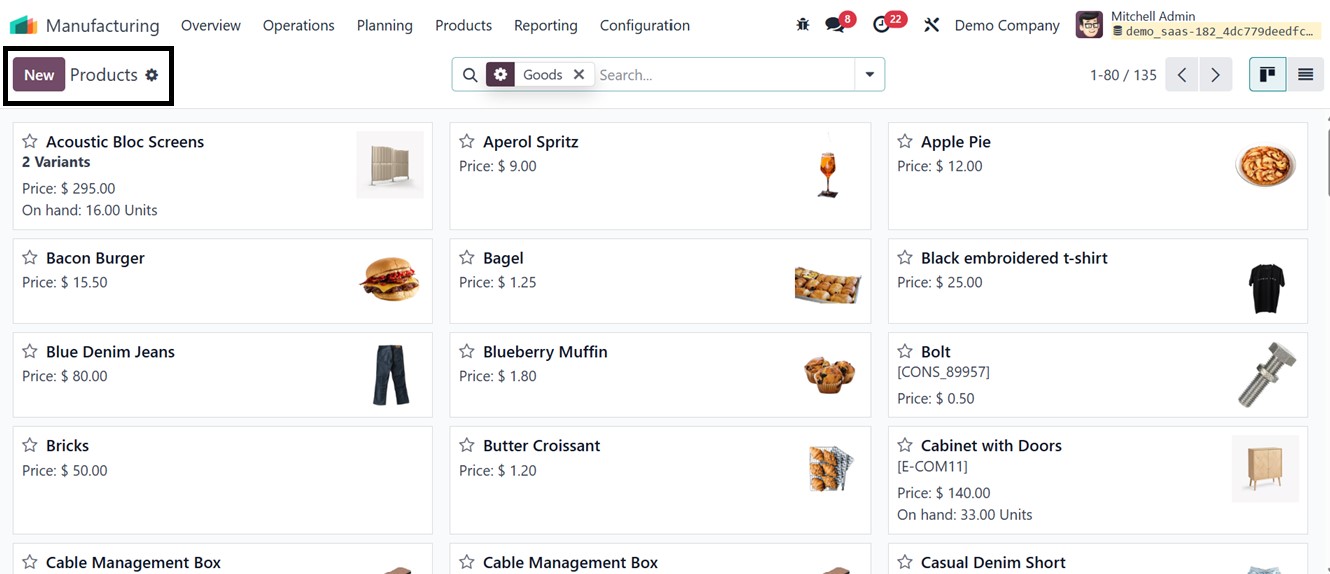

4. Products Menu

The manufacturing module offers a

centralized space to manage

and monitor products and

their variations. We can see

the available products and

the product catalog from the

Products menu, with their

name, Price, and Quantity

available, in a Kanban view,

as shown in the screenshot

below.

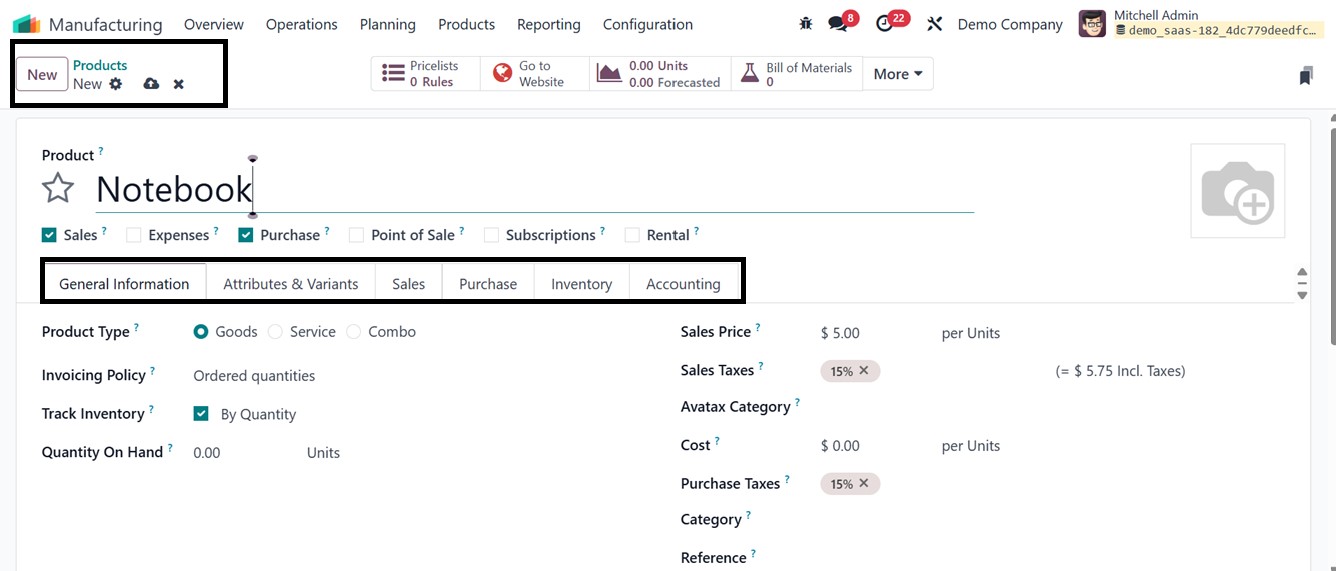

We can also add new products to

the product dashboard using

the ‘New’ button. When

developing a product, you

need to include General

Information, Attributes, and

Variants, as well as details

about the Purchase, Sales,

Inventory, and Accounting.

