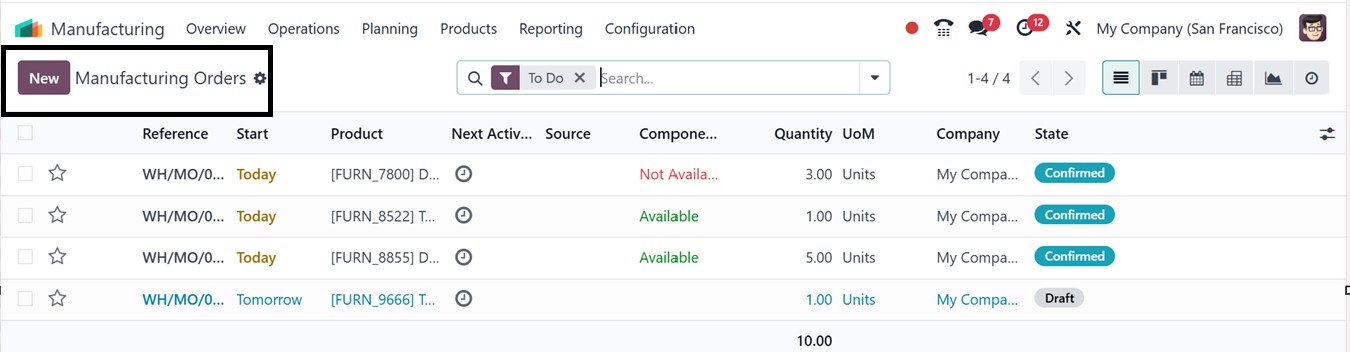

2. Operations Menu

Manufacturing a product involves

sourcing quality raw

materials, setting up

workstations, monitoring

product flow, and conducting

quality checks. In Odoo, a

Manufacturing Order (MO)

is created to initiate

production with a specific

product configuration. Two

primary ways to create MOs

are focusing on different

stages or customizing the

work center and configuring

operations for specific

products. These activities

are crucial for ensuring the

final product's quality. Upon

accessing the manufacturing

module, users are greeted by

a dashboard that showcases

existing production orders,

as shown below.

The page displays pre-configured

details, such as Reference

number, Start date, Product,

Next Activity, Source,

availability of components,

Quantity, unit of measure

(UoM), Company, and Status of

each manufacturing order. The

module also provides

different views, including

Kanban, List, Calendar,

Activity, and Pivot, allowing

users to choose a view that

best suits their needs. This

versatility enables effective

reporting and analysis.

The Group By and Filters options

inside the search bar further

enhance functionality. Users

can filter manufacturing

orders by their status (e.g.,

draft, confirmed, in

progress, or completed) or by

product type, scheduling

date, material availability,

and other options

3.1 Manufacturing Ordersr

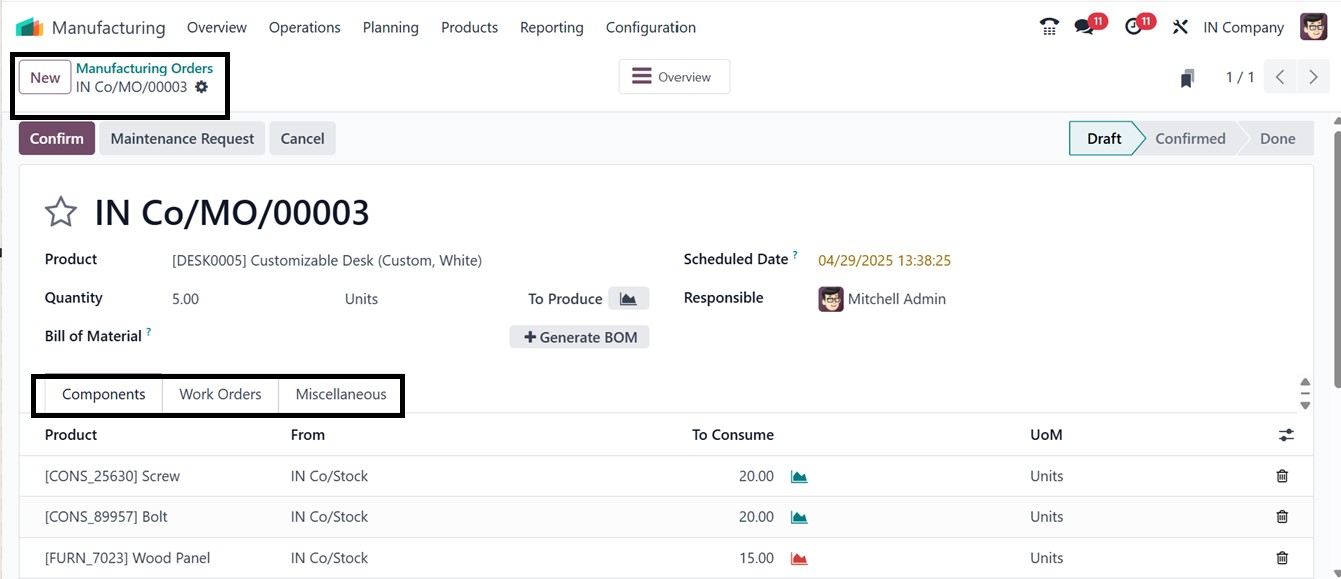

To create a new manufacturing

order, navigate to the

manufacturing module and

select the "New" option. The

creation page in Odoo 18

requires users to input key

details essential for

manufacturing operations.

These include the Product

Name, which specifies the

item to be produced, and the

Bill of Materials (BoM),

detailing the components and

their required quantities.

Users must also define the Number

of units to be manufactured,

the Scheduled Date for

production, and the

Responsible User, identifying

the person overseeing the

process. Additionally, the

Company Name must be entered

to associate the production

order with the correct

entity. Beyond these basic

details, users can further

refine the production process

by utilizing additional tabs

such as Components to manage

material requirements, Work

Orders to detail specific

tasks, and Miscellaneous for

other relevant configurations

or notes.

The Components tab allows the

addition of raw materials

using the "Add a Line"

option. Here, we can mention

the component products,

Consumption quantities, and

unit of measure (UoM), as

illustrated in the above

screenshot.

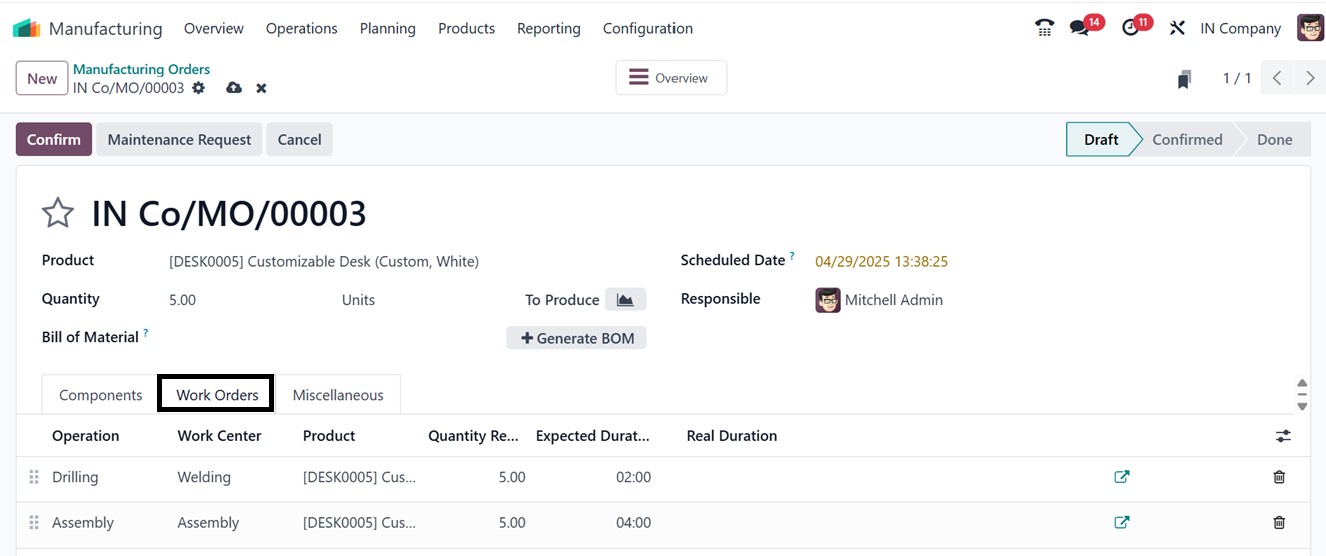

Under the Work Order tab option,

you may add the operation,

work center, product name,

quantity scheduled to start,

estimated duration, and real

duration. The tasks involved

in the manufacturing process

will determine how the

real-time is automatically

modified. After all the

information is finalized, we

can provide other details

about the work order in the

Miscellaneous tab.

