2. Maintenance Menu

The ‘Maintenance’ Menu in Odoo 18's Maintenance module streamlines

maintenance tasks, allowing users to make, track, and monitor

preventative and corrective maintenance requests. This menu consists

of two sub-menu options, including Maintenance Requests and

Maintenance Calendar. This effective maintenance management improves

plant operations, reduces costs, increases revenue, enhances product

quality, workplace safety, productivity, and minimizes errors.

2.1 Maintenance Requests

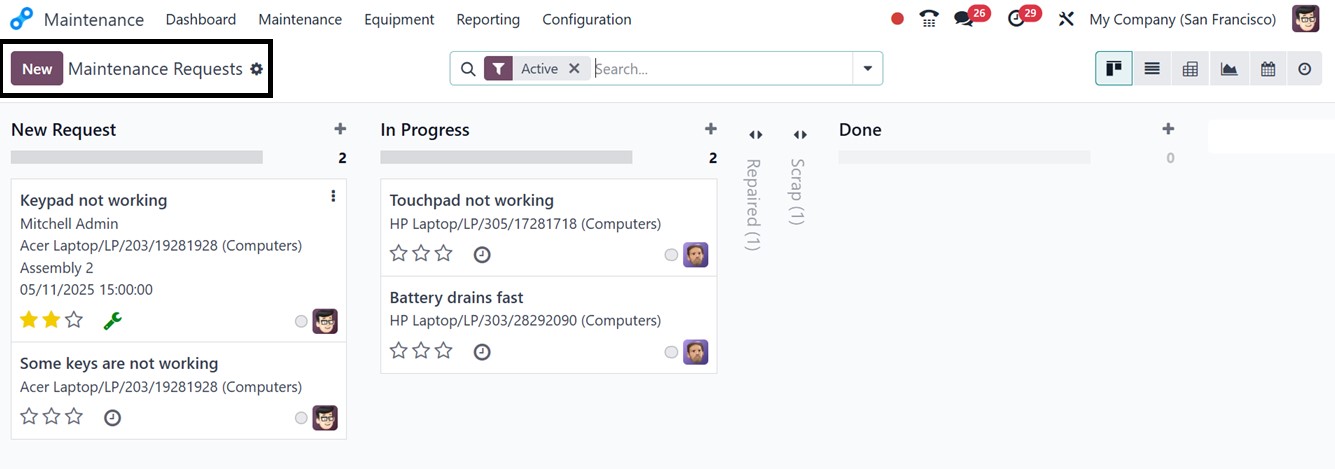

Once the equipment has been categorized and maintenance teams have

been established, users can start managing maintenance requests

through the "Maintenance" menu. You can also create a new request

from the Maintenance Request dashboard provided under each

maintenance category provided under the ‘Dashboard’ menu. By

selecting "Maintenance Request," they are taken to a dashboard

displaying all active requests along with their statuses.

