3. Planning Menu

The Planning menu in the Odoo 18 Manufacturing module offers robust

tools to help you efficiently schedule and manage work orders and

production activities across different work centers. This feature is

essential for coordinating complex manufacturing operations and

ensuring timely production output. Below is an overview of the key

planning options available under this menu.

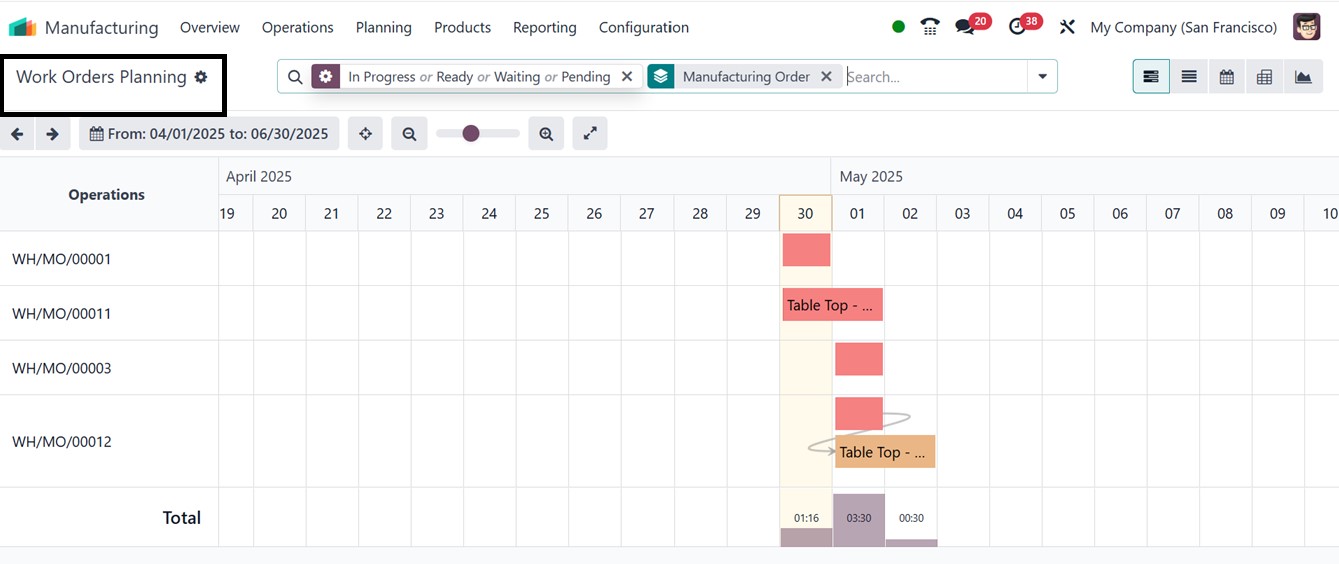

4.1 Planning by Production

The Planning by Production option allows you to schedule work orders

based on the overall production plan. When creating a manufacturing

order, you can specify the Planned Start Date for the production.

Odoo 18 automatically updates the work orders with this schedule,

which can then be visualized in a calendar-style view under the

Planning by Production interface.