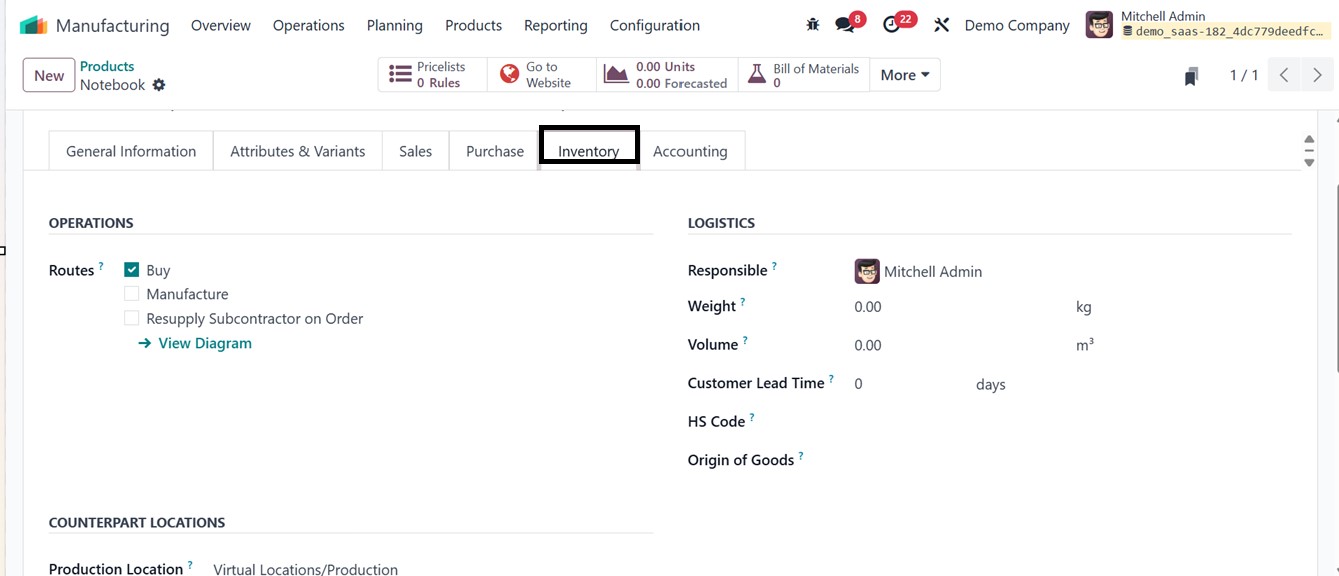

In the Inventory tab, there is a

field for mentioning the

Routes in the ‘OPERATIONS’

area, where you can specify

multiple routes and the

typical number of days

required to deliver the

product. For products

manufactured internally by

the company, the appropriate

routes can also be assigned

as ‘Manufacture’.

The product's Weight, Volume,

Customer Lead Time, Origin of

Goods, and HS Code options

can be configured using the

LOGISTICS feature. After

configuring the product

details, save the data. The

form also contains various

smart buttons to track and

manage various product data

and inventory options,

including;

- Pricelists: Displays all

sales pricelists for

pricing management

across different

customer segments.

- Go To Website: Directs to

the product's page on

the company's website

for easy access.

- On Hand Units: Displays

current physical stock

in the warehouse for

tracking inventory

levels.

- Forecasted Units: Shows

projected inventory

level based on current

stock, incoming

shipments, sales

orders, and

manufacturing orders.

- Bill of Materials (BoM):

Lists all Bills of

Materials linked to

the product for

manufacturing.

- Documents: Access files

or documents attached

to the product.

- Sold: Displays the sold

product units.

- Purchased: Displays the

dashboard of all the

purchased products.

- Reordering Rules:

Displays and manages

automatic reordering

rules.

- In/Out: Displays the

product In/Out

movement history from

one location to

another.

- Quality Points: Shows the

quality points

received while quality

checking the product.

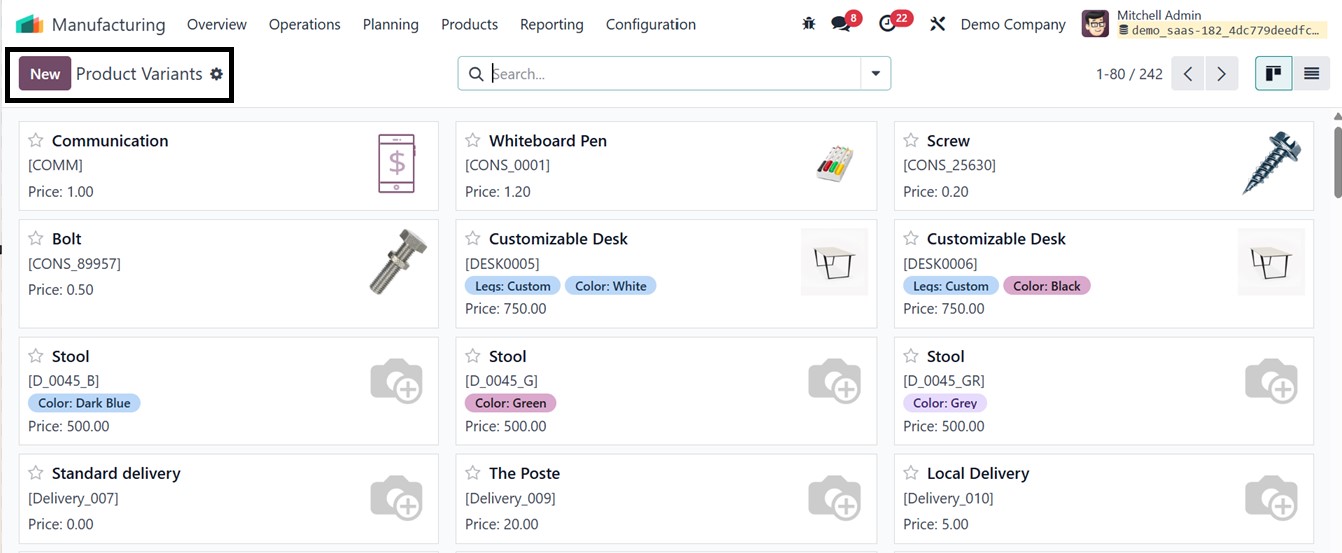

5.1 Product Variants

Odoo's product variants

streamline inventory,

pricing, and sales processes

by grouping similar items

under a single product

template while tracking each

variant individually. This

feature can be managed in the

Odoo manufacturing module

under the Product Variant

option, which displays a

dashboard of all possible

product variants created

earlier in a Kanban view as

shown below.

Creating a new product variant is

similar to the configuration

of a new product that we have

discussed in the above

section.

