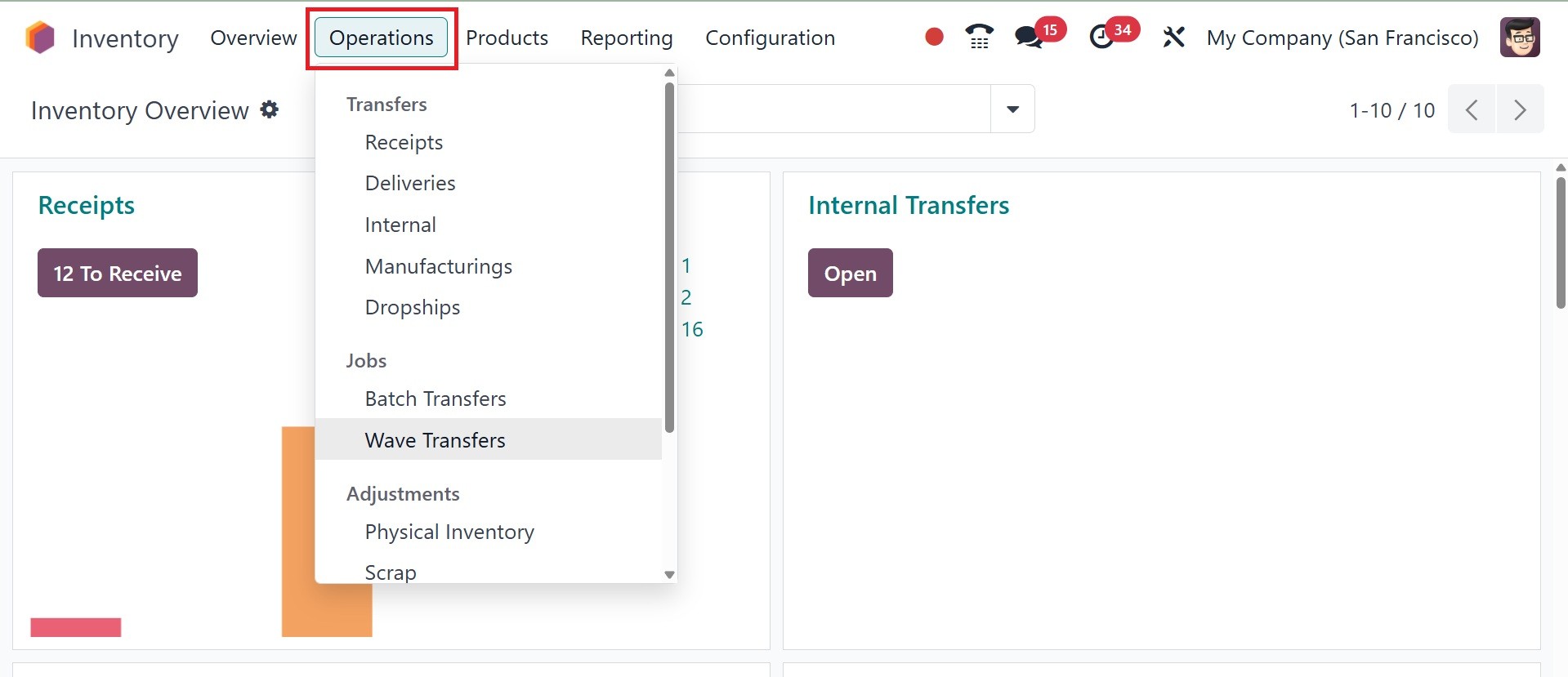

2. Operations

Operations menu in the Odoo

Inventory Module offers vital

utilities for managing stock

movement and warehouse

operations effectively. It

allows businesses to manage

transfers, batch operations,

inventory adjustment, picking

rules, and replenishments to

facilitate seamless logistics

and stock accuracy. This menu

helps optimize warehouse

processes, automate the

replenishment, and track

real-time inventory levels.

Through the use of these

features, businesses can

enhance the efficiency of

their operations and minimize

errors in managing stock.

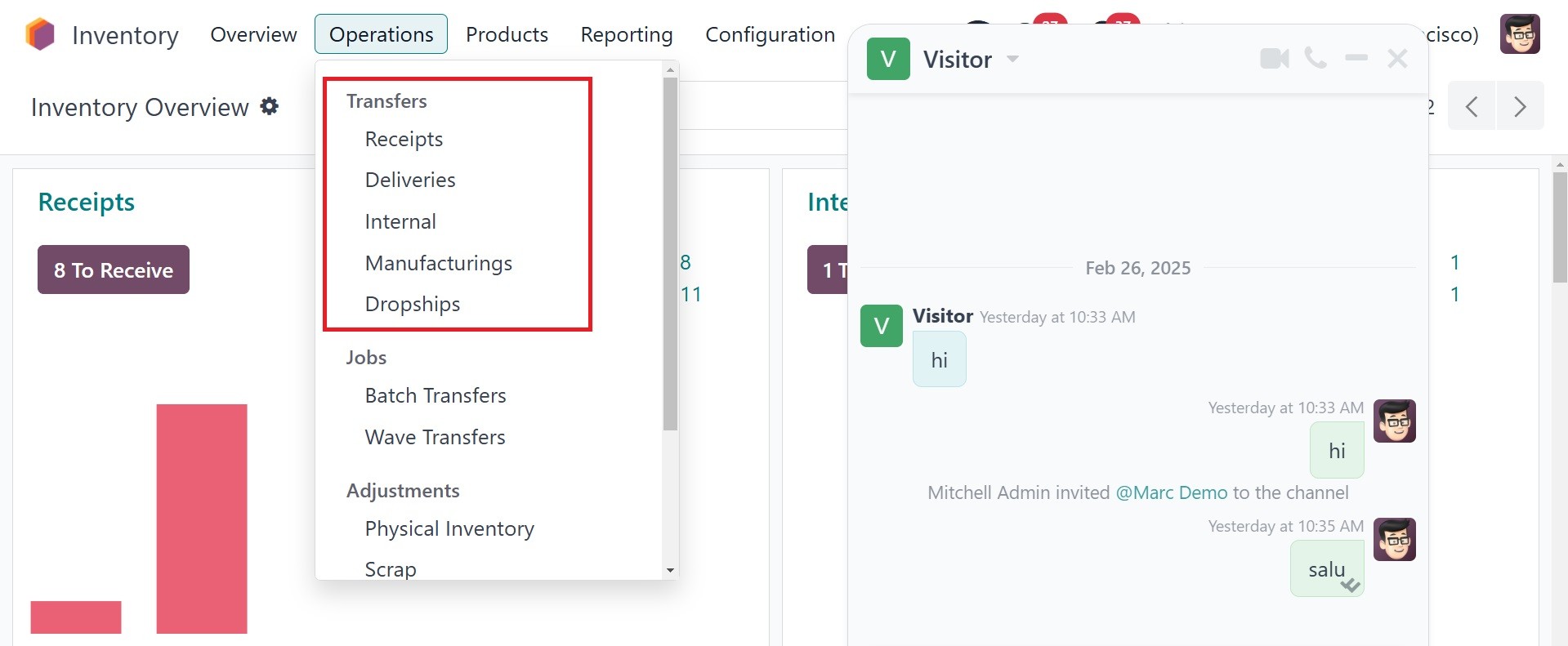

3.1 Transfers

Companies with multiple

warehouses need to manage the

flow of goods from one

location to another. Under

certain situations, the

companies might possess

different branches in

different cities, and thus it

will be extremely hard to

coordinate product transfers

efficiently. Companies often

manage such situations by

assigning main warehouses and

other warehouses for product

distribution. Product

transfers from one location

to another are simplified

with Odoo18's Transfers

feature.

Inventory transfers involve the

movement of products within

and out of warehouses.

Internal transfers are also

covered for the movement of

products within the

warehouses of the company.

Warehouse management and

setup are facilitated by the

Odoo18 ERP system, which we

will discuss in the next

section. You may control the

product transfer between the

configured warehouses and

locations by using the

Transfers option found under

the Operations menu after

defining the company's

warehouses and locations in

detail.

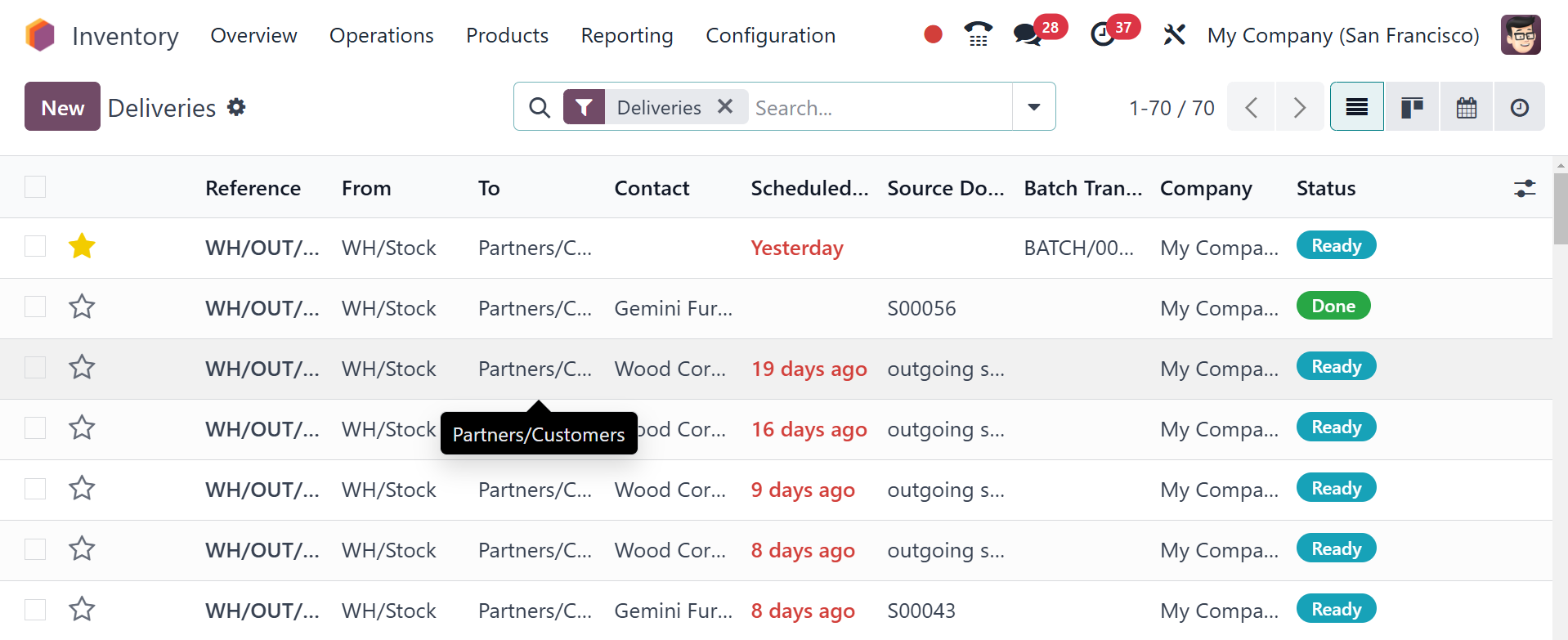

You can see transfers such as

Receipt, Deliveries,

Internal, Manufacturing,

dropship, Batch Transfer, and

Wave Transfer in the

Transfers option, as

indicated in the above image.

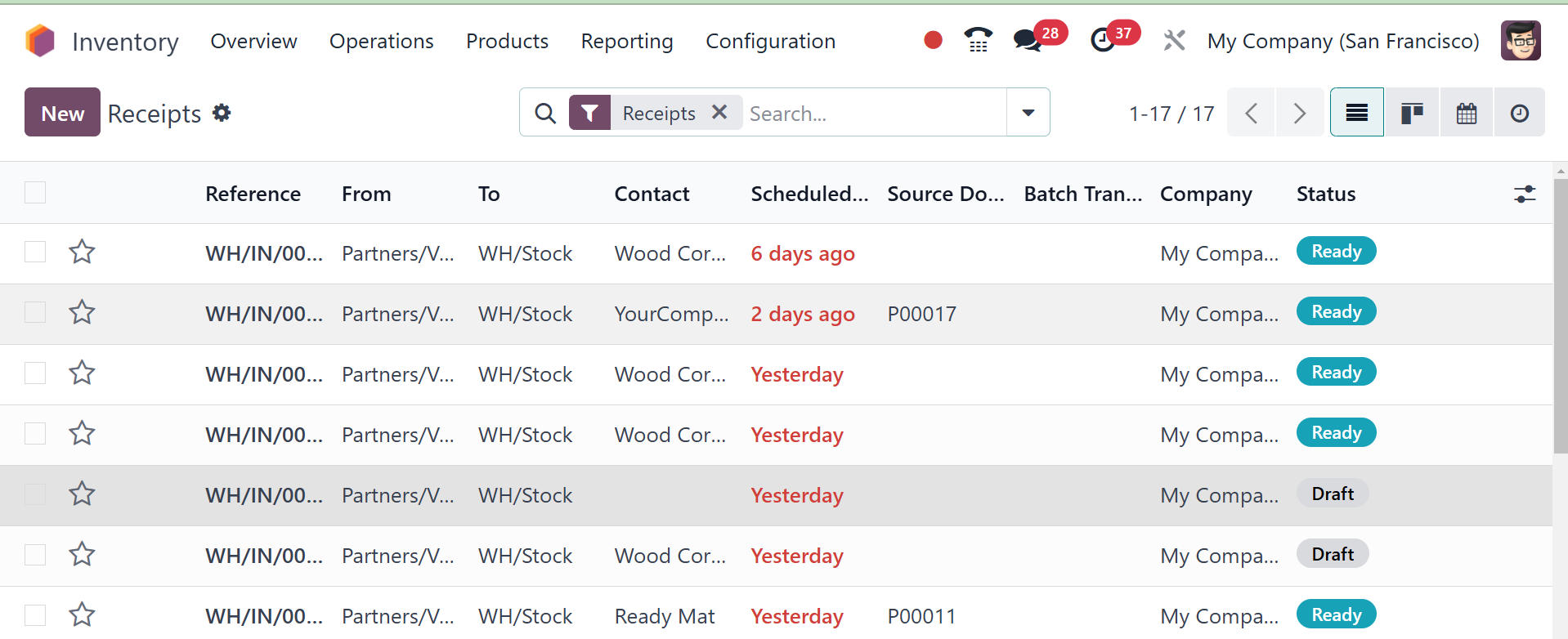

3.2 Receipt

You can see details of the

Reference, From, To, Contact,

Scheduled Date, Source

Document, Batch Transfer,

Company, and Status of the

preconfigured transfers here,

as indicated in the following

image.

You can simply finish the sorting

activities using the Group By

and Filters features. For

this site, you will also have

Kanban, Calendar, and

Location views. Let us now

see how Odoo18 allows you to

create a new transfer for the

movement of goods between two

places. Click the New button

to accomplish this.

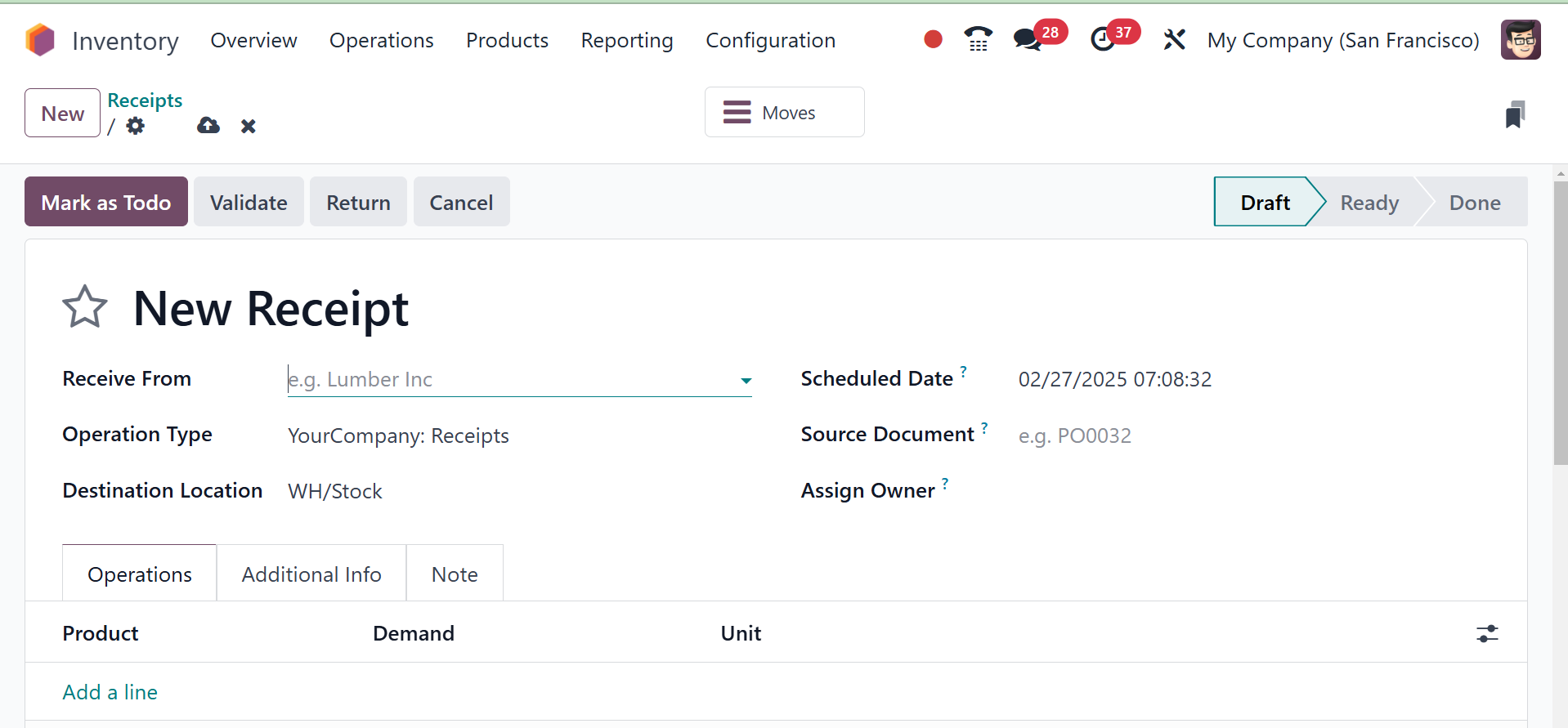

Partner id can be typed in the

Contact field of the new

transfer creation window.

Several transfer types can be

handled by this platform.

Receipt, Internal Transfer,

Delivery Orders, Returns,

Manufacturing, Resupply

Subcontractor, POS Orders,

Dropship, and Manufacturing

are some of them. In the

Operation Type field, you can

select the type of transfer

you desire for your product

movement. You can define the

source location of the

product and destination

location after selecting a

suitable Operation Type. The

Scheduled Date option can be

utilized to denote the

expected date of movement of

stock. You can mention the

reference to the document

related to this transfer of

the product under the Source

Document field. You can use

the Add a Line button on the

Operations tab to list every

item that is included in this

transfer separately. You can

define the names of the

products, their packaging,

demand, and UoM besides their

names. The amount of the

product that is going to be

transferred is called the

demand.

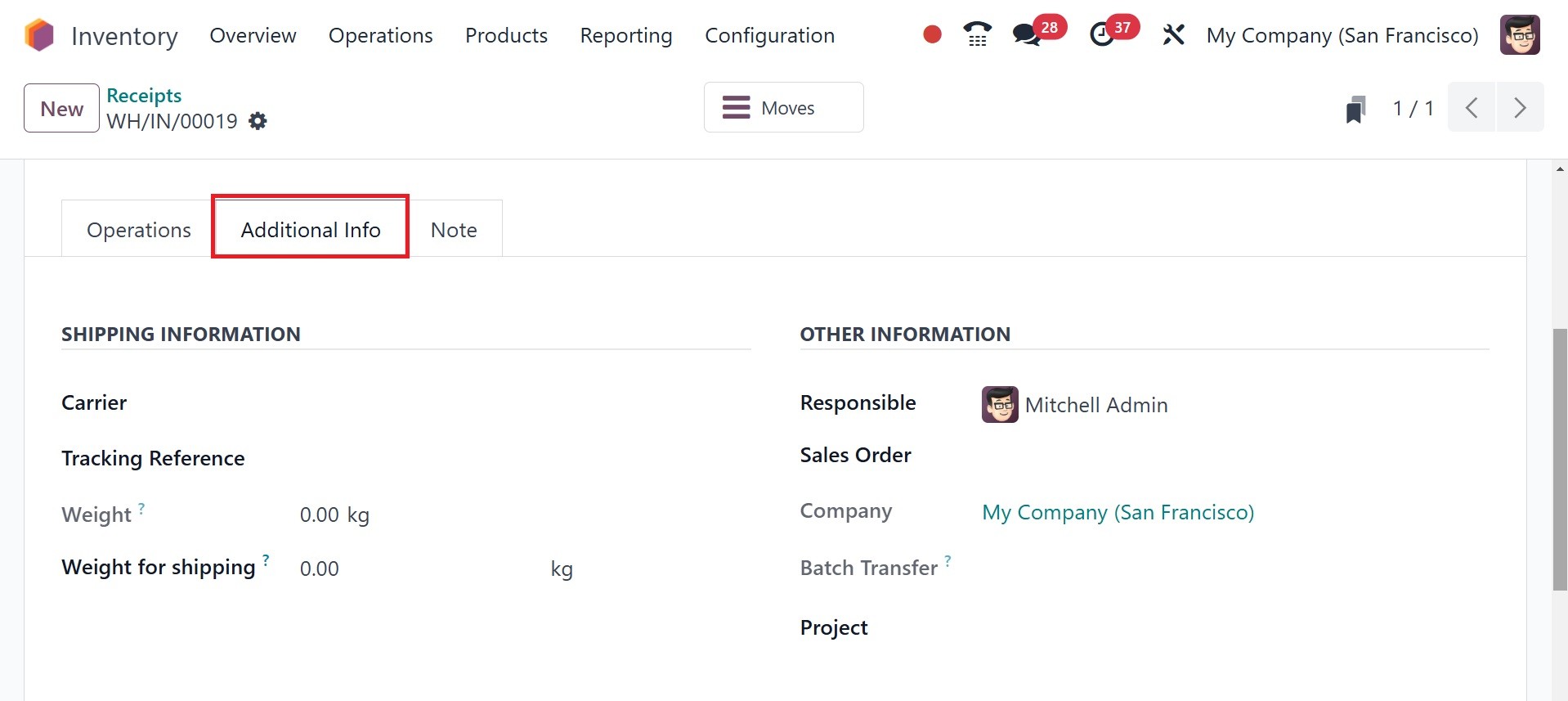

On the Additional Info tab, you

can add the Shipping

Information.

The Carrier Details, Tracking

Reference, Weight, and Weight

for shipping for the goods

under this transfer may all

be added here. The shipping

policy for the transfer may

be set up in the Other

Information section. You can

also define a Responsible

employee to be in charge of

the future activities of the

transfer. Lastly, complete

the respective fields with

the Procurement and Company

information.

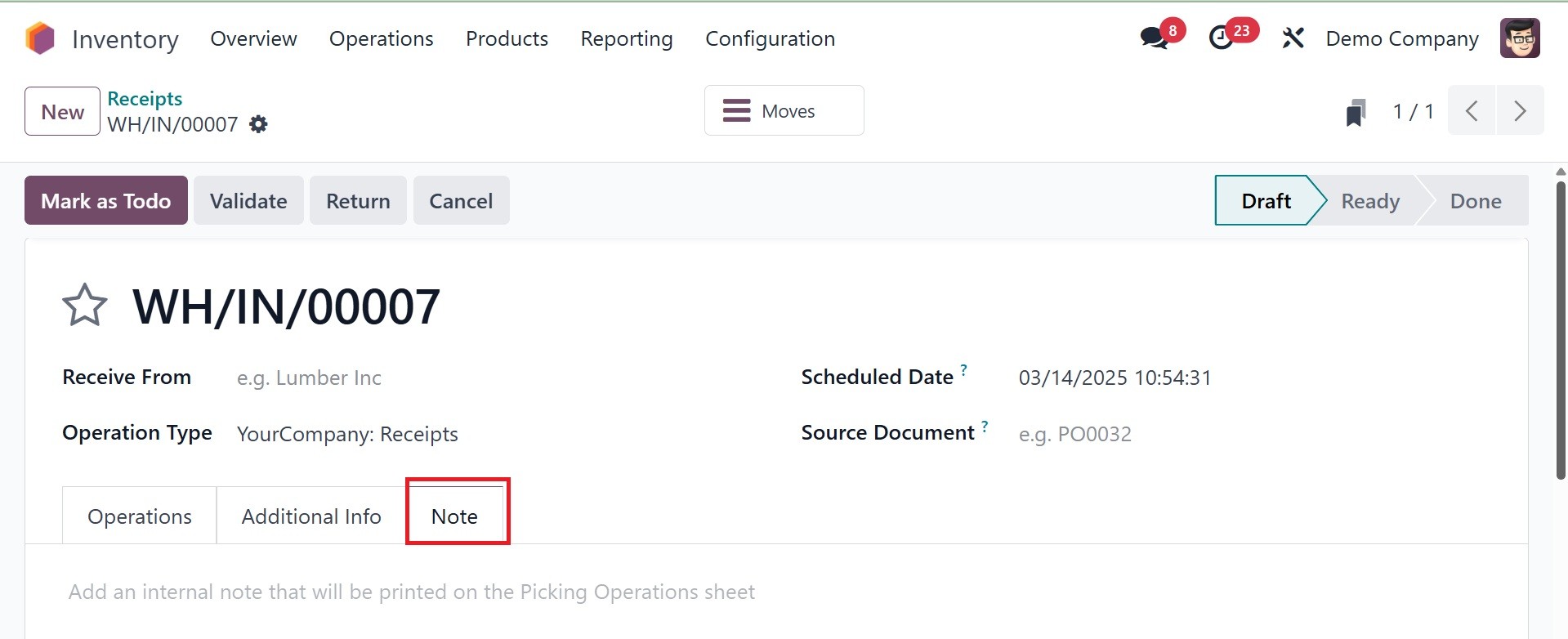

You must include internal notes

regarding this transfer on

the Notes tab. The transfer

will be stored once the Save

button has been clicked.