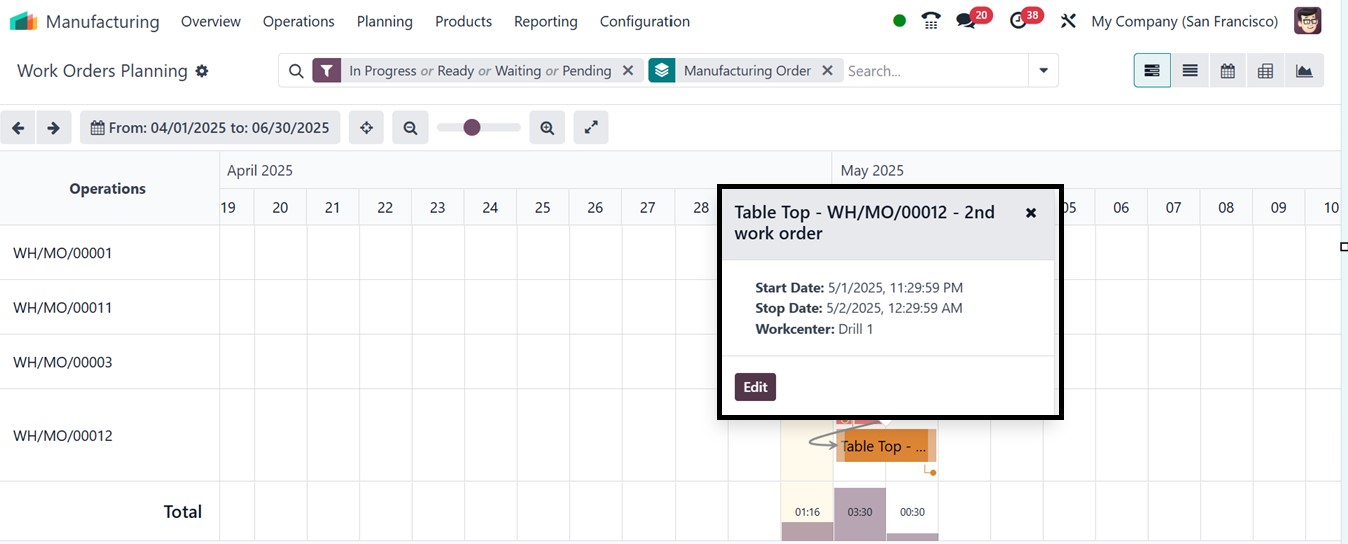

This view displays the scheduled dates for various work orders.

Clicking on a highlighted date provides a summary of the associated

work order, including its Name, Start Date, Stop Date, and Work

Center. You can select the entry to open and manage the full details

of the work order.

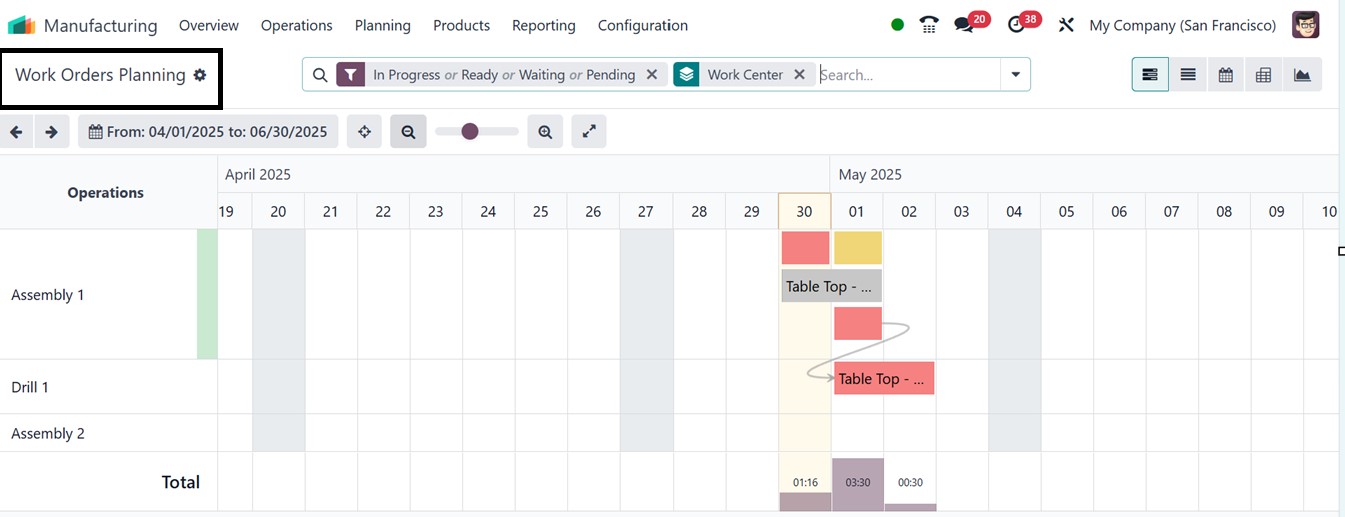

4.2 Planning by Work Center

The Planning by Workcenter view organizes work orders based on the

assigned work centers. This helps managers and production

supervisors monitor the workload across different work centers and

avoid scheduling conflicts. If multiple work orders are assigned to

the same work center on the same day, you can easily adjust and

reschedule them from this interface to balance the workload

efficiently.