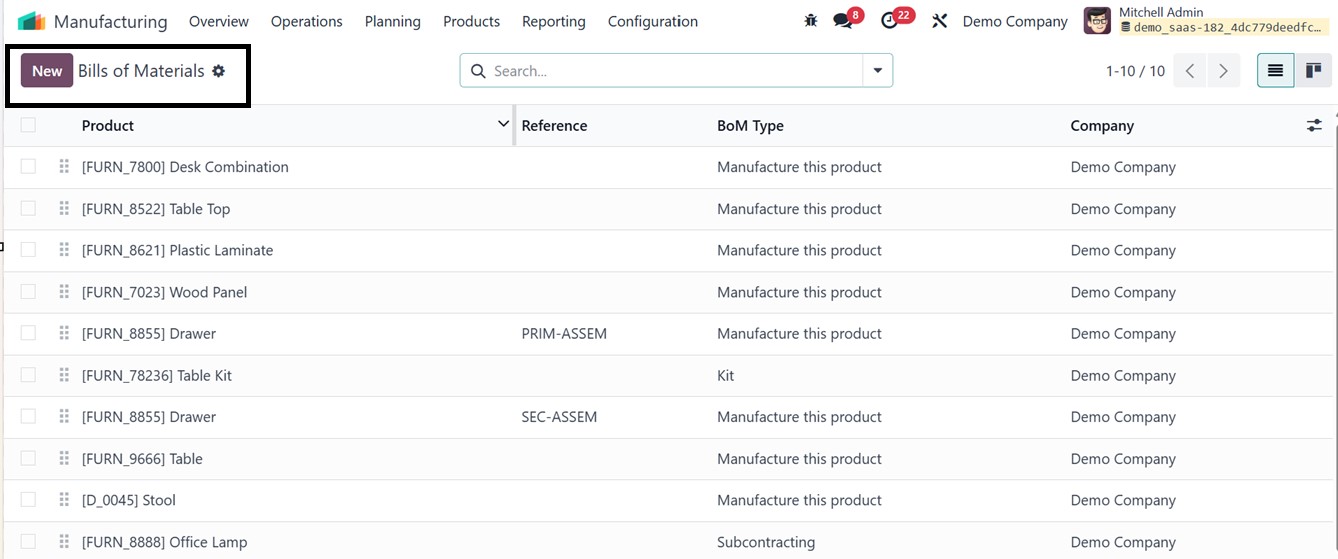

5.2 Bills of Materials

Odoo's Bills of Materials (BoM)

is a tool used in the

Manufacturing module to

define components,

ingredients, and parts needed

for a finished product. It

serves as a detailed

production blueprint,

outlining materials,

quantities, and optional

operations. Key features

include component management,

enabling multi-level or

nested BoMs, and linking

components to sub-assemblies.

We can manage these from the

‘Bill of Materials’ menu. On

the BoM page, you will find a

list of existing bills of

materials with details like

Product name, Reference, BoM

Type, and Company name.

The list view can be transformed

into a Kanban view. Then, the

advanced search bar allows

you to get customized results

through various Filters,

Group By, and Favorite

features. To create a new

BoM, use the "New" button

provided at the top of the

page. This will display the

new BoM creation form, as

shown in the screenshot

below.

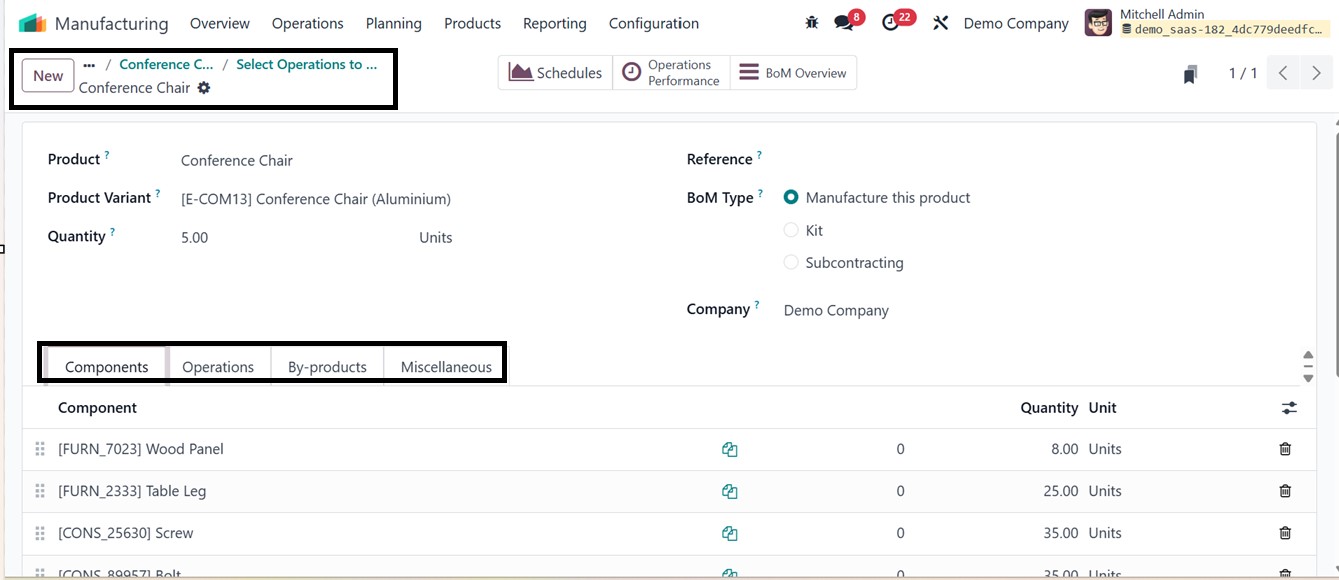

On the BoM creation page, you can

enter details like the name

of the Product, Product

Variant (selectable from a

drop-down menu), Quantity,

Reference, and BoM Type (such

as manufacturing, kit, or

subcontracting).

Additionally, you can specify

the Company name.

Components Tab: Next, add

components using the "Add a

line" option under the

Components tab. You can also

specify the quantity and unit

of measurement for each

component of the product, as

shown in the above

screenshot.