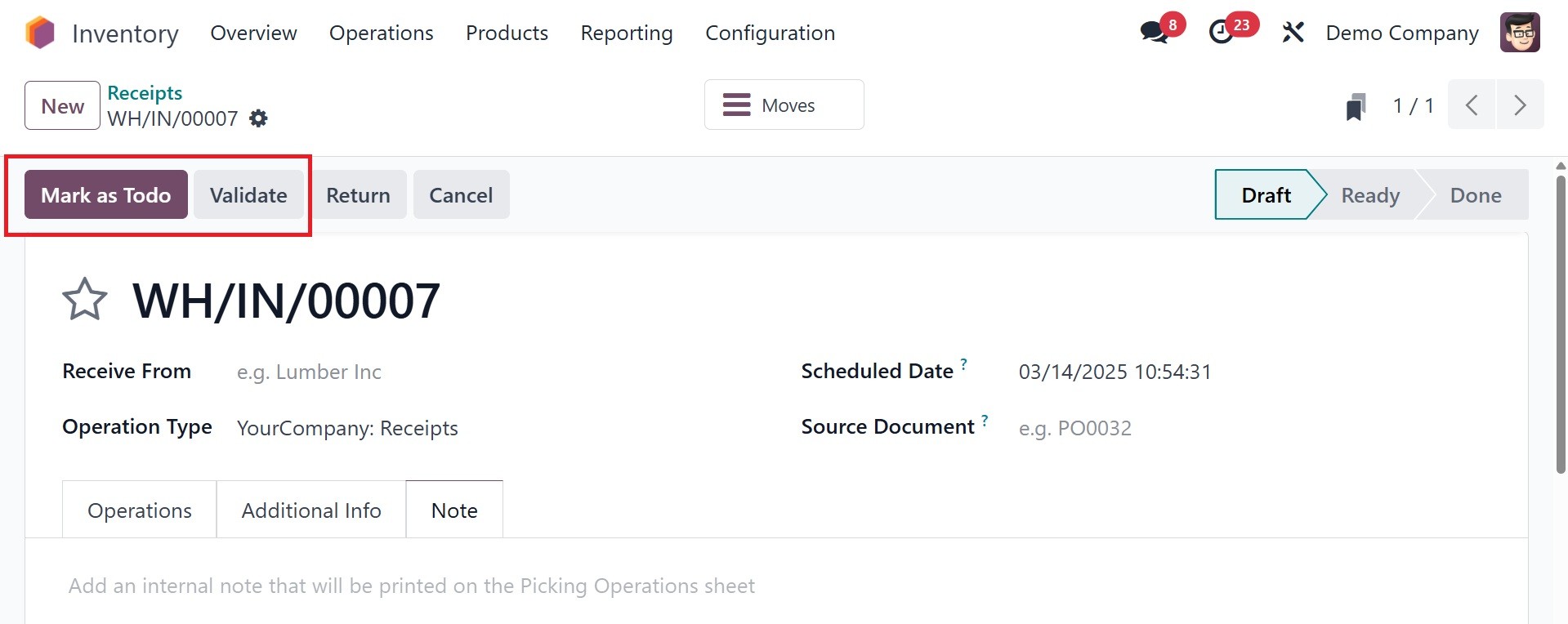

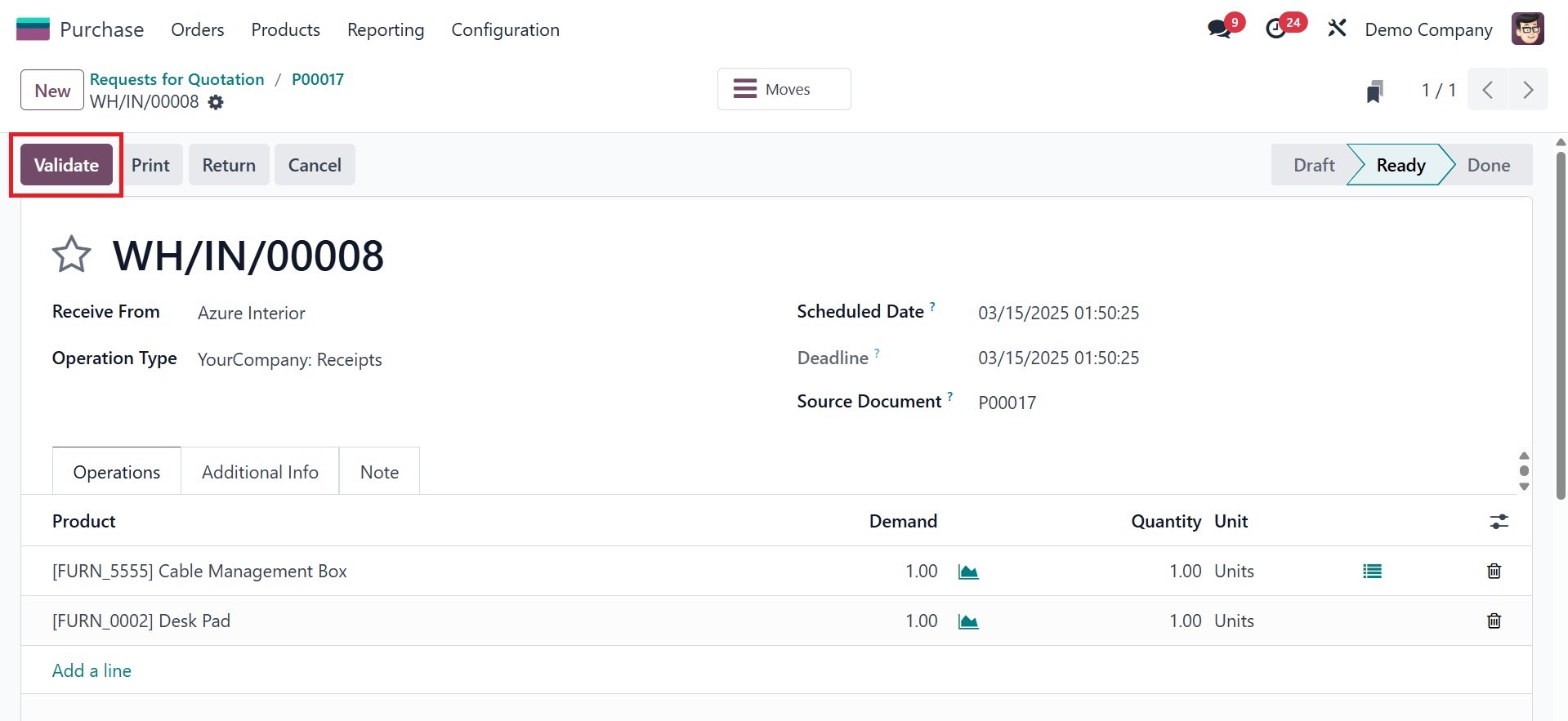

The transfer is first in the

Draft state. The transfer can

be viewed in the Ready state

if it is ready to be

processed. To move the

transfer to the Ready state,

click the ‘Mark as Todo’

button. Click the Validate

button when the transfer

process is complete, as in

the screenshot below.

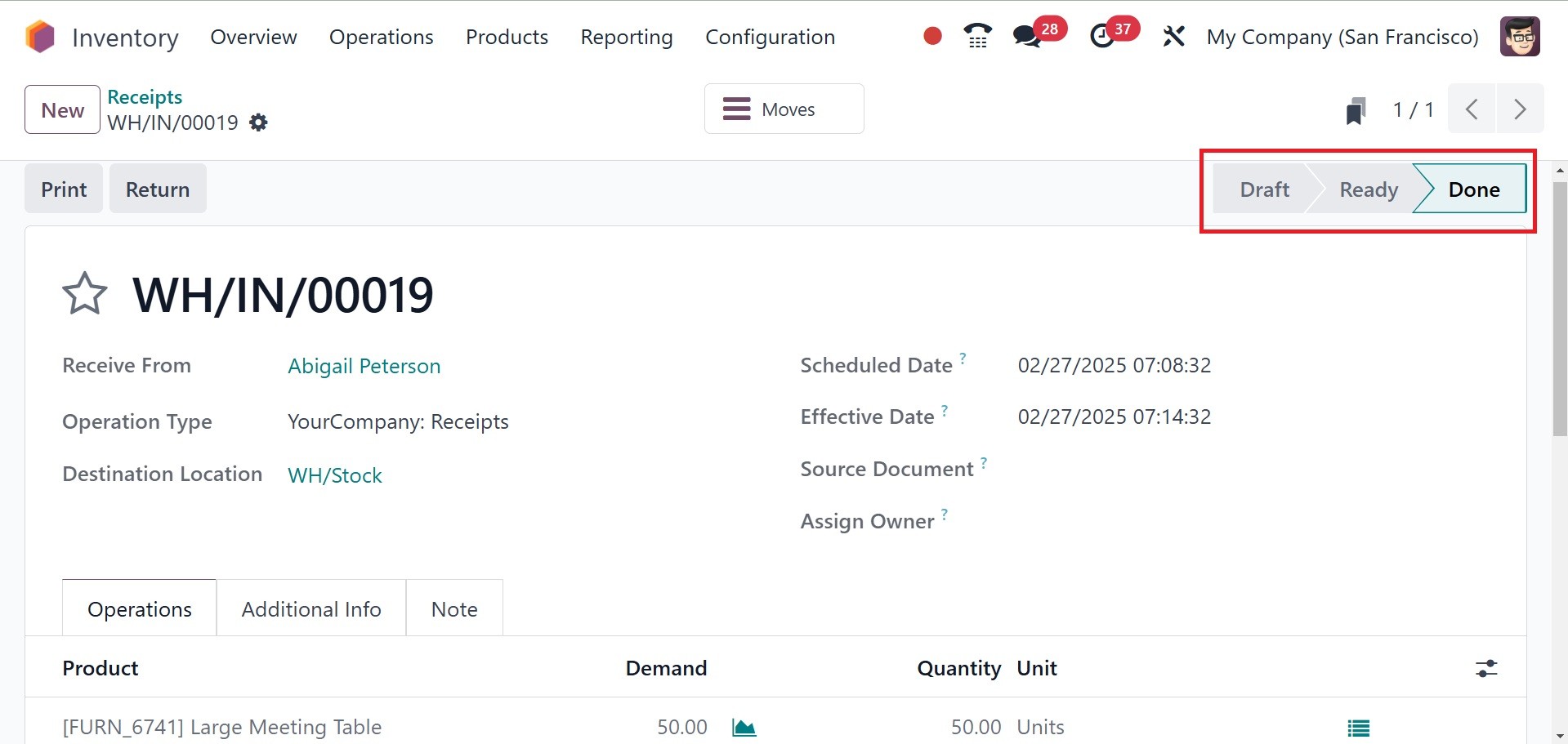

The transfer process is complete.

You can print off the transfer's

delivery slip using the Print

button. The Return button

allows you to send the items

back to the previous place.

3.3 Deliveries

It moves stock out of the

warehouse to customers or

other locations. Commonly it

is used in sales operations.

The page of deliveries will

be, as in the image below.

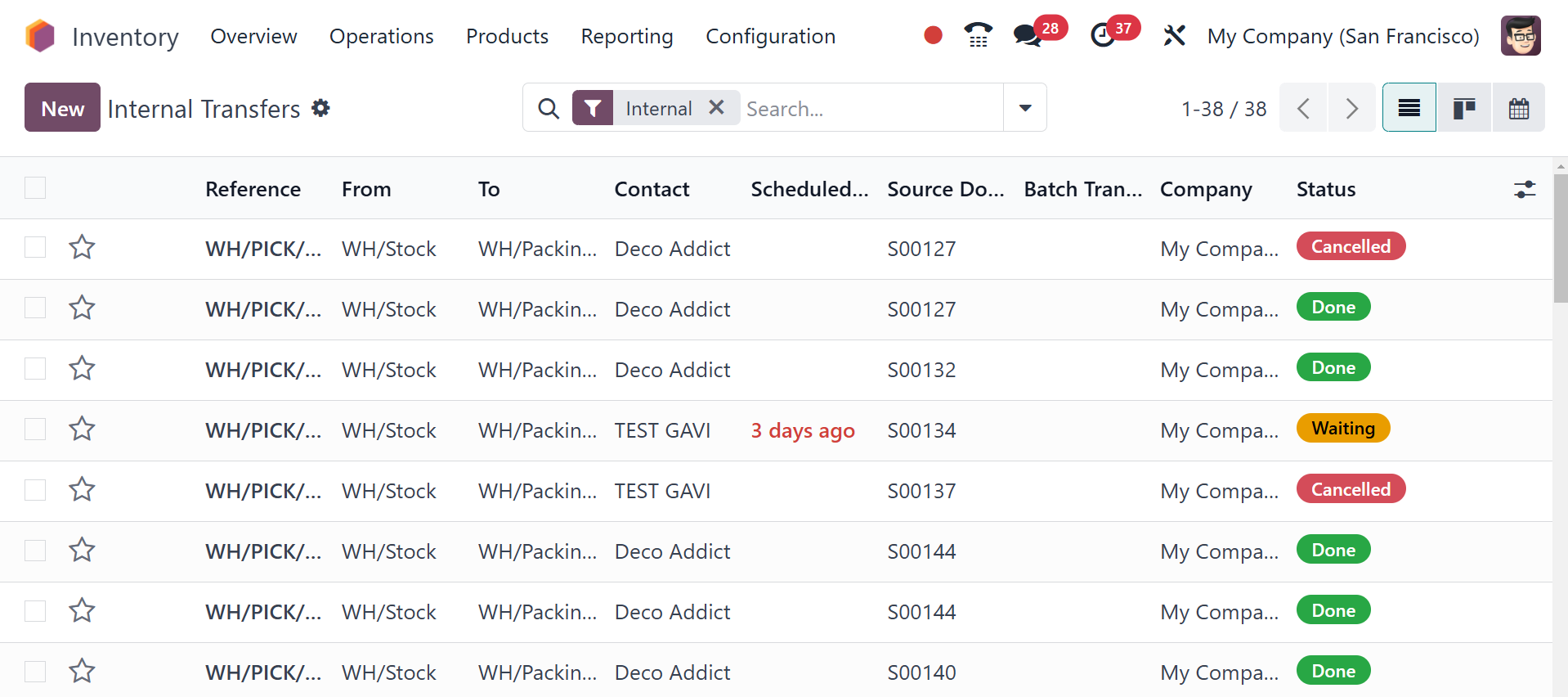

3.4 Internal

Transports inventory from one

place to another within the

same business.

utilized for moving storage

areas or transferring goods

between warehouses.

excludes outside parties.

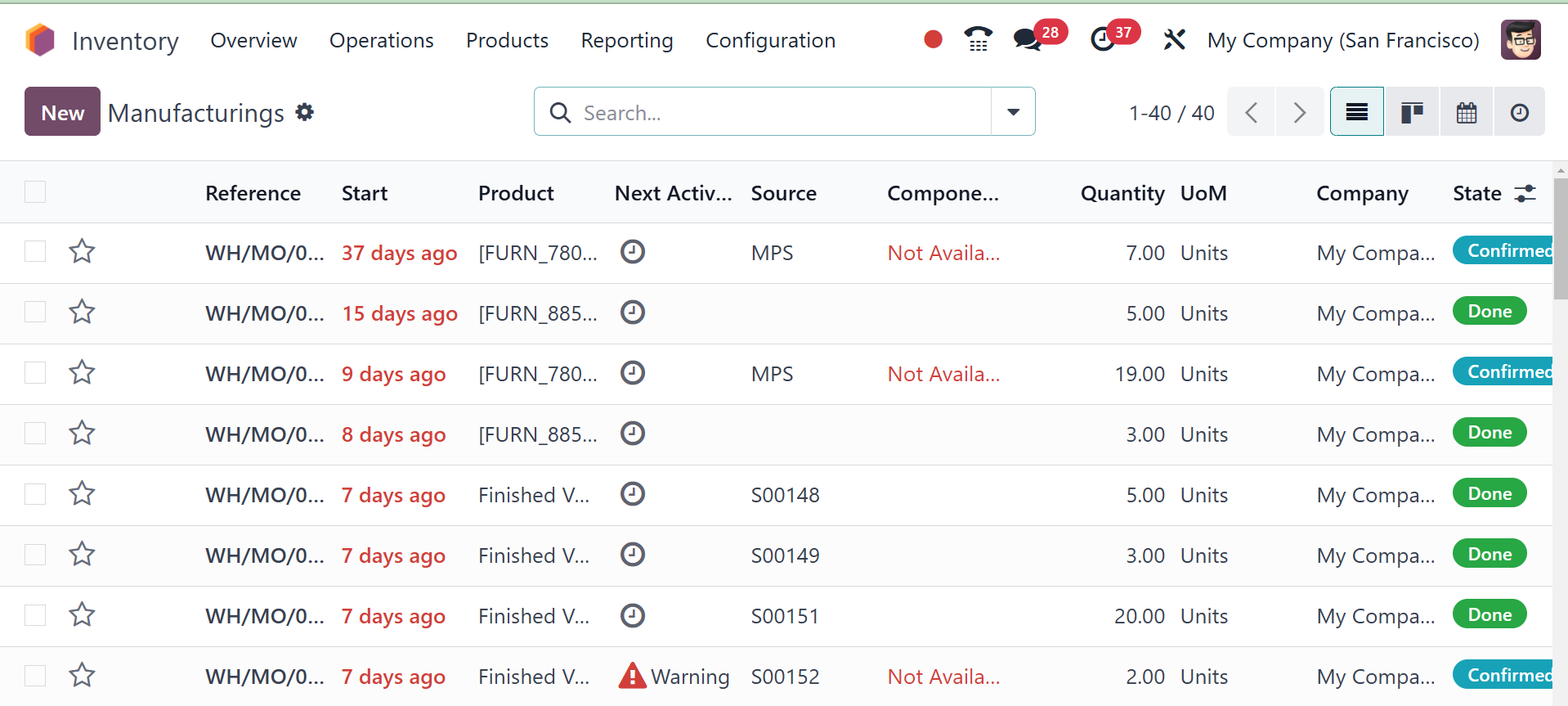

3.5 Manufacturing

It handles the movement of raw

materials to the production

area and the movement of

finished goods back to

inventory.

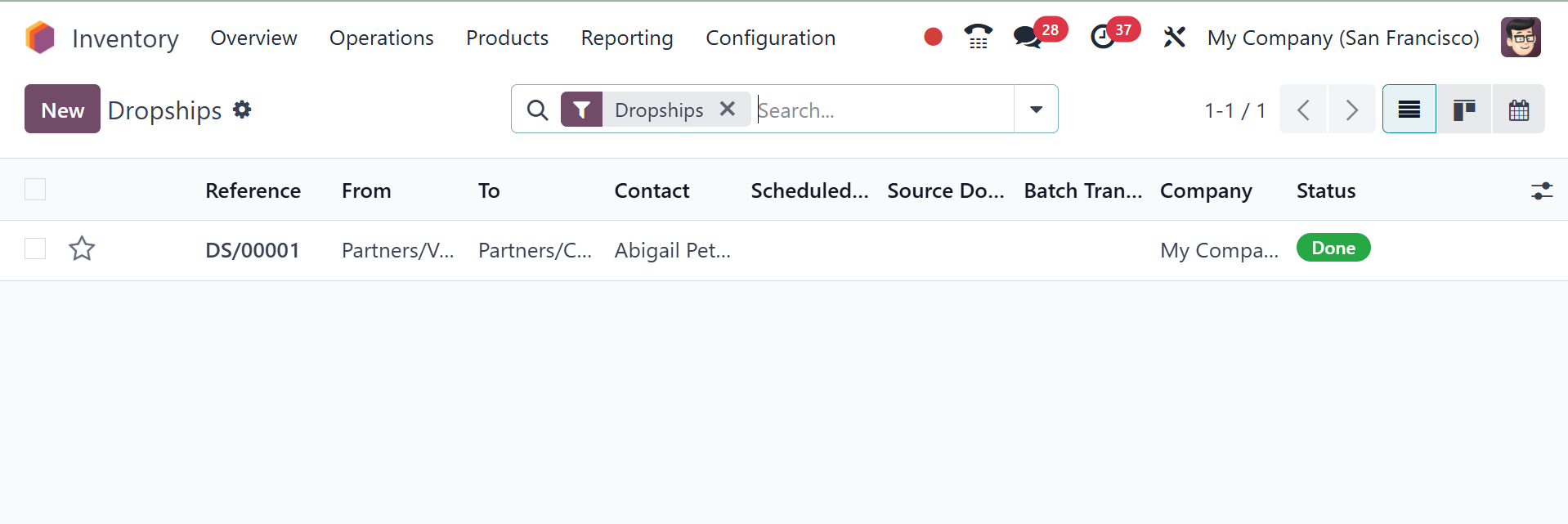

3.6 Dropship

Transports products straight from

a source to a consumer

without keeping them in

storage. No effect on the

business's stock.

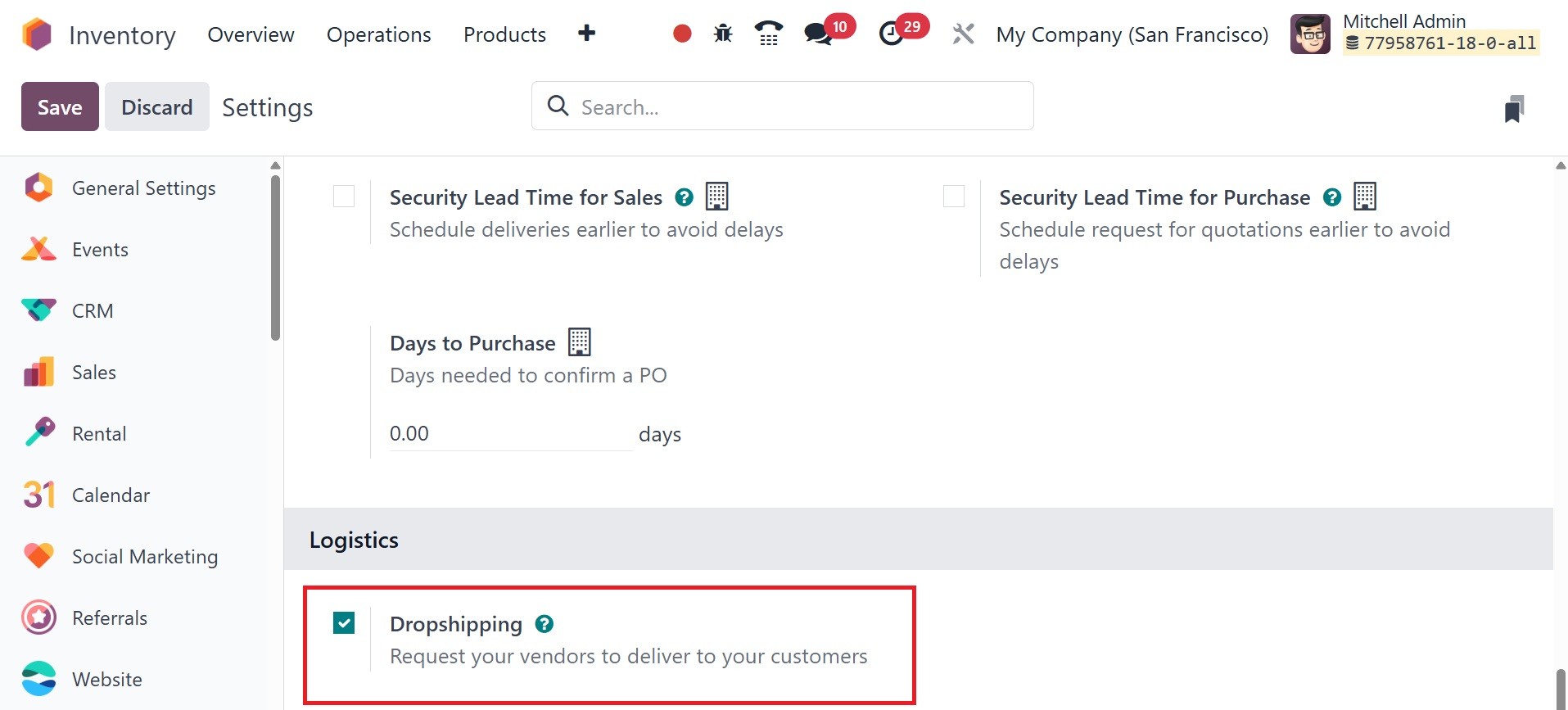

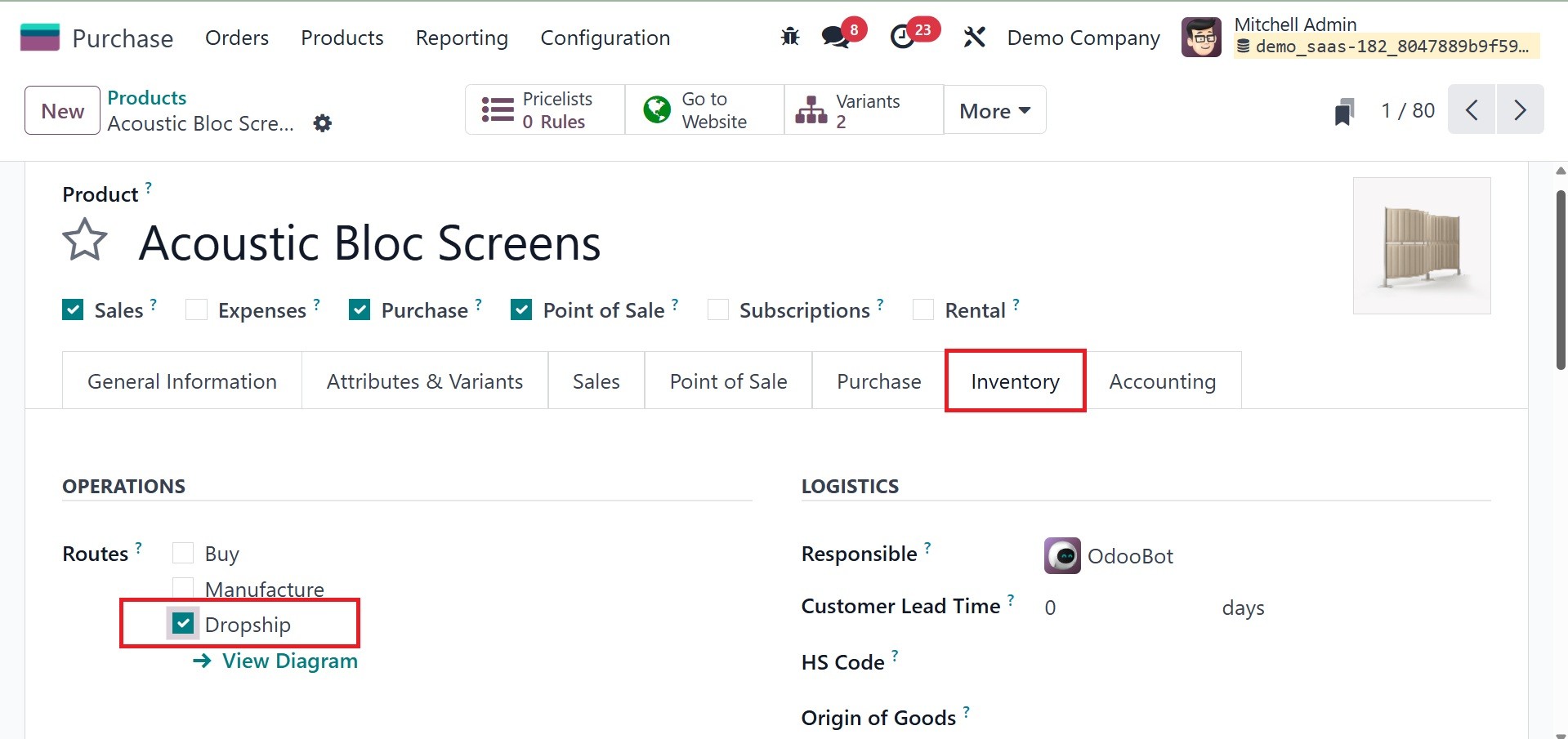

On activating the dropshipping

option in the settings, The

tab for an inventory of the

operational routes can be

found in the product

configuration, as in the

image below.