4.3 Master Production Scheduler

The Run Scheduler feature, also accessible from the Planning menu,

plays a vital role in automating material availability and

reordering processes. While this tool is commonly used in the

Inventory module, it is equally powerful in the Manufacturing module

By running the scheduler, Odoo will:

- Allocate available inventory for work orders and operations that

were previously on hold due to missing components.

- Automatically trigger Reordering Rules when stock levels fall

below minimum thresholds, ensuring that production is not

delayed due to shortages.

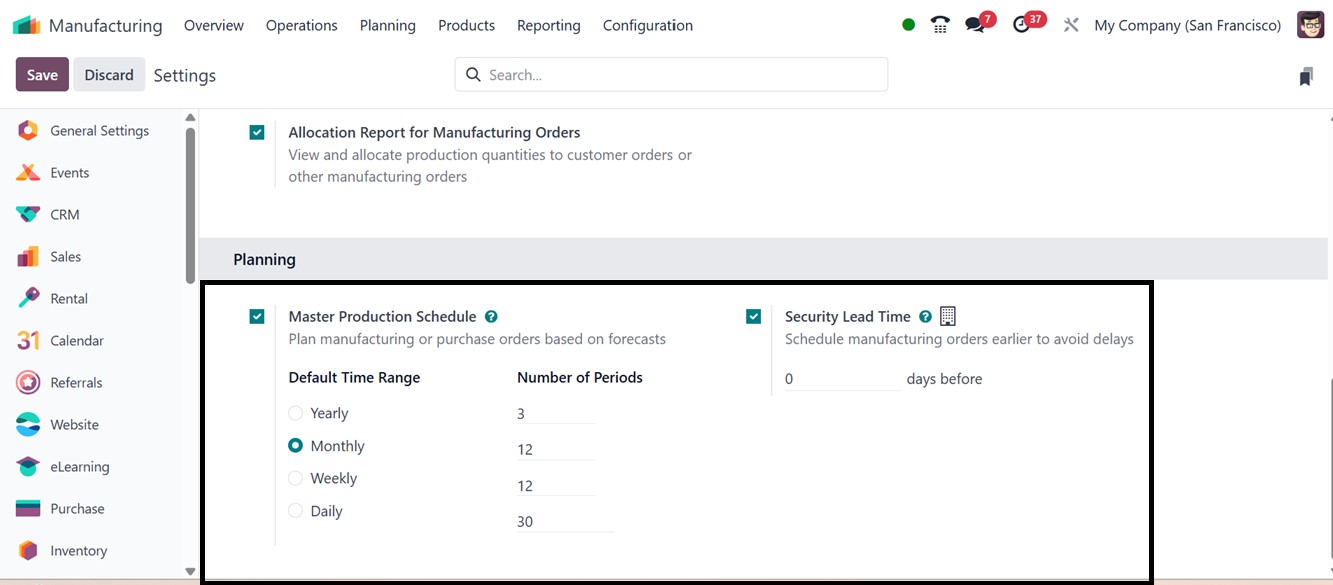

To begin using the Master Production Schedule (MPS) feature in Odoo

18, it must first be activated from the Settings menu under the

Planning tab, as illustrated in the image below

Once the functionality is enabled, you need to define the Time Range

for the schedule, which can be set to daily, weekly, or monthly.

Additionally, you can specify the number of columns that should

appear in the MPS reports, depending on the range selected. After

completing this setup, you can access the Master Production Schedule

from the Planning menu.