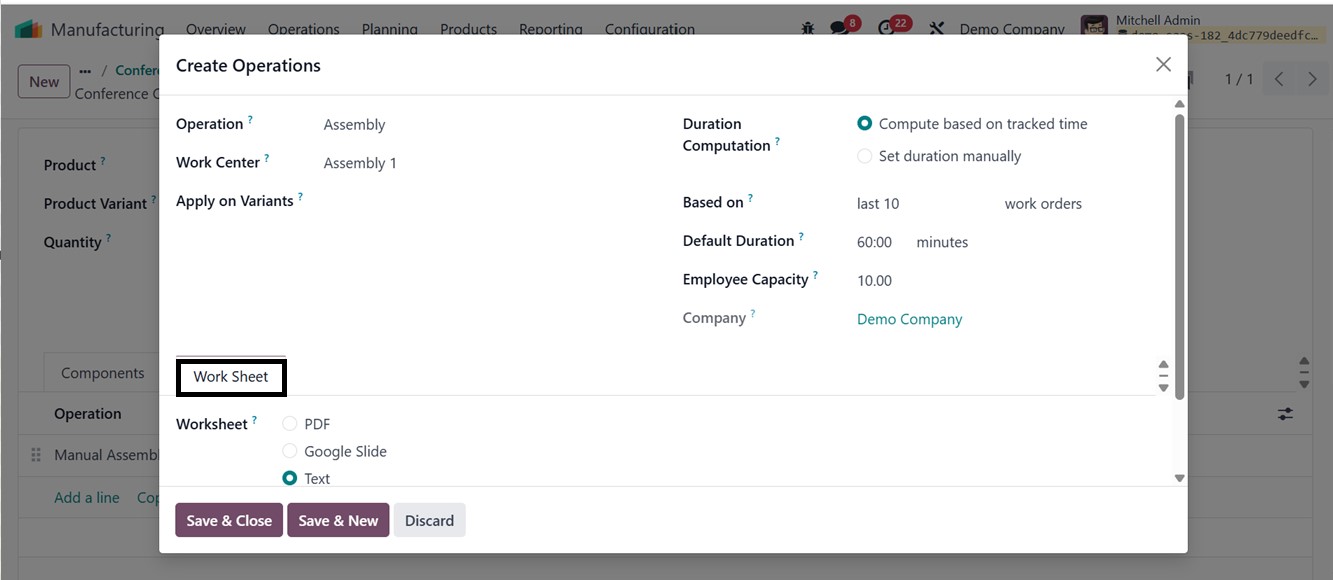

Operations Tab: In the

‘Operations’ tab, you can add

information such as operation

type, work center, duration

computation, and duration

using the "Add a line"

option. This leads to a new

page, as shown below.

You can define the name of the

work in the Operations field.

Then, choose the Work Center,

Duration. Then, set the Apply

on Variants to apply this

particular operation to a

particular product variant

without further delay, or

leave it as empty. The

duration of this operation

can be manually set or

calculated based on monitored

items using the ‘Duration

Computation’ options. You can

set the operation's duration

in two ways: either by ‘Set

duration manually’ or by

allowing Odoo to calculate it

using the ‘Compute based on

tracked time’ option. The

default duration is displayed

by default in this section.

Additionally, it is possible to

specify how many employees

are required to complete this

task in the Employee Capacity

section. Then, mention your

company's name. Under the

‘Work Sheet’ tab, you can

upload a worksheet in PDF,

Google Slides, or text format

and provide a description

about the worksheet or

operation. Finally, click the

"Save & Close" icon, or if

you want to add more, use the

"Save & New" option. These

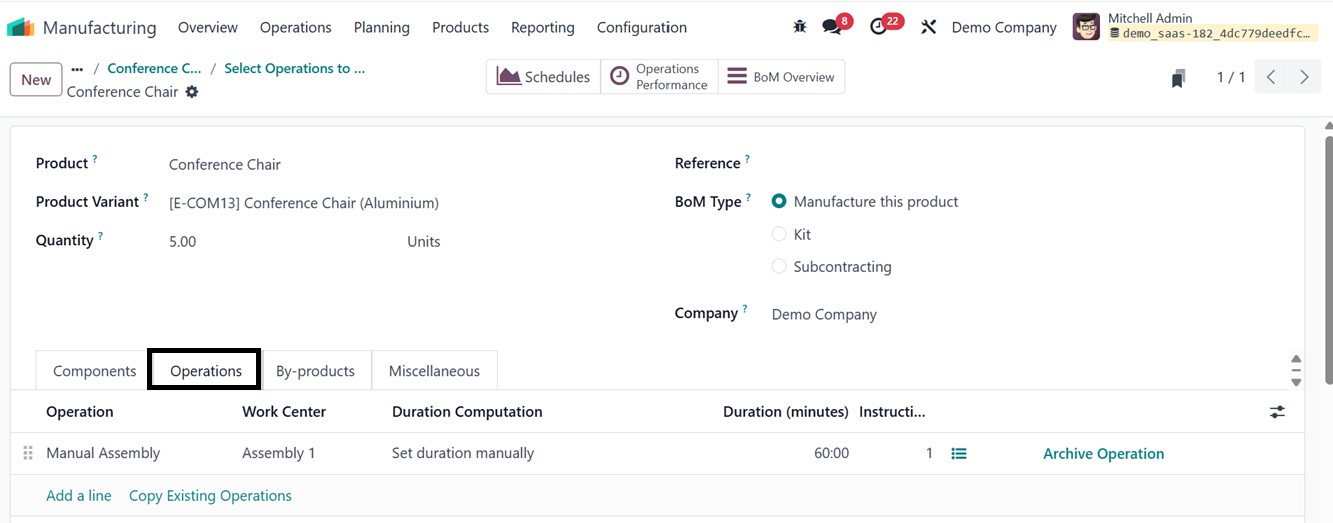

operation details will be

displayed inside the

Operations tab, as depicted

in the screenshot below.

You can repeat previously

completed operations when

doing any manufacturing

activities for this product

by using the "Copy Existing

Operations" option in the

Operations tab.