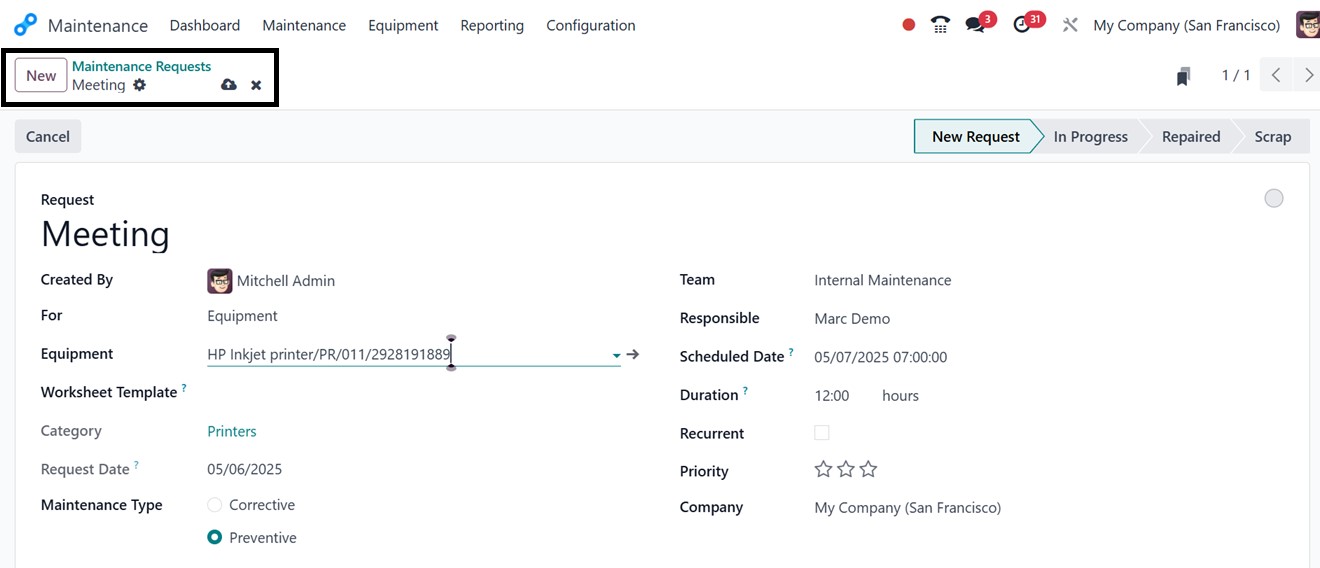

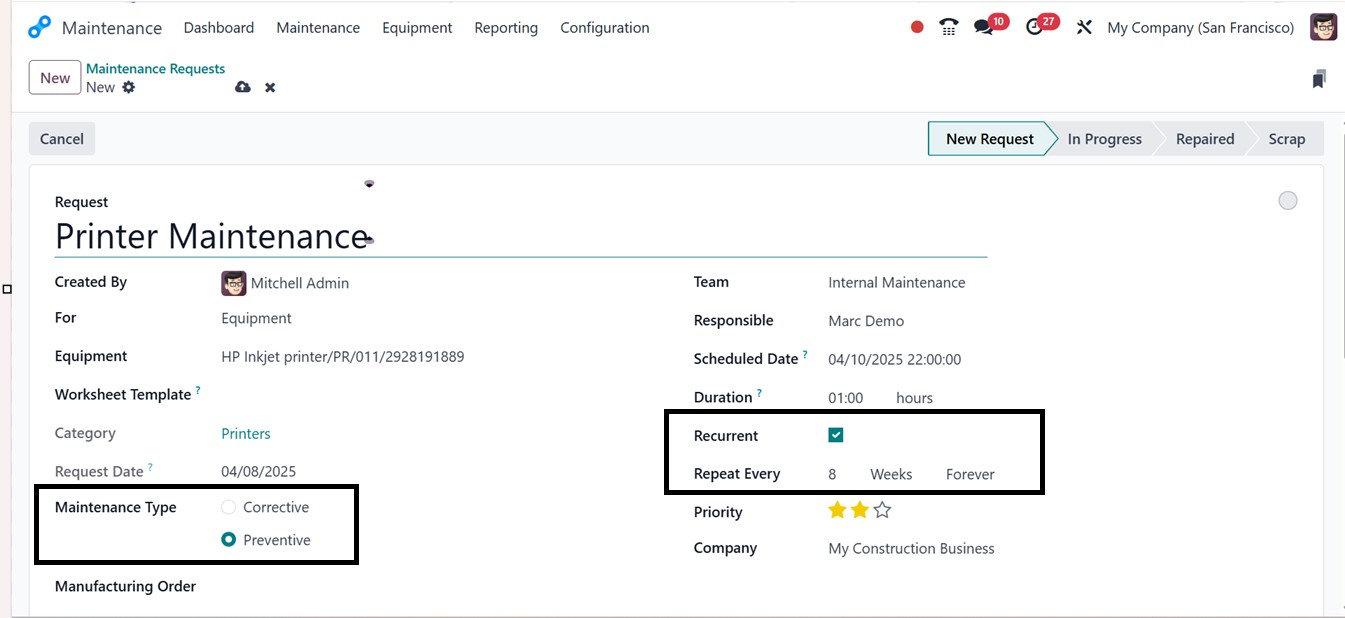

To create a new request, users can click on the "New" button and

enter key details such as the Request description, Created By, For

Equipment, Worksheet Template, Team, Maintenance Type (Preventive or

Corrective), Responsible Personnel, Scheduled Date, estimated

Duration, Priority level, and Company details.

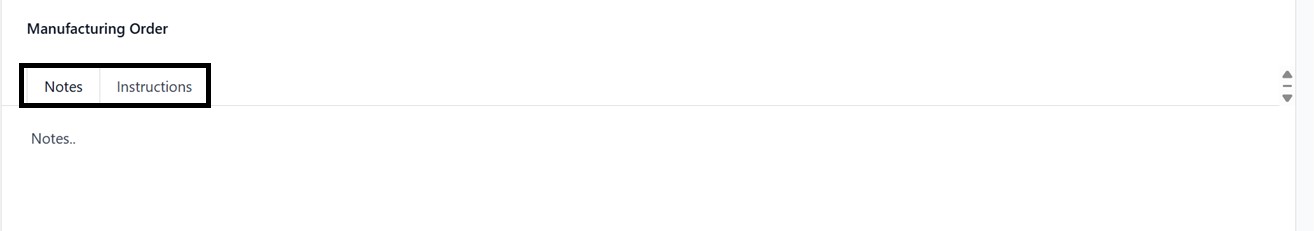

The Category and Request Date will be automatically generated as per