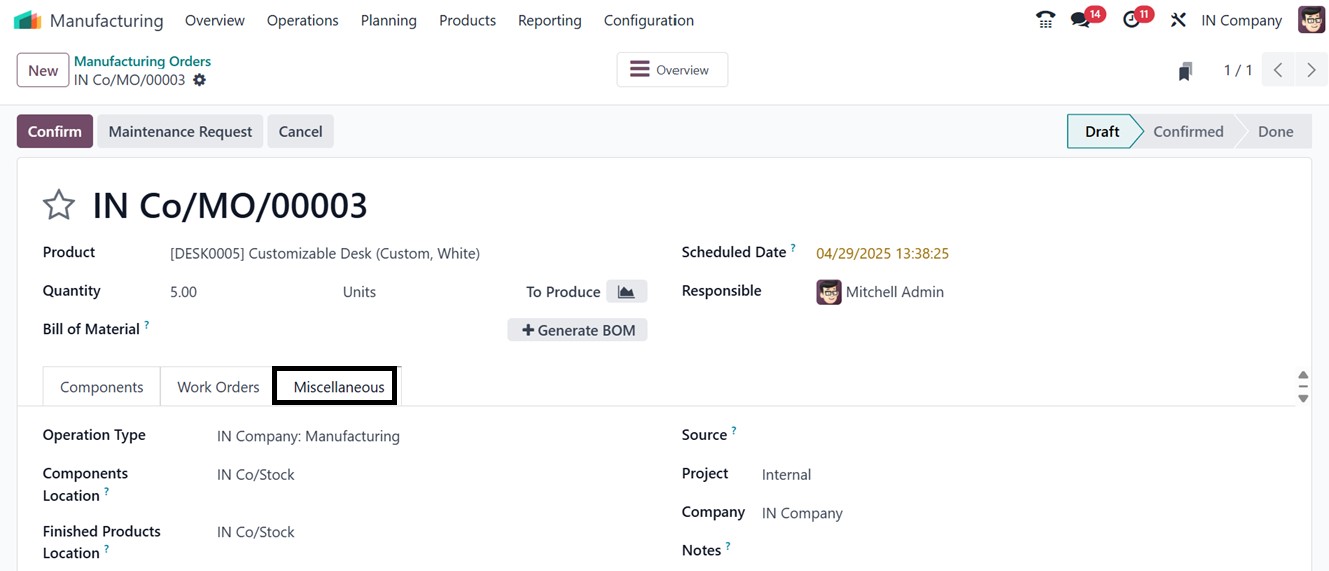

The Miscellaneous tab provides

options to enter additional

details, including Sources,

or specify Operation Types,

Projects, and the Company.

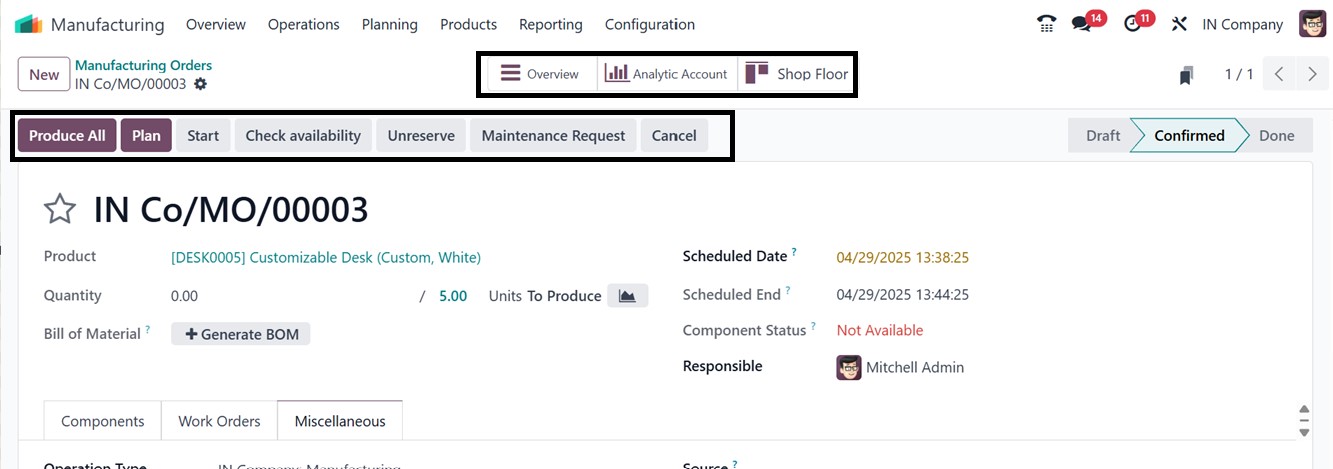

After filling in all the form

data, save the work order

details and proceed with the

work order using the ‘Confirm

’ button. This action will

trigger a new manufacturing

order creation, and we can

see some important buttons

and smart button options for

further operations, as shown

below.

We can see the availability of

the mentioned components in

the ‘Component Status’ field.

The ‘Produce All’ button can

be used to create the

manufacturer order

immediately, or we can

postpone the order by using

the ‘Plan’ button. The

‘Start’ button can be used

for start the manufacturing

process with the timesheet

recording facility. You can

also check the product

availability using the ‘Check

Availability’ button. Using

the ‘Unreserve’ and ‘Cancel’

buttons, you can unreserve

the product and its

components and cancel the

entire manufacturing order.

Finally, the ‘Maintenance

Requests’ button will help

you to send a manufacturing

request to that particular

work center or the associated

users.

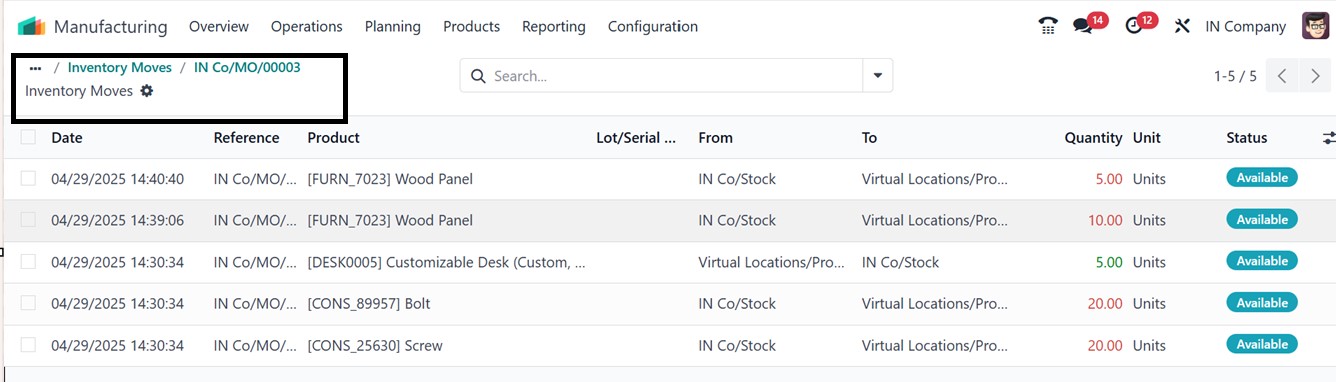

A dashboard displaying all

inventory movement

information, including the

time and location of a

component or product transfer

between sites, will appear

when you click the "Product

Moves" smart button. To

guarantee stock availability,

a few components were

repositioned in this example.

