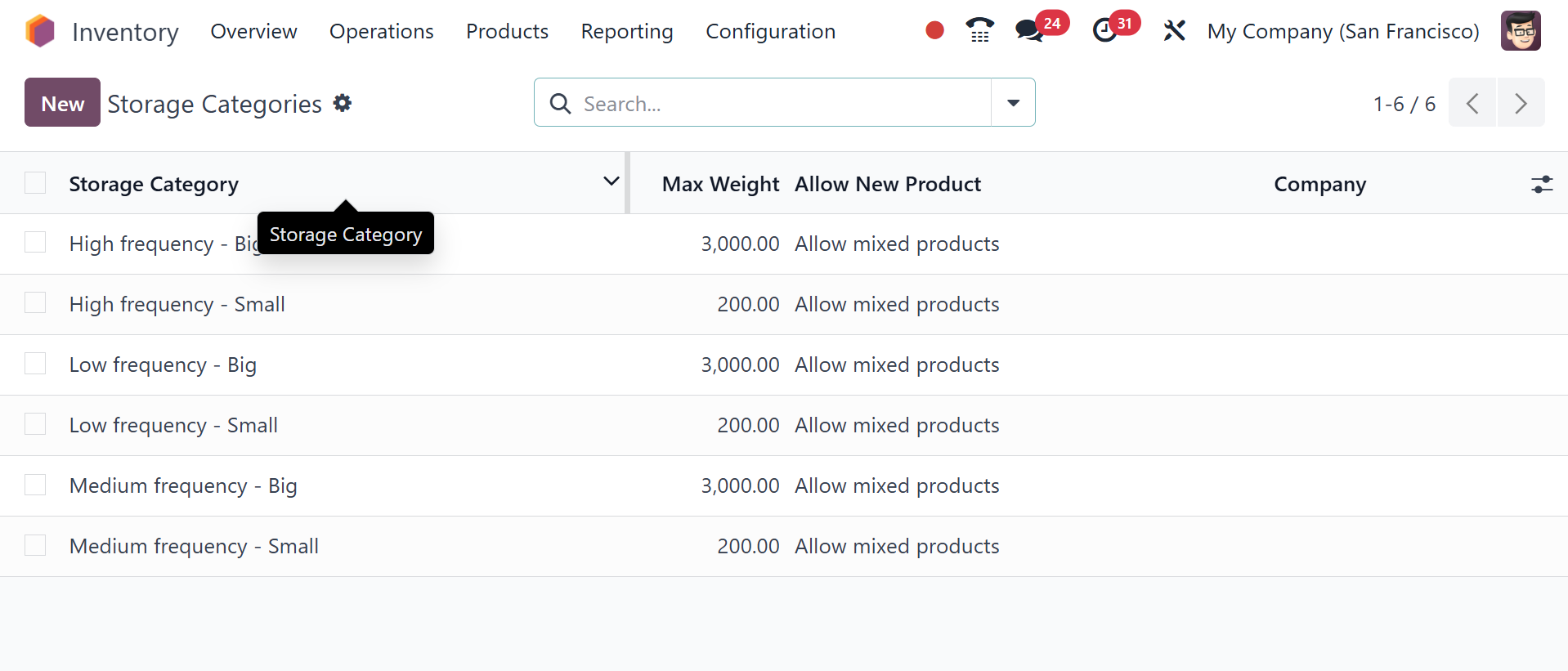

4.6 Storage Categories

The Storage Categories

functionality in Odoo will

enable you to consolidate

numerous storage locations

under one category. You can

define numerous such

categories in the Odoo

Inventory module that will be

useful to execute intelligent

put-away operations.

Prior to configuring the storage

categories, you need to

configure the storage

locations that are present in

your inventory. Then you can

consolidate them under a

particular category. By

enabling the Storage Location

from the Settings module, you

are able to create and manage

all storage locations in your

business. Once you enable

this feature, you will

receive an extra field

referred to as Storage

Categories below to specify

different categories for the

available storage.

This window's list view will

display the information

concerning the available

Storage Categories, Max

Weight, Allow New Product,

and Company. To add a new

storage category, we can make

use of the New button.

