3. Equipment Management Menu

The Equipment Menu in the Odoo 18 Maintenance module is designed to

help businesses manage and monitor assets effectively. This menu

includes two sub-menu items, including the ‘Work Centers’ and

‘Machine &Tools’ options.

3.1 Work Centers

A Work Center in Odoo is a designated space or asset, like a machine

or workstation, where manufacturing or maintenance activities occur.

In the Maintenance module, Work Centers are crucial because

equipment and maintenance requests are linked to them, and

preventive maintenance often depends on their performance and usage.

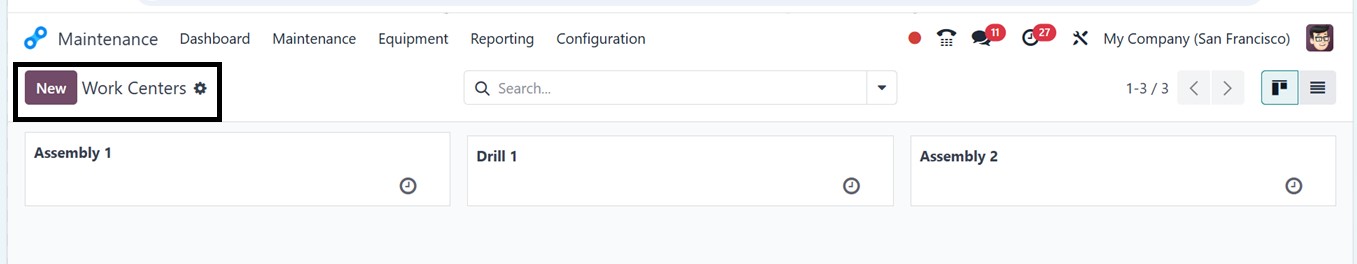

The ‘Work Centre’ dashboard from the Equipment menu provides an

overview of all the available work centers functioning in your

inventory or manufacturing system.

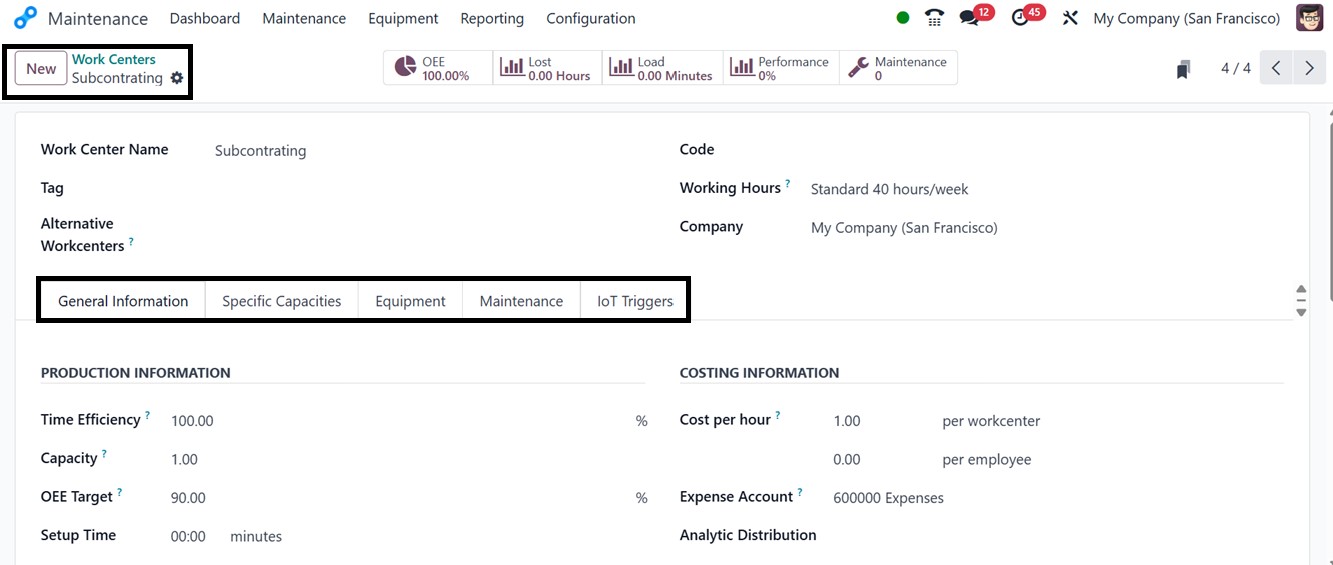

You can also create new work centers within the dashboard window by

opening a new configuration form. In the displayed form view, edit

the Work Center Name, Tag, Code, Alternative Workcentres, Working

Hours, and Company details.