Clicking the "Check

Availability" button will

initiate this operation.

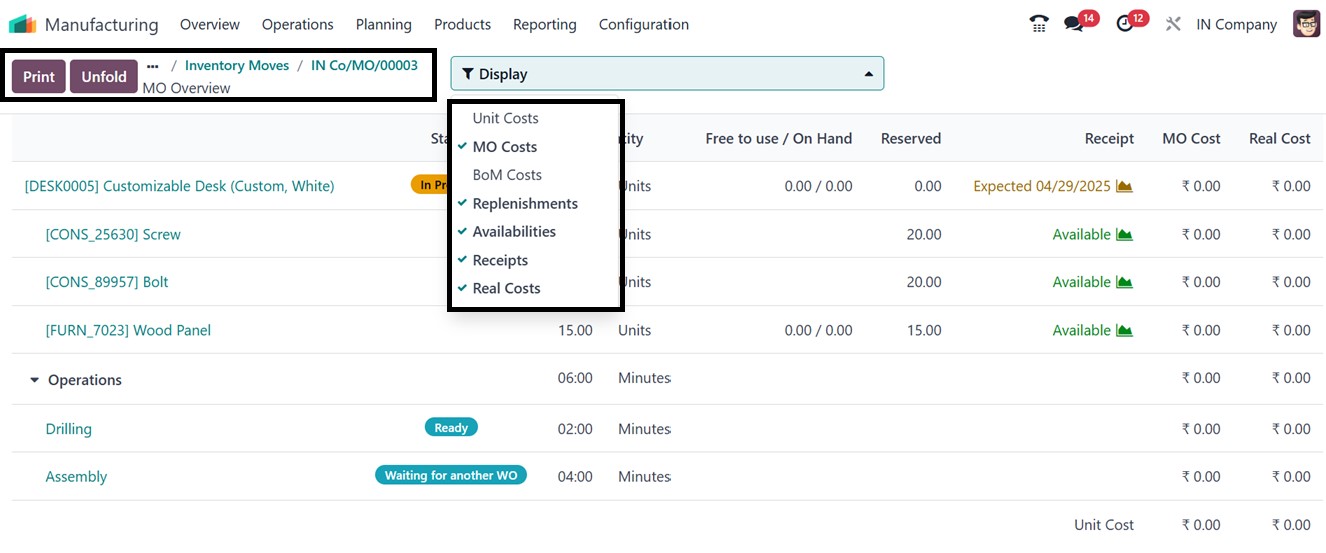

The Overview smart button will

display a complete overview

of the manufacturing process,

including the components,

operations involved in this

process, Status of the actual

product and operations,

Quantity, Reserved

Quantities, Manufacturing

Order Costs (MO Costs), Real

Cost, and other details as

illustrated in the screenshot

below.

Using the filter feature, you can

view various aspects of the

manufacturing process such as

Unit Costs, Manufacturing

Order Costs, BoM Costs,

Replenishments, etc.

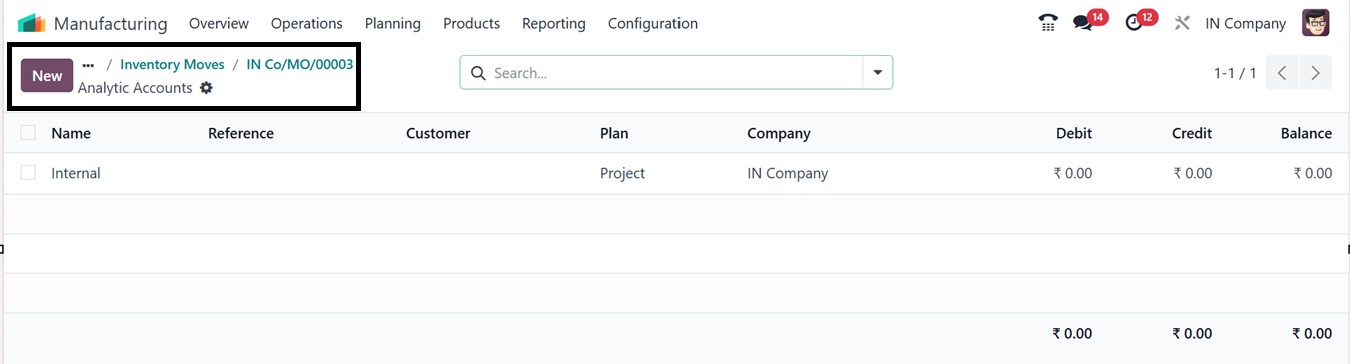

The "Analytic Account" smart

button in the manufacturing

order view connects to the

analytic account linked to

that particular order. A

deeper financial

understanding of the

manufacturing process is

provided by the tracking and

recording of debit, credit,

balance, and project-related

cost analysis using this

account.