the form fields and request date in the relevant fields. You can

also add additional information, instructions, or attachments

pertaining to the problem or equipment, like warranty cards or other

papers in other formats, as seen in the example below using the

‘Notes’ and ‘Instructions’ tabs.

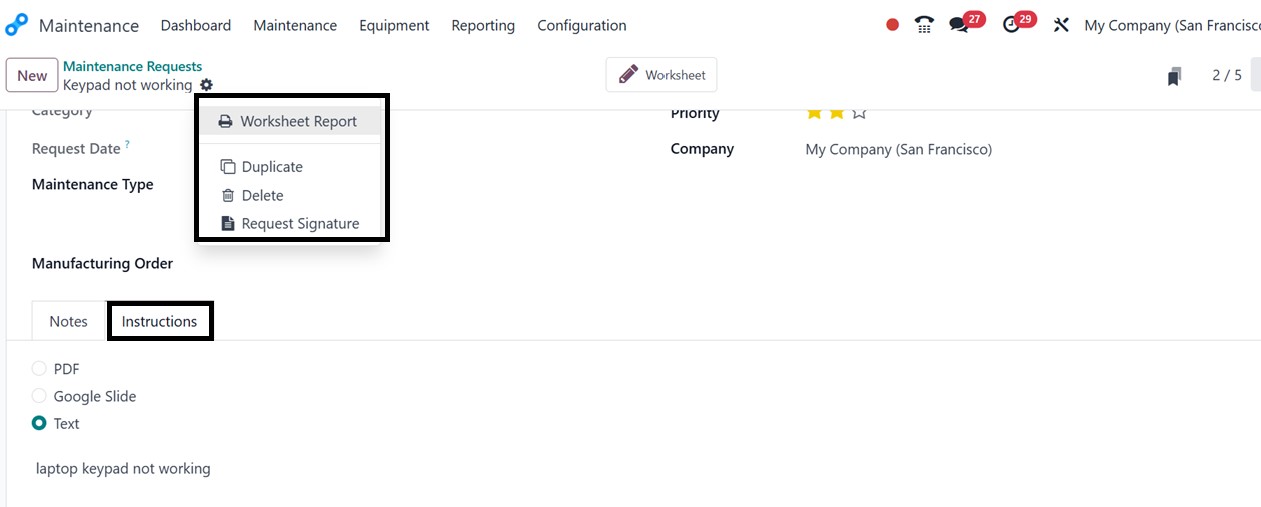

The action button provides options to print the Worksheet Report,

Delete, Duplicate, or Request Signature to proceed with the

maintenance request.