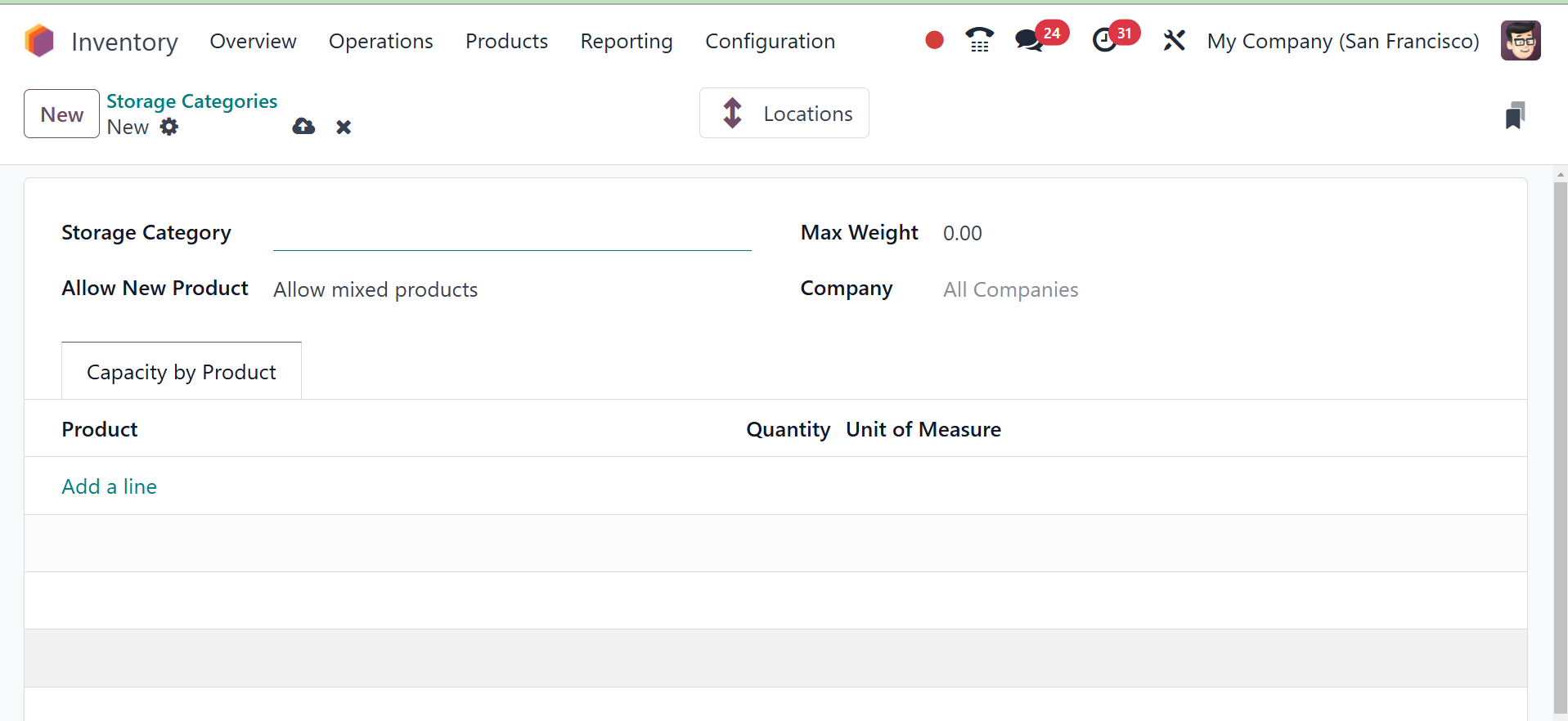

The name of the new storage

category can be entered in

the provided space. In

addition to this, you can

enter the maximum weight that

can be stored under this

category. If you wish to

permit new products to the

locations under this

category, you can provide

conditions for this in the

Allow New Product field. You

can permit new products if

the location is vacant, if

all products are identical,

or permit mixed products.

In the Capacity by Package field,

you can refer to the Package

Type and its Quantity using

the Add a line button that

can be added in this

category. The products that

can be added to this storage

category too, can be

indicated in the Capacity by

Products tab. Saving via the

Save button will add a new

storage category for your

inventory. The intelligent

Location button will provide

the information of the

location that has been

included under this specific

category.

4.7 Putaway Rules

An effective warehouse management

system is responsible for

products being kept at the

right location in the

warehouse. If the warehouse

holds risky and hazardous

items, you ought to take them

under your protection by

providing them with a

separate place where you can

keep them away from contact

with other goods. For

performing these operations

automatically, the Odoo

Inventory module brings

forward the Putaway Rules

that will guide you in

pushing goods to rightful

locations. This aspect will

prevent improper storage of

items in your inventory. With

the putaway rules, you can

move items from the receiving

locations to the most

suitable location in the

warehouse itself.

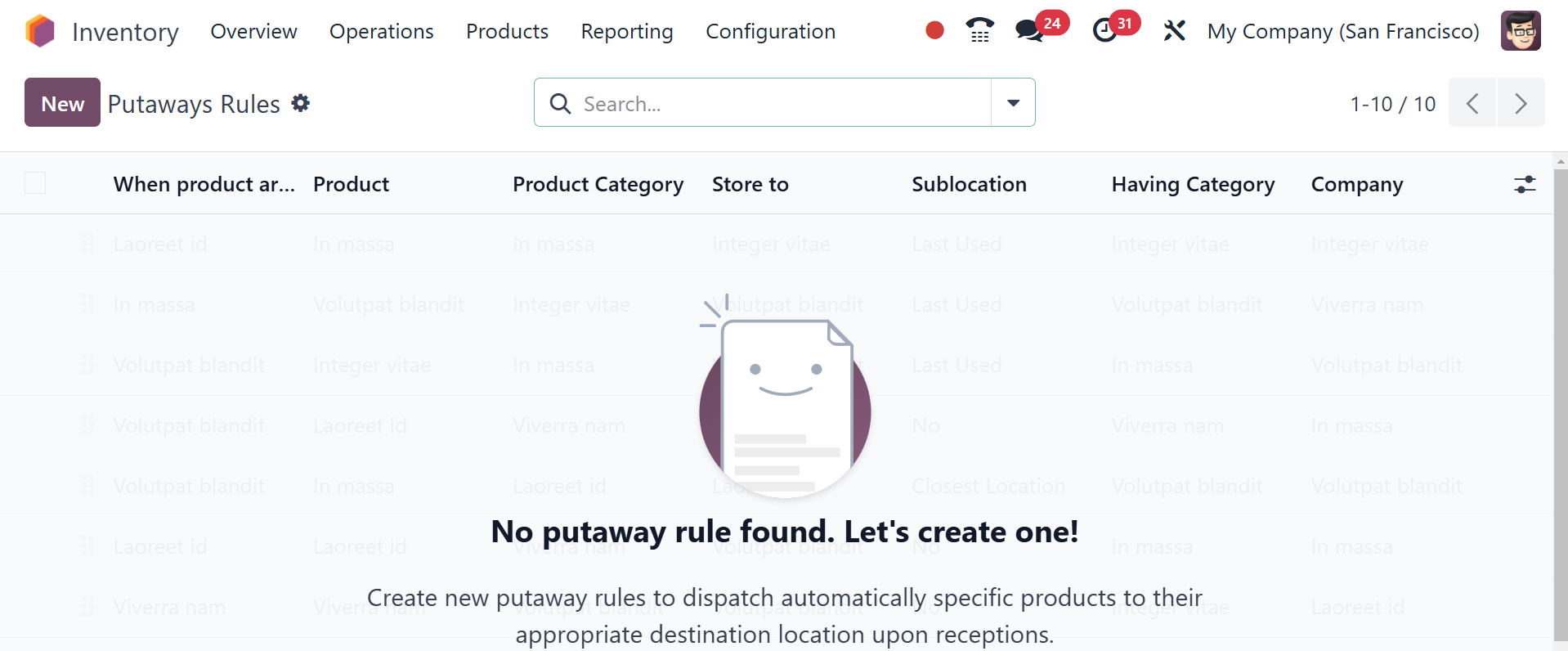

The Putaway Rules window can be

opened through the

Configuration menu of the

module. The following

screenshot presents the list

of previously set putaway

rules. In this, you will be

provided with the information

of When the product arrives

in, Product, Product

Category, Package Type, Store

to sublocation, Having

Category, and Company.