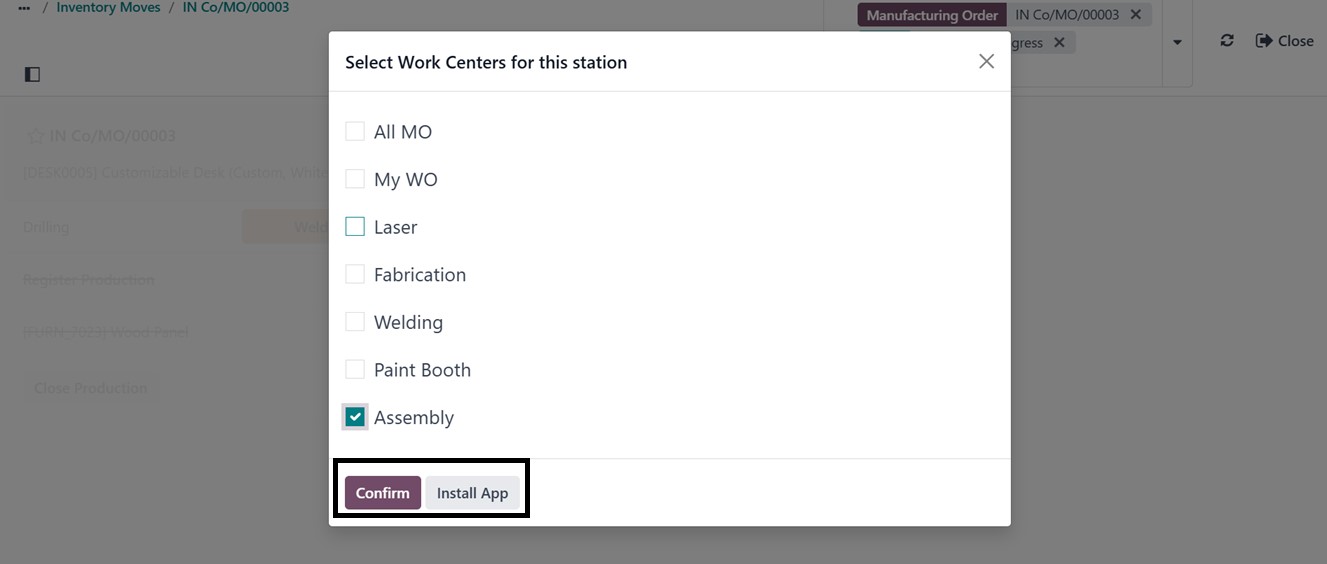

The ‘Shop Floor’ tab will show

the work order tablet view of

the manufacturing order. So,

you have to choose the work

center for this station and

confirm it

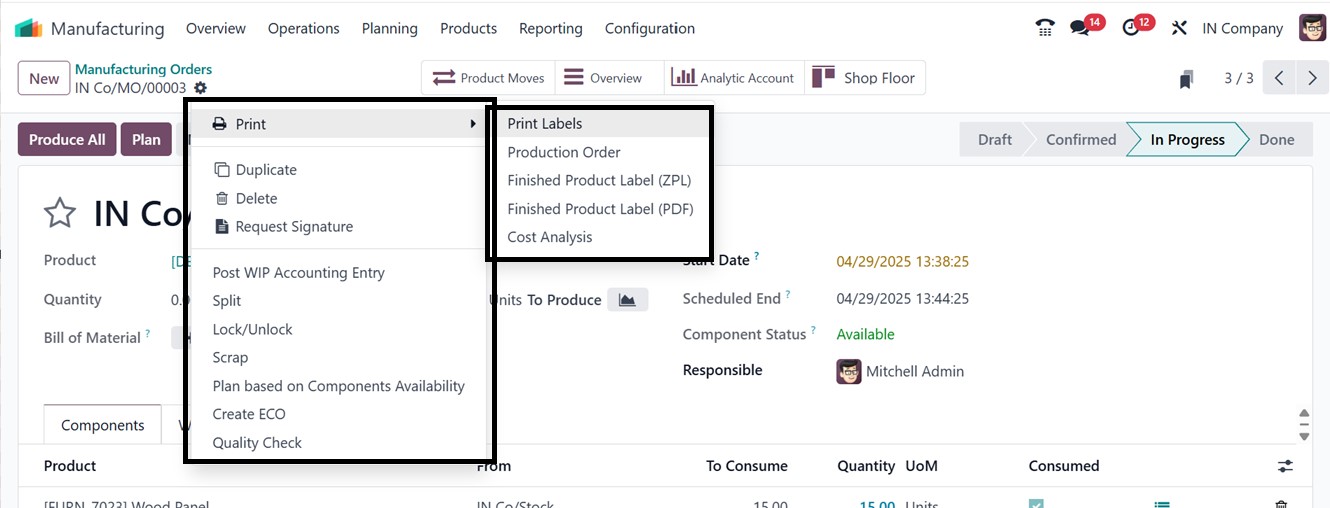

The ‘Action’ button placed at the

top left corner of the form

view can be used to Print,

Delete, and Duplicate the

form data. Users can also

utilize the ‘Request

Signature’ option to sign the

work order documents.

You can also create Split orders,

lock and unlock work orders,

Mark scrap orders, Plan

orders based on component

availability, create ECO

orders, and Quality check the

produced products using the

respective icons placed under

the ‘Action ’ menu.

Using the Print button, we can

print the data for future

analysis or for a better

understanding of the

procedures. The display

filter allows you to

include/exclude MO Cost, Real

Cost, BOM Cost, Unit Cost,

etc, to the MO Overview.

Finally, you can schedule the

manufacturing order using the

‘Plan’ button or immediately

start the process using the

‘Produce All’ button. The

Security Lead Time feature,

available under the

Configuration menu, helps

schedule production ahead of

time to prevent delays. It

enables manufacturers to

input safety days to ensure

on-time production and

mitigate potential

disruptions.

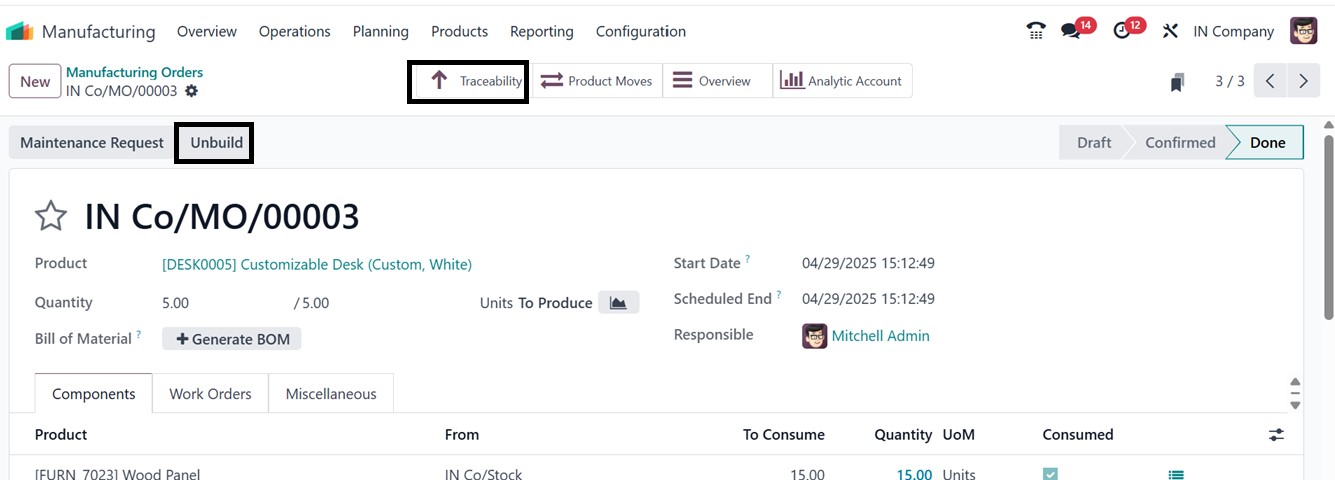

After producing the manufacturing

order, odoo will display an

‘Unbuild’ button to unbuild

the product if any mistakes

or quality issues arise.

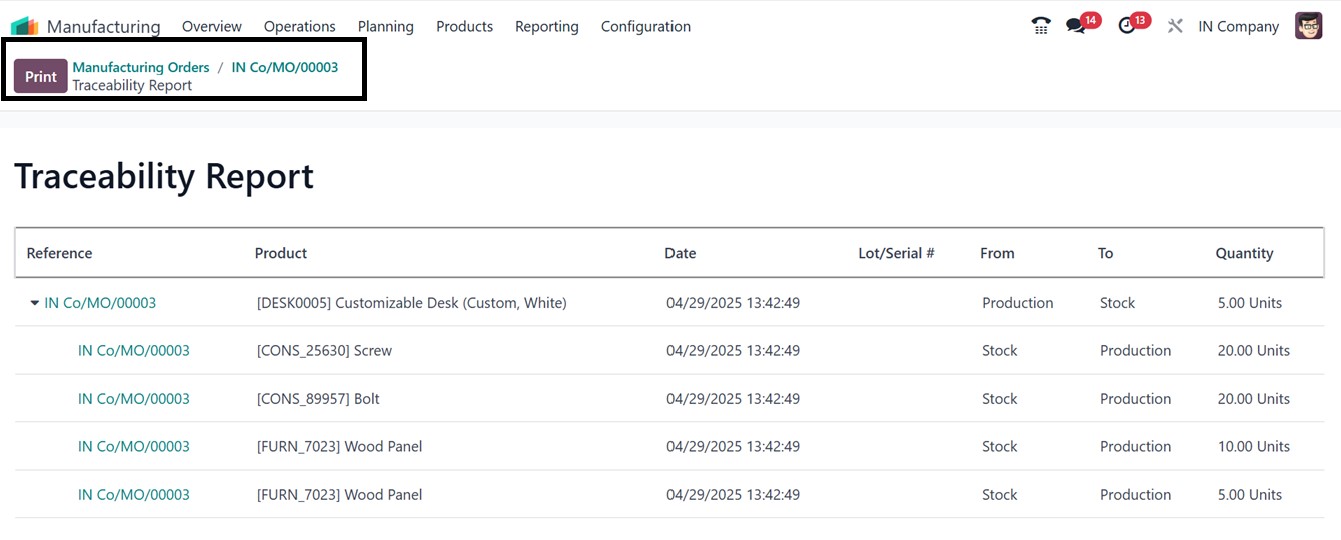

By selecting the "Traceability"

smart button, you can see the

product traceability report.