In Odoo 18, the configuration of a work center begins with entering

key production details under the General Information tab. This

includes fields such as Time Efficiency, which defines the estimated

duration for completing tasks in the work center, Capacity, which

represents the number of units that can be processed simultaneously,

and OEE Target, indicating the intended overall equipment efficiency

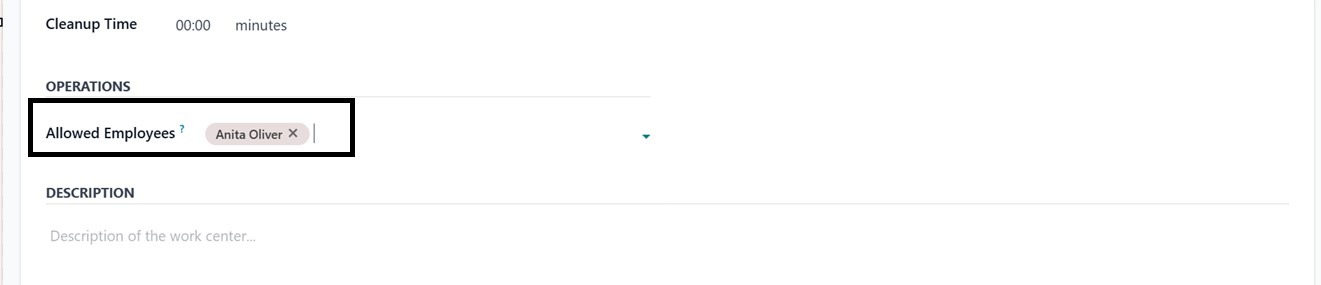

percentage. To enhance security and ensure only authorized staff can

operate within the work center, you can enable the Allowed Employees

option under the OPERATIONS section.

The Costing Information section allows you to define the operational

cost per hour for both the work center and its assigned personnel.

You can also link an Analytical Account to track costs related to

materials and activities. Setup and cleanup times can be configured

here as well, and any additional notes or specifications about the

work center can be entered in the Description field.

For cases where specific products have unique capacity requirements,

the Specific Capacities tab allows you to define those details. By

clicking Add a Line, you can input the product name, its unit of

measure, and the number of units that can be produced concurrently

in that work center.

The Equipment tab is used to list the tools and machinery associated

with the work center. You can specify the equipment name, the

responsible technician, category, and important metrics such as MTBF

(Mean Time Between Failures) and predicted Next Failure dates.

Equipment already configured in Odoo can be selected from a pop-up

list.

Additionally, the IoT Triggers tab supports integration with external

devices. You can use the Add a Line function to define each device’s

ID, associated key, and the action it should trigger. Once all

configurations are complete, the work center is ready for use.

Odoo provides smart buttons on the work center form view that give

insights into ongoing operations. You can monitor scheduled

activities, track Overall Equipment Effectiveness, analyze

Productivity Losses, evaluate Work Center Loads, and review overall

Performance. These reports help you assess efficiency, identify

areas of downtime or slow performance, and measure how actual

performance compares to expected timelines. By leveraging these

features, manufacturers can ensure optimal use of their work centers

and maintain high productivity levels.