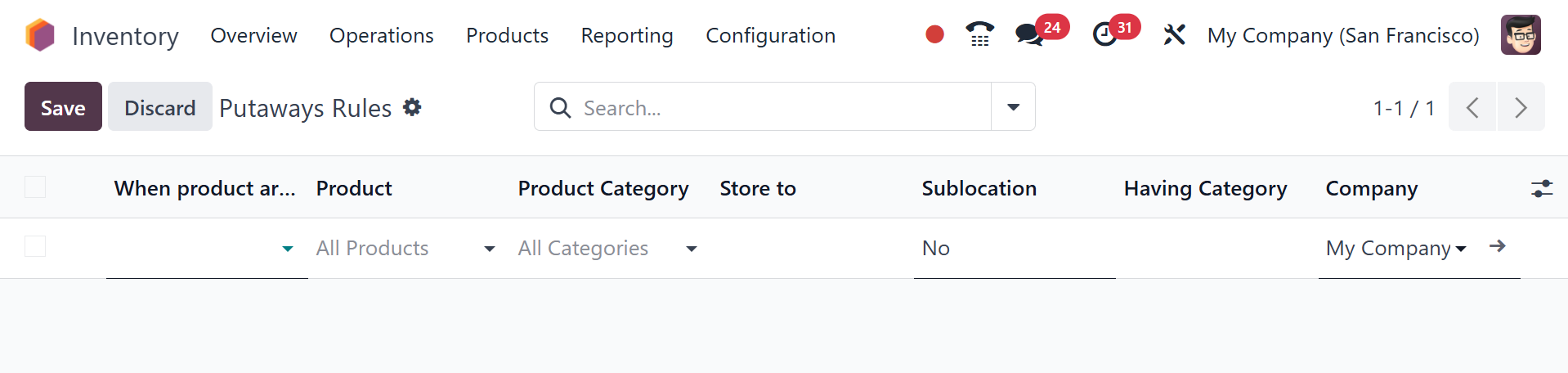

It is simple to create new

putaway rules in Odoo. Click

on the New button and a new

line will be created below

the available list. In this,

you can enter the product

name, product category, and

package type in the

respective fields.

The receiving location of the

product can be defined in the

When product arrives in the

field. In the Store to

Sublocation field, you may

include the location where

you want the product that

comes to the receiving

location moved. The

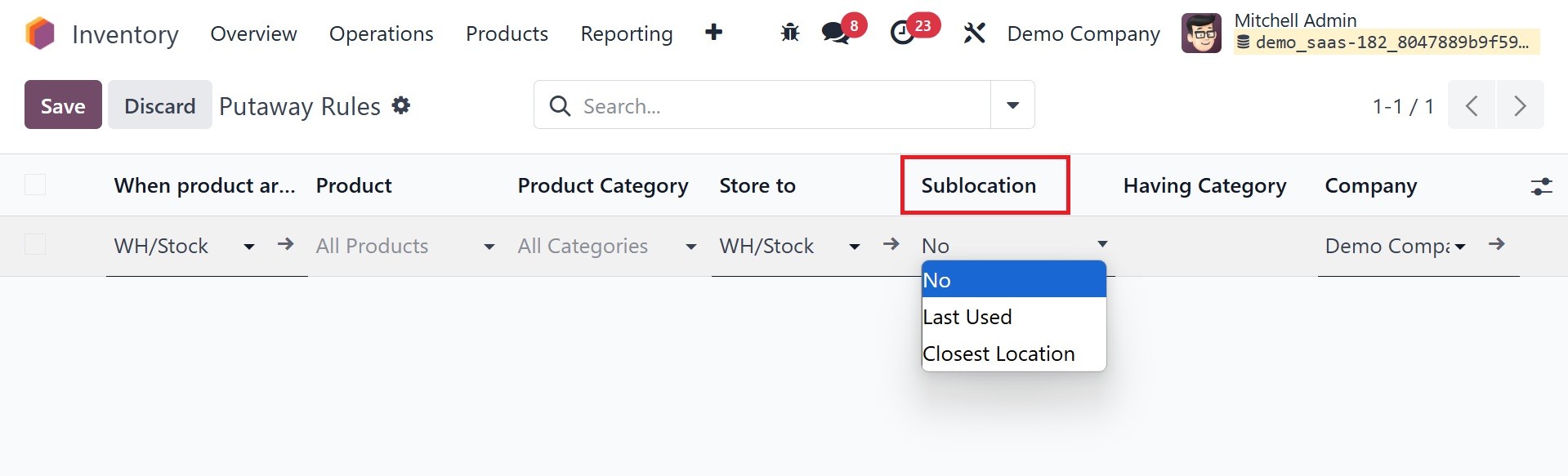

Sub-location Option in Odoo

Inventory aids in deciding

how products are allocated to

various storage areas inside

a warehouse when setting up

Putaway Rules. Under

Sub-location, the three

primary choices are:

No (Stamped Out Location): The

merchandise is always shipped

to a certain, predetermined

address. It is helpful in

cases where products have

fixed storage locations.

Last Used Location: Incoming

stock is routed by the system

to the product's most recent

usage location. Perfect for

goods that constantly switch

storage locations according

to the availability.

Closest Location: When a product

arrives, Odoo automatically

chooses the closest

sublocation to store it. It

is beneficial for maximizing

warehouse space and cutting

down on employees' commuting

time.

You can specify the category of

the sublocation in the Having

Category field. You may

follow by noting the Company

and then click the Save

button. When a product

belonging to a specific

product category in a

specific package type reaches

the destination location

described here will be

shifted to the said

sublocation of the company by

default. Finally go to the

Save icon.