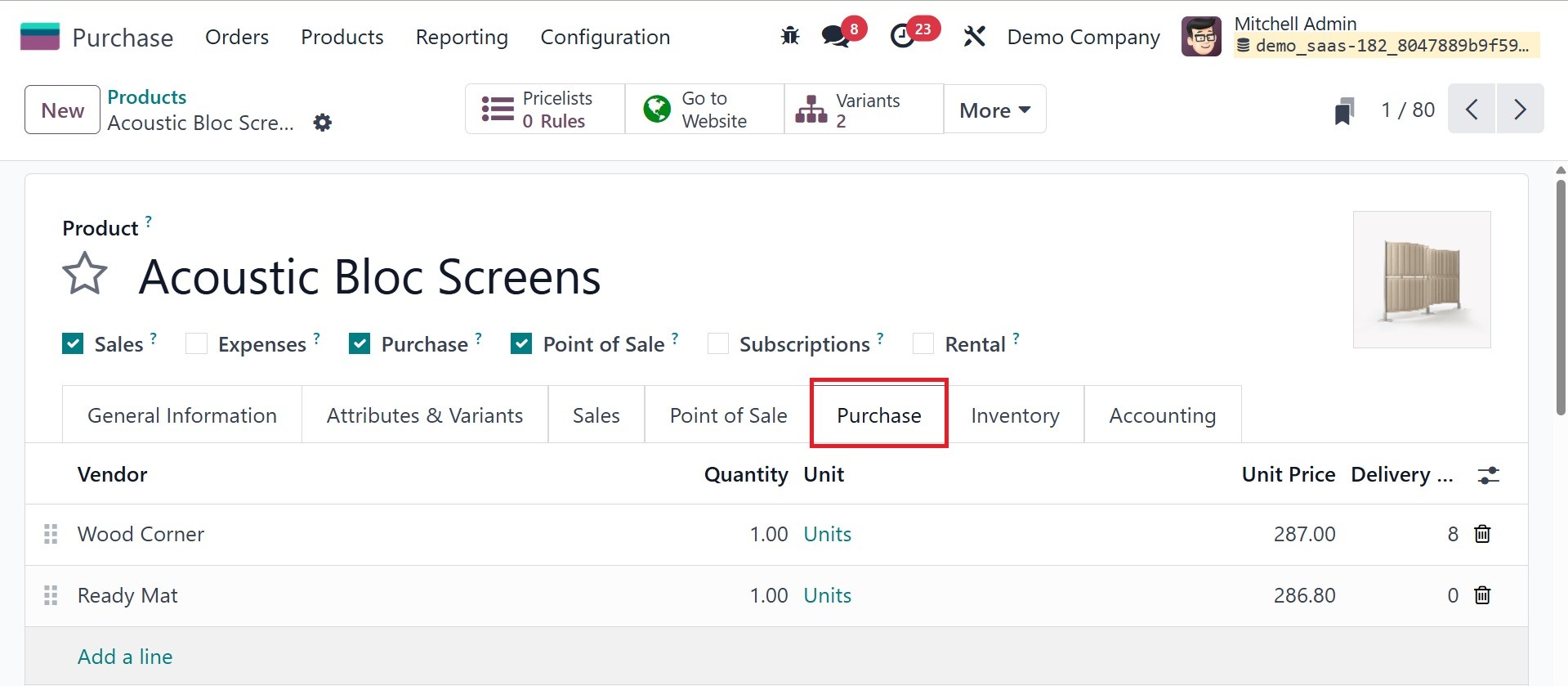

This parameter can be used to

specify a product's routes.

Additionally, remember to add

a vendor from the purchasing

tab of the product form.

When a purchase order is made,

this will be the seller of

the product.

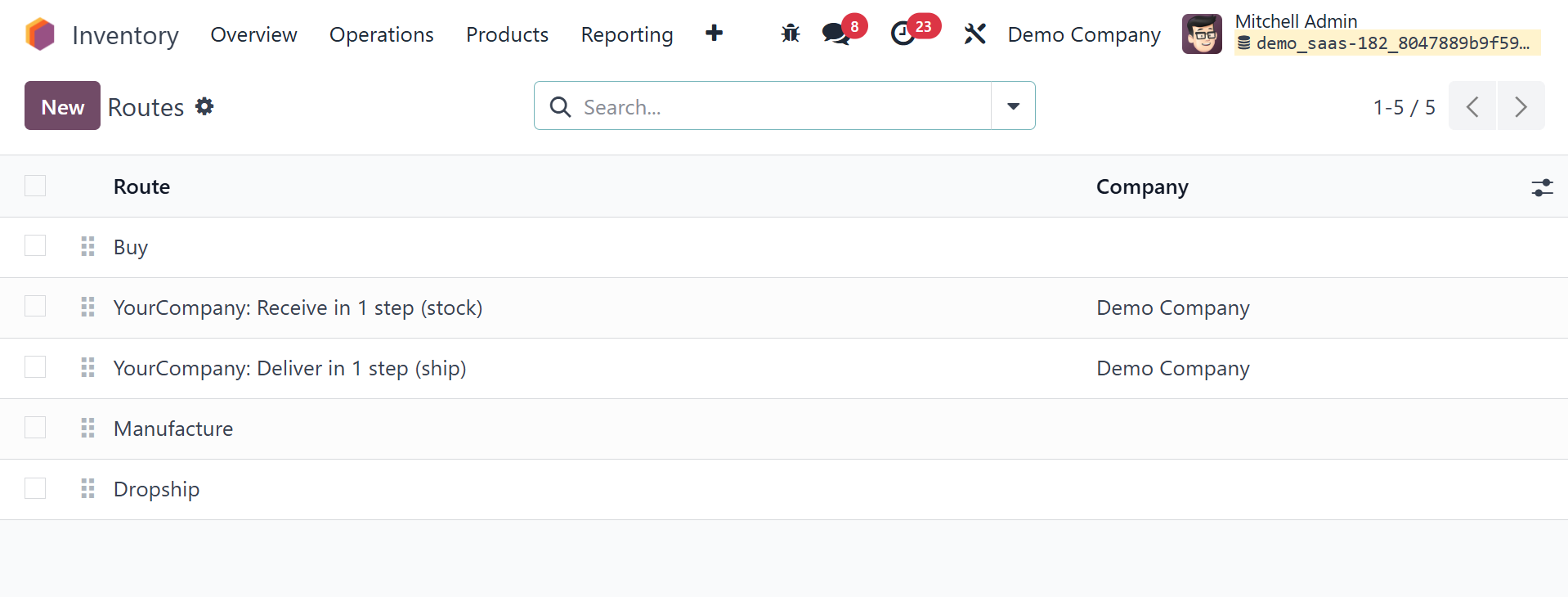

Additionally, you can configure

or create new routes by

heading to the settings tab

of the inventory module,

which will bring up the

Routes menu.

The pathways lead to the

dropship, where you can make

any necessary adjustments.

This part contains the sequence

number and name of the

operational route. You can

select which product

categories and items this

route is accessible for by

filling out the section that

appears. To make this route

the default path for products

that go through the specified

warehouse, you can turn on

the Warehouse option as

needed. Since dropshipping is

a direct delivery method from

the supplier to the buyer, it

typically doesn't require a

warehouse.

Turning on the selling order

lines also allows you to

choose this path from the

line. The details of the

route are described on the

Rules tab.

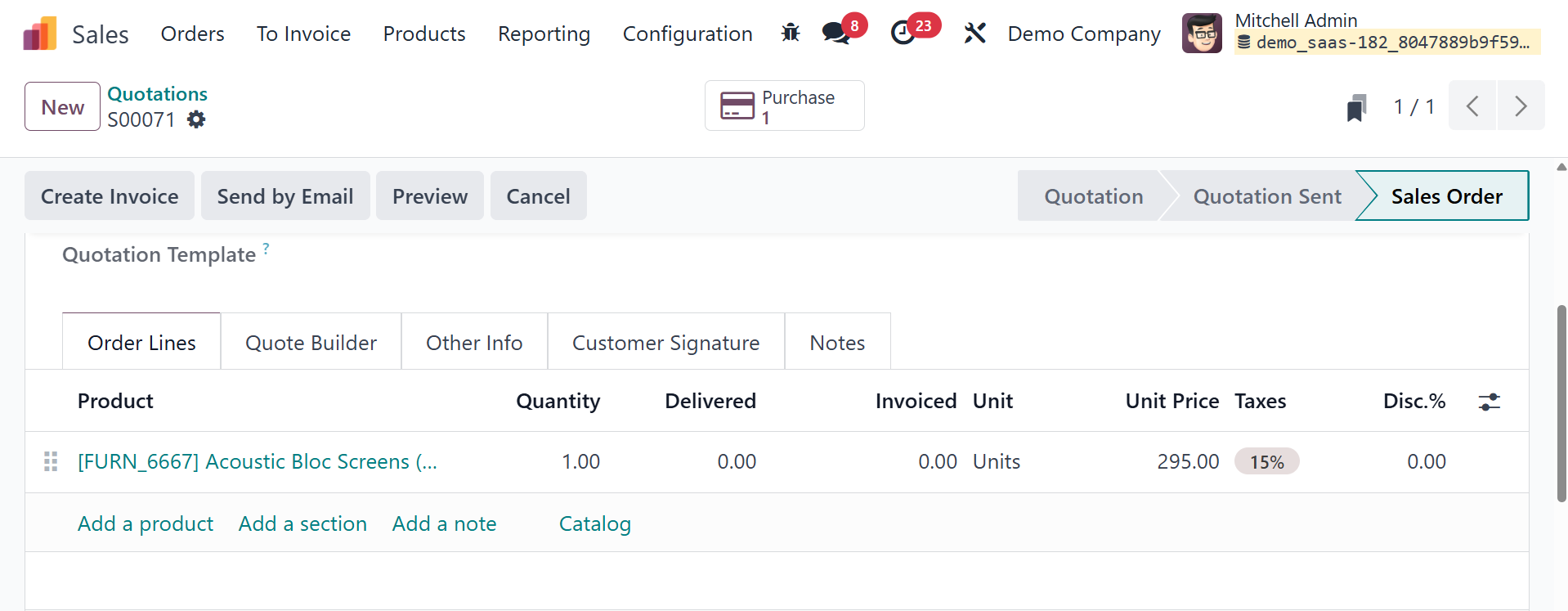

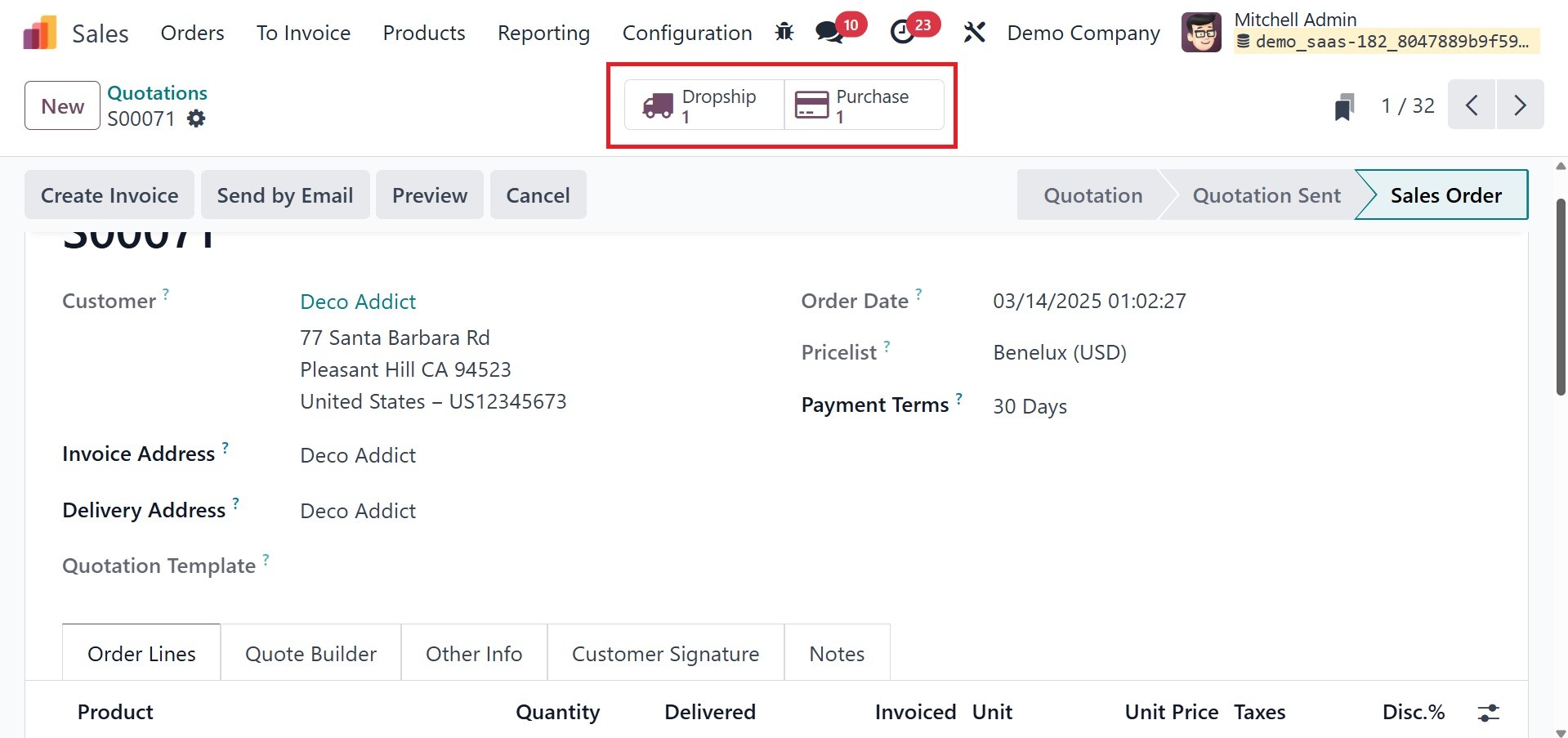

Now, create a sale order for the

goods that includes

information on the

dropshipping process; when a

customer places an order, the

product will be shipped

directly from the supplier to

the customer.

Additionally, you can use the

sales module to create a sale

order for this product.

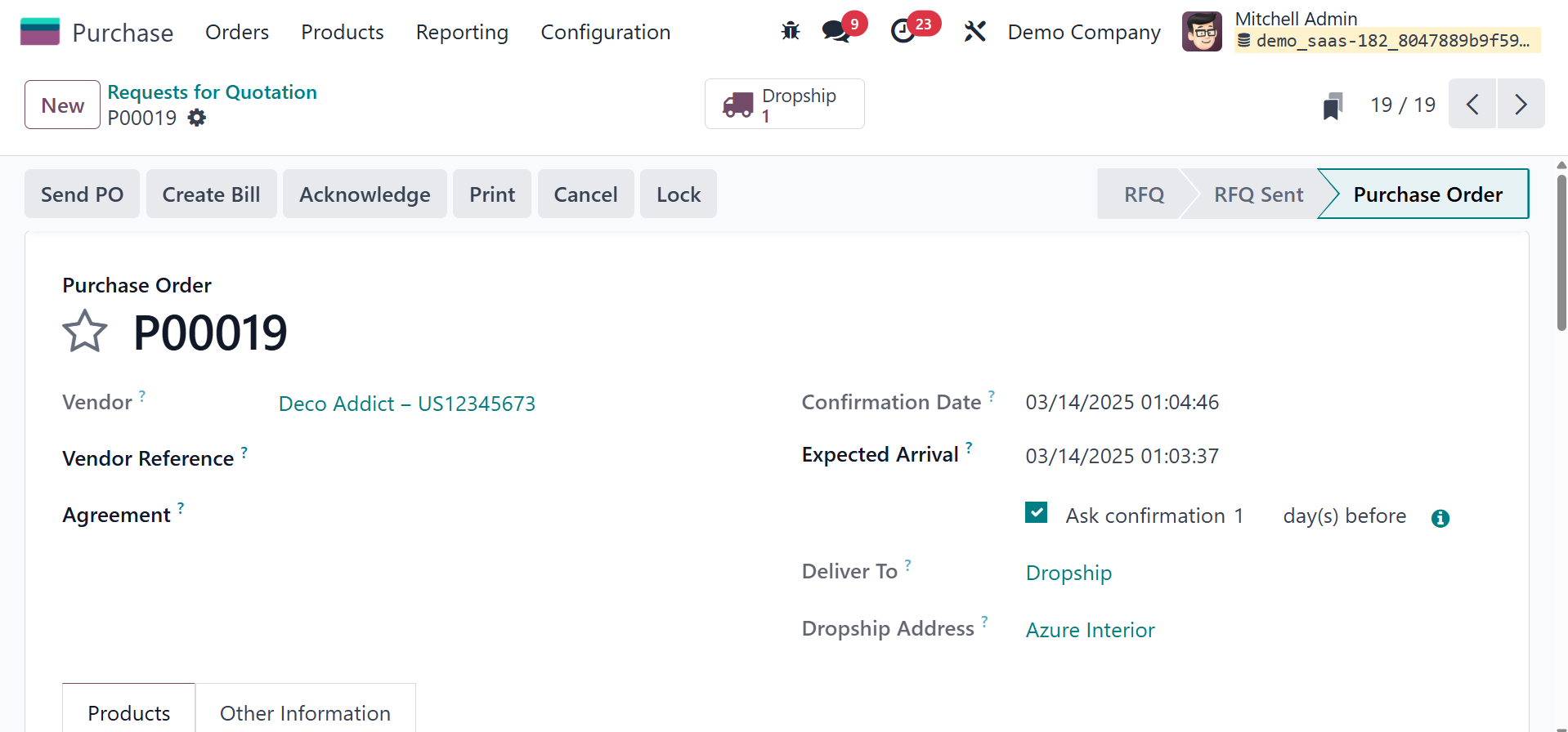

As a result, a purchase order

will be placed to initiate

dropshipping. The RFQ's

status as a purchase order is

confirmed. A purchase order

will appear.

The vendor selected when you open

the purchase order is the one

we mentioned on the product

form's Purchasing tab.

In compliance with the applicable

sale order criteria, the

product and quantity are also

updated. Dropshipping is

used, and the customer

specified on the sale order

serves as the delivery

address.

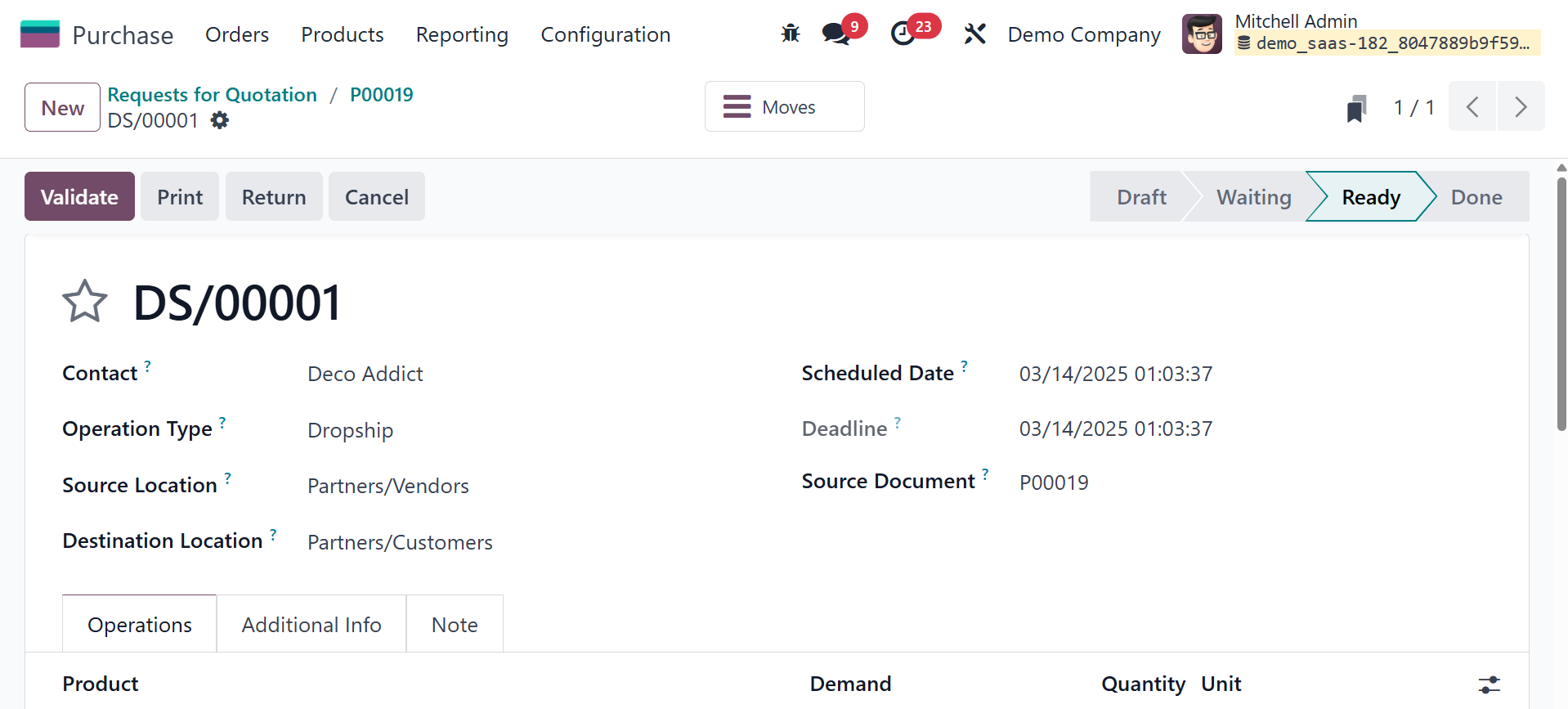

A dropship smart button for

validation will show up when

the purchase order has been

validated.