3.2 Machines & Tools

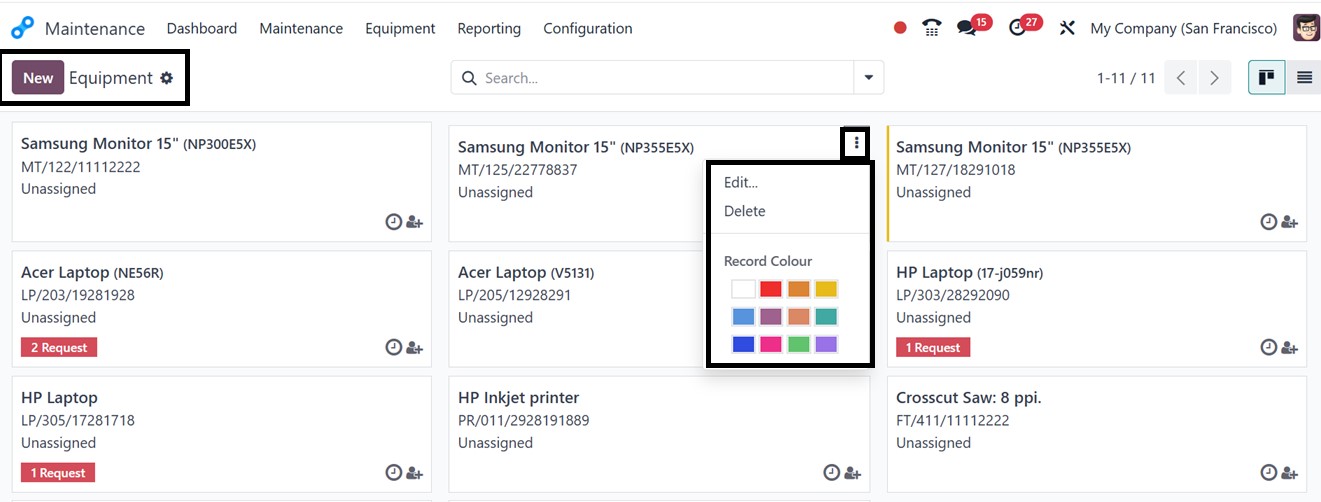

The ‘Machines & Tools’ option within the Maintenance module helps

organizations maintain a comprehensive list of all maintenance

equipment. The Kanban dashboard provides a comprehensive overview of

equipment, including model numbers, serial numbers, assigned

statuses, activities, and associated maintenance requests, as

illustrated in the screenshot below.

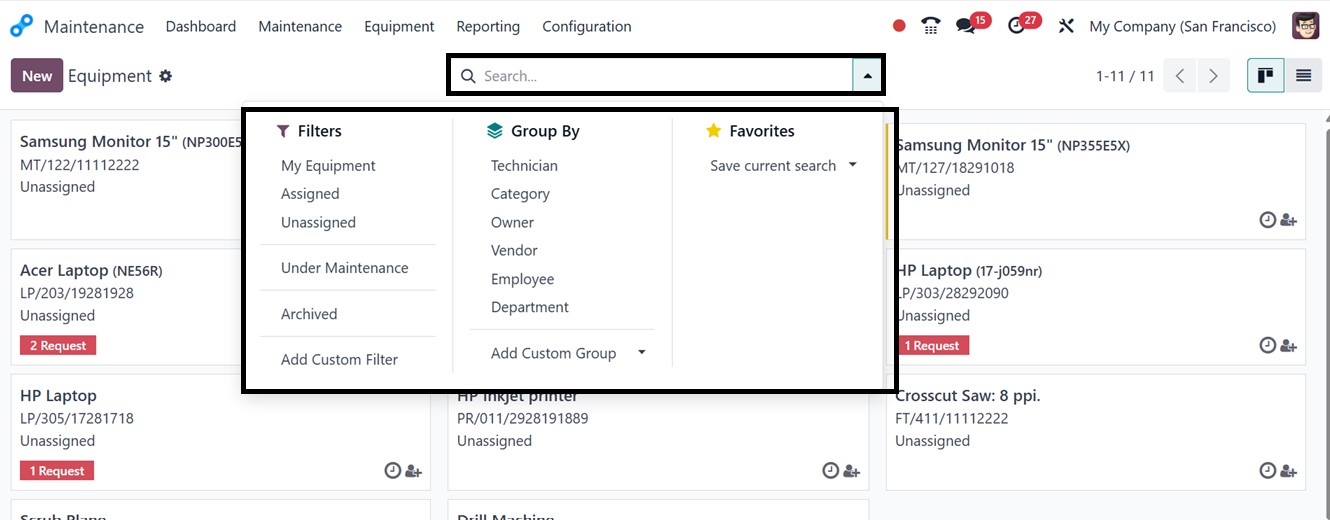

Each equipment card includes Edit and Delete options, accessible via

the three-dot icon. The advanced search bar contains Filters such as

My Equipment, Assigned, Unassigned, Under Maintenance, Unread

Messages, and Archived options to sort and filter the equipment. You

can also create customized filter options using the ‘Add Custom

Filter’ button. The Group By tool further categorizes equipment

based on technicians, categories, owners, vendors, employees, and

departments. This also helps to create custom groups as well as

highlight important equipment using the ‘Favorites’ filter option.

You can manage or create any scheduled activities regarding the

equipment through the clock icon provided in each equipment card.