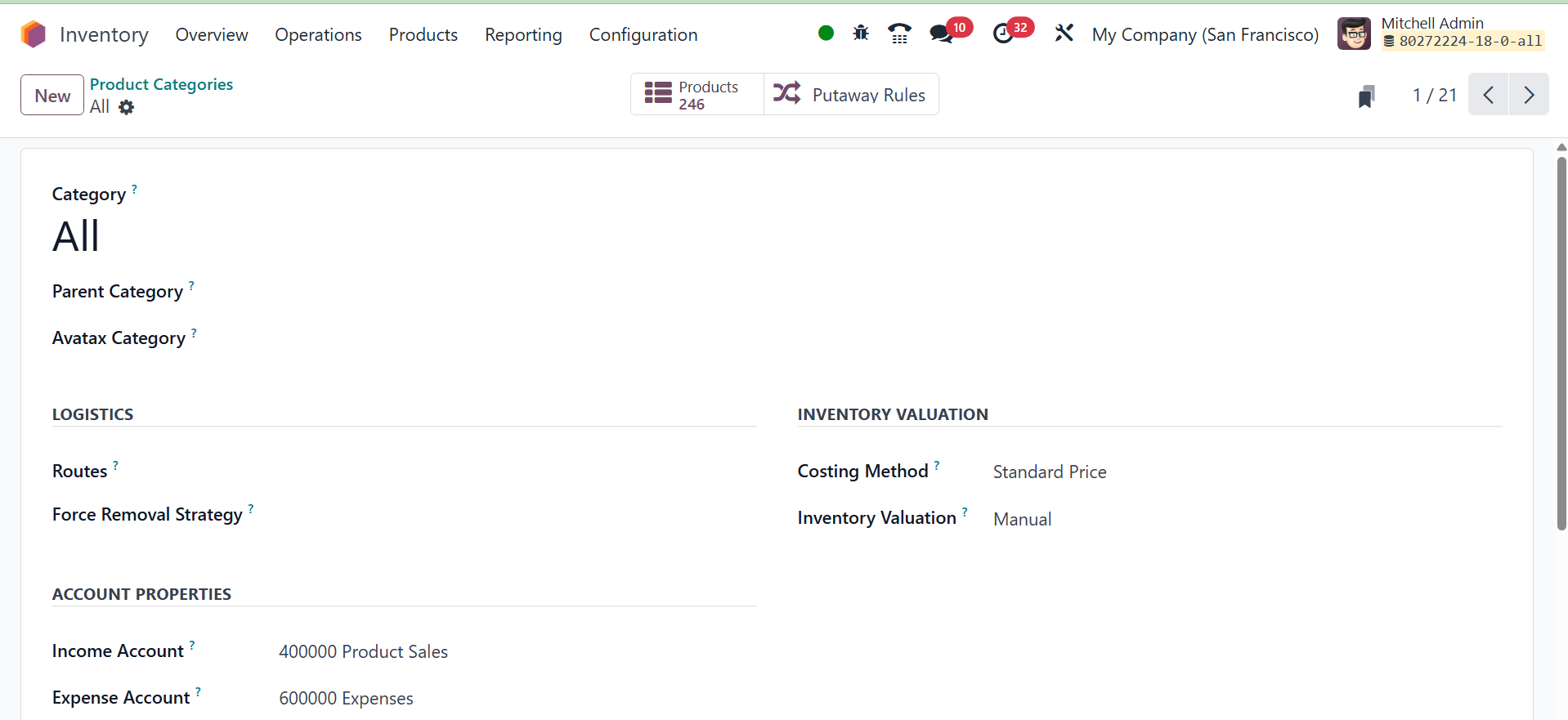

4.8 Product Categories

It is crucial to put in place a

well-thought-out inventory

management system that

facilitates classification.

Make use of Odoo ERP

software, which makes it

simple to create and modify

product categories and

enables flexibility in

response to shifting business

requirements. Review and

update your categories

frequently to account for new

items or shifts in consumer

preferences. Your inventory

system will stay current and

adapt to changing consumer

demands thanks to this

flexibility. For even more

granularity, think about

using subcategories. Dividing

more general categories into

more focused subcategories

makes it easier to organize

information precisely and

makes searching easier for

both customers and staff.

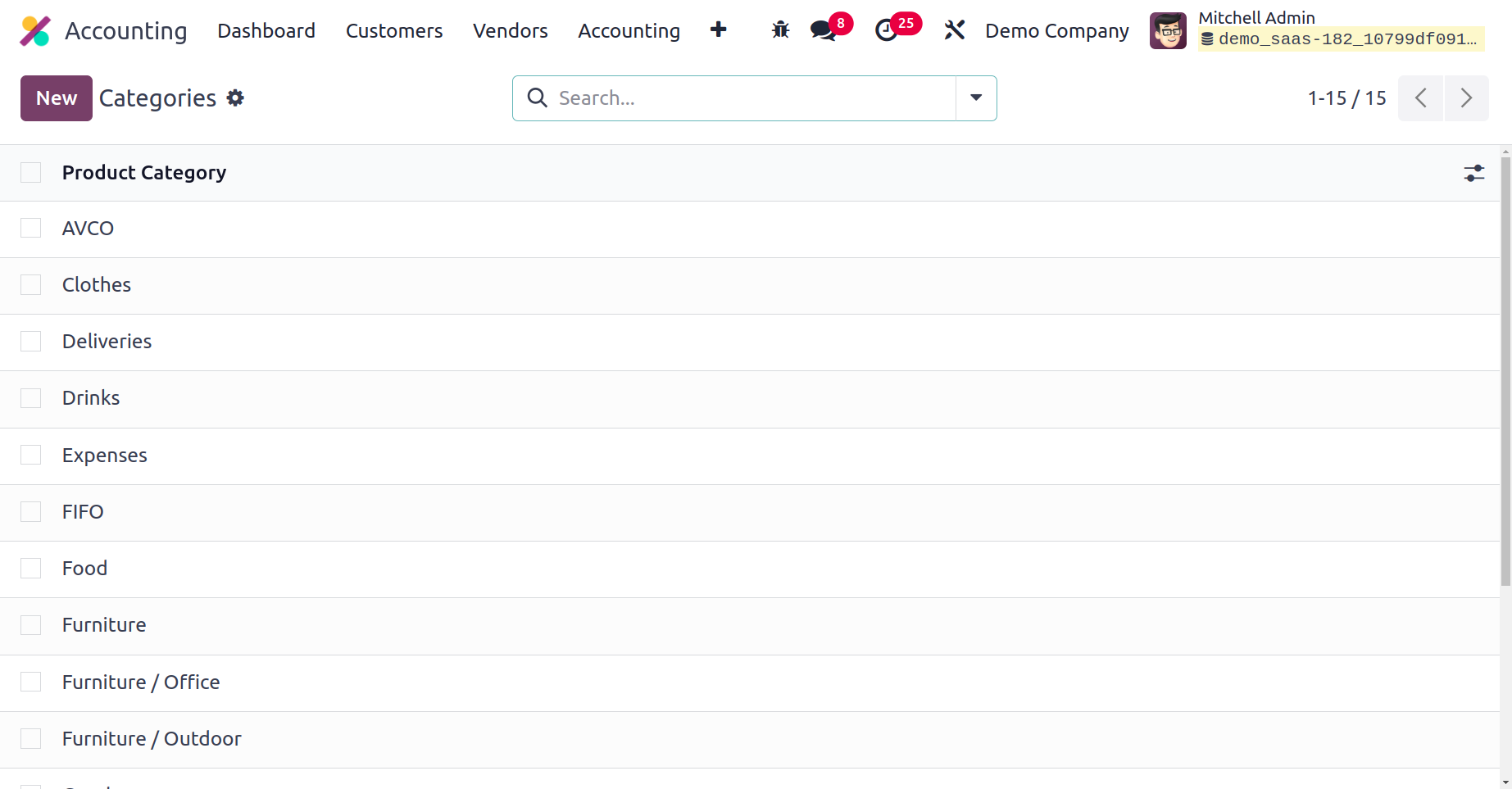

Start by opening Odoo 18's

Inventory module and going to

the "Configuration" section.

A thorough list of pre-configured

product categories will be

available once you arrive.

These categories give you a

starting point for inventory

organization, making it

simple to classify things

like office supplies,

apparel, and gadgets. Click

the "New" button to create a

new product category and

start customizing your

inventory structure. This

stage is essential for

customizing how your products

are arranged to meet your

unique business requirements.