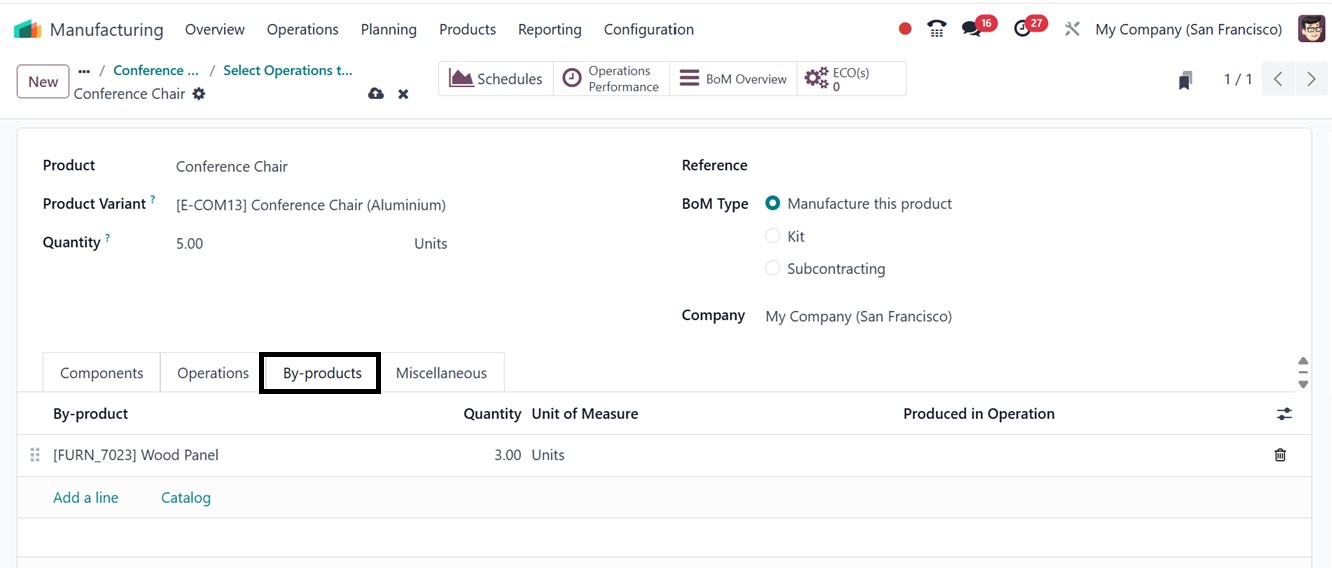

Once you activate the work orders

and by-products options from

the settings window, tabs for

operations and By-products

will appear, and you can then

add by-products by clicking

the "Add a line" option under

the by-product tab or you can

directly select from the

product catalog window by

clicking on the ‘Catalog’

button, as illustrated in the

screenshot below.

Here, you can specify the

by-products by choosing a

Product, Quantity, Units of

Measure, and Produced in

Operation. So, during the

mentioned operations, the

By-products will be produced.

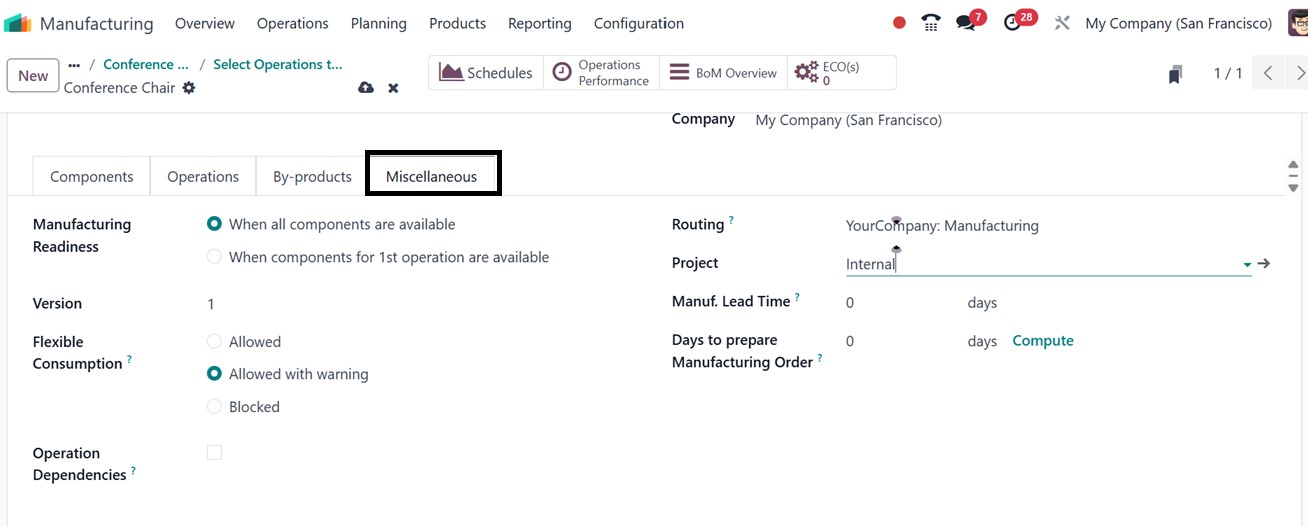

Miscellaneous Tab: In the

Miscellaneous tab, you can

set "Manufacturing

Readiness," which defines

whether all components must

be available before starting

or if only the initial

components are needed. This

setting helps decide when

production can begin. Then,

you will find the "Flexible

Consumption" setting option

that can determine if the

consumption of materials can

vary from what is specified

in the BoM. It can be set to

either Allow, Blocked or

Allow with warning.

The Bill of Materials (BoM)

form's "Version" field is

used to note the BoM's

version or revision number.

It facilitates improved

control and traceability by

tracking modifications to

parts, processes, or

quantities across time. This

feature is especially

important in sectors where

accurate versioning is

essential for maintaining

production history,

compliance, and quality

assurance. The ‘Routing’

field allows you to define a

route that generates

manufacturing orders using a

Bill of Materials (BoM)

aligned with the product's

"Manufacturing" route. Here

we will set up the operation

type “YourCompany:

Manufacturing” produce the

item with route manufacturing

as defined in the operation

type.

In Odoo 18, the ‘Manufacturing

Lead Time’ is the average

amount of time needed to

create a final product. The

approach also accounts for

component lead times when a

product has a multi-level

Bill of Materials (BoM),

adding them together to

determine the overall

manufacturing time. This

helps establish when

components must be supplied

to the subcontractor in order

to fulfill deadlines, which

is very helpful when working

with subcontracted items.