The 'Assign' icon is utilized to assign specific equipment to a

designated responsible individual. To add new equipment, click on

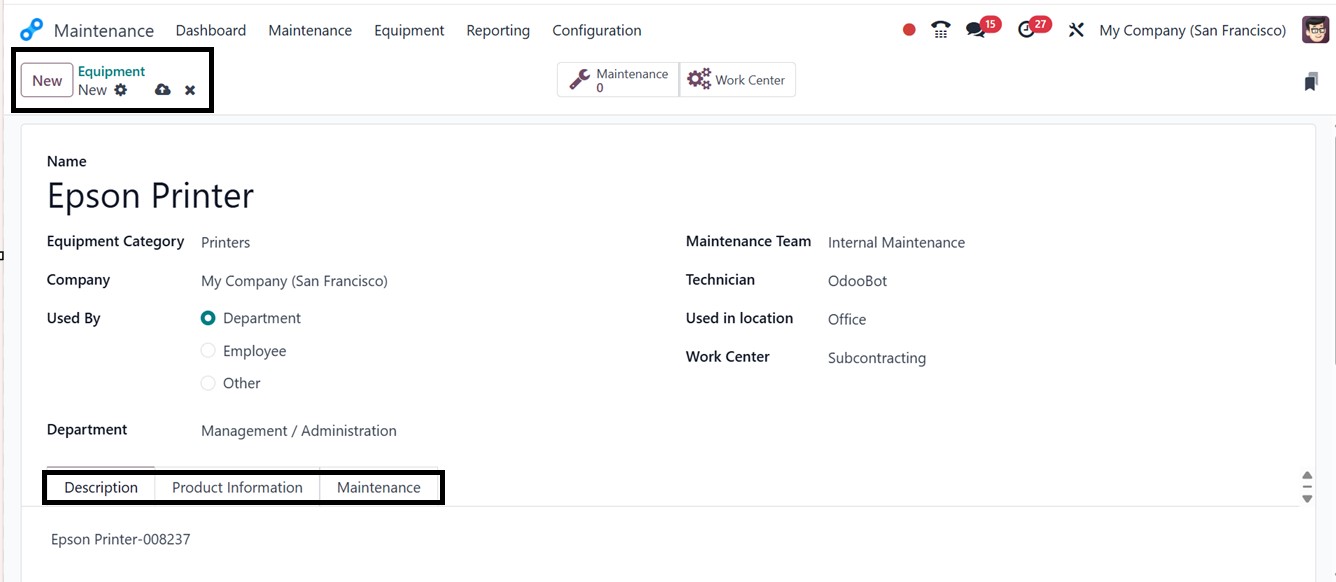

the ‘New’ button. In the displayed settings window, you have to

enter the key details such as the Equipment Name, Equipment

Category, Company, Used By, Department, Maintenance Team,

Technician, Used Location, and Work Center, as shown below.

Additional information or any notes regarding the equipment can be

stored under the Description tab.

Important information, including Vendor Data, Model Specifications,

Related Expenses, and the Equipment's Warranty Expiration date

specifics, can be configured in the Product Information tab.

The Maintenance tab, on the other hand, helps guarantee prompt repair

and optimal operation by defining regular maintenance programs and

measuring the Expected Mean Time Between Failures (MTBF) of the

equipment.