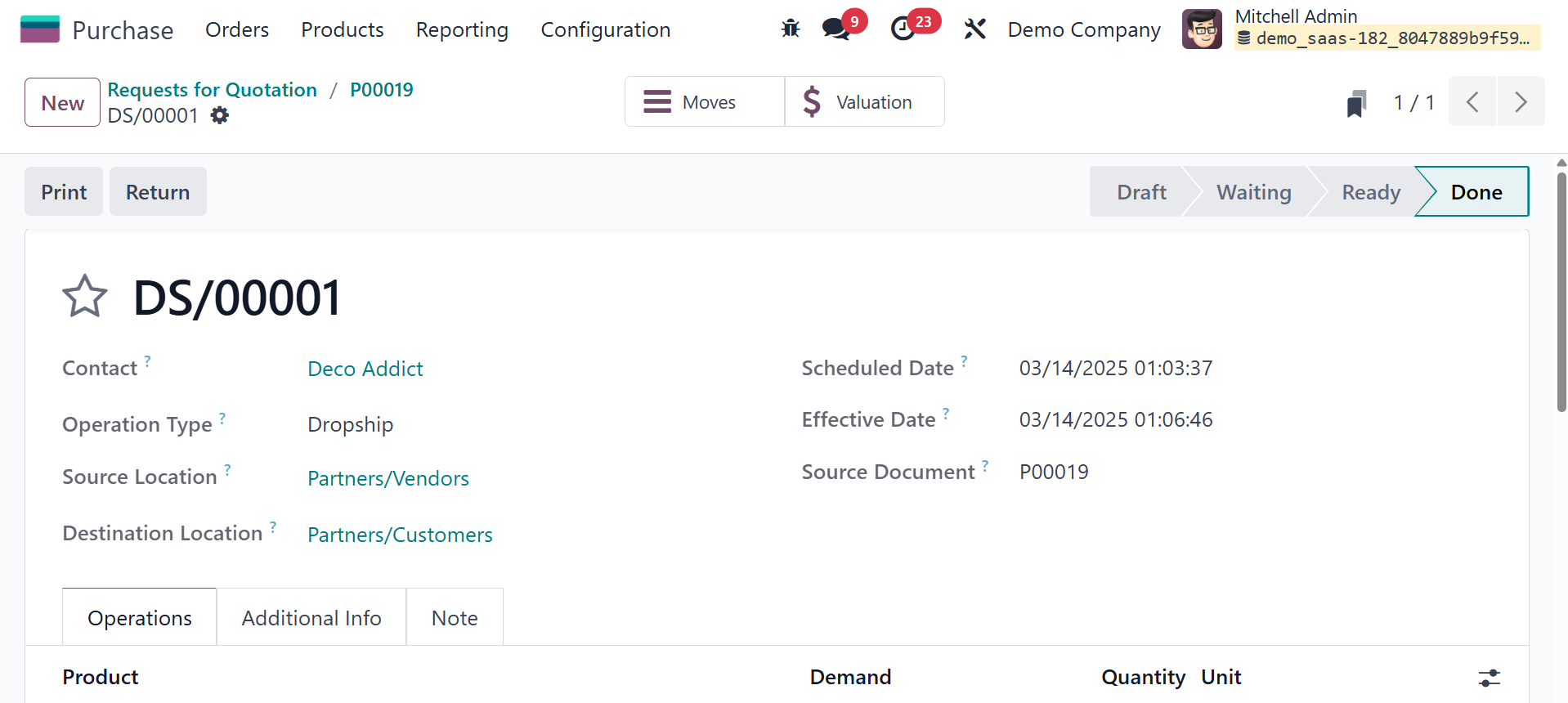

As you can see, in the form

mentioned above, the delivery

address is the destination

location. The dropship may

now be confirmed. Create a

bill for the purchase order

and document payment after

the dropship has been

confirmed. I'm going back to

the sale order.

As you can see, the supplied

quantity has been adjusted

here because the seller sent

the merchandise directly to

the client.

Once all of these procedures are

completed, the products will

be purchased from the

supplier in accordance with

the purchase order and

supplied to the customer in

accordance with the sales

order.

3.7 Batch Transfers

Using the Batch Transfer tool in

Odoo18, you can perform

multiple transfers at once.

You can use this tool to

perform batch transfers,

which will save you time and

effort. All transfers

included in the batch are

carried out at the same time

when transferring in batches.

The issues involved in

handling bulk transfers can

be minimized by using this

method.

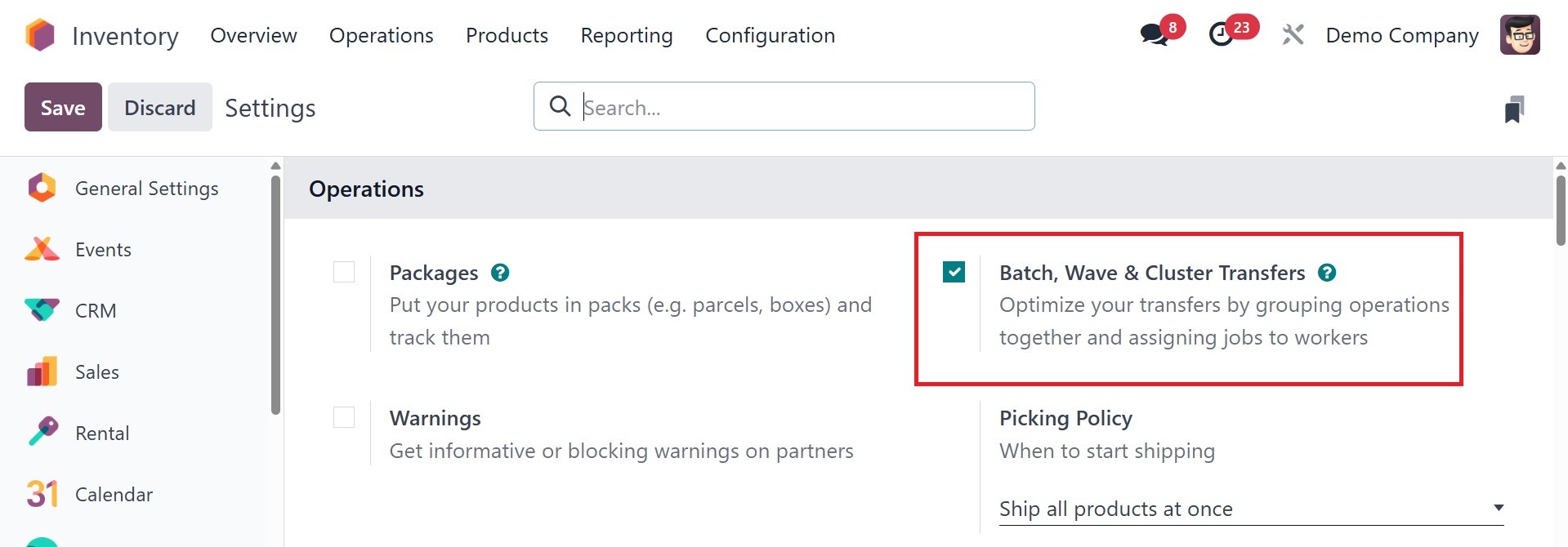

As can be observed in the picture

below, the Inventory module's

Settings menu enables you to

quickly enable the Batch

Transfer option.

After selecting the Batch

Transfer option, click the

Save button to save the

updated changes. You may now

manage batch transfers from

the platform that is

available under the

Operations menu, as seen.

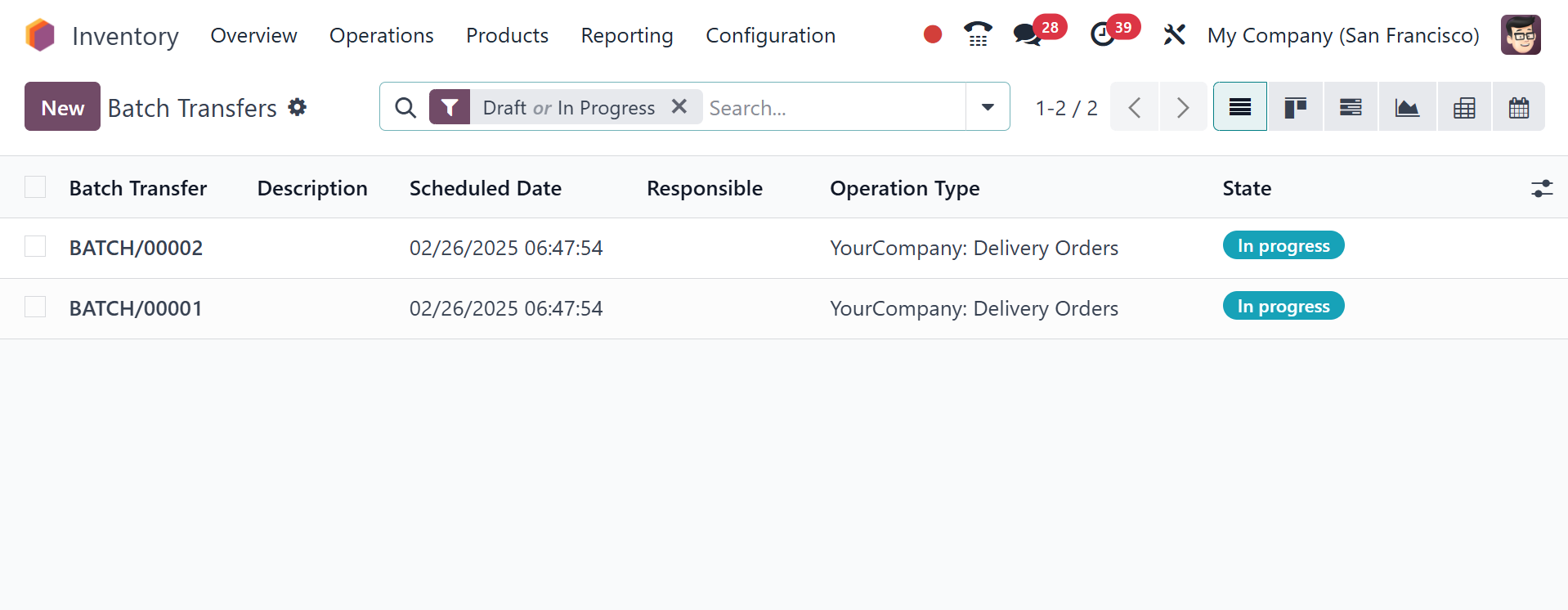

Here you can observe a list of

previously created batches

and details for Batch

Transfer, Scheduled Date,

Responsible, Operation Type,

Company, and State. You may

also switch the perspective

of the platform to be a

Kanban perspective. From

here, begin a new batch

transfer using the New

button.

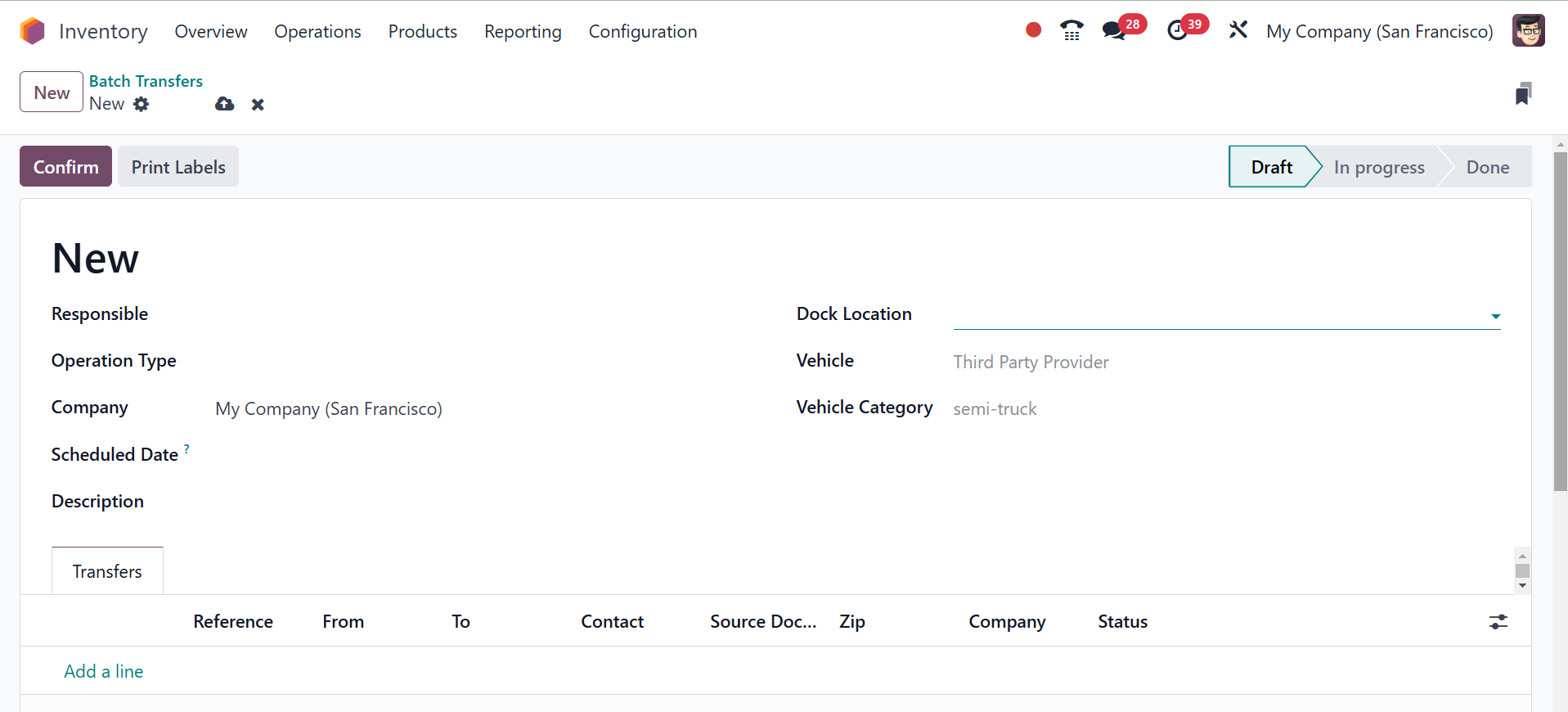

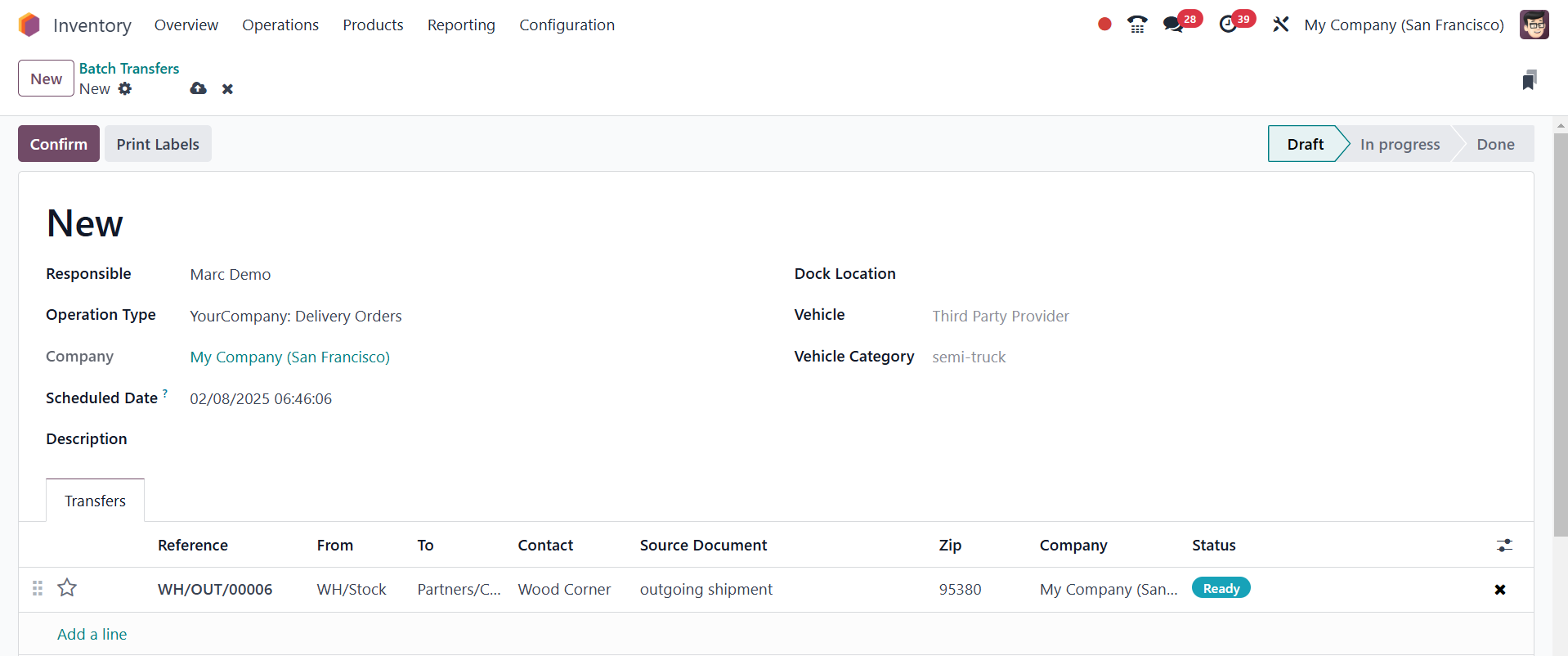

You may assign an employee to do

this batch transfer's

upcoming tasks in the

Responsible box. Complete the

blanks for Operation Type and

Company. Odoo18 allows you to

add transfers with this

operation type to this batch

by giving the Operation Type.

You can schedule the

transfer's expected date

manually in the Scheduled

Date column. Unless manually

specified, the date for this

transfer will be set

automatically by Odoo18 to

the first scheduled date of

the transfer that belongs to

the batch. There, you have

the options of dock location,

vehicle, and vehicle category

to add as well, which is

available on activating the

Dispatch Management system

option in the settings.

Now, you may use the Add a Line

option on the Transfer tab to

add transfers to this batch

one at a time.

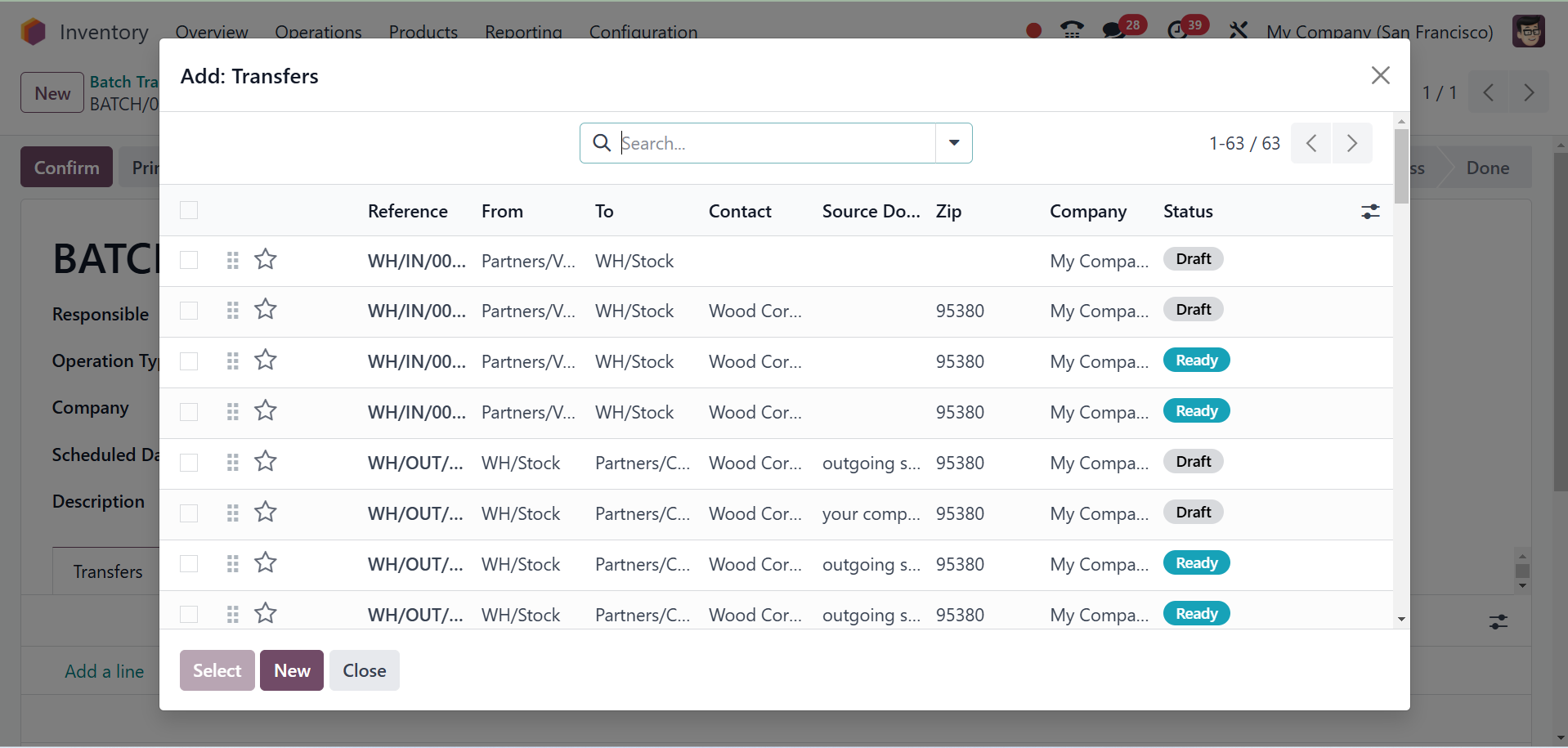

You will get a new pop-up window

as soon as you click on the

Add a Line button where you

can select the transfers for

this batch. You will be shown

a list of different transfers

for the selected operation

type in different phases. The

transfers can be selected

from the list. Select

transfers of the same stage

either in waiting or ready

status, if feasible. You may

use the Select button to

include them in the batch.

The selected transfers' list will

be added automatically to the

batch, as can be viewed in

the above figure. You can use

the icon ❌ in the following

screenshot to delete any of

the transfers from the batch.

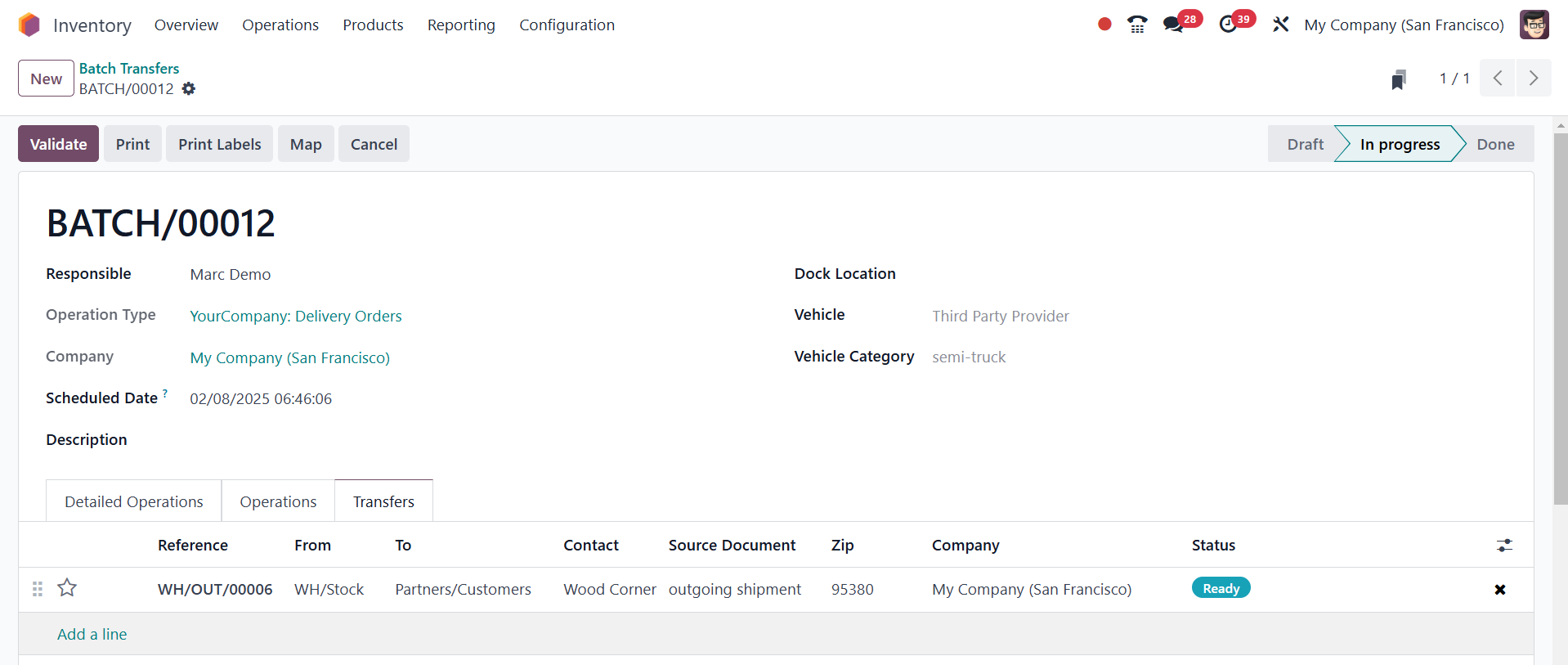

Using the Confirm button once

the availability has been

confirmed, you can complete

the transfer. Then, you can

complete the batch transfer

process by clicking on the

Validate option.