Use the chance to methodically

supply particular details as

you explore the new product

category's settings window.

This entails entering details

like the category name,

description, and any

pertinent characteristics

that set the category apart.

This methodical technique

guarantees that your product

categories are exactly in

line with your company's

needs, which helps to create

an orderly and effective

inventory management system.

You can give the newly formed

category a relevant name in

the "Category" column, which

will make management and

recognition easier. The

"Parent Category" field

indicates a higher category

that might have lower

subcategories, often known as

kid categories. A systematic

method for classifying and

arranging products is

introduced by this

hierarchical arrangement.

Consider the parent category

"Electronics," for example,

which acts as a large

umbrella beneath which

subcategories such as

"Laptops," "Smartphones," and

"Accessories" are nested. In

addition to improving the

items' organized layout, this

hierarchical structure makes

navigating easier and makes

the system more effective and

user-friendly.

Odoo and AvaTax work together

smoothly to provide precise

sales tax calculations for

all US states and territories

as well as all Canadian

provinces and other

territories. Beyond the

fundamentals, it manages

several Canadian tax

components such as GST, PST,

and HST, giving it a flexible

option for companies doing

business in both Canada and

the US.

With its flexible removal methods

that may be used at different

source sites, the Force

Removal Strategy stands out

in the Logistics tab of the

product category setup

window. These methods are

essential for picking

operations optimization

because they reduce worker

distance, guarantee quality

control, and manage products

according to expiration

dates.

First In First Out (FIFO), Last

In First Out (LIFO), First

Expiry First Out (FEFO),

Least Packages, and Closest

Location are the five main

removal methods that cover a

range of options, as shown in

the accompanying figure.

Every technique has a

specific function in

warehouse management.

FIFO (First In, First

Out):

This method prioritizes picking

products that entered the

warehouse first. It's

suitable for perishable goods

or items with short shelf

lives.

LIFO (Last In, First Out):

This method picks products that

entered the warehouse most

recently. It's commonly used

for products without a shelf

life or where the order of

use doesn't matter.

FEFO (First Expiry, First

Out):

This strategy prioritizes picking

products with the nearest

expiration date. It's crucial

for items with limited shelf

lives, ensuring products are

used before they expire.

Least Packages:

This strategy prioritizes picking

products with the fewest

remaining packages. It can

help optimize inventory and

reduce handling time by

minimizing the number of

packages picked.

Closest Location:

This strategy prioritizes picking

products based on their

physical location within the

warehouse. It minimizes

travel distances for

warehouse staff, especially

when multiple locations hold

the same product.

By concentrating on the actual

locations of things within

the warehouse, the "Closest

Location" approach departs

from chronological order.

This strategy offers a

different approach to

strategic inventory

management and is frequently

used for products that retain

a constant level of quality

throughout time.

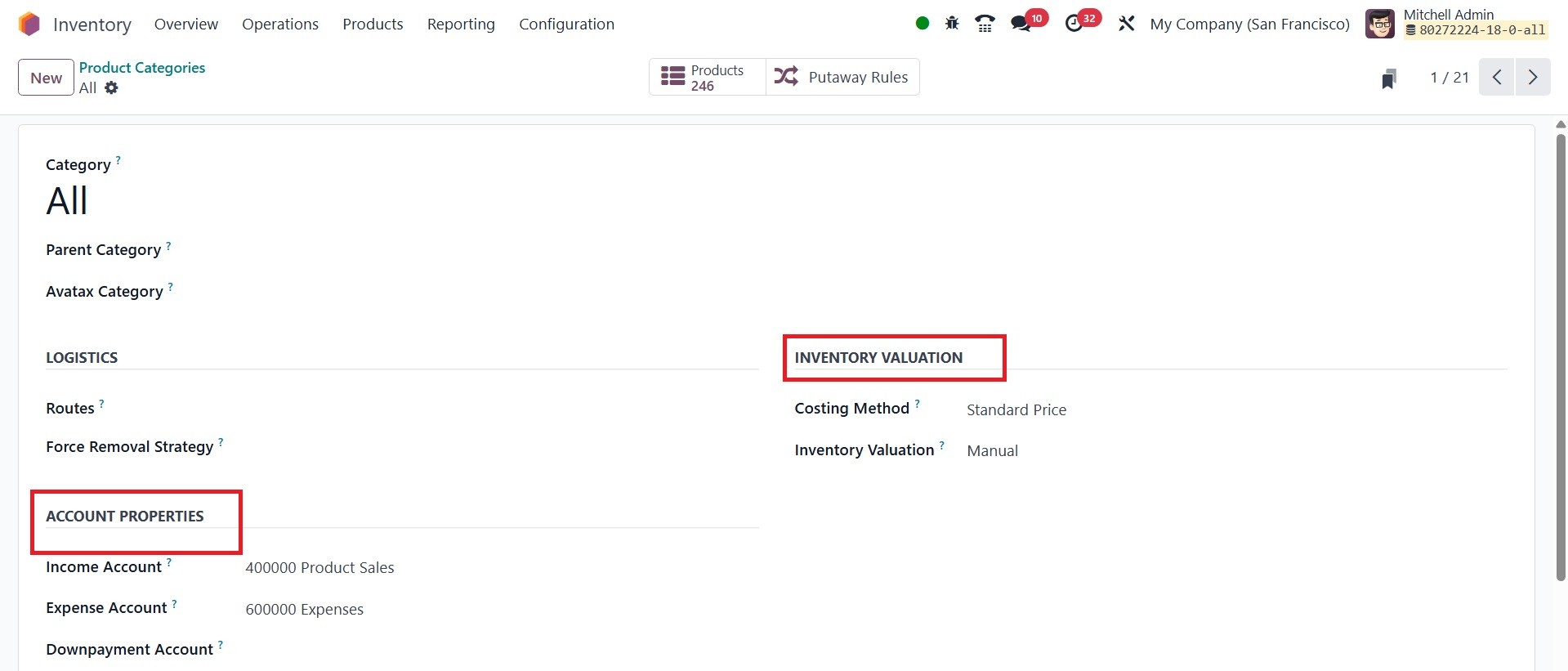

Both the Income Account and the

Expense Account for the

product category must be

specified under the Account

Properties tab.

The "Income Account" in Odoo's

product category settings is

usually linked to the money

received from a product's

sale. The goal of this

account is to carefully

monitor the money coming in

from product sales. On the

other hand, the "Expense

Account" is closely related

to the charges or expenses

related to the product. It is

essential for keeping track

of the costs associated with

the product's purchase or

manufacture. You may

effectively manage and

classify your financial

activities by configuring

these accounts inside the

product category settings,

which guarantees a thorough

picture of both sales income

and cost of goods. The

downpayment accounts option A

down payment account is a

particular type of accounting

account that is used to track

payments made in advance to a

vendor or client. These

payments are paid prior to

the completion of the invoice

or the actual delivery.