As seen in the picture below,

this report includes detailed

information on every product

that was part of the

manufacturing order.

3.2 By-Products and Work

Orders

Demanding by-products from a

manufacturing order will be

helpful for the efficient use

of components and for

reducing scrap items.

Monitoring quantities,

confirming production

outcomes, and ensuring

precise inventory updates are

possible for both primary and

secondary goods created

during the manufacturing

process.

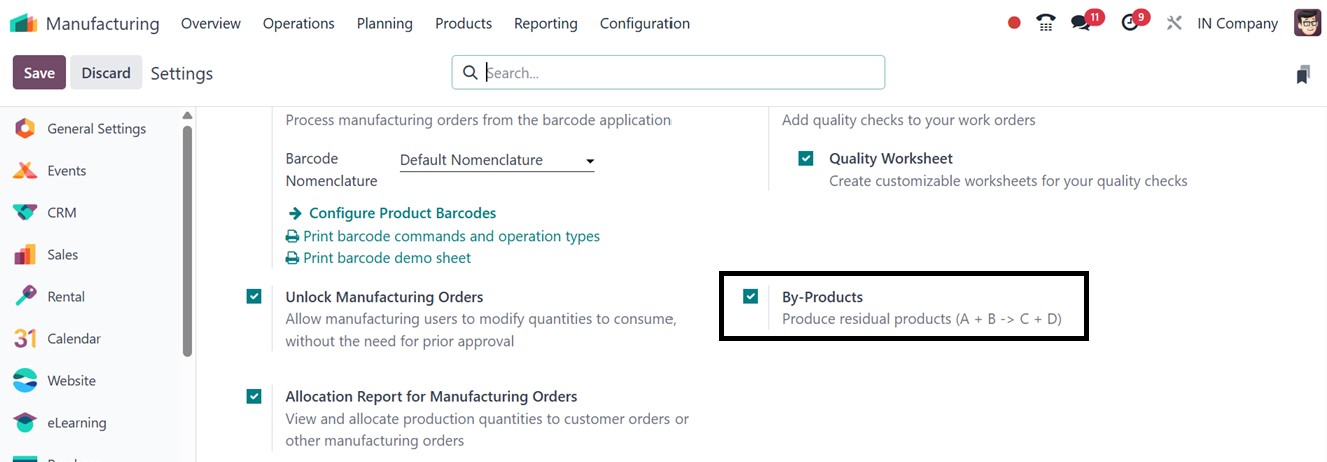

If required, users can activate

the By-Products feature in

the settings menu. This

enables the option to specify

any by-products produced

during manufacturing

alongside the main product.

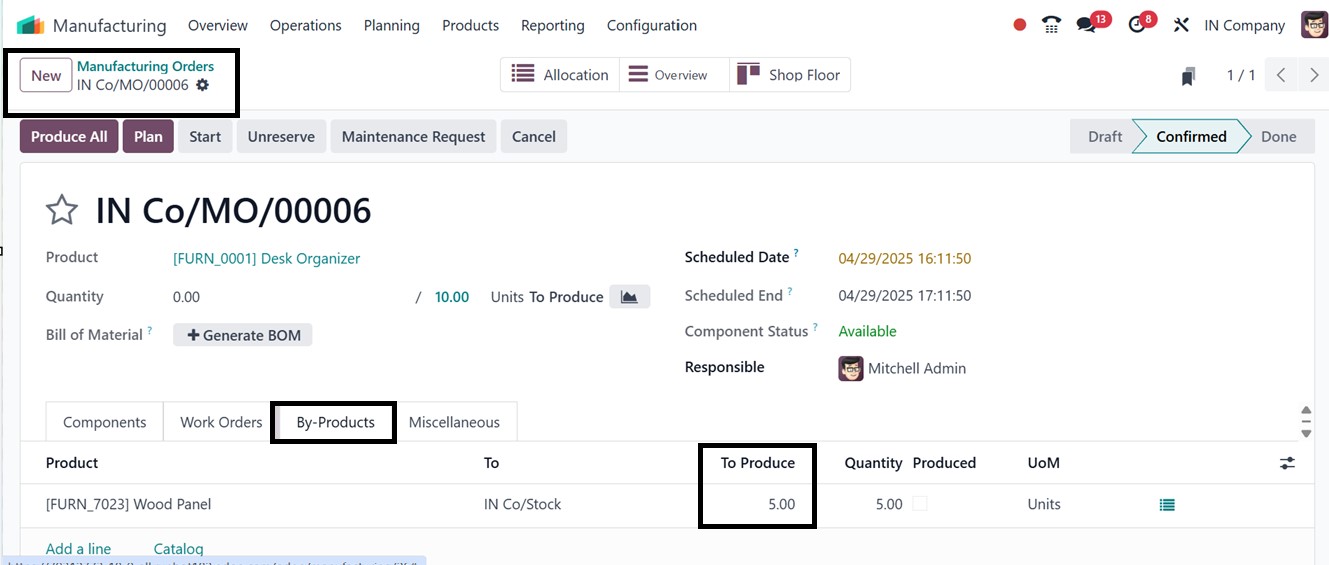

Activating this feature will open

an extra tab option in the

manufacturing Order

configuration form named the

‘By-Products’ tab. Users can

add by-products by selecting

"Add a Line" and providing

necessary details, such as

product name, UoM, and serial

number.

Once the manufacturing order is

created and saved, users have

the option to confirm it.

Upon confirmation, proceed

with the production process

using the ‘Produce All’

button.