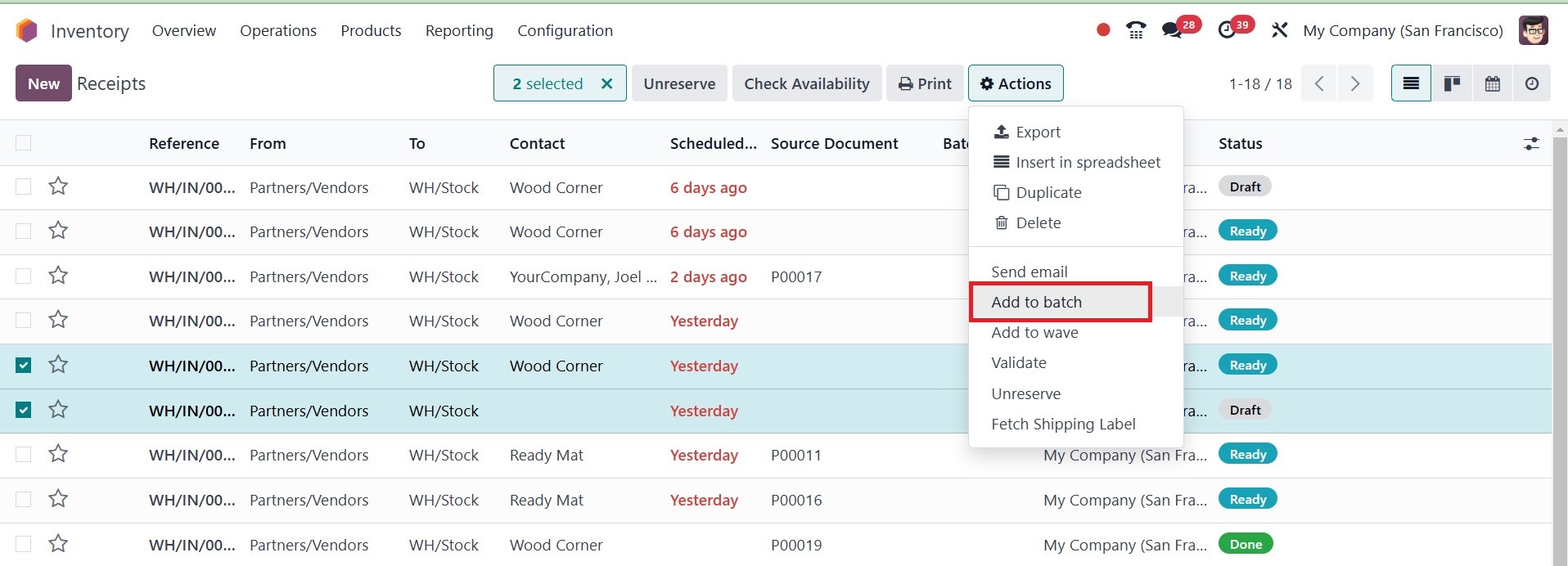

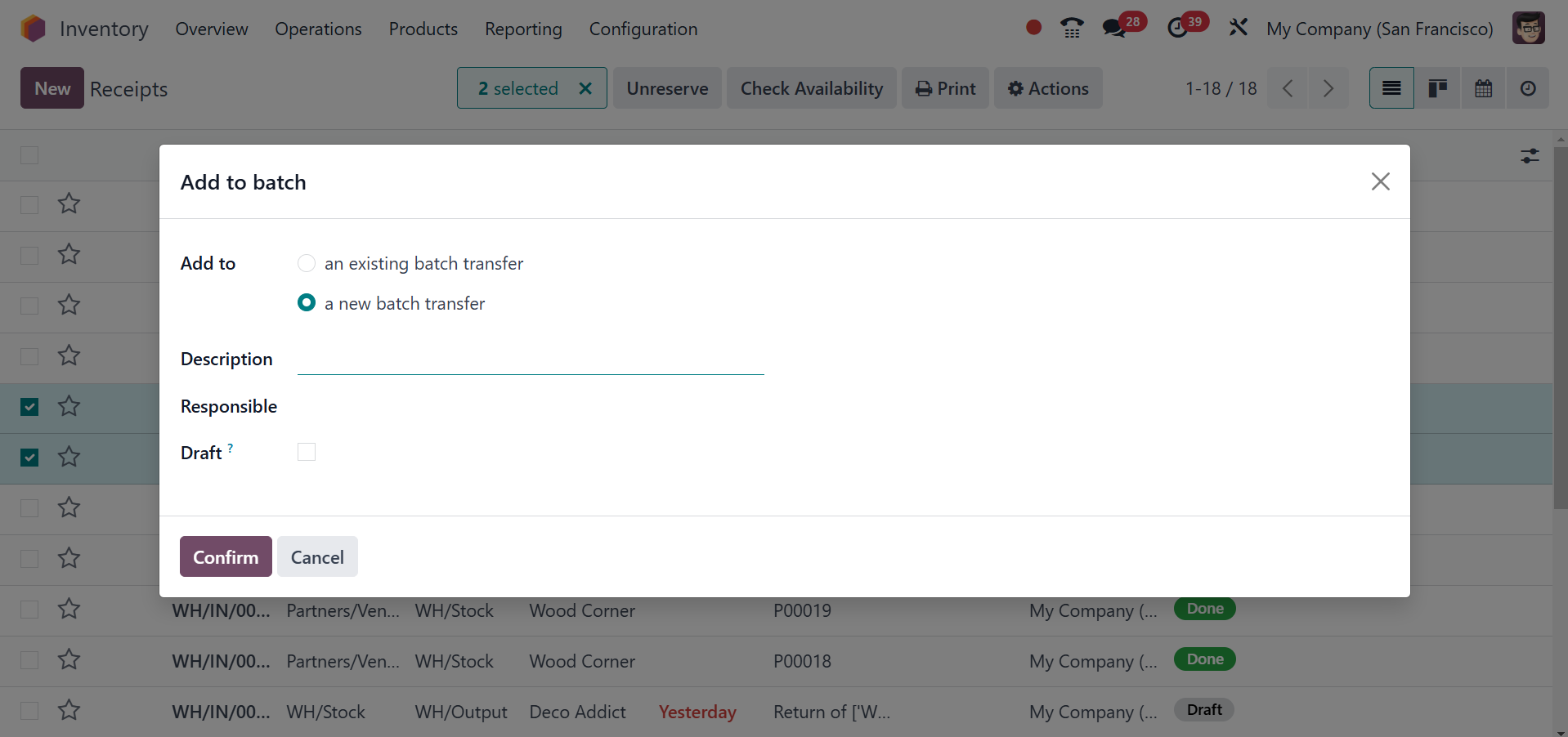

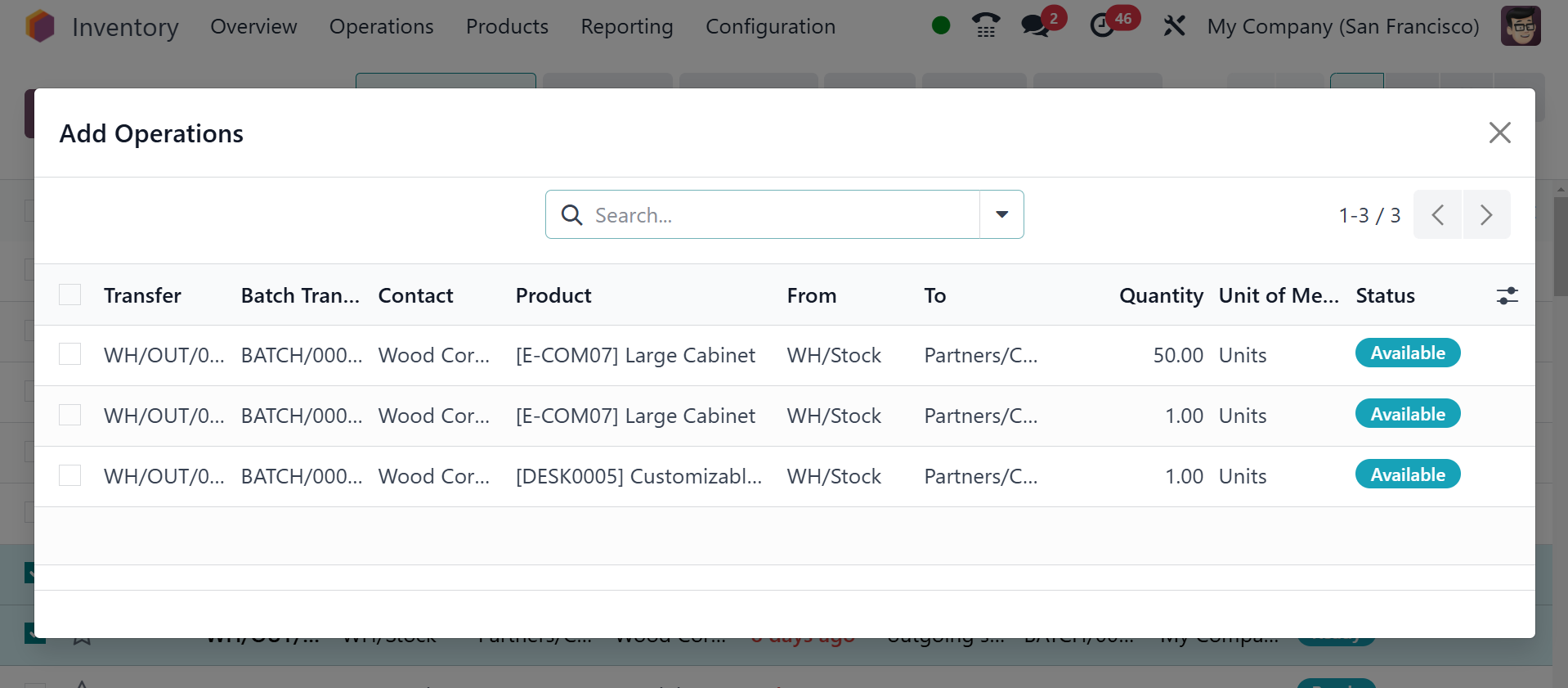

From the Transfers menu, it is

also possible to create new

batches of transfers. This is

possible through access to

the Transfers platform found

under the Operations menu.

The transfers to include in a

batch are selected from the

existing list of available

transfers. Ensure the

selected transfers all have

the same operation type and

status. Following the

selection of the required

transfers, an Action button

is then visible.

The Action button gives you the

option to incorporate the

selected transfers in a

batch. Select the "Add to

Batch" option.

The selected transfers can be

added to an existing or a new

batch transfer. You can

specify the Responsible

employee in the given field

for a new batch transfer.

Enable the Draft option to

generate the new batch in the

draft state. A new batch

transfer will be generated in

the Inventory module after

clicking the Confirm button.

You can track and manage the

new batch transfer from the

Batch Transfer portal.

3.8 Wave transfers

The Wave Transfer method does the

same thing as the Batch

Transfer option. With this

method, you are able to

transfer a significant amount

of merchandise from one

location to another. A

transfer, though, can't be

removed from a wave transfer

once added. The wave transfer

method is more advanced

compared to batch transfers.

Make sure to enable it from

the Settings menu in order to

receive this feature in the

Odoo18 Inventory module.

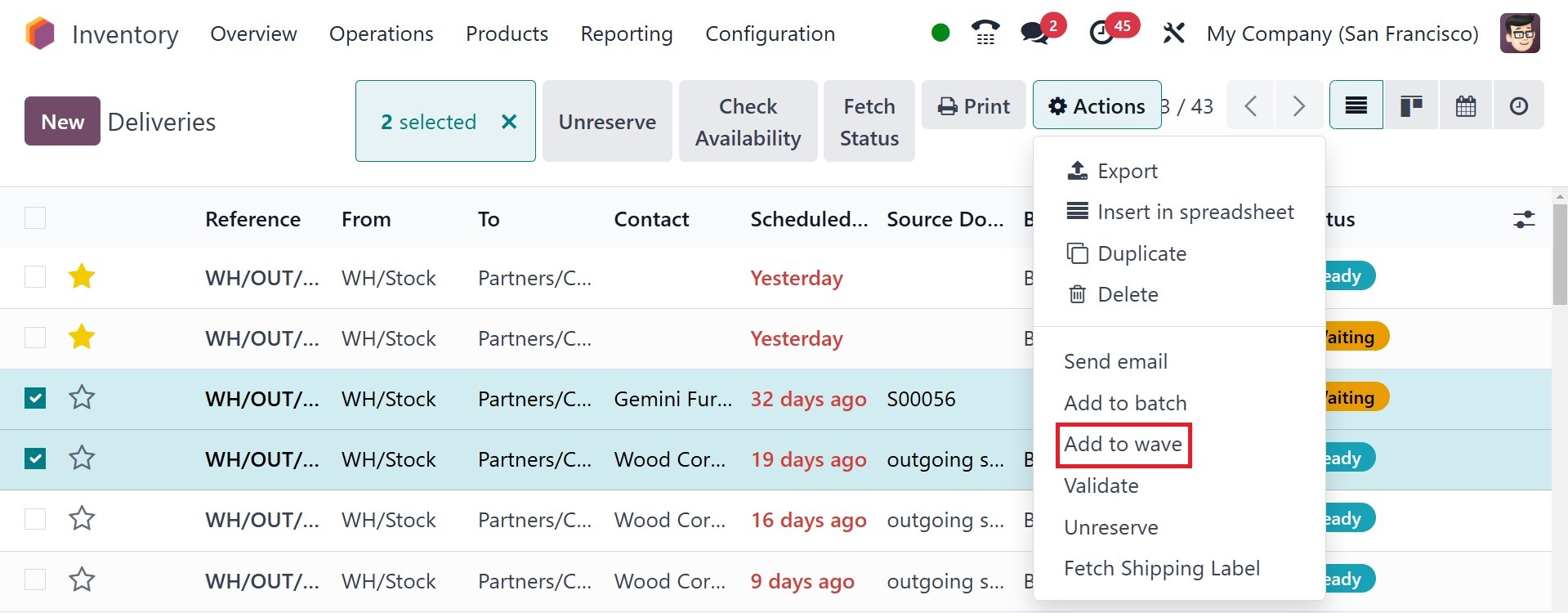

You are able to access the

Transfers window once the

Wave Transfer feature has

been activated. In order to

add transfers to a wave

transfer, select the

transfers from the Transfers

window with the same status

and operation type.

Once you select the required

transfers, the Action button

will be displayed on the

screen, where you can select

the Add to Wave option. A new

pop-up will be displayed on

the screenshot when you click

this button.

The selected transfers may be

included in a new transfer or

an already-existing wave

transfer. For a fresh wave

transfer, you need to find an

officer in the Responsible

field. To complete, click the

Confirm button.

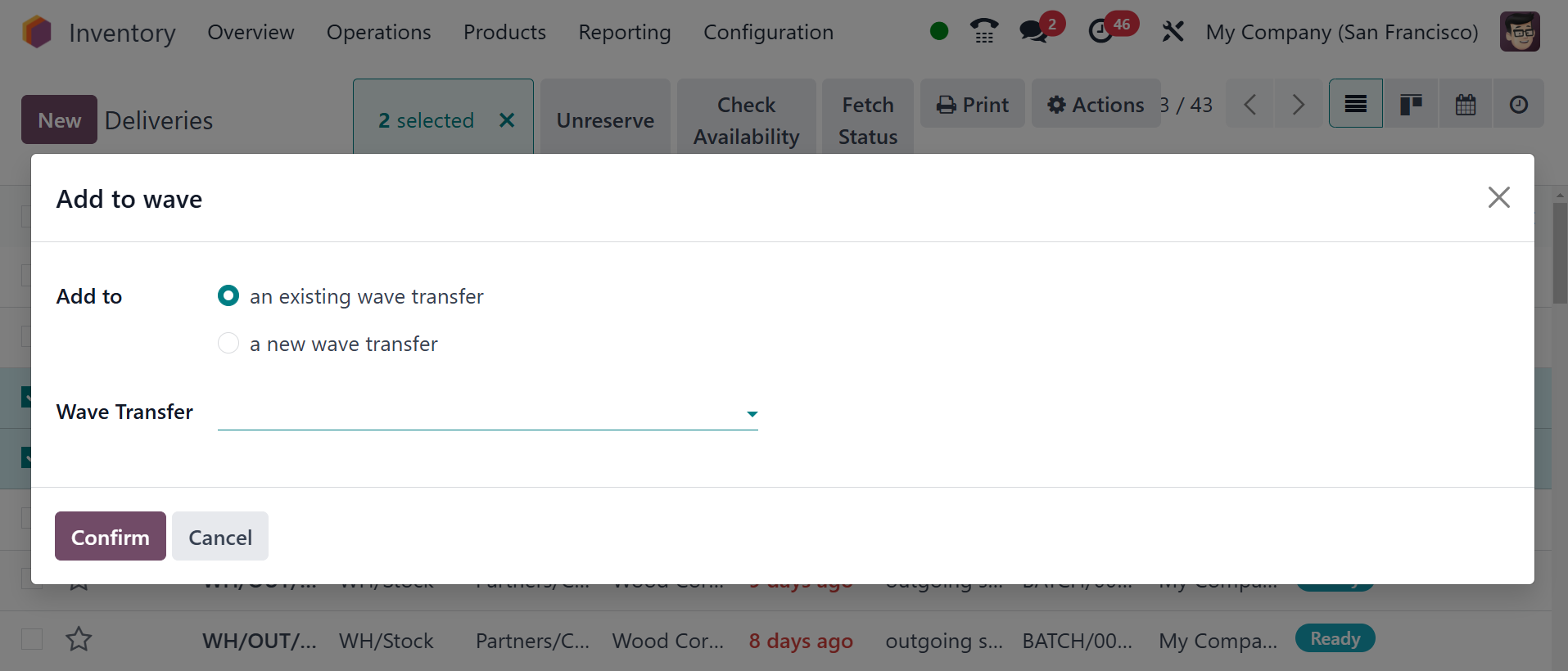

As soon as you approve the

transfer, all orders from the

chosen transfers will appear

on your screen. Select the

required orders from the

list, then select Add to

Wave.

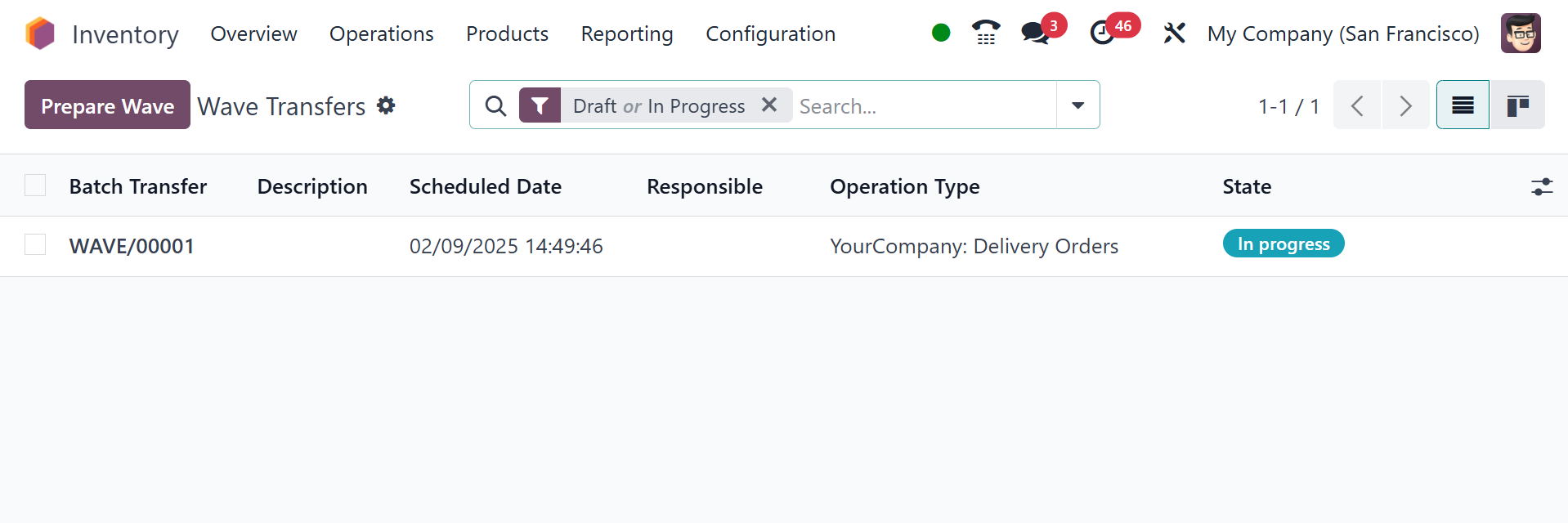

You can see the newly created

wave transfer from the Wave

Transfer platform in the

Operations menu.

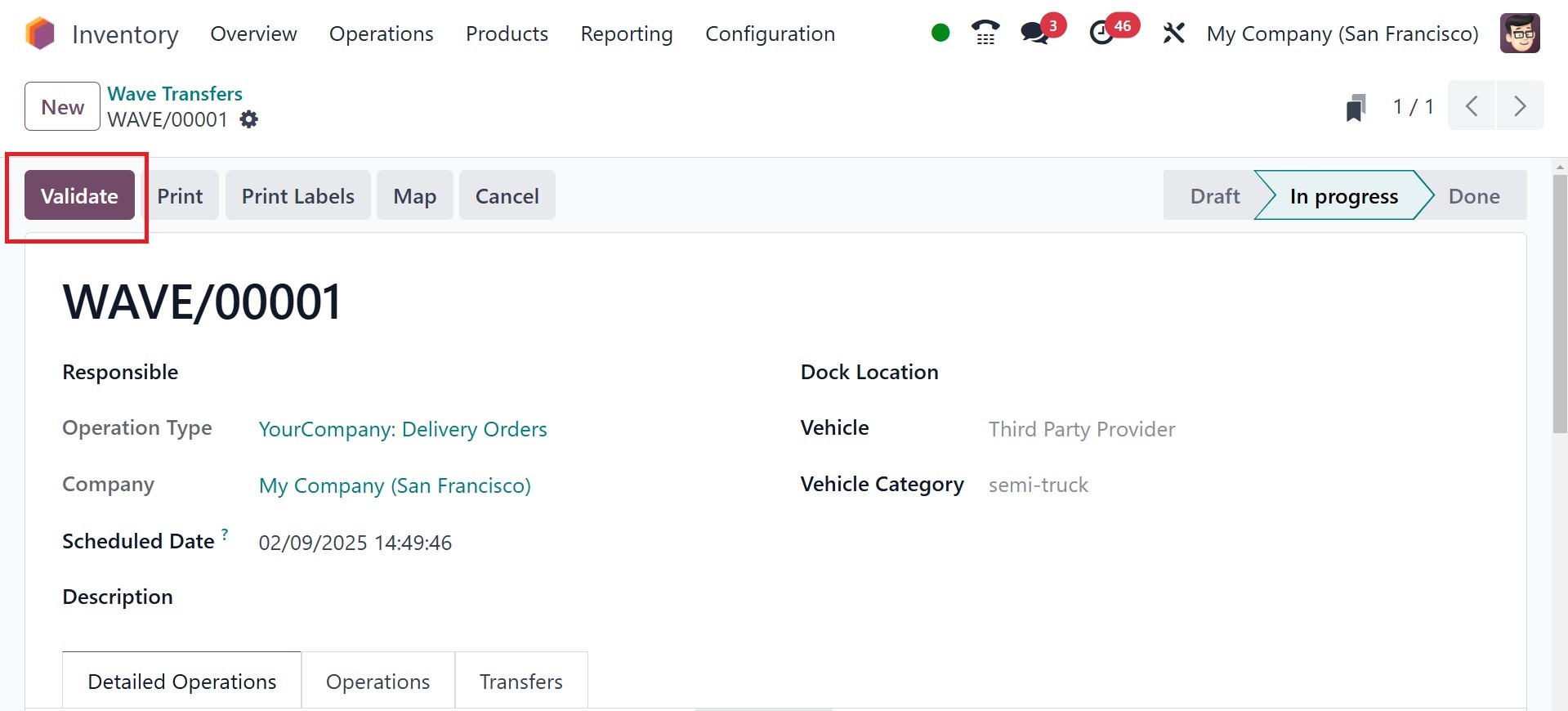

The details of the Wave Transfer,

Scheduled Date, Responsible,

Operation Type, Company, and

State will be shown in the

preview of the list. A new

window will open when you

click on the Wave transfer to

confirm the transfer.

Click the Validate button to

complete the transfer.