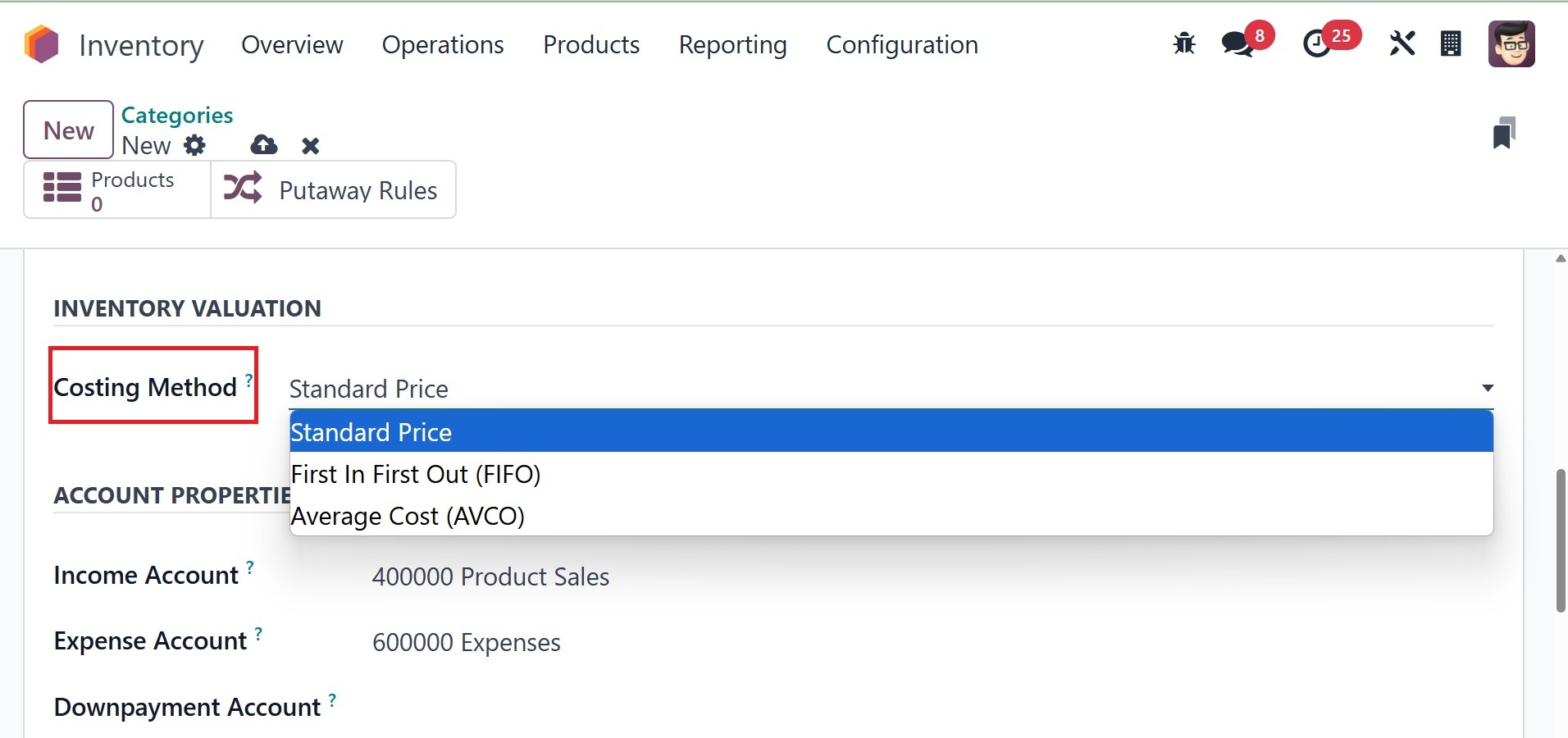

Costing techniques are essential

to Odoo inventory valuation

since they give companies a

variety of choices to suit

their particular

requirements. One such

strategy is the "Standard

Price," which keeps the cost

per unit constant despite

price swings in the market.

Despite the fact that actual

cost changes are dynamic,

this constant number never

wavers.

A more flexible approach to

valuation that takes into

account the continuous

fluctuations in costs is

provided by the "Average

Cost" method, in which the

system dynamically determines

the mean cost of every unit

in stock.

The "First In First Out (FIFO)"

approach ensures a systematic

flow that reflects the

chronological order of

acquisitions for those who

value chronological accuracy

by assuming that the first

products entered to the

inventory are the first to be

sold.

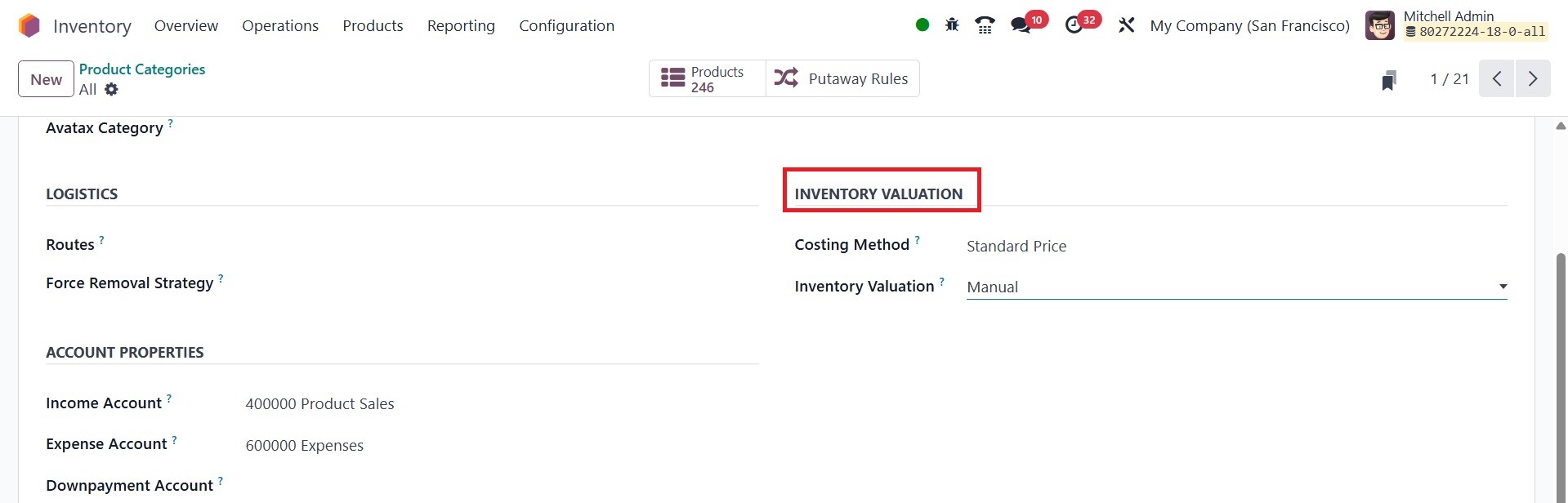

Under the inventory valuation,

you have the costing method

and inventory valuation

options.