Additionally, by drafting and

verifying manufacturing

orders beforehand, the ‘Days

to Prepare Manufacturing

Order’ option enables you to

plan ahead. This makes sure

there is enough time to make

semi-finished products or

restock essential parts

before the last stage of

manufacturing starts.

If you wish to set dependencies

between operations that

affect work order statuses

upon confirmation and

planning, enable the

"Operation Dependencies"

feature. If no specific

parameters are set, Odoo will

assume that all operations

can start concurrently. To

use the Operation

Dependencies feature, you

must first enable the "Work

Order Dependencies" options

from the settings window.

Once all the information is

entered, you can save the BoM

by clicking the "Save" icon.

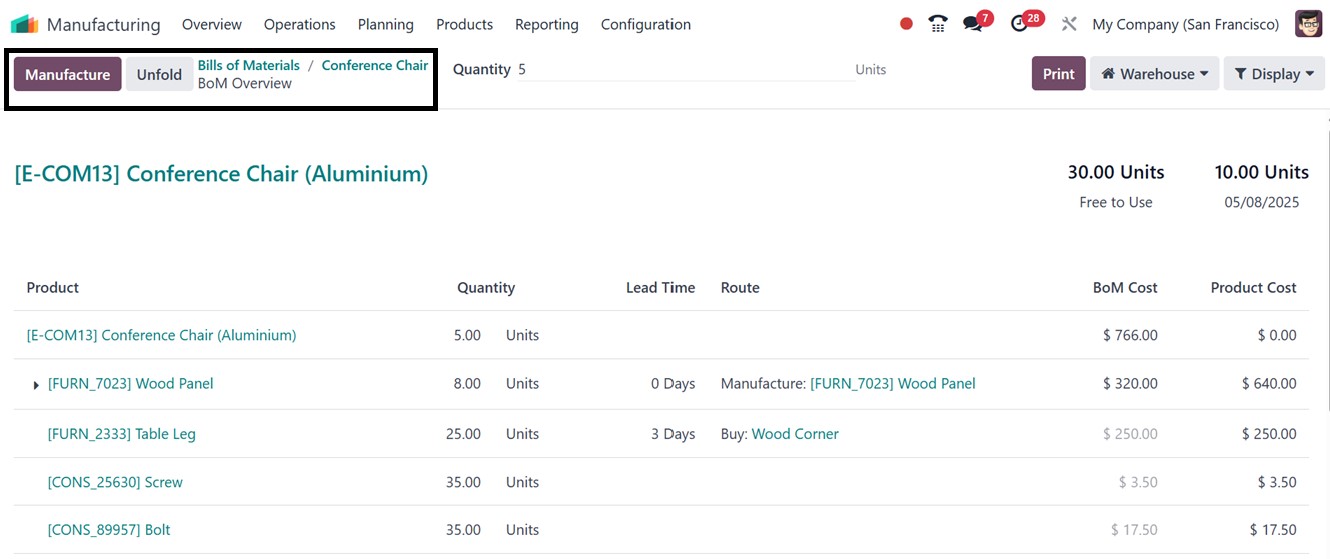

Once the BoM configuration is

complete, this can be used to

create a manufacturing order

for the corresponding product

in Odoo. Then, a

comprehensive assessment of

every operation pertaining to

this BoM product will be

available via the "Operations

Performance" smart button.

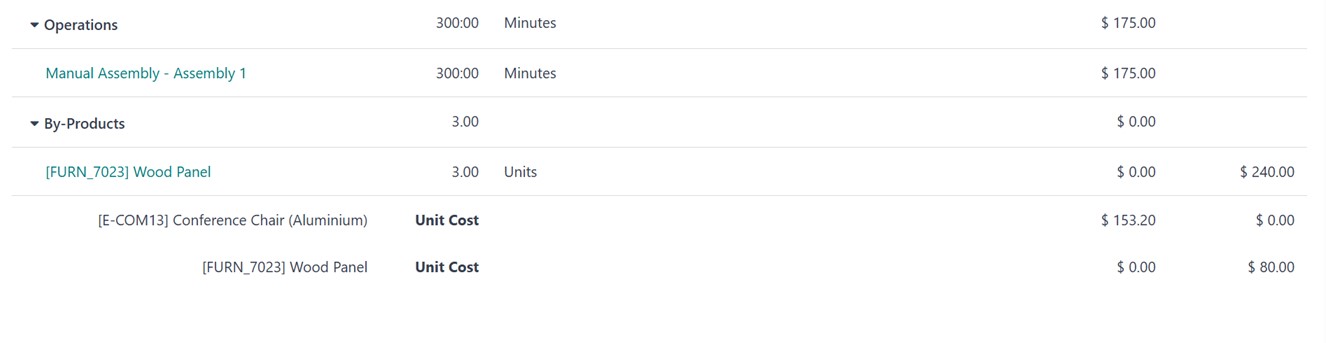

The whole overview of this

BoM product, including its

operations, by-products, lead

time, and other details, will

then be shown by clicking the

"BoM Overview" smart button,

as depicted in the

screenshots below.

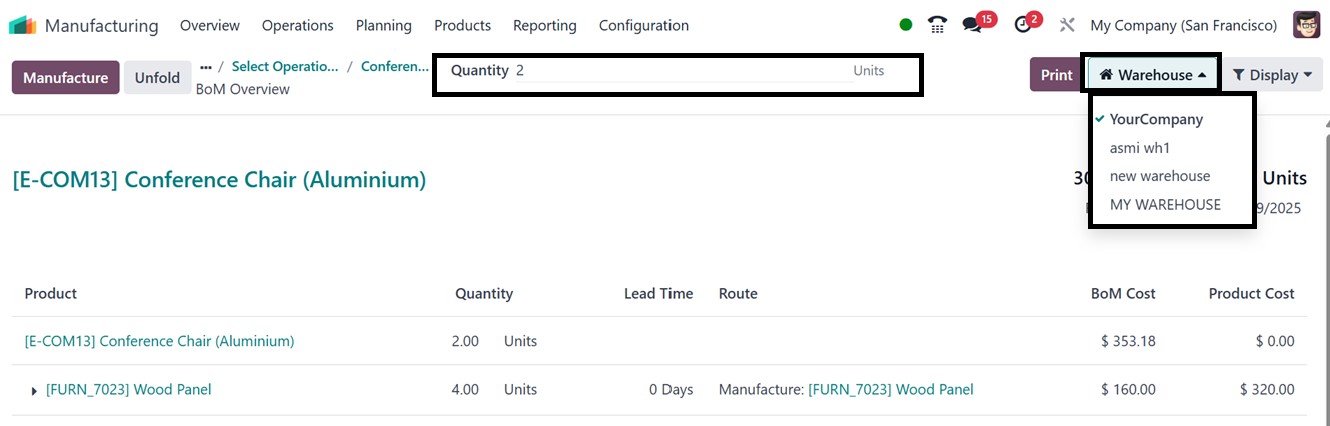

The 'Quantity' filter option

allows you to adjust the

number of units for a given

product and see how it

affects different

cost-related data. By

changing the amount, you can

see the latest estimates for

the Bill of Materials (BoM)

Cost, Product Cost, and other

pertinent parameters, as seen

in the screenshot below.