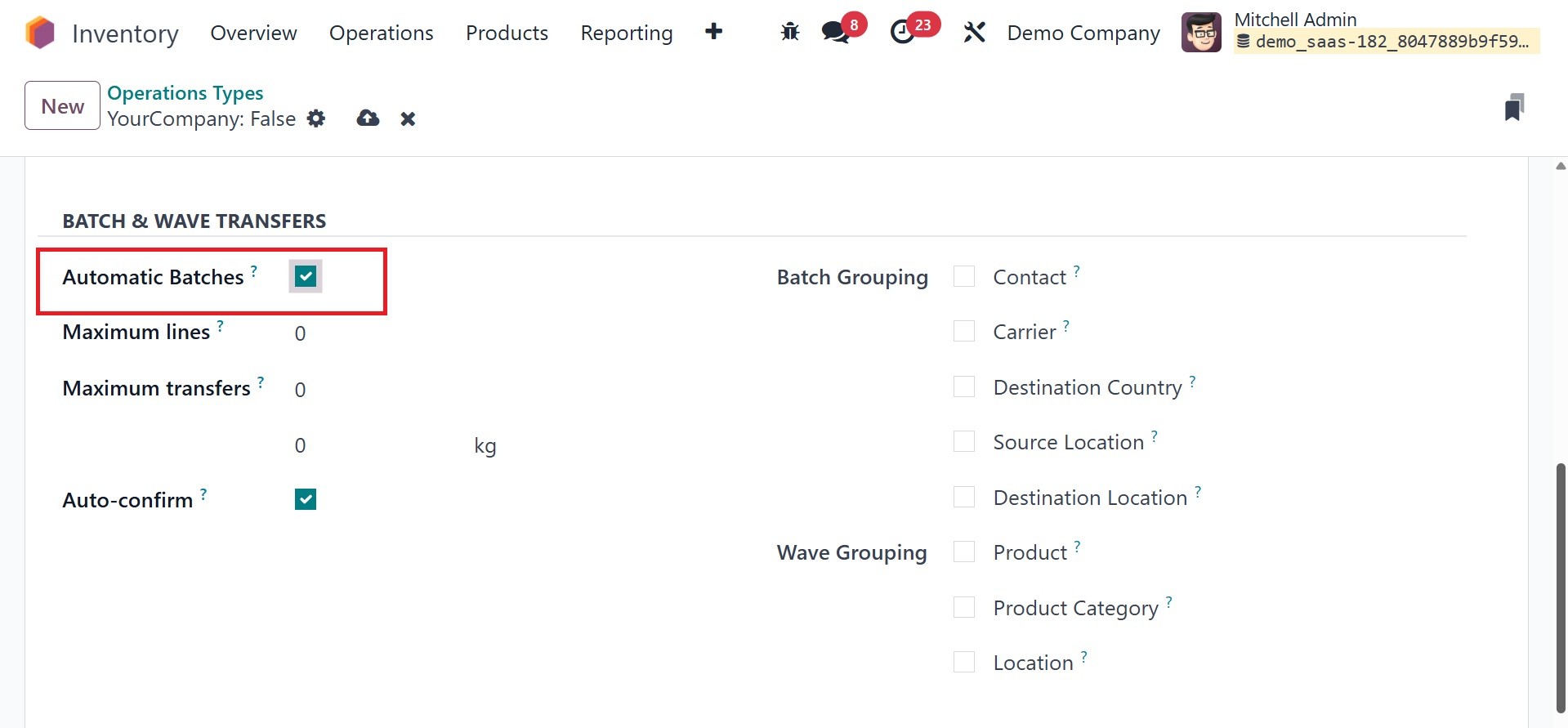

You can also have the option of

automatic batch and wave

transfer under the operation

types option, as in the image

below.

On activating the option, you are

provided with the options,

like maximum lines, maximum

transfers, auto confirm,

batch grouping, and wave

grouping, respectively.

Cluster picking is a warehouse

order fulfillment strategy

where pickers gather items

for multiple orders into a

single cart or container,

reducing travel time and

improving efficiency. It's a

derivative of batch picking,

but instead of sorting

products into separate

containers, pickers sort them

into different order packages

within the same cart.

3.9 Physical Inventory

According to the physical

inventories available in your

company currently, there can

be some situations when

certain changes in the

inventory will be required.

The changes you have done in

the inventory must also be

updated in the inventory

records for ensuring proper

inventory control. You can

make changes to the inventory

records in Odoo18 according

to the availability of

physical stock, with the help

of the Physical Adjustment

platform.

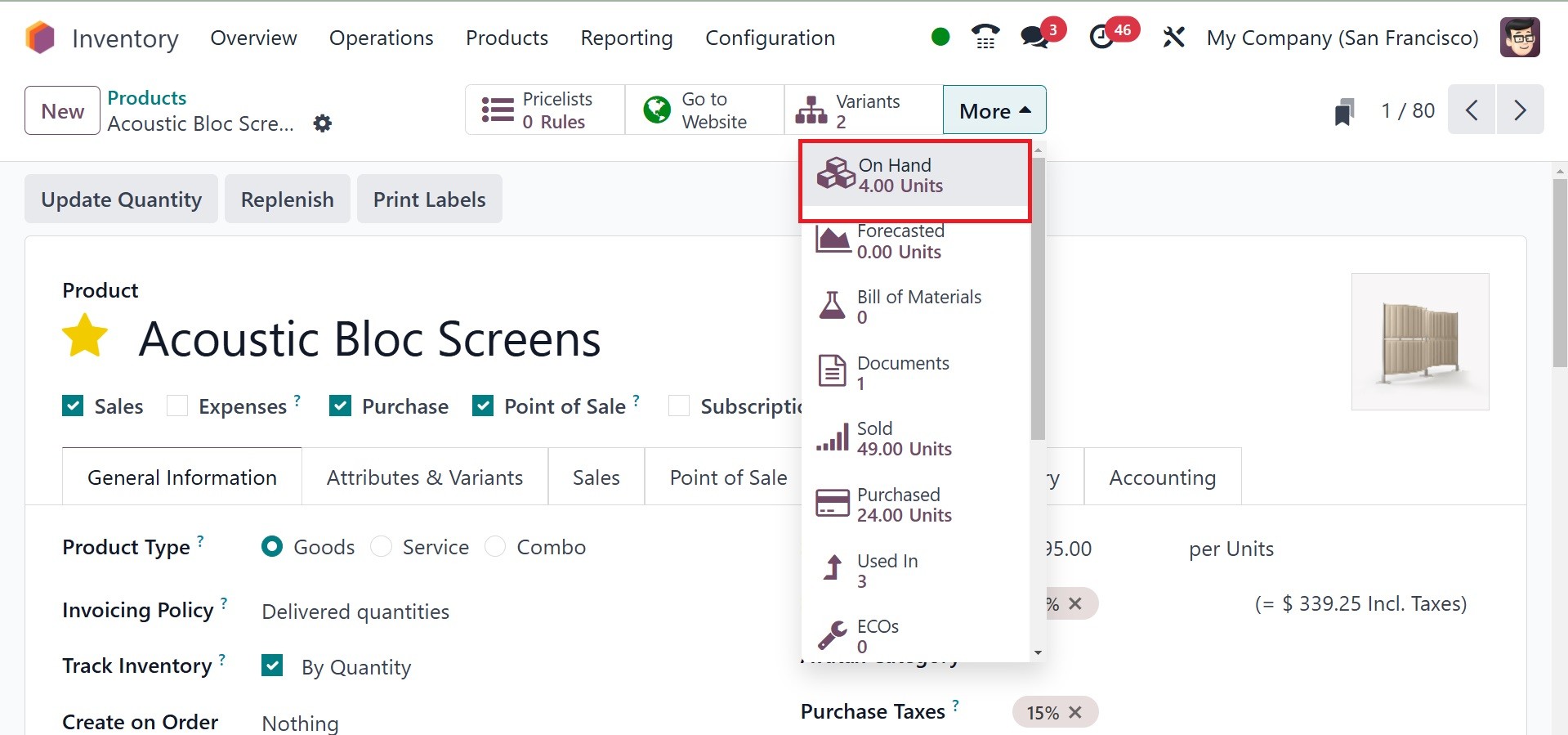

With Odoo18, you are able to

update your inventory

immediately from the window

of product description. On

every product, you will be

able to locate the Update

number button as indicated

below, in an effort to

properly record the number on

hand at your company's

warehouses.

Click the smart button

(highlighted in the image) to

view the information on the

quantities On Hand on this

page. You can alter the

product's amount by clicking

the Update Quantity button.

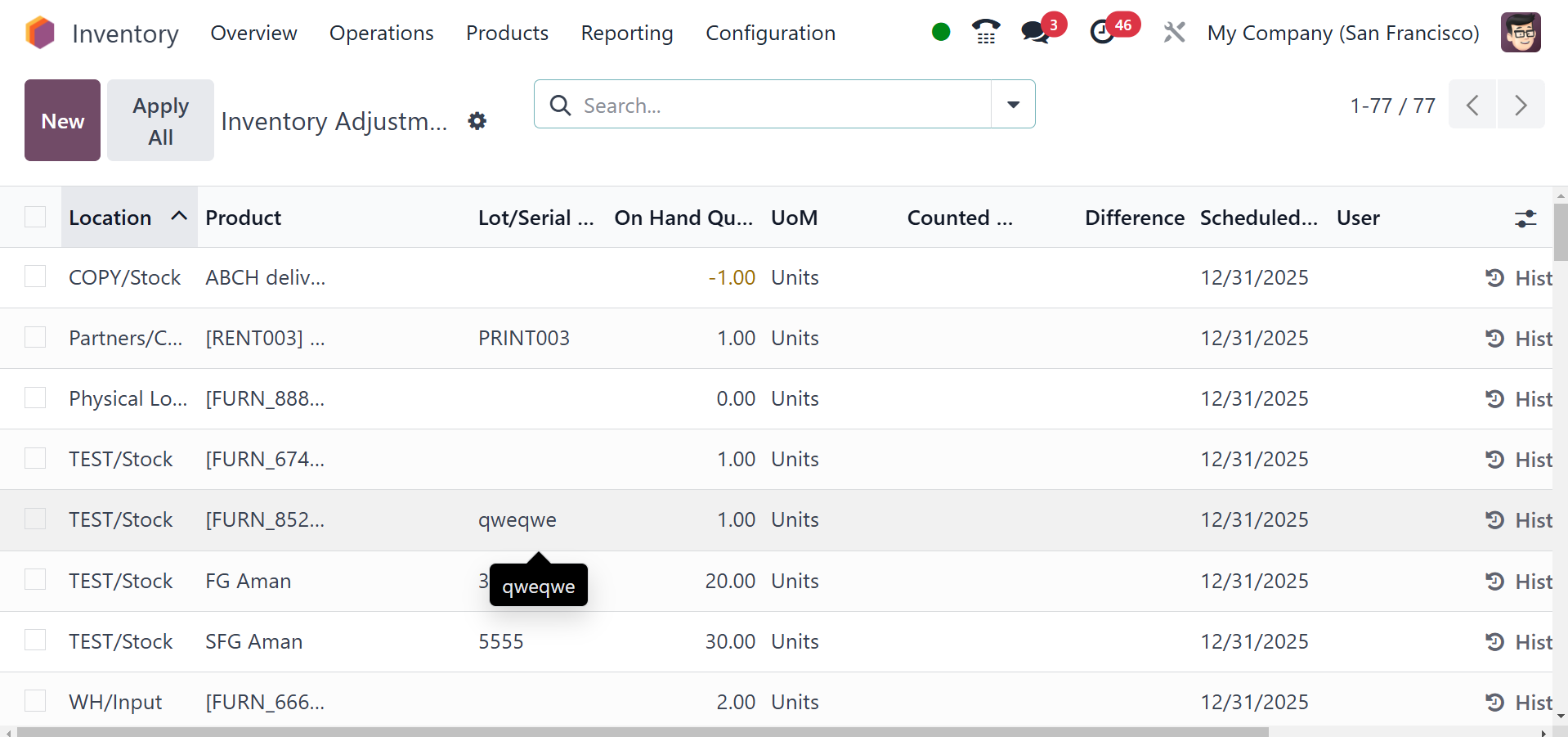

To manage all of these inventory

revisions, you can find a

special platform called

Physical Inventory in the

Odoo18 Inventory module's

Operations menu.

The records of each inventory

modification can be viewed on

this platform. You can update

the quantity of multiple

items at once with this

window.

Through this window, you can

retrieve details of Location,

Product, Lot/Serial Number,

Package, Owner, On Hand

Quantity, UoM, Counted

Quantity, Difference,

Scheduled Date, and User.

You can adjust the amount in

relation to the stock on hand

by clicking on the New

button. In this, you have to

enter the relevant field with

the Counted Quantities for

the given lot/serial number.

Odoo18 will automatically

show the difference between

the On Hand Quantity and the

Counted Quantity as soon as

you refer to the Counted

Quantity.

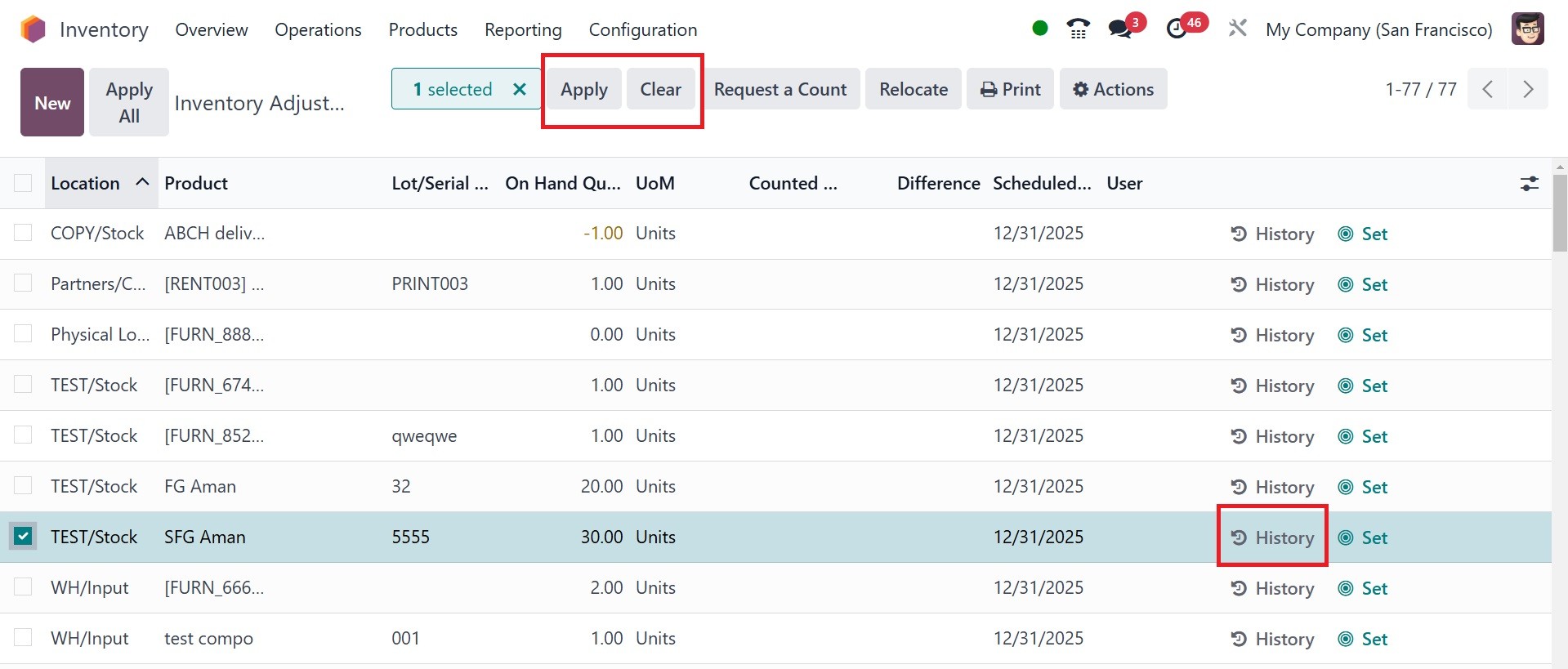

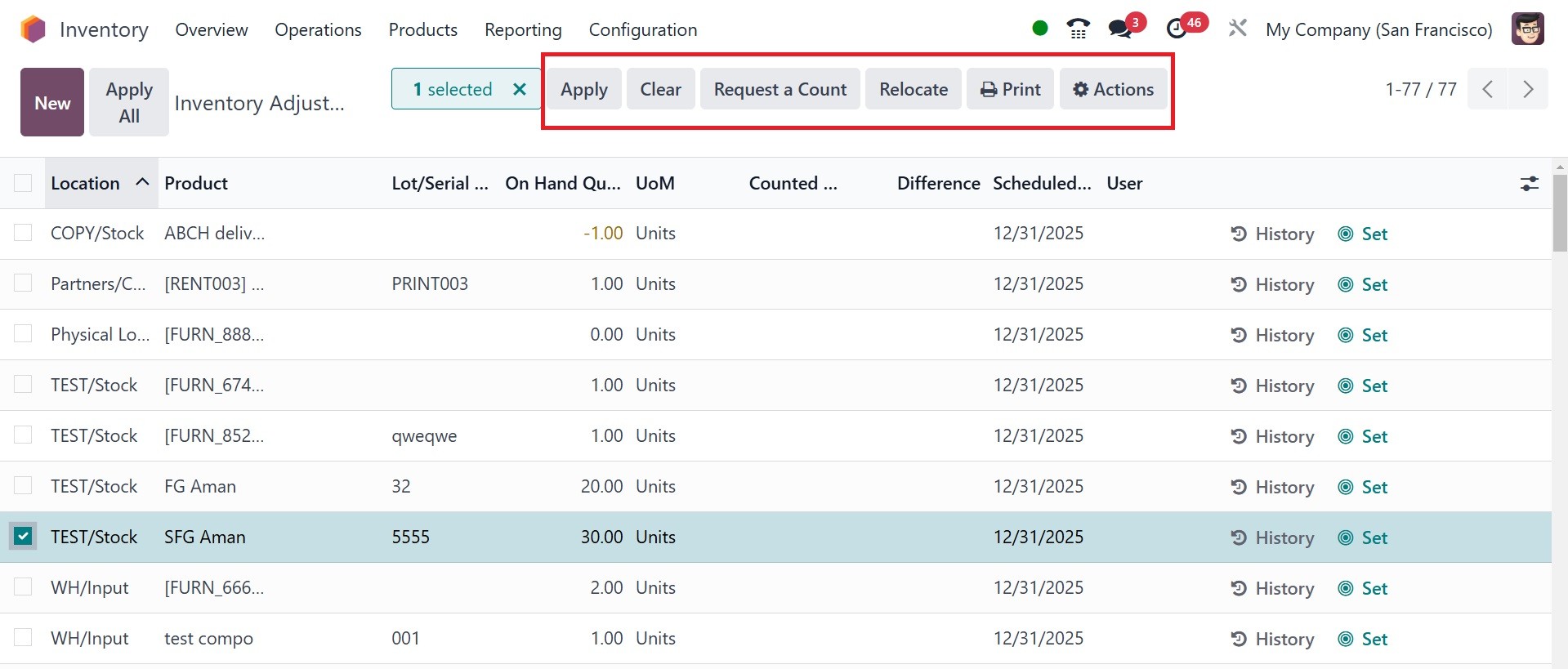

With the Apply option, you are

now able to update the

records with this inventory

change. You can choose the

Clear option in case no

inventory changes are needed.

The History button enables

users to see the history of

inventory changes done to a

product. You will be given

some additional buttons to

manage the available

inventory adjustments by

selecting them from this

window. To implement the

selected modification along

with the rest, press the

Apply button. You can reverse

all of the selected settings

simultaneously by clicking

the Clear button.

Click on the Apply button, as

shown in the figure, to

implement the updated

inventory changes for the

concerned products.

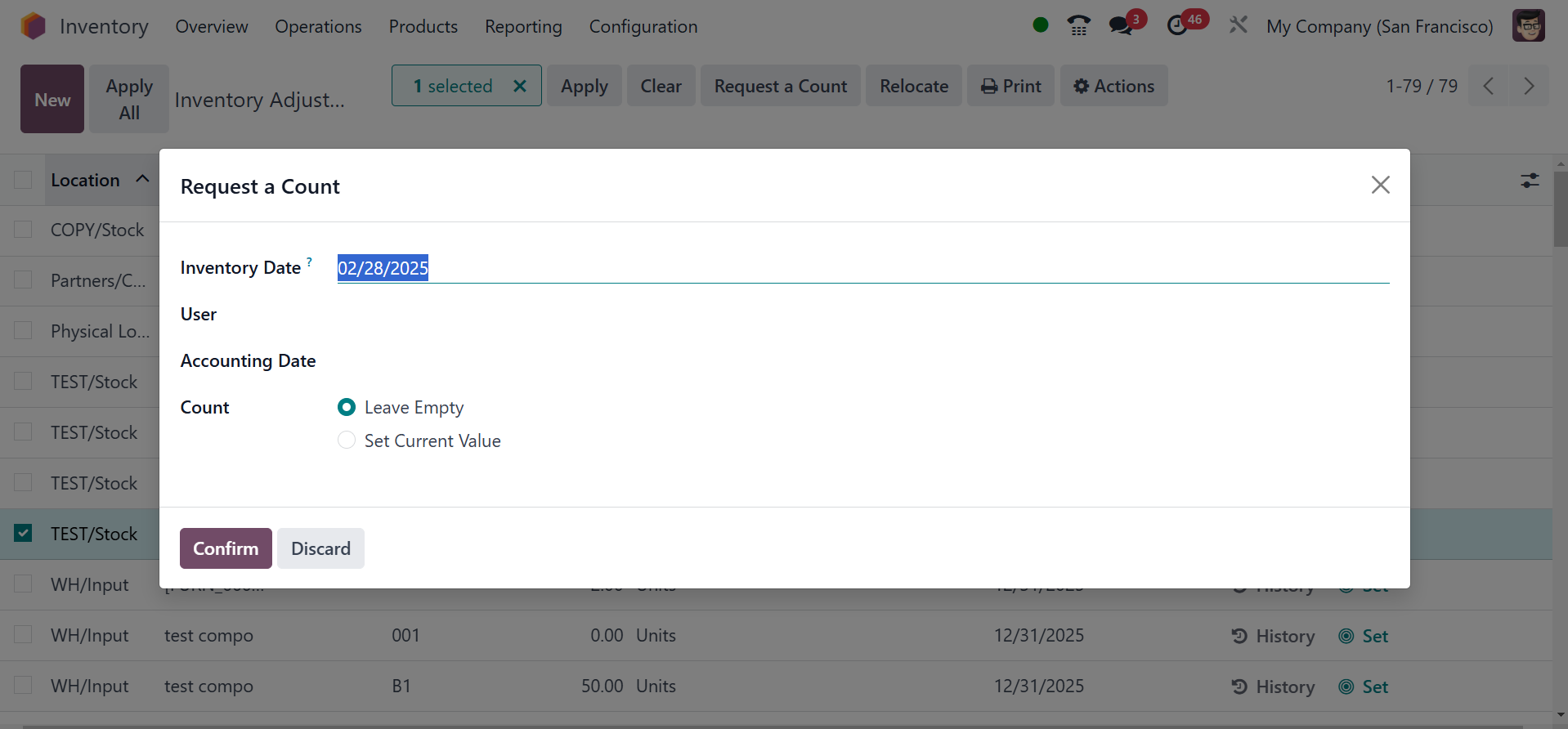

The Request a Count button

enables you to request a

count for the chosen

inventory modifications. You

can specify a date through a

pop-up window to have the

inventory delivered on that

day. You may leave the Count

field empty or modify the

current value according to

your requirements. Choose

"Confirm" from the menu. In

Odoo 18, we treat inventory

modifications in the same

way.

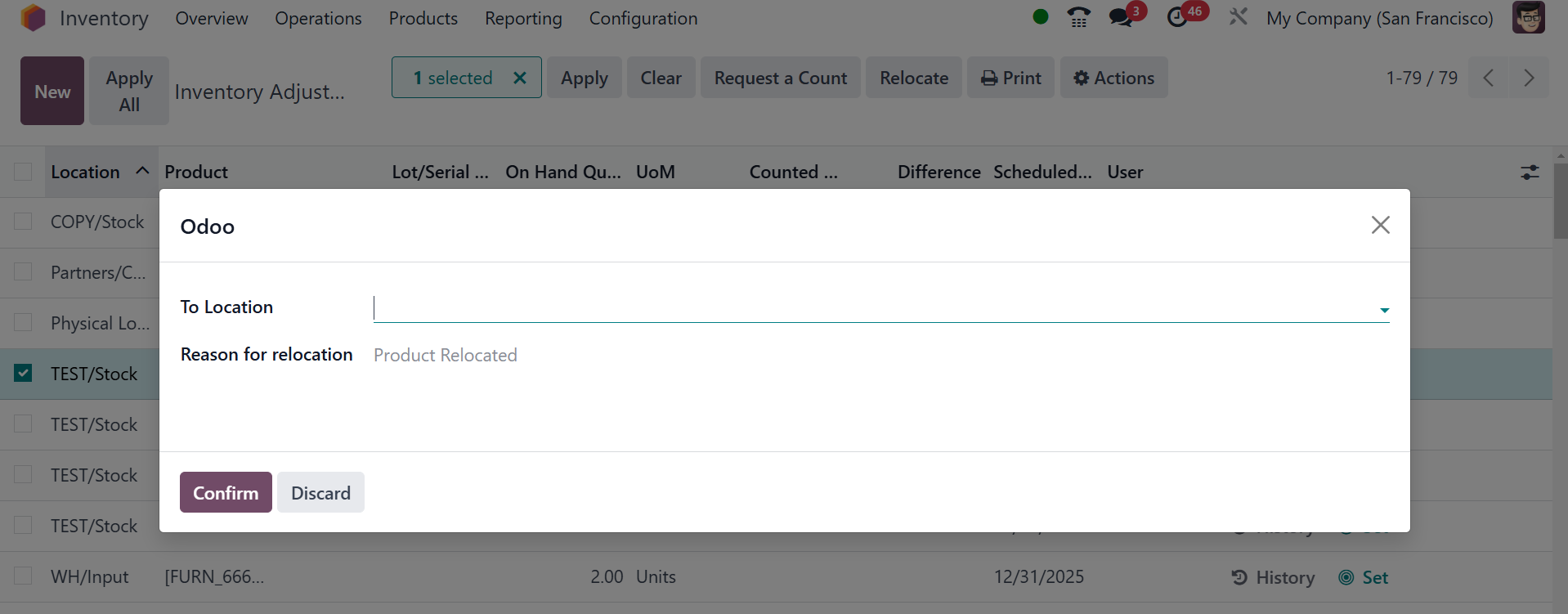

Moving products from one location

to another is made simpler

with Odoo 18's "Relocate"

option. In the popup box, you

can add To Location, To

Package, and explain why

you're moving. Then, confirm.