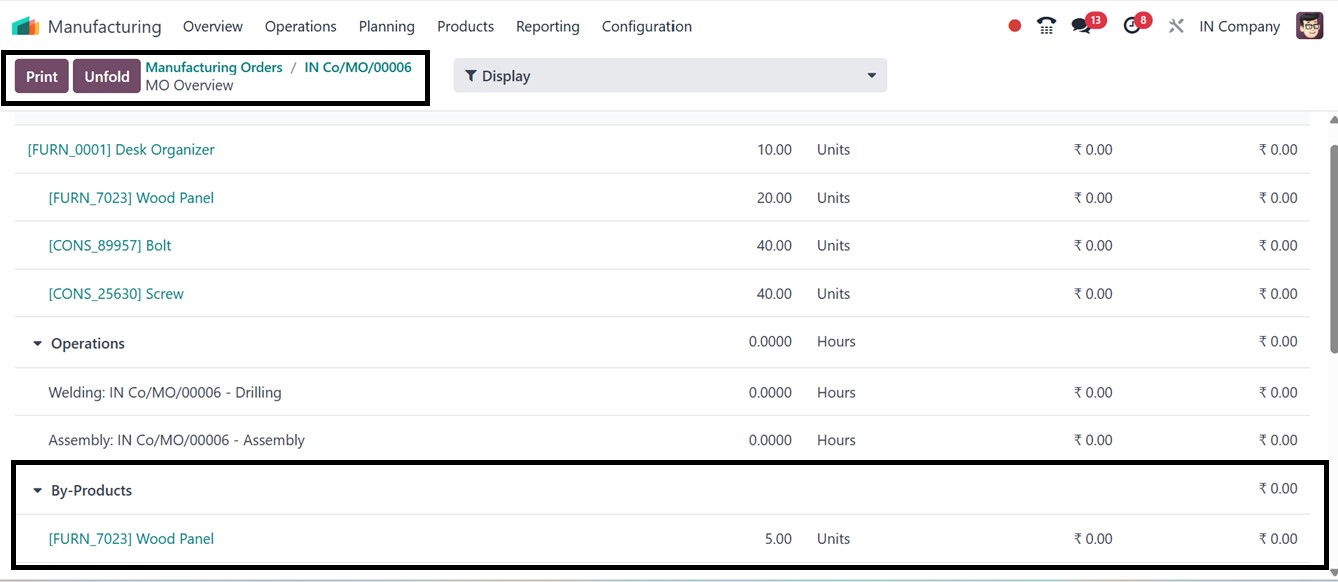

The "Overview" button allows you

to evaluate by-products

produced after finished items

are produced. This section

summarizes the production

order, including secondary

outputs or by-products

specified in the bill of

materials (BoM), as depicted

in the screenshot below.

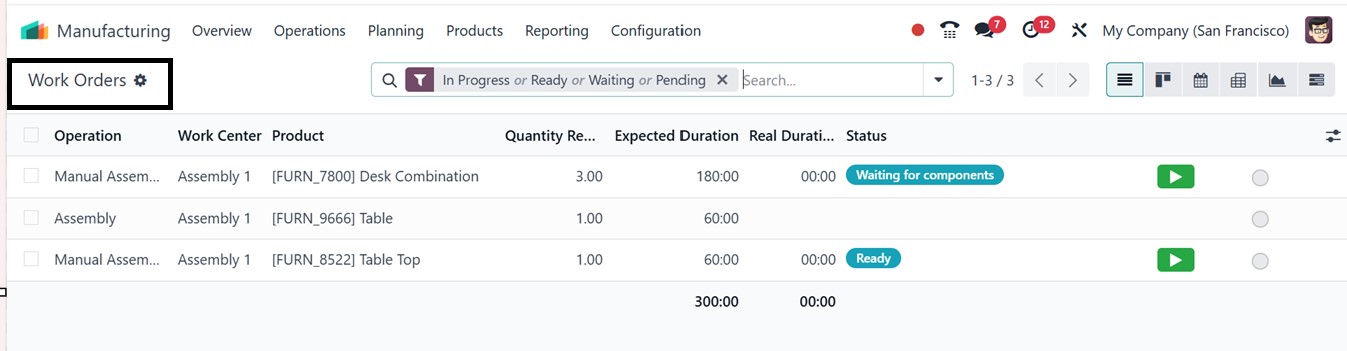

3.3 Work Orders

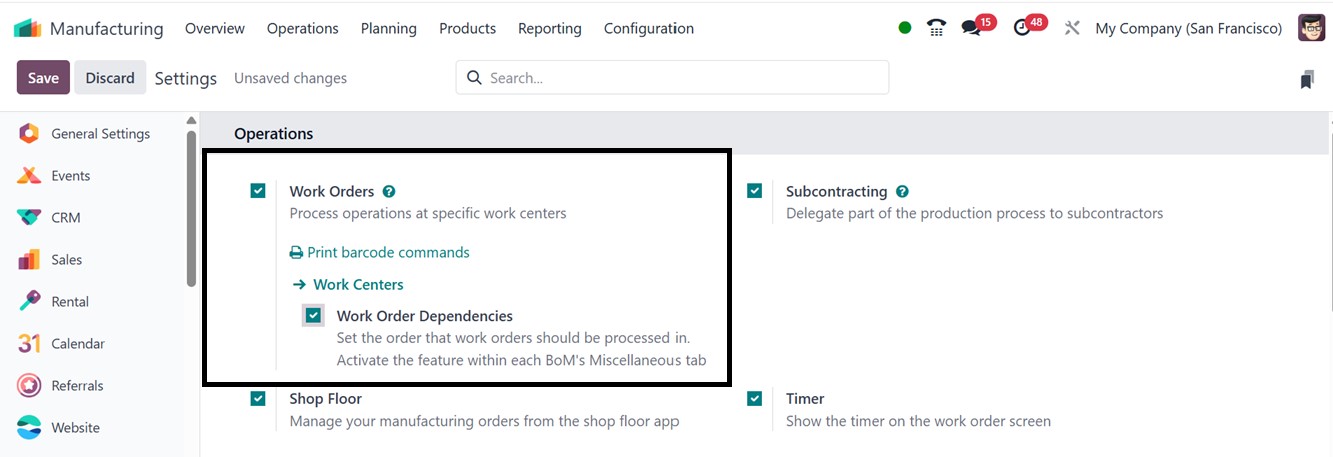

The management and organization

of work orders are crucial

for effectively coordinating

all activities related to

product production. When work

orders are initiated, options

are available from the main

menu of the manufacturing

module. If you enable the

Work Orders feature in the

settings menu, the average

work order details will be

displayed on a separate page.

If work orders have already been

created, they will be listed

on the ‘Work Orders’

dashboard window with

information including the

Operation, Work Order,

Product, Quantity Remaining,

Expected and Real Durations,

and the current status of

each work order, as depicted

in the screenshot below.

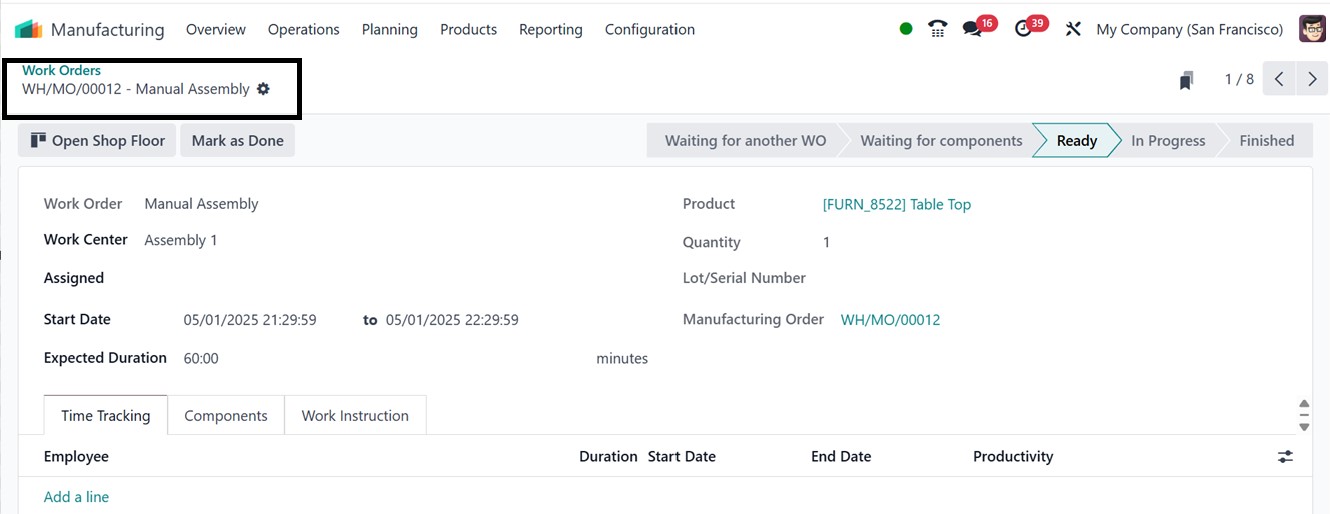

The Pivot, Graph, and Kanban

viewing choices on this page

let you select the format

that best suits your

analytical and workflow

needs. You may start the

process by clicking the Start

button next to any work

orders that are still

waiting. Clicking on any work

order entry will open its

work order form for better

understanding, as depicted in

the screenshot below.