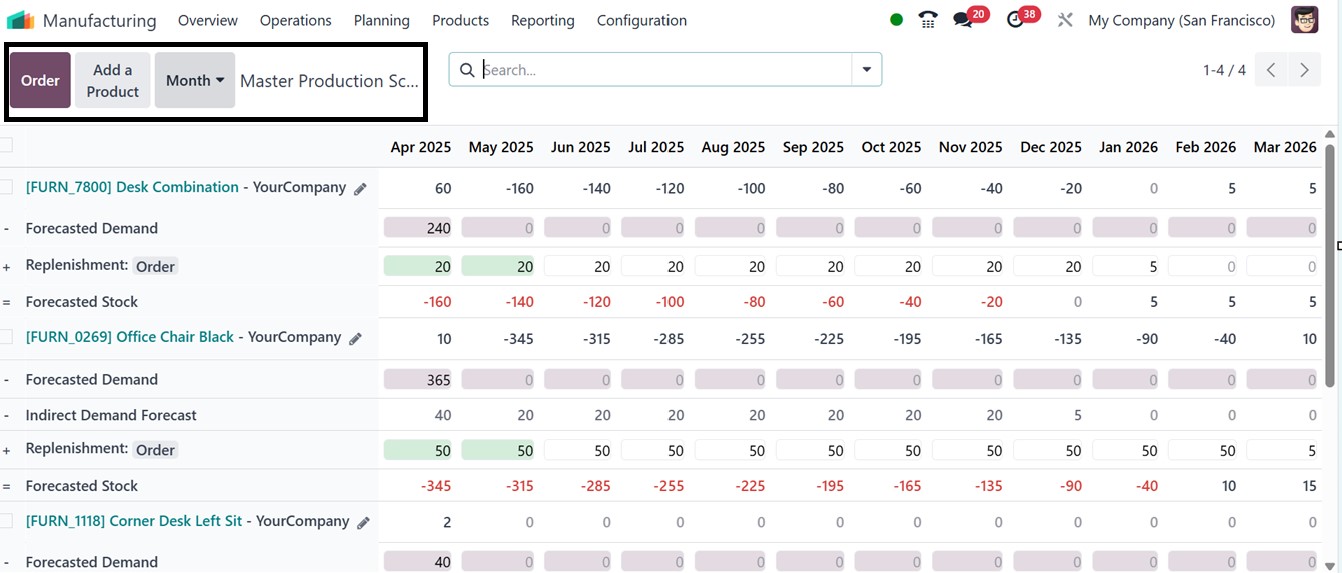

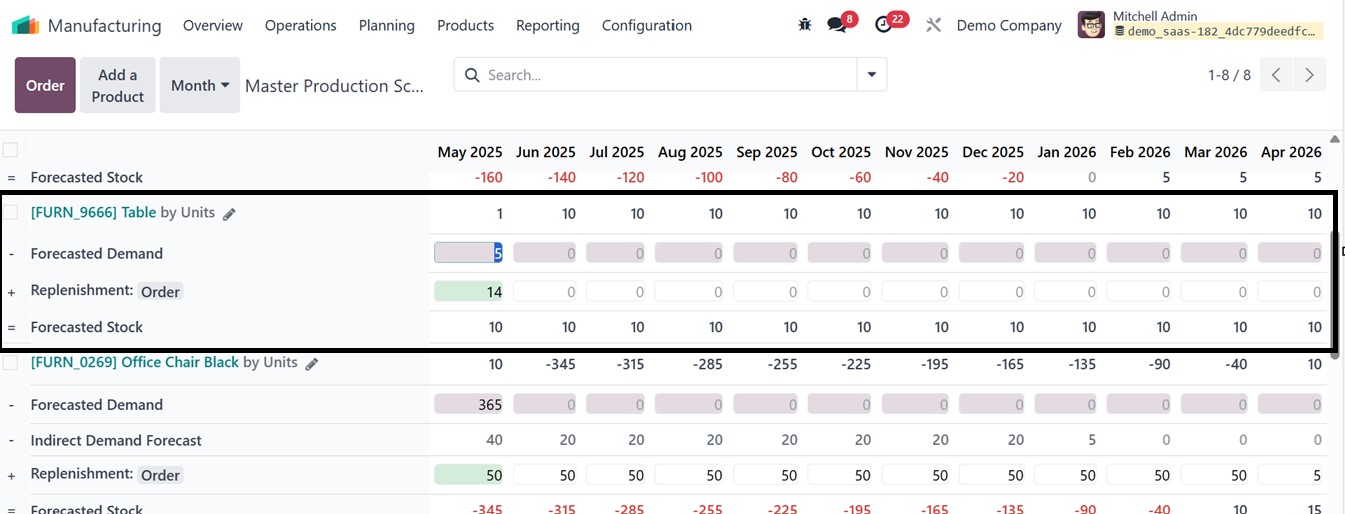

A number of essential inventory and planning parameters that support

effective production management are included in the data presented

in the Master Production Schedule (MPS) window including the

Starting Inventory, which displays the stock on hand at the start of

the period; Actual Demand, which indicates the verified demand for

the product; and the Indirect Demand Forecast, which projects

possible future requirements based on patterns or related requests.