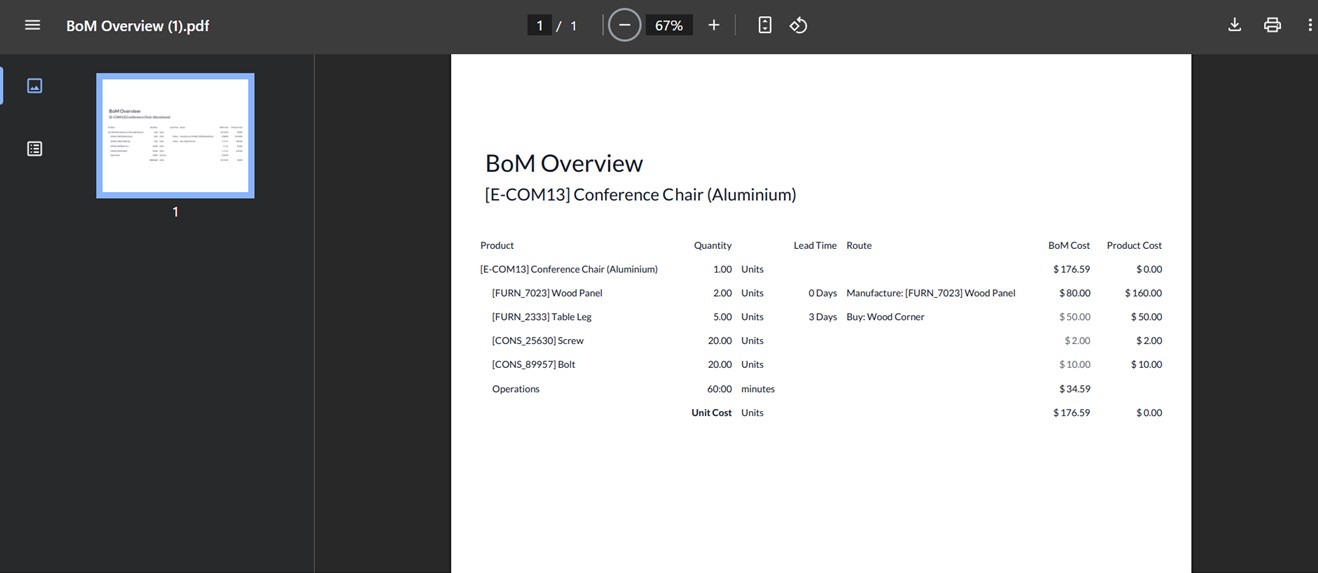

The ‘Print’ button on the BoM

overview window will download

the BoM details in a

printable document format, as

shown below.

The ‘Warehouse’ filter allows you

to switch the warehouse

associated with the BoM.

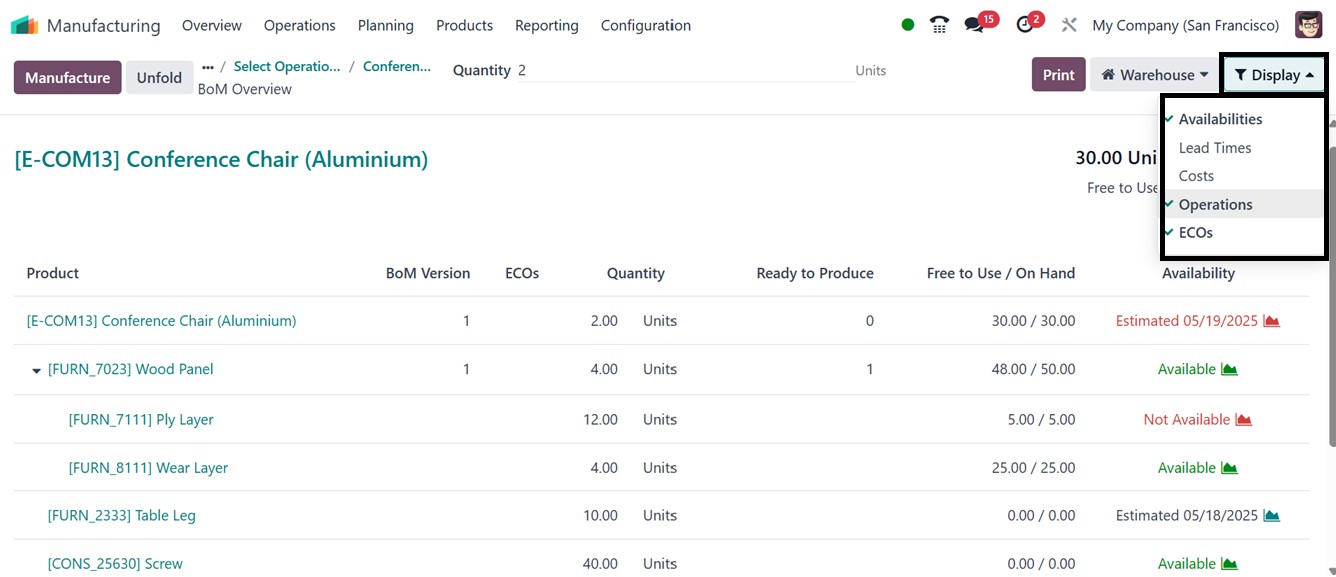

Additionally, the ‘Display’

filters let you adjust the

BoM overview to show

different perspectives such

as Product Availabilities,

Lead Times, Costs,

Operations, and ECOs,

providing a more detailed

analysis as shown below.