This feature is essential for

effectively overseeing and

managing the different phases

of the production process. If

required, you can edit any

changes to the work order

from this configuration form.

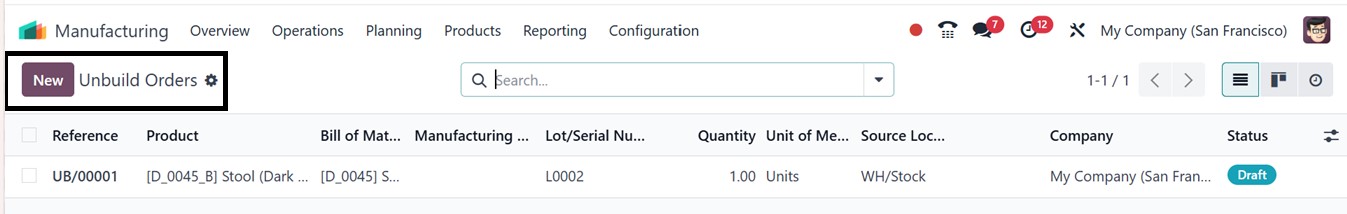

3.4 Unbuild Orders

The unbuild method in Odoo

enables the disassembly of a

completed product into its

individual components, making

it easier to manage and track

these processes. The

manufacturing module in Odoo

provides a list of all

created and unbuilt orders in

its ‘Unbuild Orders’ window

from the ‘Operations’ menu.

If any unbuilt orders have

already been established in

your manufacturing

application database, they

will appear on this window

with their Reference Id,

Product, Bill of Materials,

Manufacturing Order,

Lot/Serial Numbers, Unit of

Measure, Source Location and

other details in a dashboard

list view, as shown below.

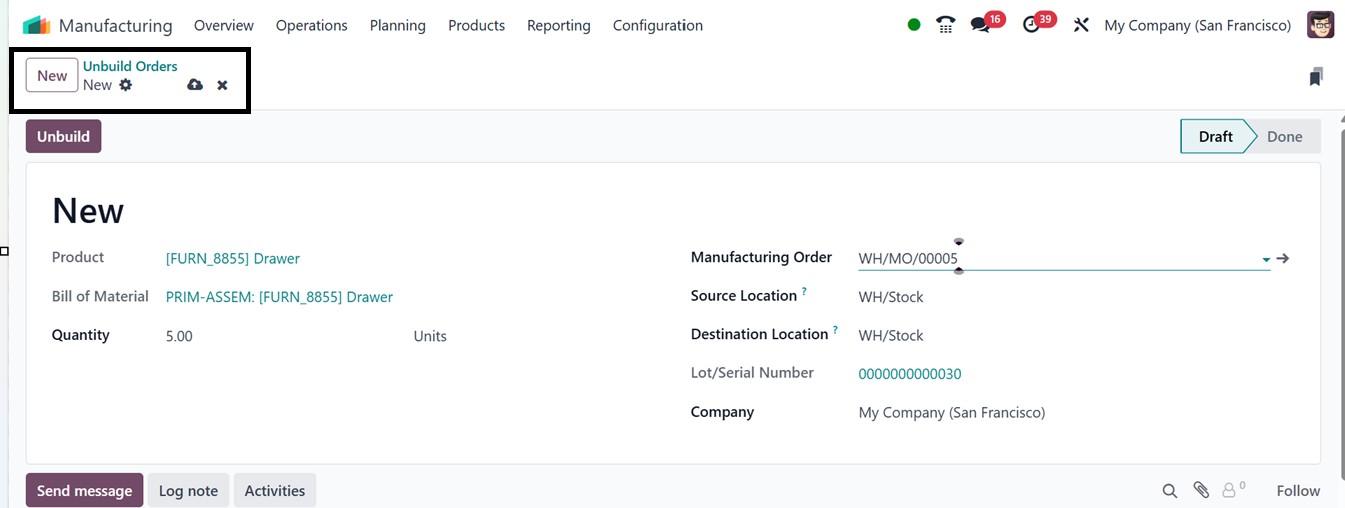

The list can be filtered or

organized using the "Group

by," "Favorites," and

"Filter" features. To create

a new unbuild order, click

the "New" button. The

screenshot below shows the

unbuilt order creation page.

You can enter information such as

the Product name, Bill of

Materials, Quantity,

Manufacturing Order,

Lot/serial number, Source

Location, Destination

Location and Company name on

the form field. Then, click

on the "Save" icon when all

the data has been provided.

After saving, click the

"Unbuild" button to finish

the unbuild order draft. If

required, you may use the

action menu's Delete and

Duplicate options from the

‘Actions’ button of the form

to remove or duplicate the

unbuilt order.