While Actual Replenishment logs the replenishment quantities that

have already been completed, the To Replenish field shows the

quantity that remains to be supplied. Furthermore, Available to

Promise displays the stock that may be assuredly committed to new

orders without compromising current commitments, while Forecast

Stock represents the expected inventory level at the conclusion of

the planning period.

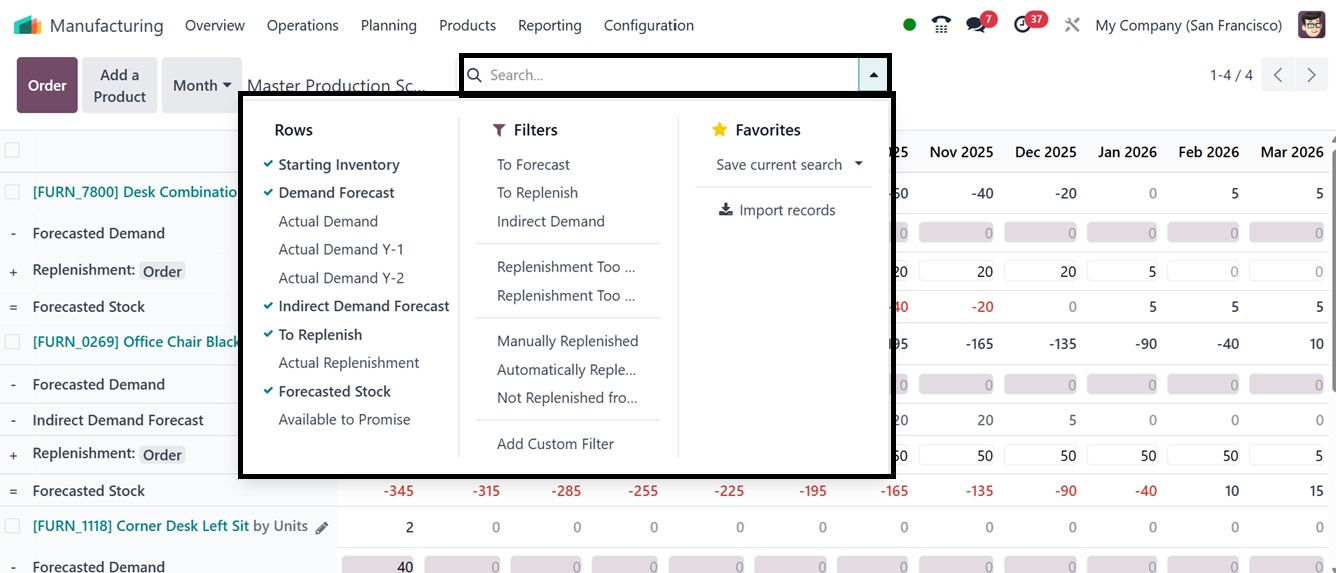

The MPS interface displays columns based on the selected Time Range.

You can further enhance the display by adding additional rows using

the options available in the Rows menu provided in the search bar

area.