Inventory Valuation Method

defines whether the stock

journal entires need to be

record during a delivery or

receipt.

Manual: Requires you to manually

update inventory values based

on physical stock counts.

Automatic: Automatically updates

inventory values based on

purchase prices and other

relevant data.

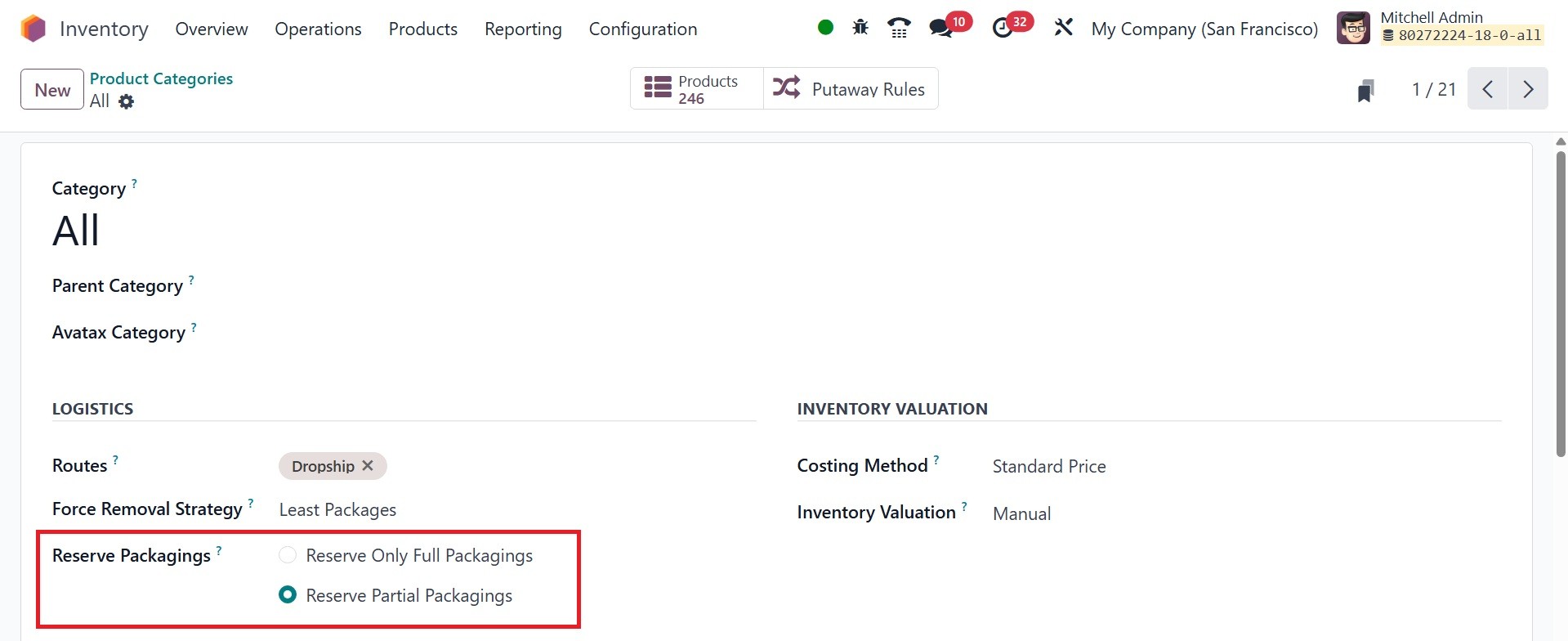

Another section Reserve

Packagings in product

category can be reserved in

full or partial quantities

for outgoing shipments.

Partial packaging flexibility

expedites order fulfillment

by allowing the immediate

shipment of available items,

while awaiting the rest.

To configure packaging

reservation methods, go to

Inventory app ‣ Configuration

‣ Product Categories. Then,

click New, or select the

desired product category.