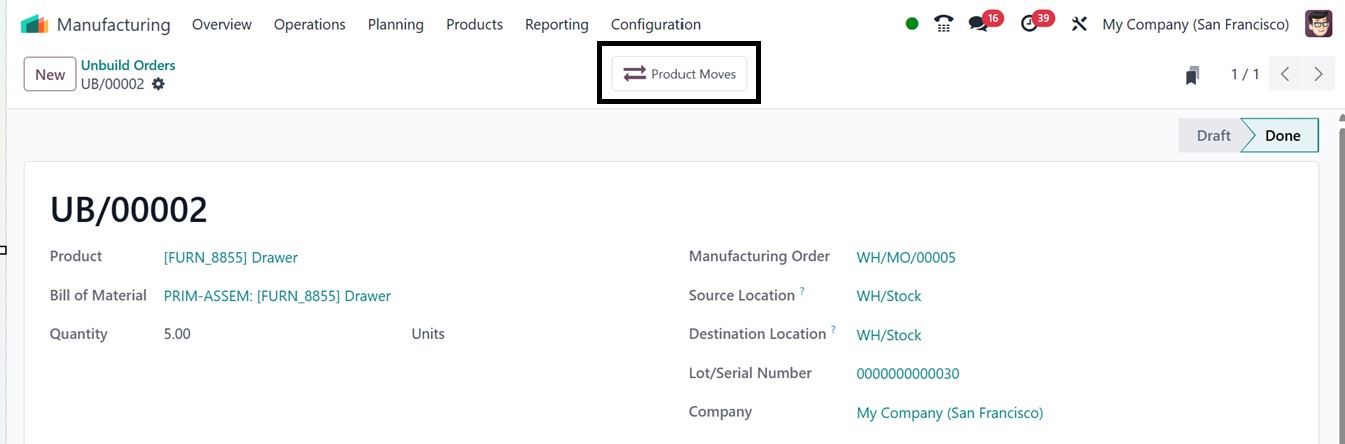

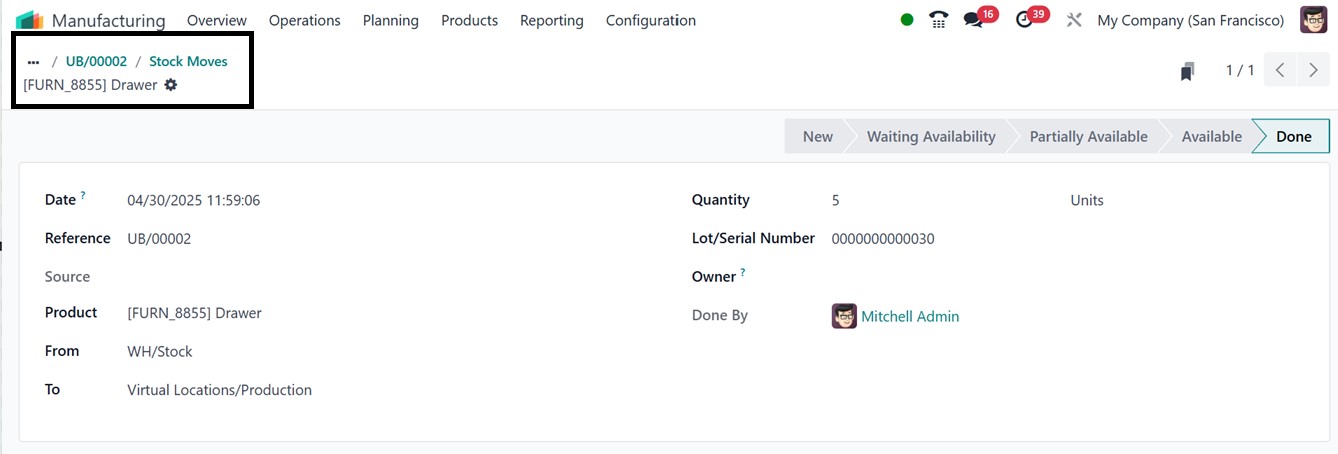

The "Product Moves" smart button

offers comprehensive details

on how products are moved

from their starting point to

their final destination. To

see this information, just

click on the dashboard's

product move entry, as shown

below.

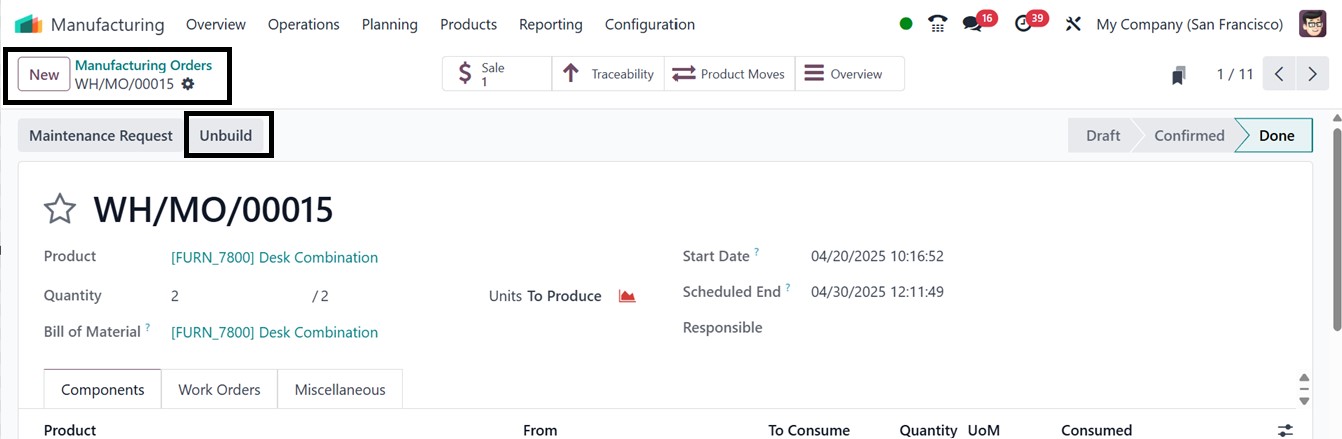

You can utilize the unbuild

capability even after a

normal manufacturing order is

finished. If the finished

product is flawed or damaged

after all manufacturing

processes have been

completed, you can quickly

undo the process by selecting

the "Unbuild" button on the

manufacturing order form, as

seen below, As a result, the

system is able to deconstruct

the final product and

appropriately return the

parts to stock.

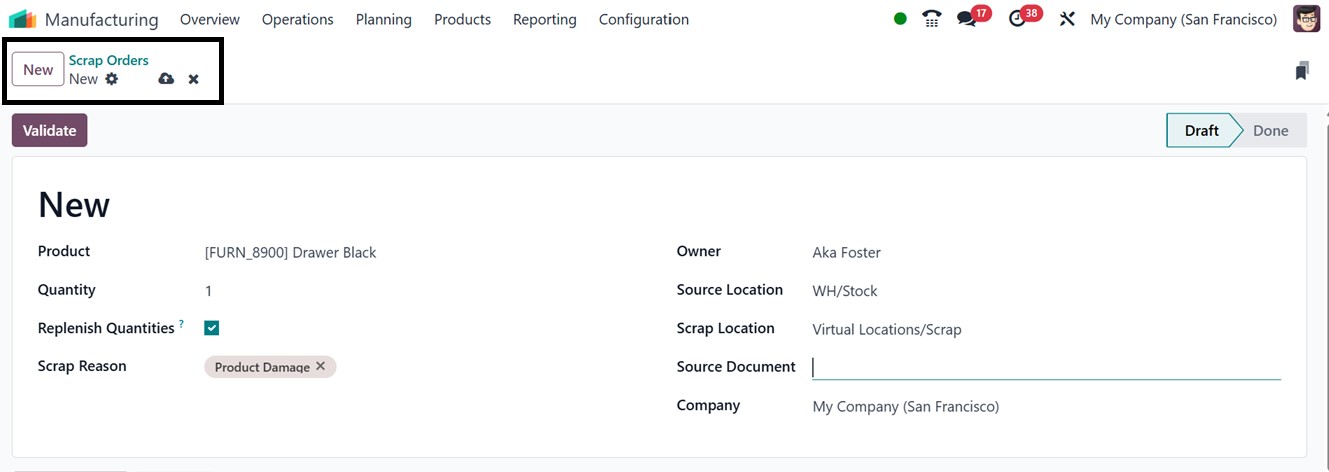

3.5 Scrap Orders

The ‘Scrap orders are an

essential part of the

production process for

handling discarded or damaged

product components. Removing

scrap items is a crucial step

that ensures defective parts

are properly managed after

the production process is

verified.

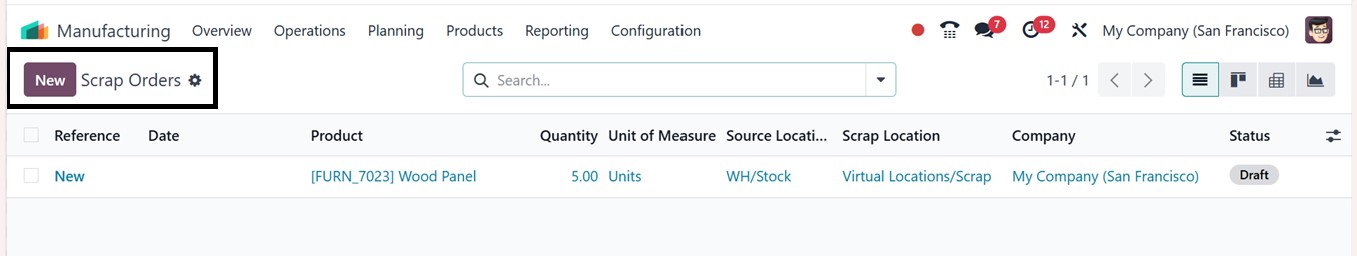

You can choose the "Scrap"

option from the Operations

menu. This will take you to

the scrap orders dashboard.

You will also have access to

a list of previously

completed scrap orders if

they are available, as shown

in the screenshot below.

From the dashboard, open a new

Scrap Order creation form. In

this section, you can specify

the name of the Product and

the Quantity to be scrapped.

Afterward, provide the

Lot/Serial Numbers, Replenish

Quantities, Scrap Reasons,

Source Location,

ScrapLocation, and Source

Document details for future

reference and better scrap

management.

Finally, select the "Validate”

option to confirm the scrap

order. Upon validation, this

order will be displayed in

the Scrap menu dashboard.

After confirming the Scrap

order, you can check the

product movement history

details from the “Product

Moves” smart button.