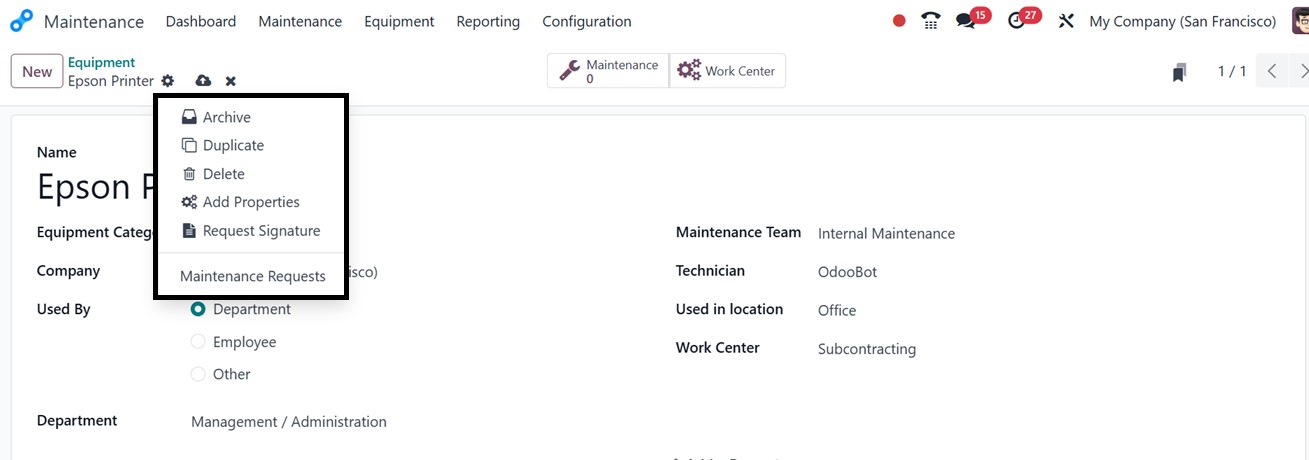

Once all the details are edited and saved, you can utilize the

‘Action’ menu placed on the form to manage the equipment records by

deleting, duplicating entries, archiving old records, adding more

form fields, requesting signatures, or creating new maintenance

requests when necessary. These operations can be done using the

Delete, Duplicate, Archive, Add Properties, Request Signature, and

Maintenance Requests buttons, respectively.

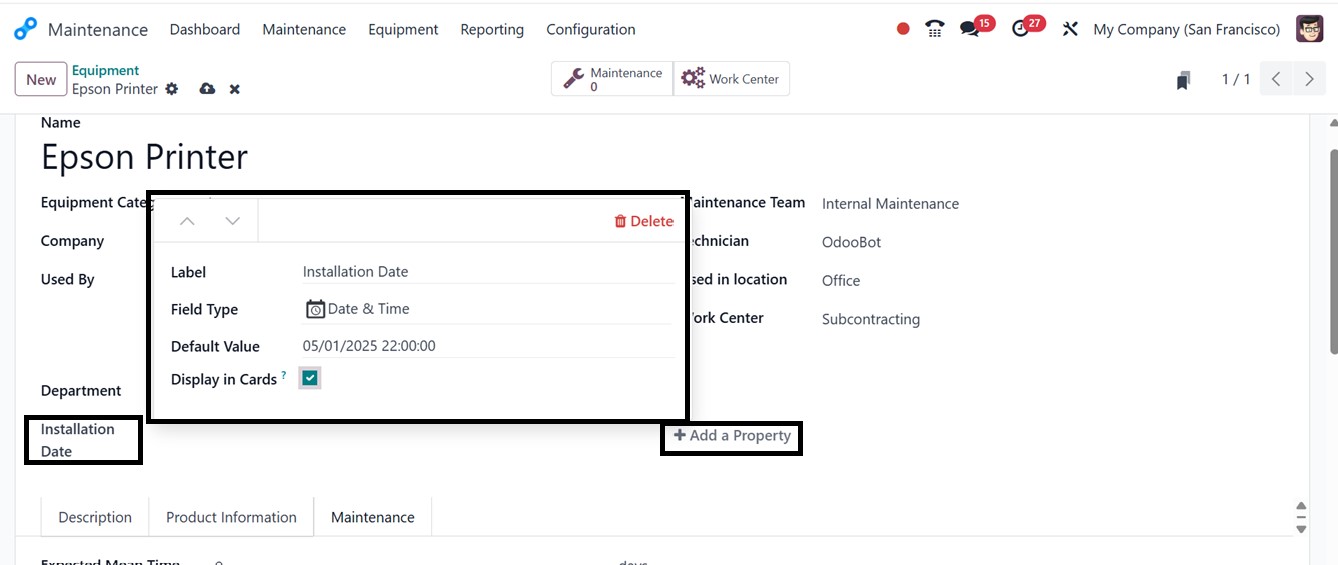

To add more form fields, click on the ‘Add Properties’ button and

edit the Label Name as the field name. The ‘Field Type’ can be set

as a normal Text Box, Date, Date &Time, Decimal, Integer, Check Box,

Selection Menu, etc as per the field specifics or requirements.

Then, the ‘Default Value’ can be provided for default fields that

cannot be edited by the user, and the Display in Cards option to

display whether or not to display this property field in calendar,

card or kanban views, as illustrated below.

If required, you can keep adding more fields once the field data has

been stored. The "Maintenance Request" button allows you to manage

all the maintenance requests for that particular piece of equipment.

By doing this, you will be directed to a dashboard showing all of

the requests made for that specific device.