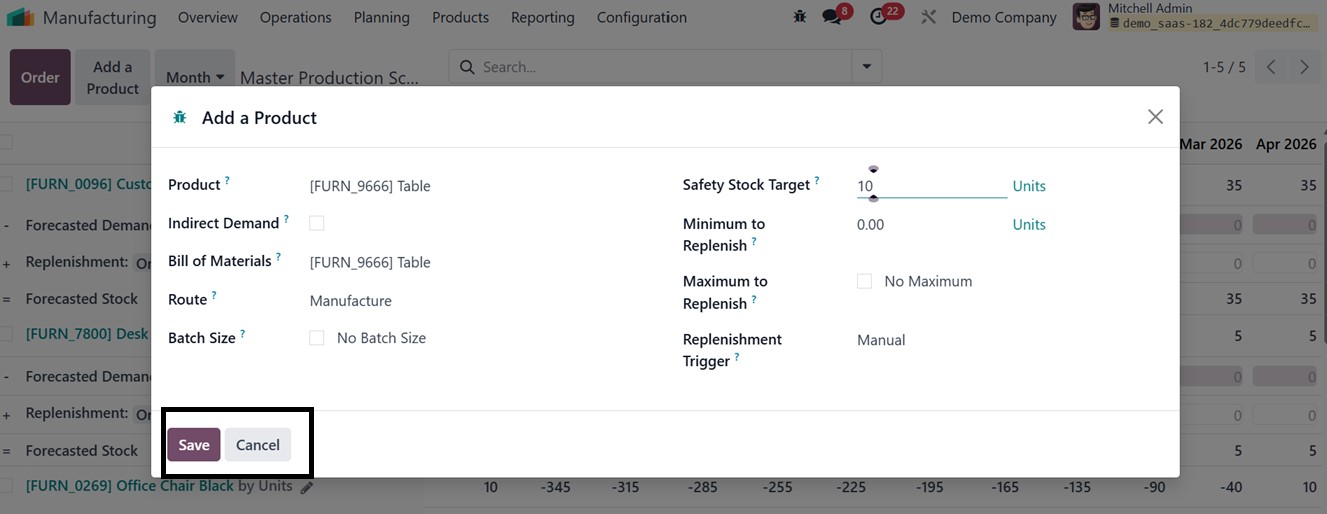

It's important to note that Odoo can only generate a manufacturing

order through replenishment if the product’s route of operation is

configured as "Manufacturing". After confirming that the correct

routes are set for the product, you can click on Add a Product to

include it in the MPS. This action will trigger a pop-up window that

will prompt you to input specific details like the Product, Bill of

Materials, Route, Batch Size, and mention whether it is an Indirect

Demand to not display this product in the ‘To Forecast’ filter in an

MPS dashboard.

In the Safety Stock Target field, you must specify the minimum

quantity of the product that should always be available in stock.

The Minimum to Replenish value ensures that Odoo 18 will replenish

at least this amount whenever replenishment is required, except when

the demand is zero. The Maximum to Replenish field defines the

highest amount that should be replenished for the product in any

given period. If actual demand exceeds this maximum, the excess will

be automatically rolled over to the next time period. Once all the

fields are filled, click the Save button.

For example, if the product has an on-hand quantity of 20 units, this

will be recorded as the Starting Inventory for the current month.

The MPS screen will show inventory information projected for the

next twelve months. You can manually input estimated demand in the

Forecasted Demand section for the current month. Based on this data,

the system will automatically calculate the Suggested Replenishment

quantity, indicating how much should be ordered through a purchase

or manufacturing order. The Forecasted Stock will reflect the

expected inventory level at the end of the period, as depicted in

the screenshot below.

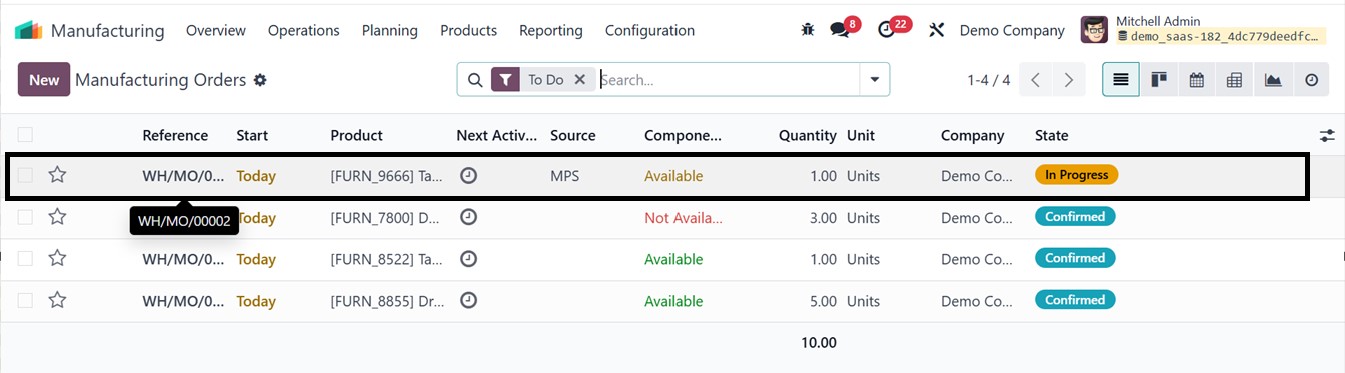

Depending on how the product’s operational route is configured, Odoo

will generate either a Manufacturing Order or a Purchase Order once

you press the Replenishment button. To view the replenishment orders

generated, navigate to the Manufacturing Orders dashboard. These

records will indicate that the replenishment originated from the

Master Production Schedule, as depicted in the screenshot below.