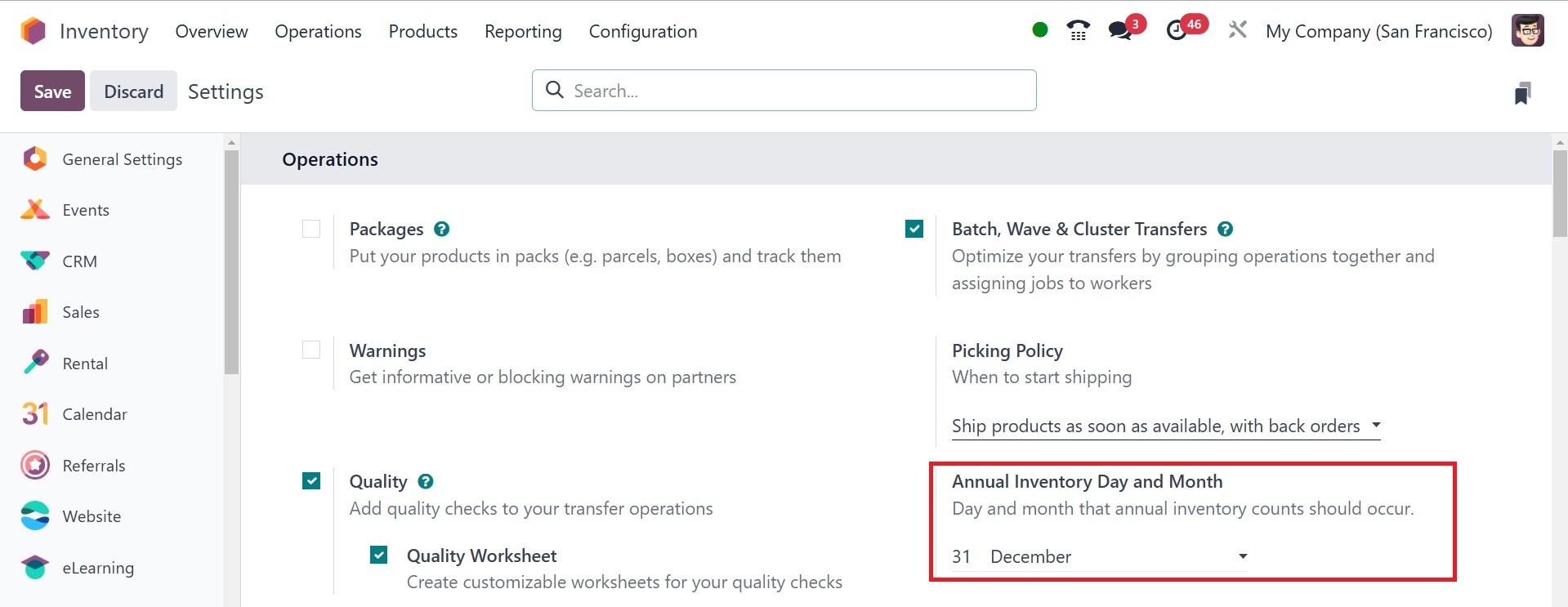

The module's Settings menu allows

you to choose the day and

month when the yearly

inventory counts will be

conducted.

As shown in the example, you can

use the Annual Inventory Day

and Month option to choose

the day and month that yearly

inventory should be counted.

3.10 Scrap

Inventory considered scrap

consists of broken or

non-working products.

Products approaching or past

their expiration dates can

also be considered scraps.

There is a likelihood that

broken or expired products

will be found in checking the

inventory. We must dispose of

these items as soon as

possible since we cannot sell

broken or expired products.

The majority of the time, the

products with minor damage

are used in repair processes.

The reusable parts of the

scraps can be used during the

recycling processes. You can

save money and, above all,

the environment by using a

more intelligent scrap

management system. The

scraper that was removed from

the inventory can be

transported to a location for

scrap.

You can assign a location for

scrap from among the

available storage locations

in the warehouse. Let us find

out how the handling of the

location of scrap in your

storage is simplified by

Odoo18. The handling and

configuration of storage

locations in the Odoo18

Inventory have already been

discussed. You can configure

a location for scrap with the

same process. You can

accomplish this by going to

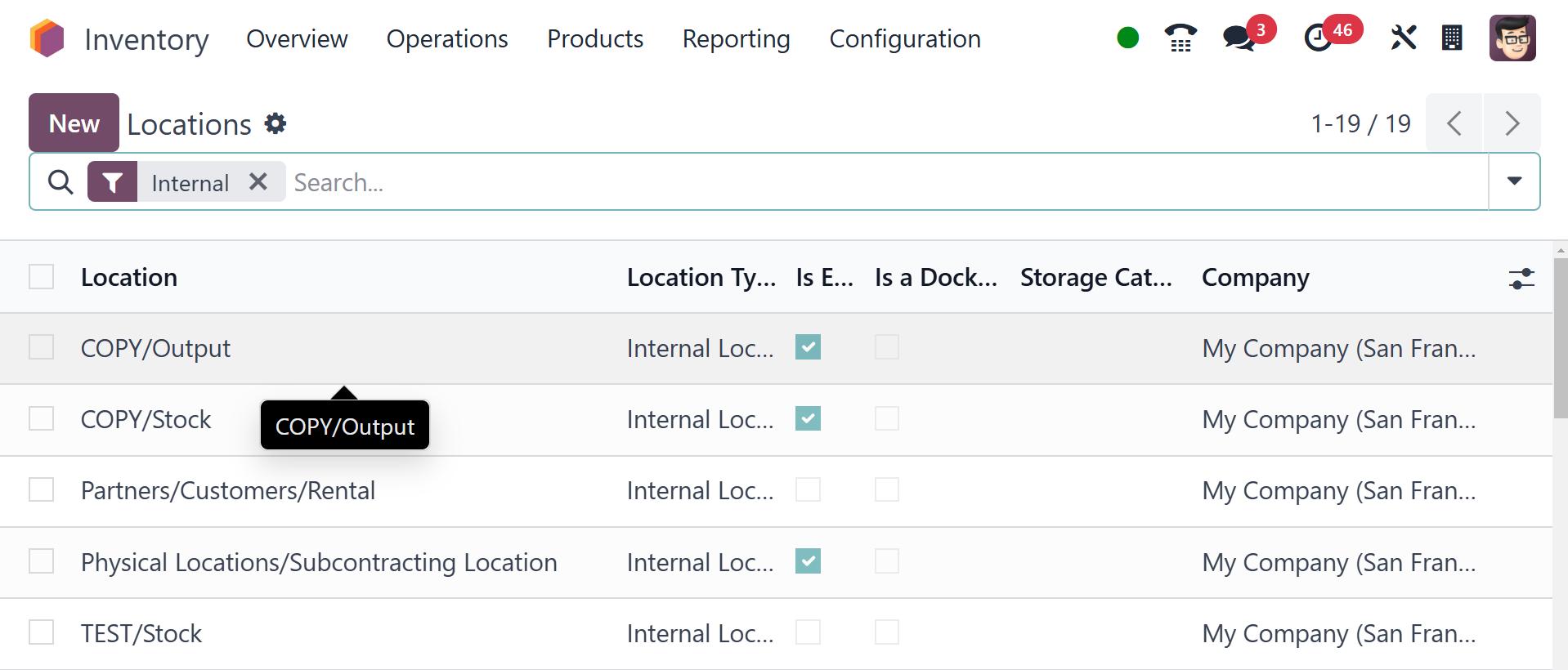

the Locations menu under the

Configuration menu. The

opening of a new window is

illustrated below.

Click the New button to create a

new scrap location.

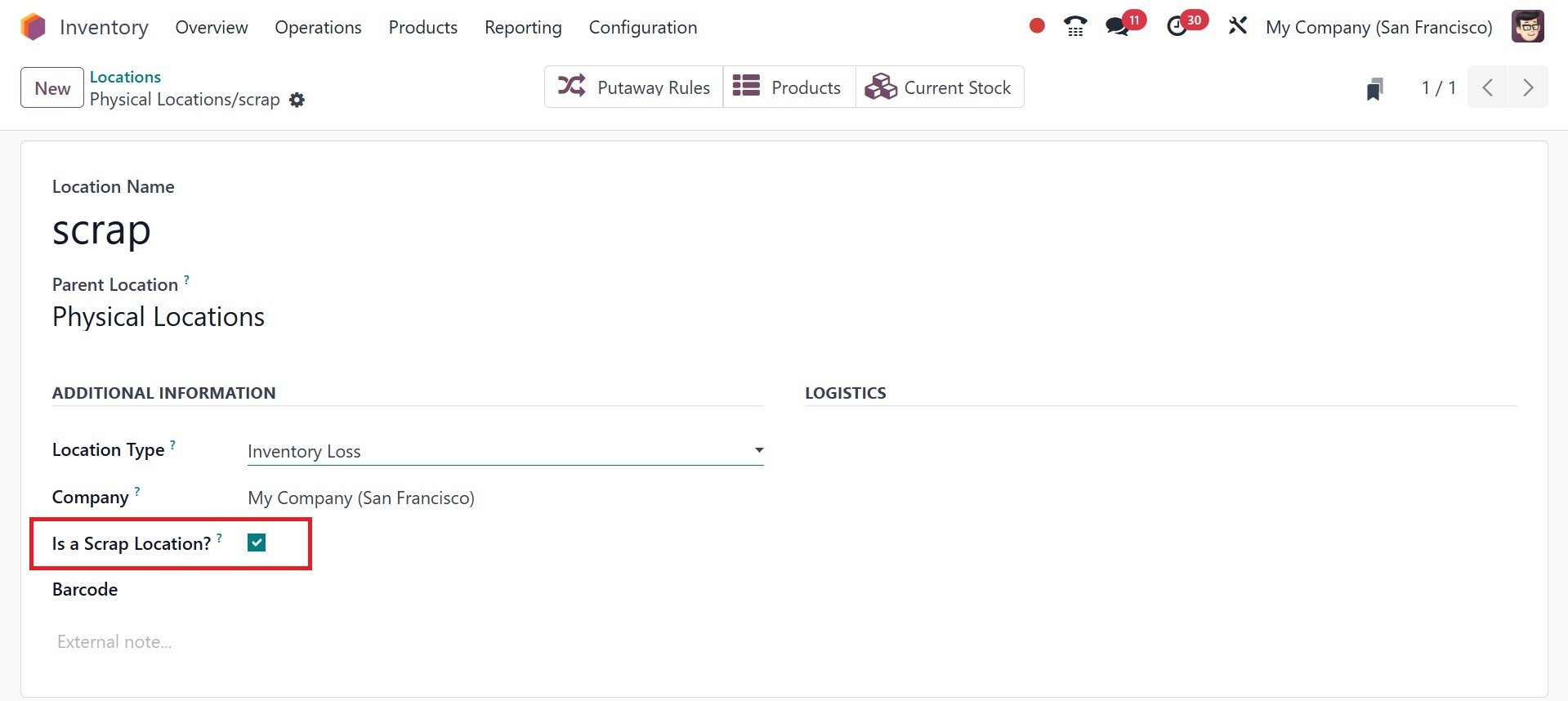

You can type the name of the

location in the field

available in the window for

the new place creation. In

this case, the location is

named Scrap Location. The

rest of the steps are

identical to those we

described in the previous

Location configuration

section. The most important

step is to enable the Is a

Scarp Location field in order

to handle this place as a

scrap location. You may click

the Save button once you have

inserted all applicable

details. In the storeroom,

we've completed assigning a

location for scrap. Through

the use of this method, more

scrap locations may be

established.

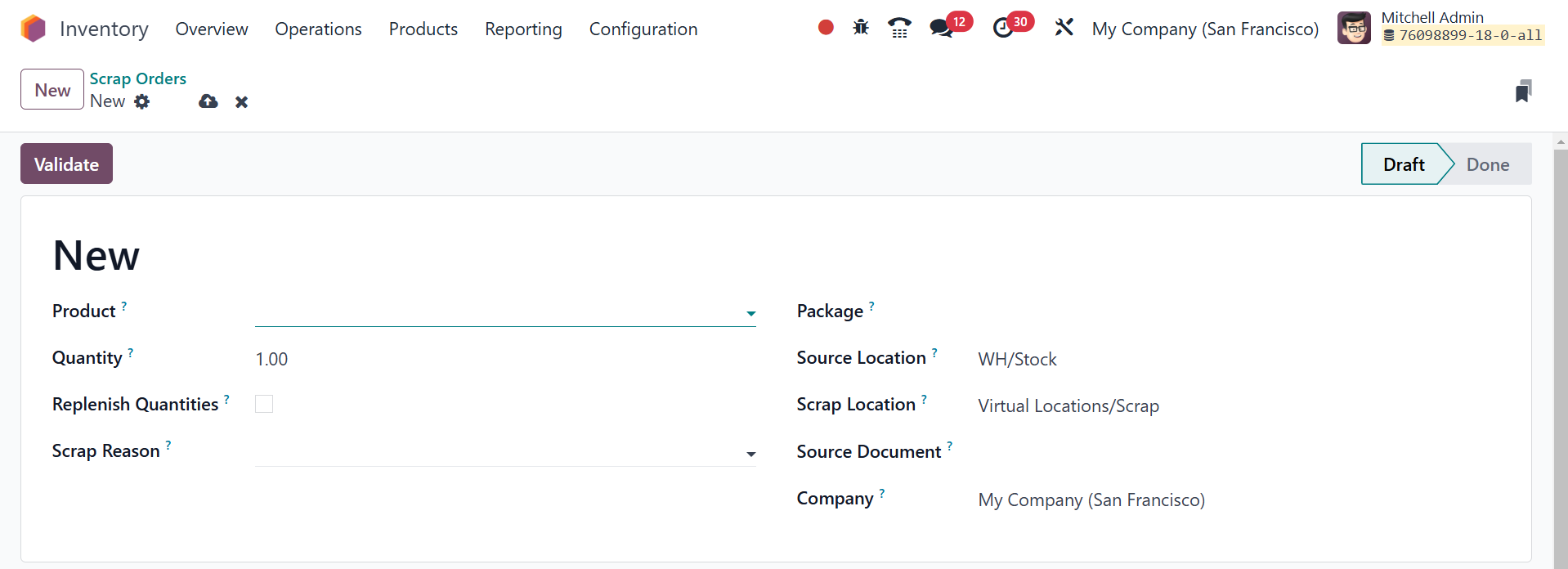

On opening the scrap option from

the operation tab, all the

fields for the name of the

scrap product, quantity,

package, and owner are

present here. The Source

Location of the product will

be shown. You can select the

scrap location from the

drop-down list in the Scrap

Location field if you wish to

relocate broken or expired

items there. The product will

be relocated to the specified

scrap location when you press

the Validate button. The

delivery orders will be

decreased by the quantity of

the scrap product. The new

page will be, as in the image

below.

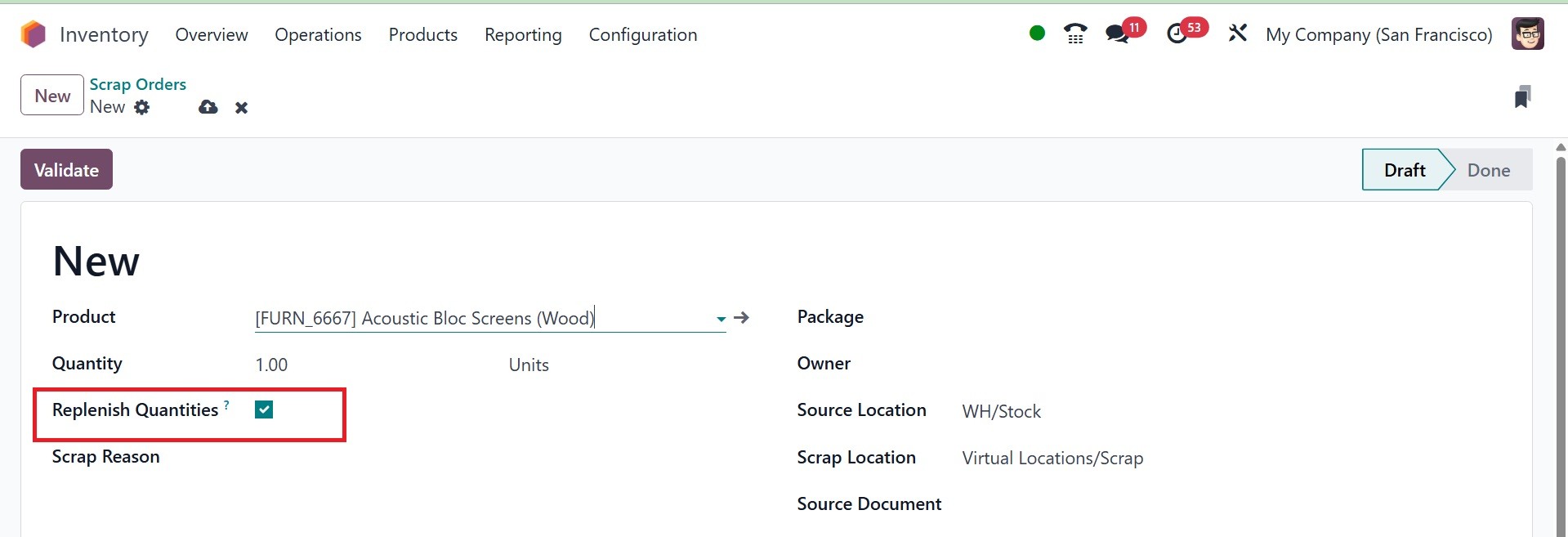

If a replenishment rule is set up

for the product being

scrapped, and if the product

should be replenished, tick

the checkbox for Replenish

Quantities.

The pre-set and programmable

options under the Filters and

Group By features can be used

for sorting.

3.11 Landed Costs

The extra amount the company has

to pay for a product at the

time of purchasing is

referred to as the "Landed

Cost." It involves shipping,

handing charges, import duty,

and various other expenses.

All the extra costs are being

added with the actual cost of

the product to arrive at the

selling cost. Various

companies will adopt a

different approach based on

their organizational policy

to compute the landing cost.

You can calculate the landing

cost and split it over each

of the quantities of the

products in the Odoo18

Inventory module to revise

the selling price.

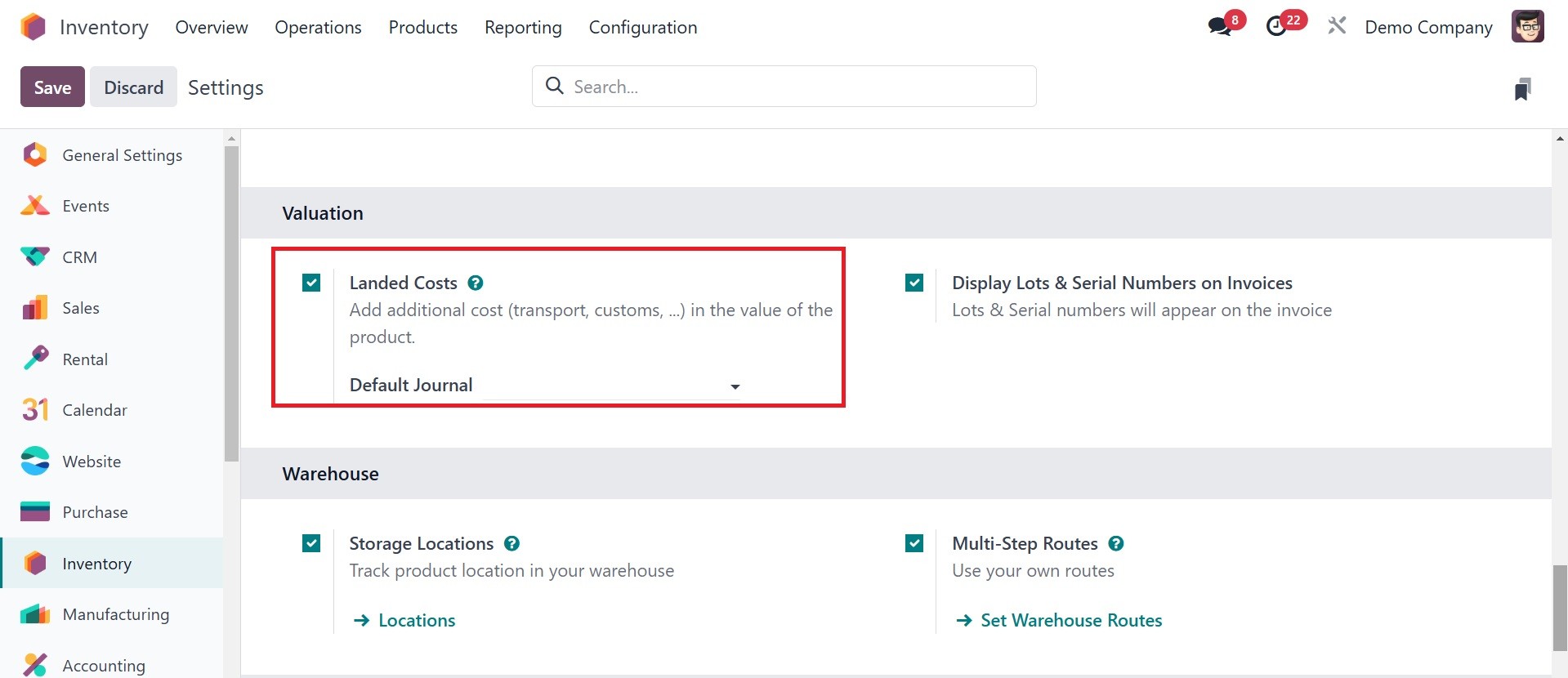

To enable the Landed Costs

feature as shown in the

picture below, go to the

Settings menu.

By enabling this feature, you can

include user-defined landing

costs on your items. You can

first build a buy order of

some items under the same

product groups and mark the

order to better understand

the landed cost's

functionality. On products

with an AVCO or FIFO costing

method established, you can

define landing costs.

Inventory valuation of such

products should be Automated.

This is the condition for the

landed cost that you need to

account for when tailoring

it.

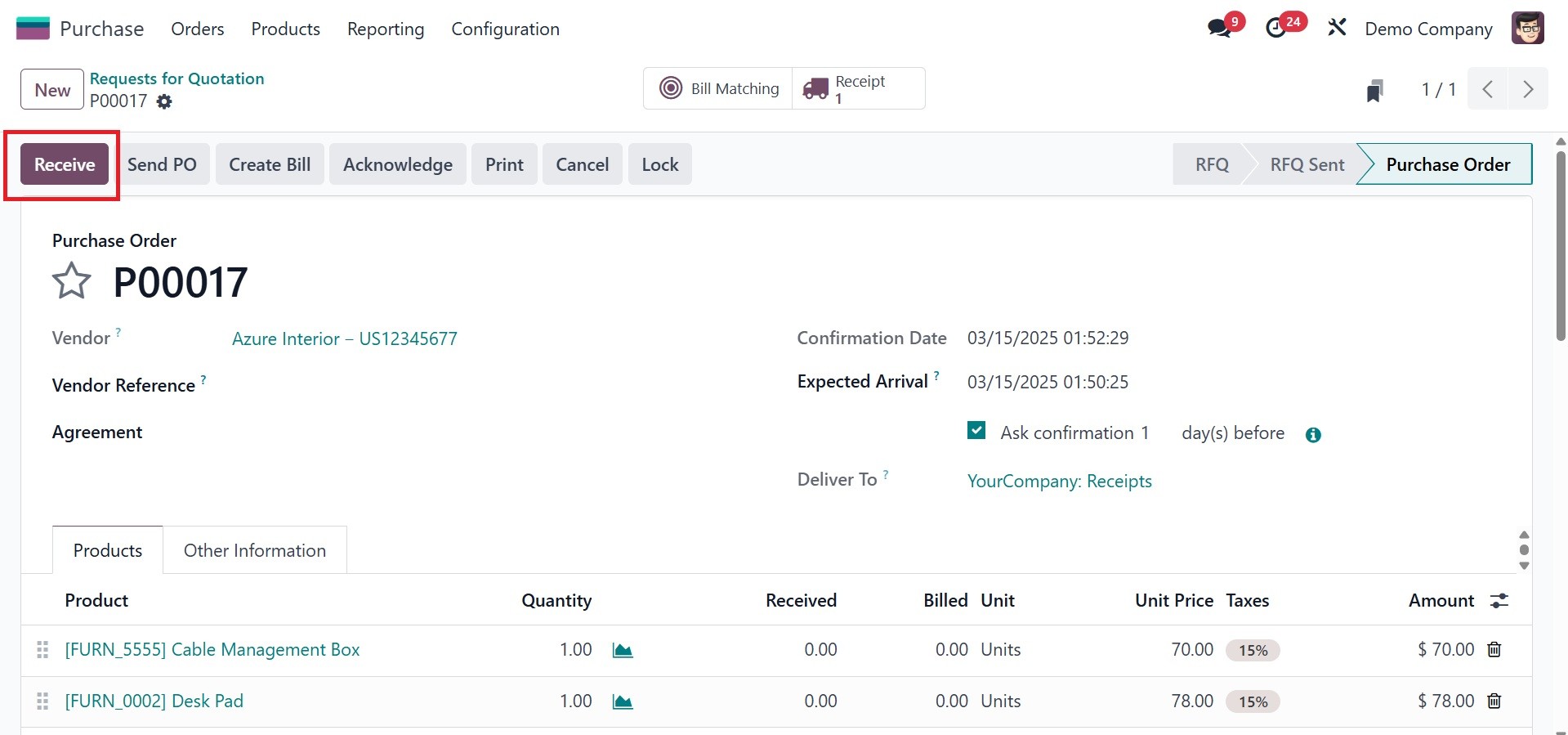

Under the Products line, you can

view the unit costs of the

products as you buy them.