The "Worksheet" smart tab will show the worksheet linked to that

particular request when the request setup is finished.

Corrective vs. Preventive Maintenance

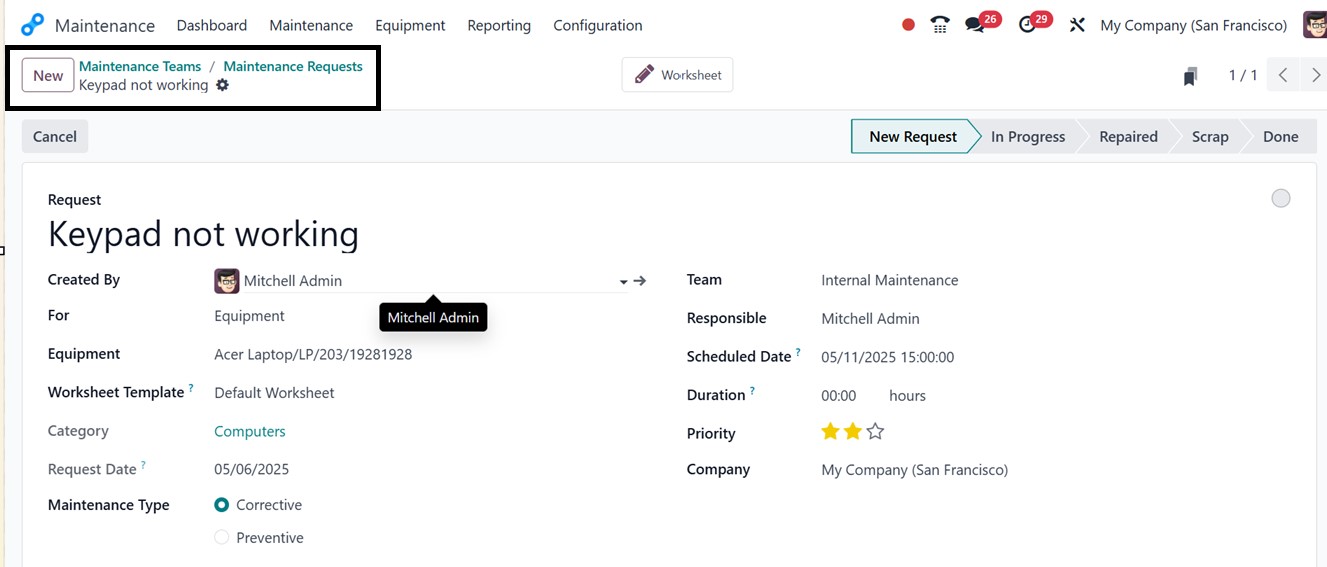

Maintenance requests in Odoo can be categorized as either corrective

or preventive. Corrective maintenance is performed when an issue or

failure has already occurred and requires immediate attention to

restore functionality. Preventive maintenance, on the other hand,

focuses on regular servicing and inspections to avoid potential

failures in the future.

To schedule preventive maintenance, users can select "Preventive" in

the Maintenance Type field and define a recurrence frequency to

ensure routine servicing is conducted on time, as depicted in the

screenshot below.

This proactive approach helps minimize unexpected equipment failures

and extends the lifespan of machinery and tools.