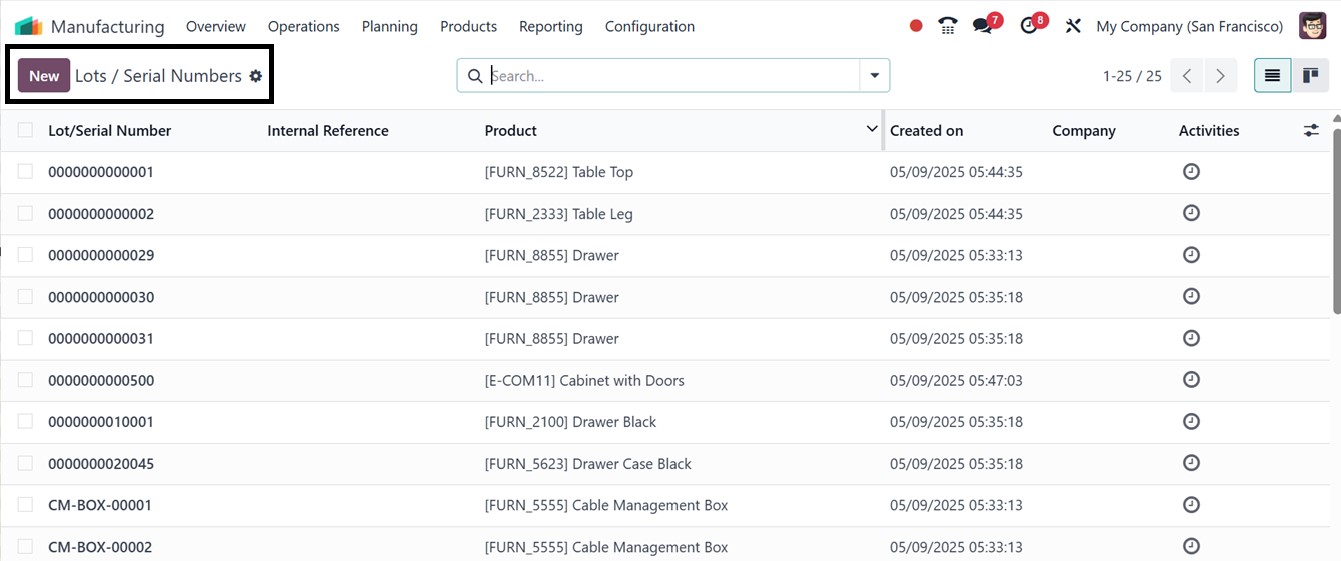

5.3 Lot/Serial Numbers

Odoo 18's manufacturing module

features Lot/Serial Numbers,

a powerful tool for product

traceability and quality

control. It assigns unique

identifiers to products or

batches, enabling precise

tracking throughout the

production process. This

feature is particularly

useful for industries

requiring strict regulatory

compliance, ensuring

accountability and

simplifying recalls.

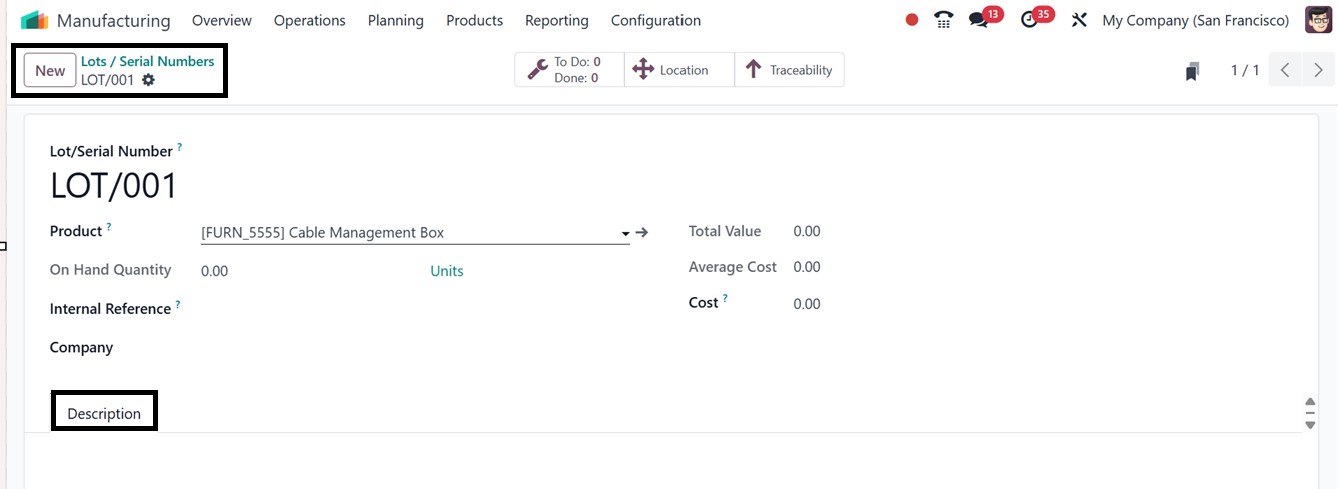

The “Lot/Serial Numbers” window

of the “Products” menu will

show all the previously

configured Serial and Lot

numbers with their Internal

Reference, Products, and

Created dates, as you can see

from the screenshot below.

It's also simple to generate

fresh Lot/Serial numbers with

this window using the ‘New’

button. Once a new creation

window has opened, edit the

details, including the

Lot/Serial Number, to meet

your needs or the policies of

your business. Then, the

product, internal reference

number, and price should be

mentioned.

In the "Description" tab box, we

can also include a

description of the product.

Editing the other field data

is limited to the

Manufacturing module's

enterprise edition.

After completing the editing and

saving the details. We can

check the location of this

product and its traceability

report from the “Location”

and “Traceability” smart

buttons, respectively. The

pending and completed tasks

or work orders associated

with this specific product

will be displayed when you

click the "To Do" smart

button. The action menu

placed on the upper left side

of the configuration form

helps us print the lot/serial

number, delete it, or

duplicate it. Additionally,

the “Add properties” option

can be used to add extra form

fields according to the

requirements.