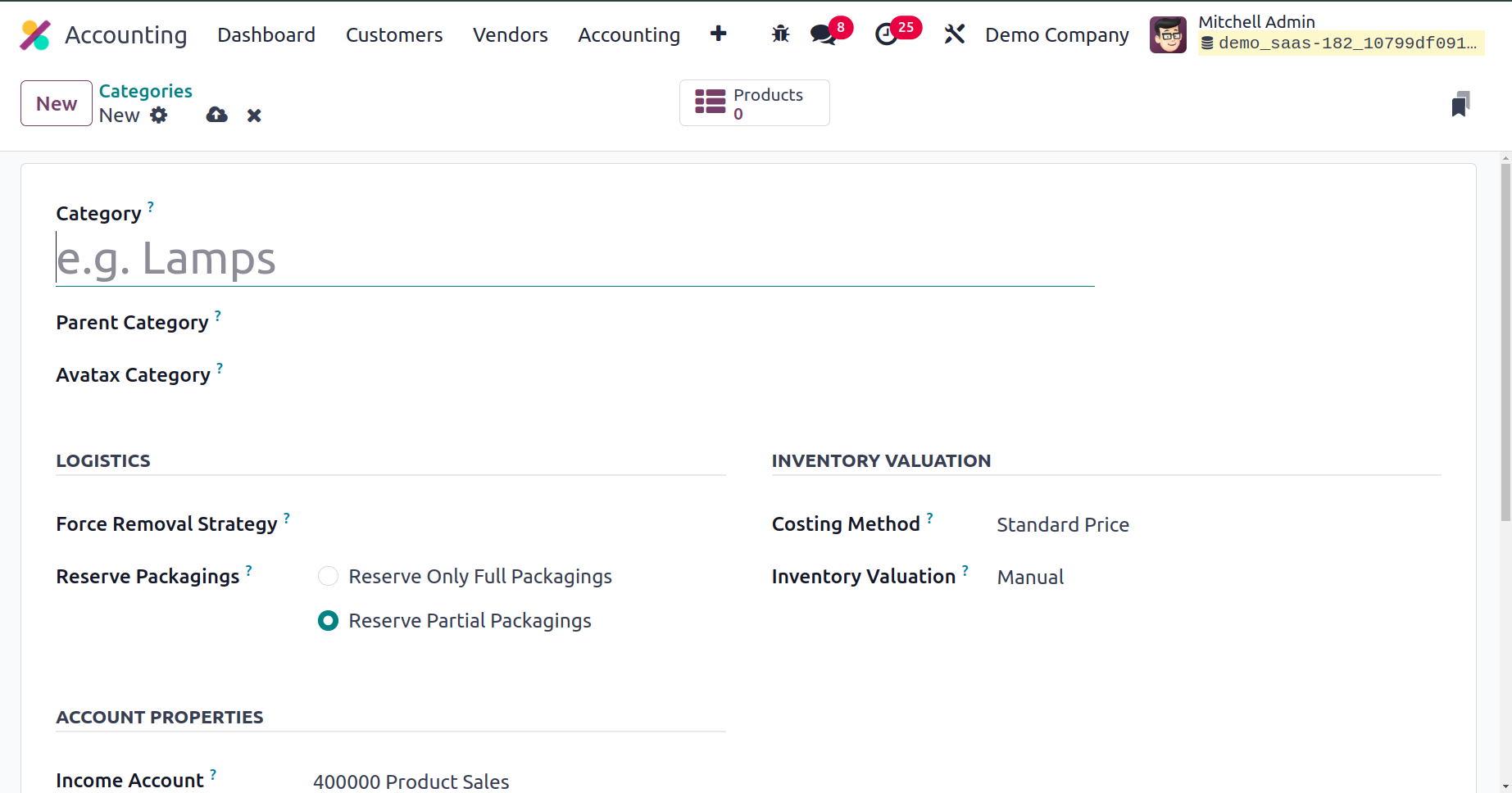

On the product category’s form,

in the Logistics section,

Reserve Packagings can be set

to Reserve Only Full

Packagings or Reserve Partial

Packagings. To see the

Reserve Packaging field, the

Product Packaging feature

must be enabled. To enable

this feature, go to Inventory

app ‣ Configuration ‣

Settings, scroll to the

Products section, tick the

Product Packagings checkbox,

and click Save.

Take a look at the following

example to better assess the

possibilities according to

business needs:

Each package contains twelve

units of a product. The order

requires two packages. Only

twenty-two units are

available. Only twelve pieces

are set aside for the order

when Reserve Only Full

Packagings is chosen.

In contrast, 22 units are set

aside for the order when

Reserve Partial Packagings is

chosen.

These various methods give

companies the freedom to

modify their inventory value

plans in accordance with

particular requirements and

current market conditions.

Whether choosing the

consistency of Standard

Price, the flexibility of

Average Cost, or the

timeliness of FIFO, Odoo's

strong platform forms the

basis for thorough inventory

control.

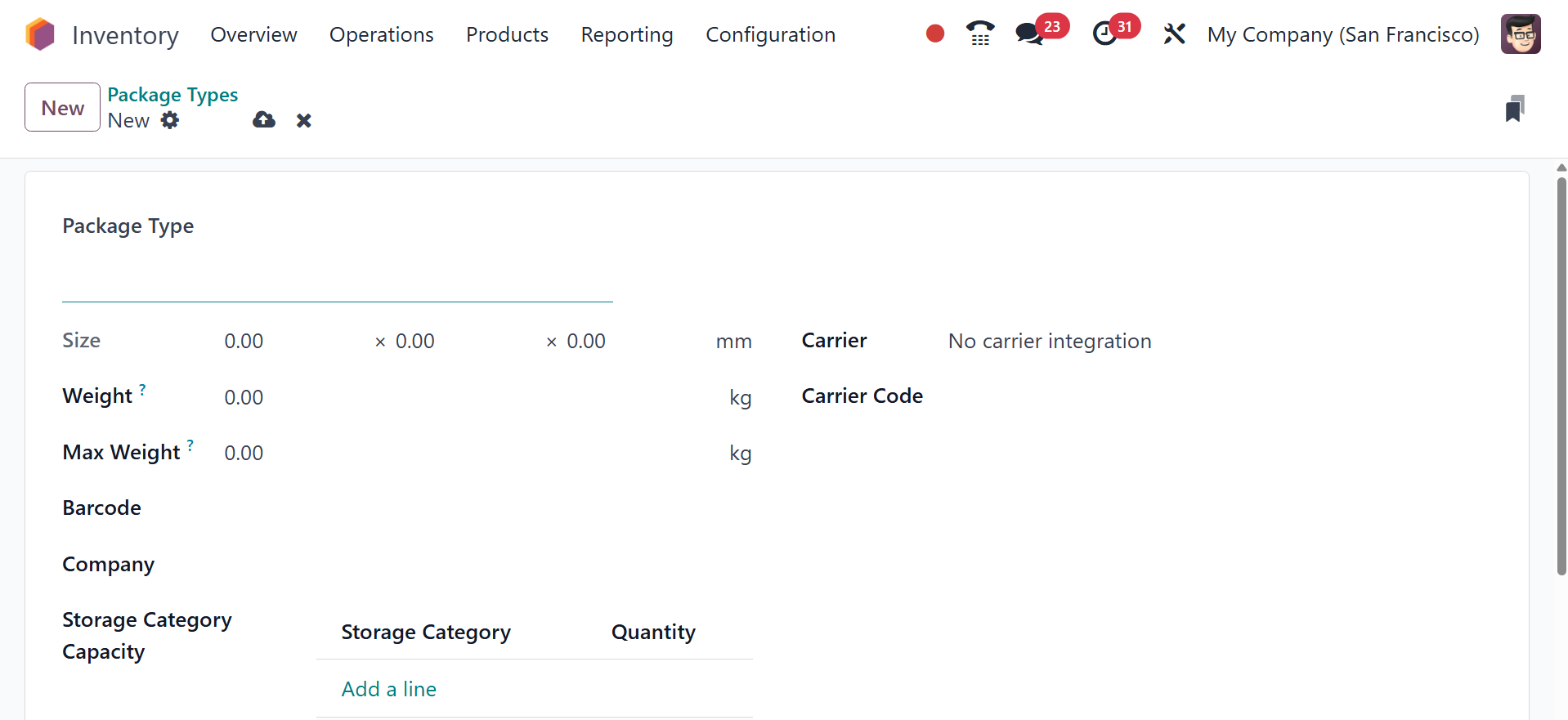

4.9 Package Types

In the Odoo Inventory module, you

can define and manage various

package types to better

organize and handle different

product packaging needs,

including delivery

operations. These package

types are configured through

the Configuration menu,

allowing you to define

specifics like size, weight,

and carrier details.

Here, you can see the options

like carrier, package type,

height, width, length, max

weight, and carrier code. To

create a new one, go to the

New icon.

Here, you can add the above

mentioned details as well.