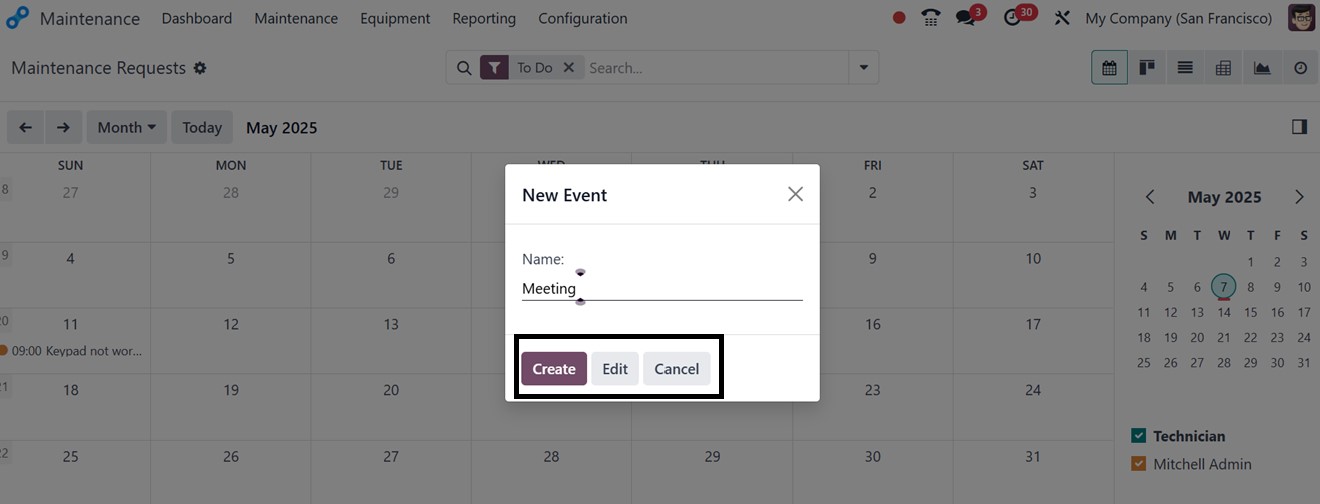

2.2 Maintenance Calendar

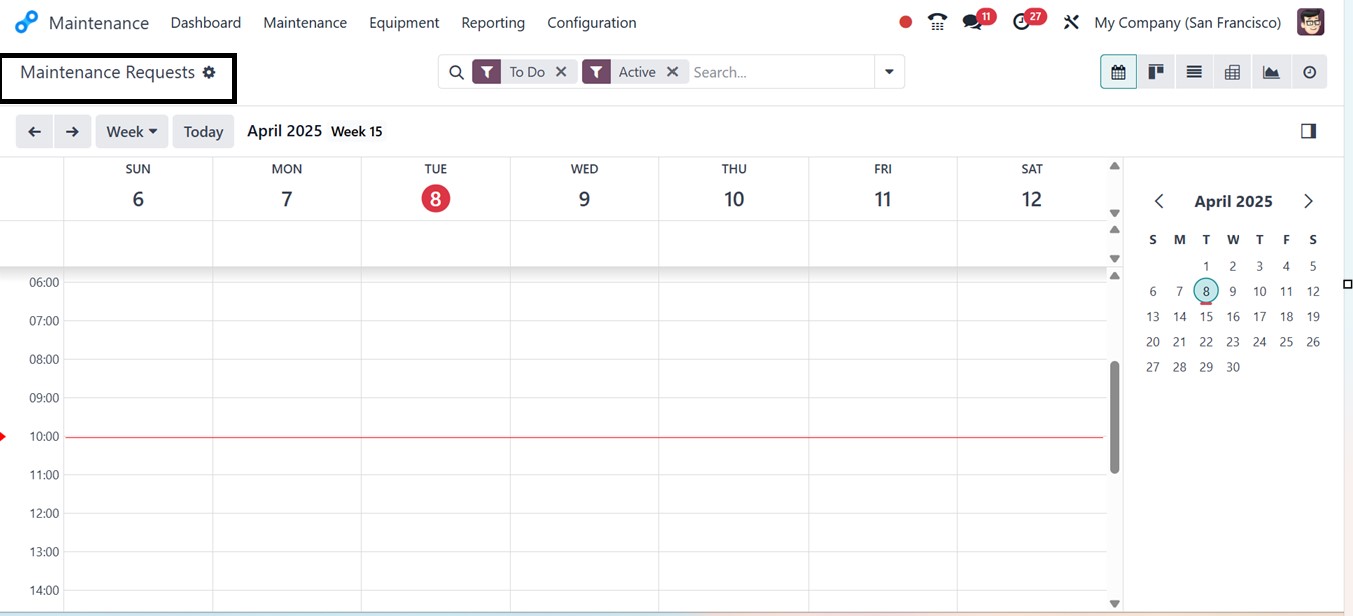

The “Maintenance Calendar” provides a visual representation of

scheduled maintenance requests, allowing users to plan and allocate

resources efficiently. Users can view tasks by day, week, month, or

year, making it easy to track ongoing and upcoming maintenance

activities

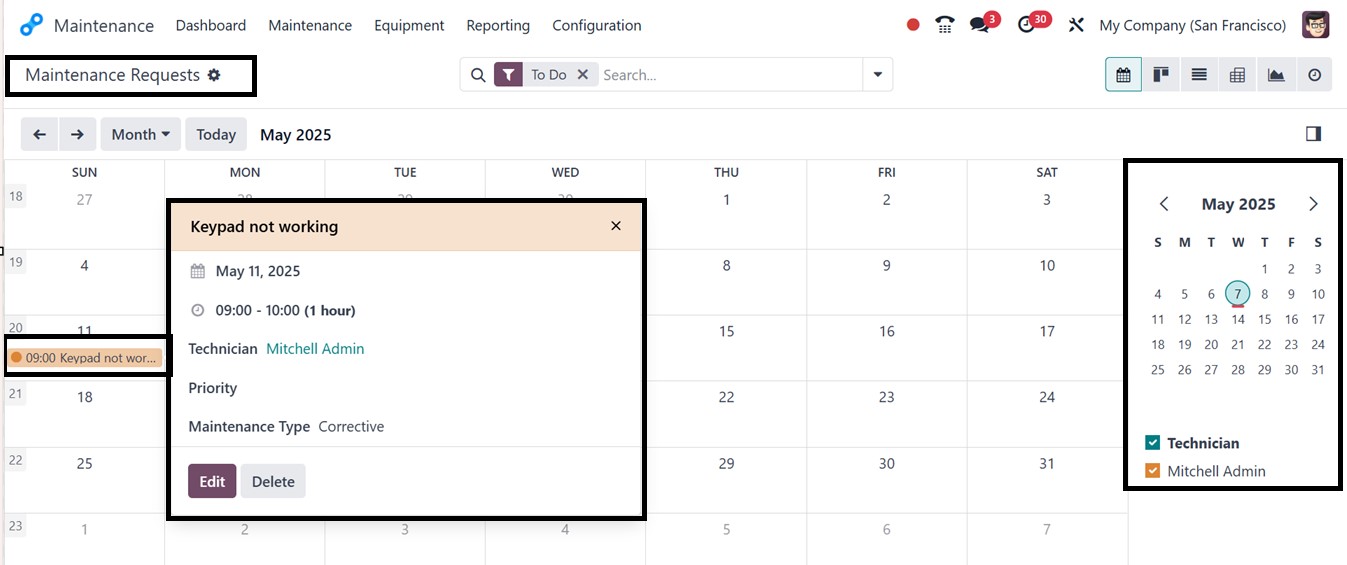

Clicking on a specific date displays a summary of scheduled tasks,

and users can edit or reassign tasks directly from the calendar

view, as illustrated in the screenshot below.

Additionally, new maintenance requests can be created from the

calendar by selecting a date and entering the Event Name, ensuring a

seamless scheduling process.

Once the event has been created, click the "Edit" button on the

request card in the calendar view to amend specific event or

maintenance request details using the form view, as seen in the

picture below.