Your purchase will be

finalized once you press the

Confirm Order button. When

you press the Receive button,

these items will be posted to

your inventory records.

You may now retrieve the items in

inventory. Through clicking

on the Validate button, you

can confirm whether the

products have been

transferred successfully. The

goods that were bought are

now being stored in the space

marked on the receipt. When

you are selling these items,

you may add landed cost to

the price.

Think about shelling out a little

cash for the transfers so you

can send these products to

where you need them. You can

include your lost money in

transfers as an additional

charge on merchandise. You

can make charges on the

products utilizing the landed

cost feature in Odoo 18

Inventory.

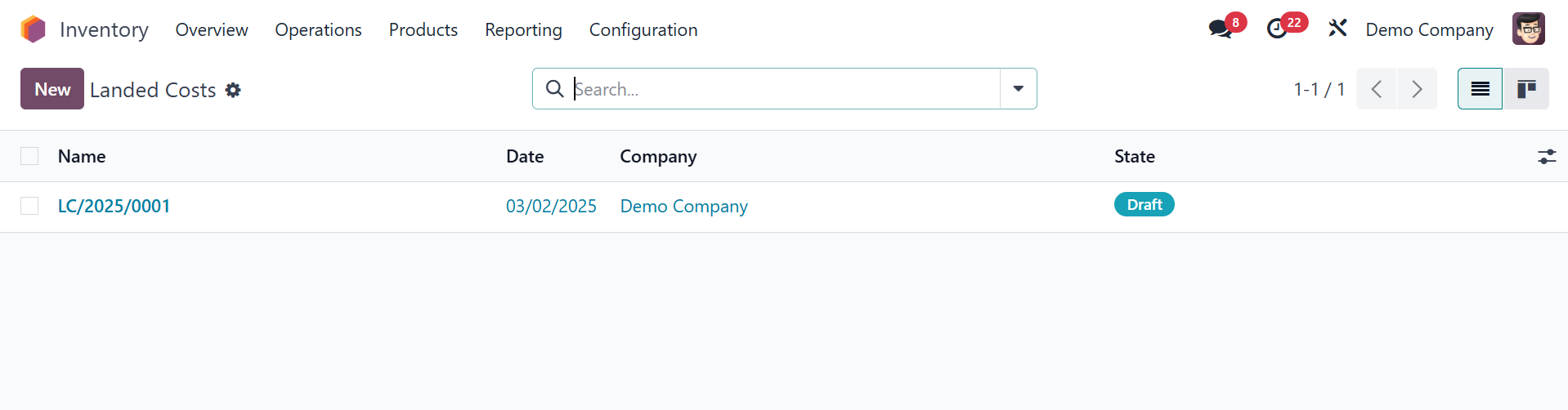

Do this by visiting the Inventory

module's Operations menu. As

demonstrated in the

screenshot below, the Landed

Costs platform is accessible.

You are able to retrieve the

details of the previously

added landed charges from

this window. You are able to

create a new landed cost by

clicking the New button.

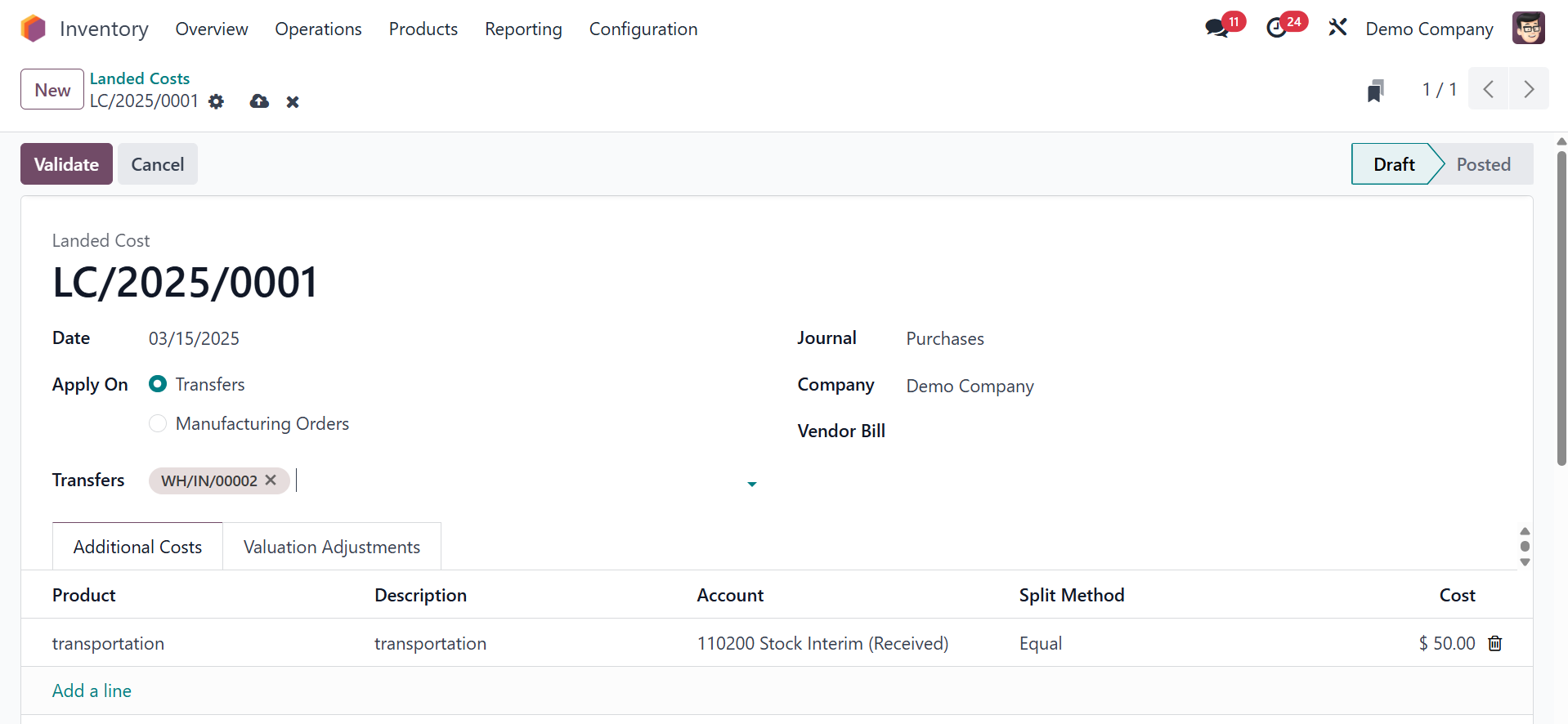

You can place the date of

creation in the respective

field here. On transfers or

manufacturing orders, you are

able to specify the new

landed cost. As we need to

add landing costs on

transfers, we are able to

select Transfers in the Apply

On field. In the Transfers

section, you can provide the

receipt ID we generated

above. The fields there

enable you to enter the

Journal of the goods,

Company, and Vendor Bill.

With the Add a Line button,

you can specify the extra

costs in the Additional Costs

tab.

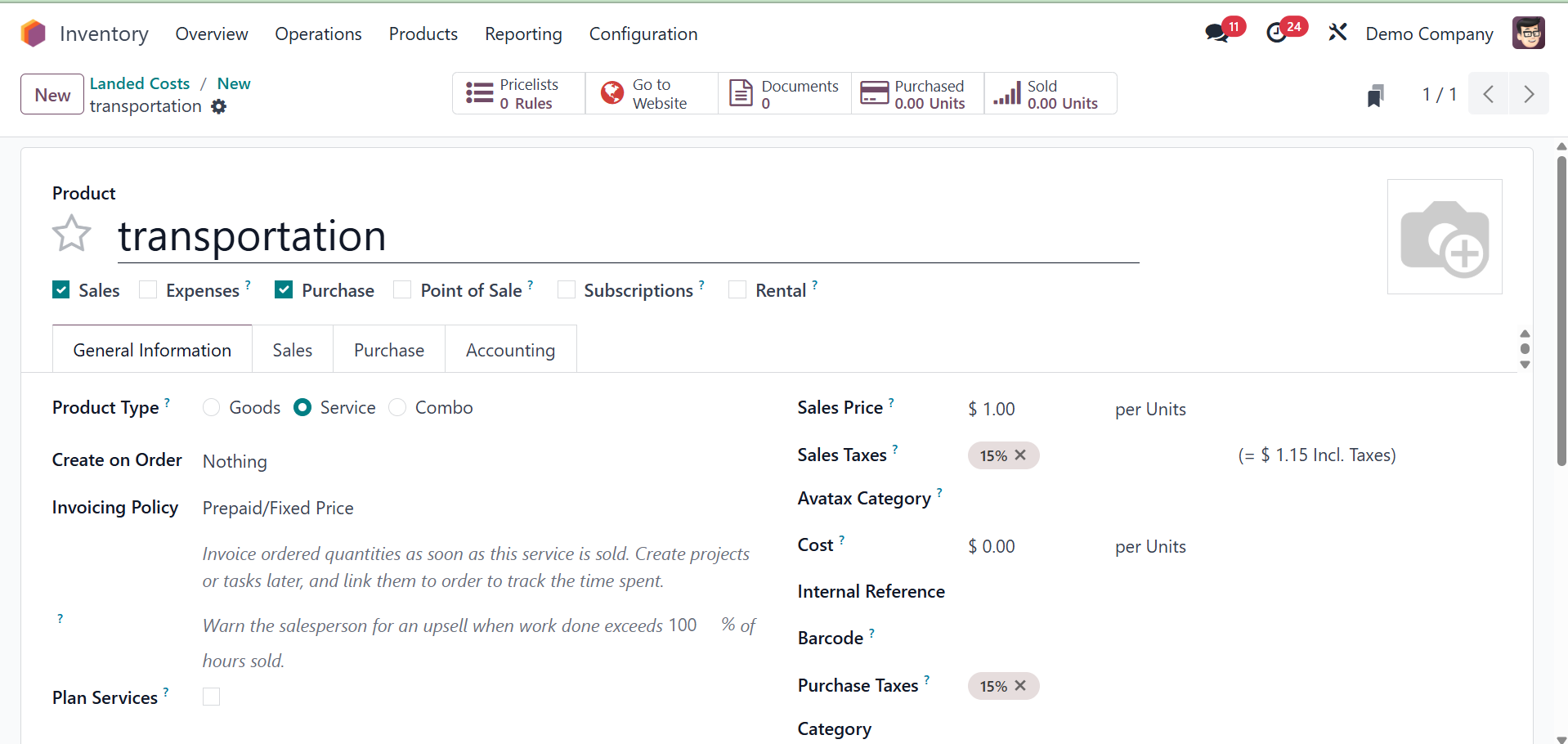

In this case, we considered table

top to be an independent

cost. When setting up

transportation as an extra

charge, keep in mind to save

it as a service product, as

shown in the figure below.

After you've indicated the

Product, Description, and

Account details, you may

select the relevant Split

Method.

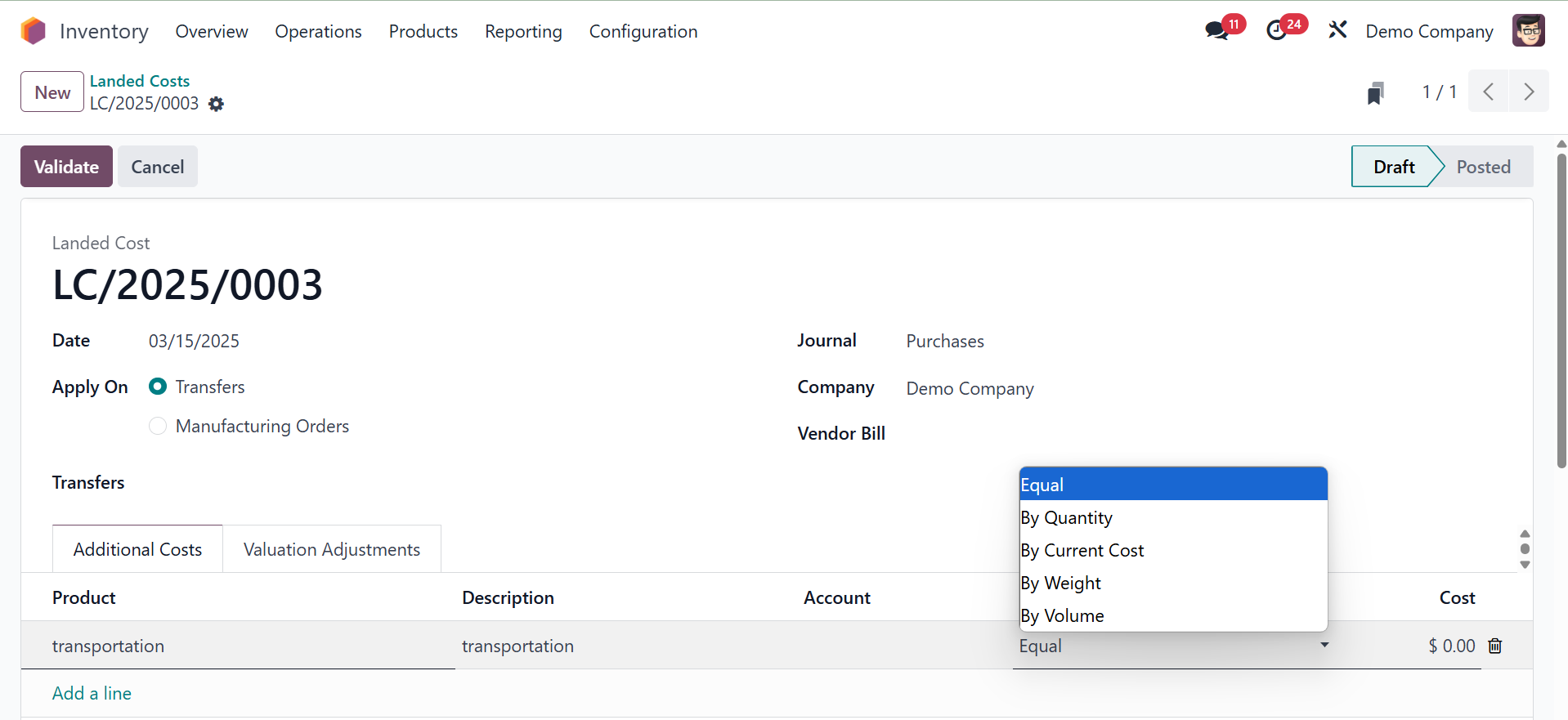

How the Split Method will split

this landing cost amongst the

products enumerated in the

transfer receipt will be

determined by the Split

Method. As per your company's

policy, it can be set up in

the form of Equal, By

Quantity, By Current Cost, By

Weight, and By Volume. In our

case here, we may use the

Equal split option. Hit the

Compute button to calculate

the landed cost.

With the Validate button, you are

now able to validate the

landing cost. This cost will

be included in the goods'

selling price. This method

might increase your sales

profit by establishing landed

expenses for your products.

3.12 Replenishment

An essential inventory process

that assists you in

maintaining an appropriate

quantity of items in your

inventory is replenishment.

You must stock the inventory

according to demand to ensure

a continuous supply of items.

Here, the Odoo18 ERP System

provides instant support to a

company's replenishment

processes. Replenishment can

be performed in two ways. You

can use both the product

management window as well as

the Replenishment module of

the Inventory module for

stocking products.

The Operations window in Odoo 18

Inventory module provides you

with the access to the

Replenishment management

window. There is a list of

preloaded replenishment

orders on this advanced

platform.

The Search Box is available by

which individual

Replenishment orders can be

searched. Pre-selected and

selectable Filter options

available offer an easy

method to recover required

information. In combination

with the Group By facility,

it can be easy to group

orders on Location, Product,

as well as on Category. On

the left part of the window,

you'll notice a custom sort

panel, by which it's possible

to order information as per

Locations.

You can separate all the

replenishment requests and

manual replenishment with the

Trigger option.

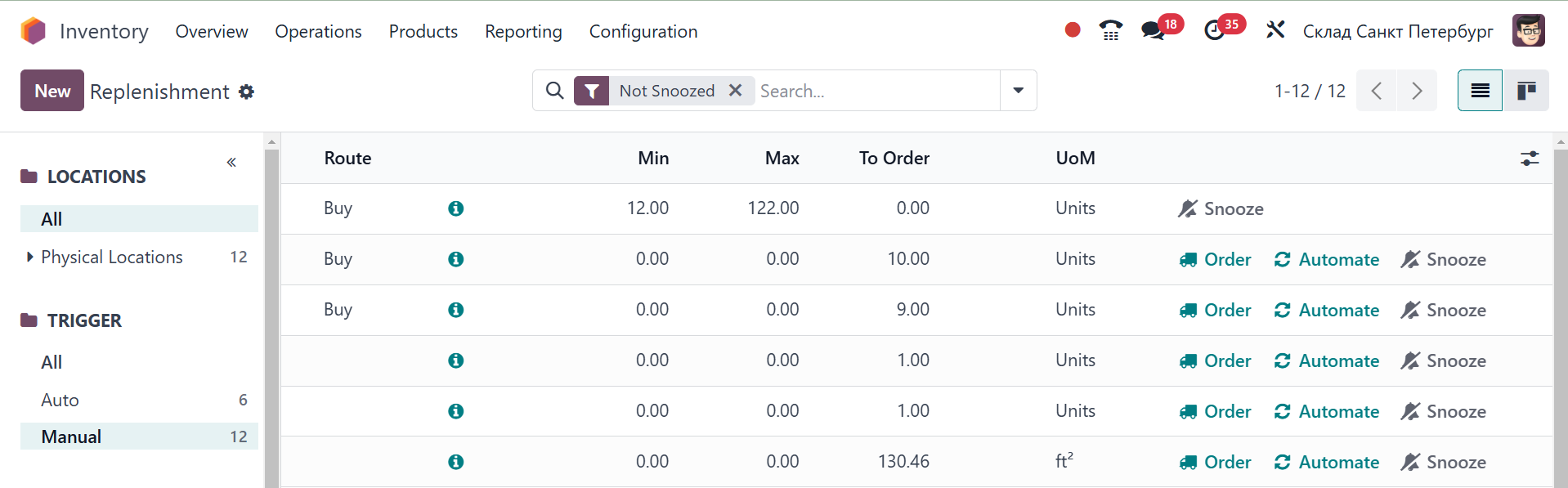

The list preview includes the

following information:

Vendor, Forecast, Preferred

Route, Location, On Hand,

Minimum Quantity, Maximum

Quantity, To Order, and UoM.

You can manually create a

fresh refill by clicking the

fresh button. Details on a

product's refill will be

displayed in a new line.

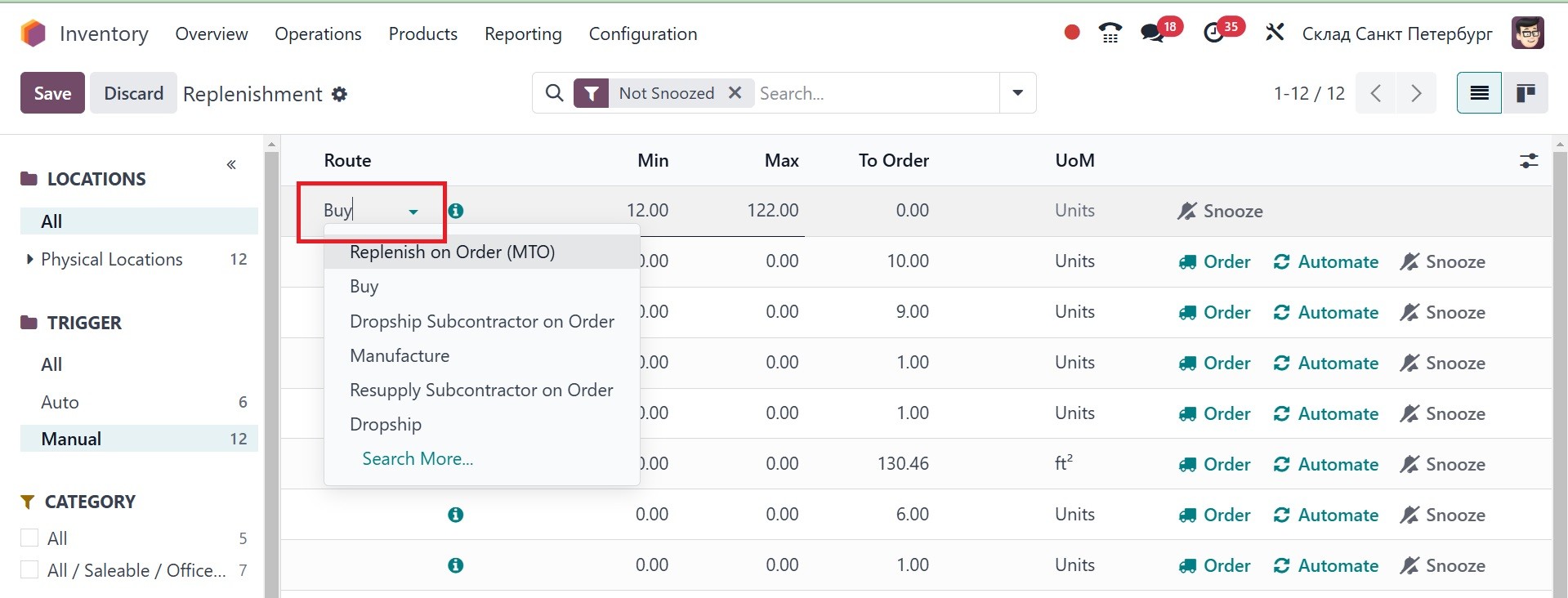

The product's Location, On Hand,

and Forecast will

automatically be filled in

the respective fields when

you enter the product name in

the specified field. The

drop-down option that is

offered enables you to select

the Preferred Route.

The minimum and maximum levels of

the product that need to be

replaced should then be

stated. You will be presented

with two choices to place the

order for the product, like

Order Once and Automatic

Orders, as soon as you enter

the To Order quantity. You

can easily create

replenishment by creating a

request for quotation by

choosing the Order Once

button. The replenishment

orders will be processed

automatically once you click

the Automatic Orders button.

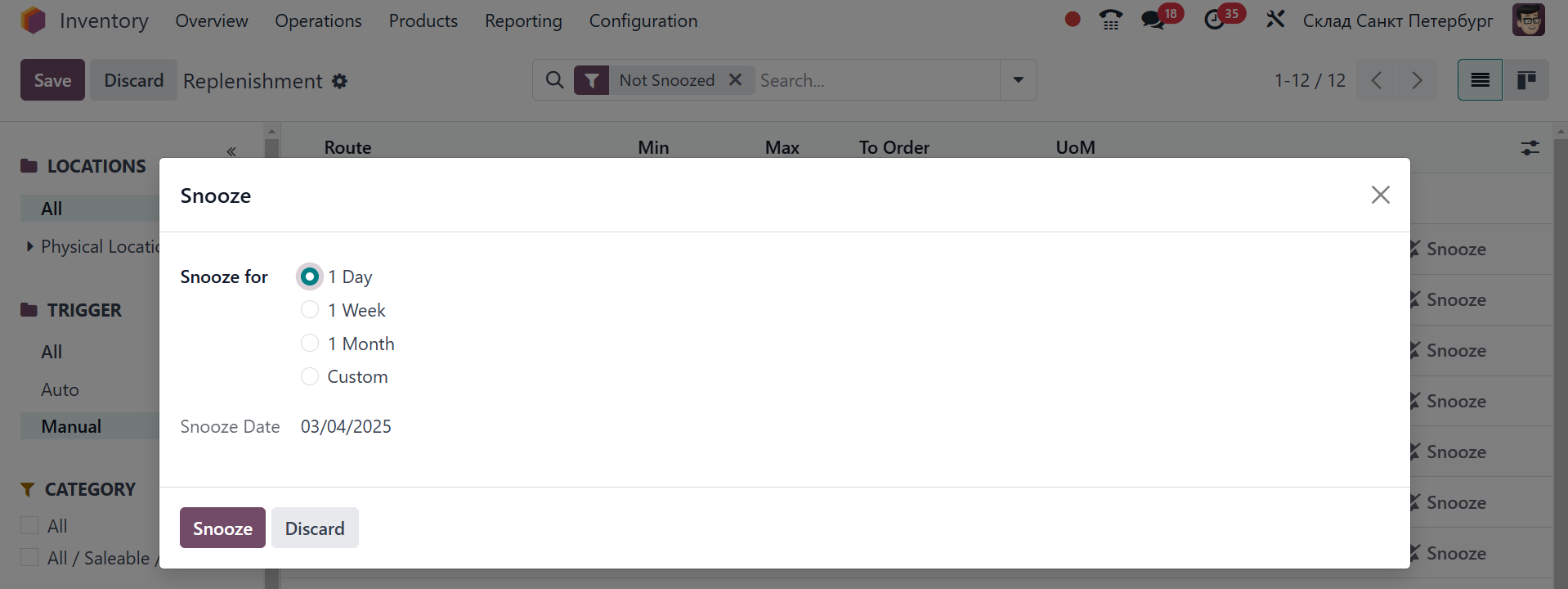

With the use of the Snooze

facility, you can delay the

process for a certain period

of time.

You can choose to delay the

process for a day, a week, a

month, or a custom period of

time with this option. You

can also set a Snooze Date on

this pop-up window.