6. Reporting

The Odoo 18 Manufacturing module

enhances production

management with robust

reporting capabilities,

providing detailed insights

into "Work Orders" and

"Overall Equipment

Effectiveness," enabling

informed decision-making and

process optimization,

enhancing productivity and

operational success.

7.1 Work Orders

Odoo 18's Manufacturing module's

Work Orders reporting offers

a comprehensive view of

production processes,

enabling businesses to

monitor and analyze

individual work orders'

performance. This data helps

identify areas for

improvement, optimize

resource allocation, and

align production schedules

with business goals,

enhancing productivity and

control.

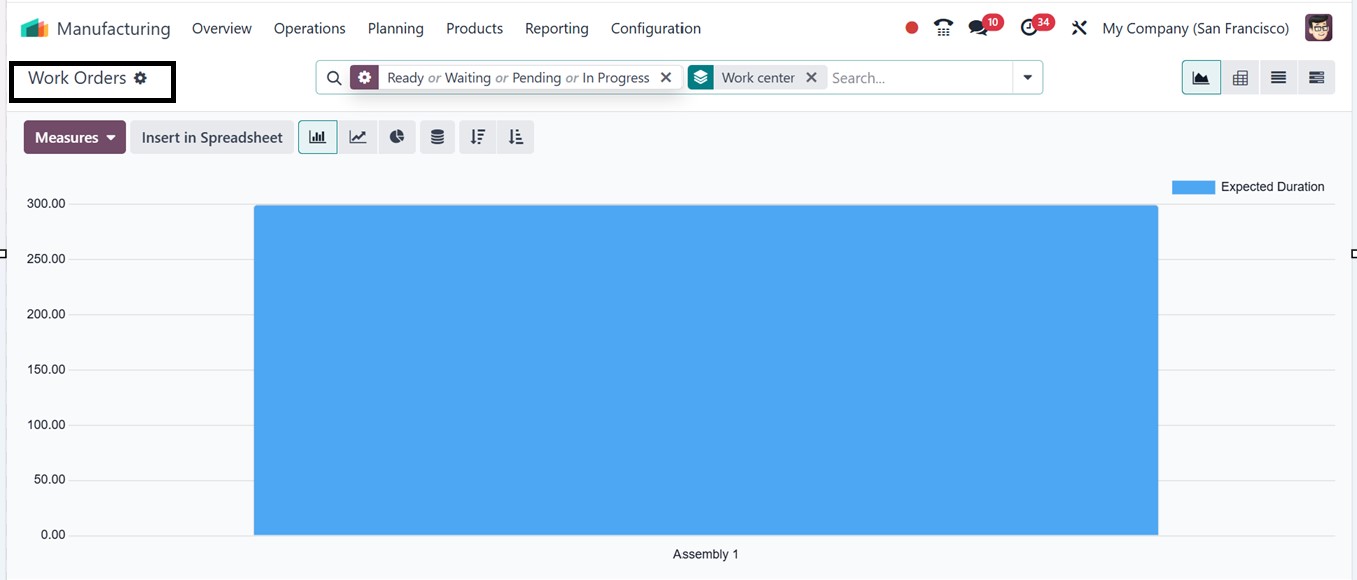

The ‘Work Orders’ reporting

section will provide the

analysis of all the work

orders which are ready,

waiting, pending, or in

progress as illustrated in

the screenshot below.

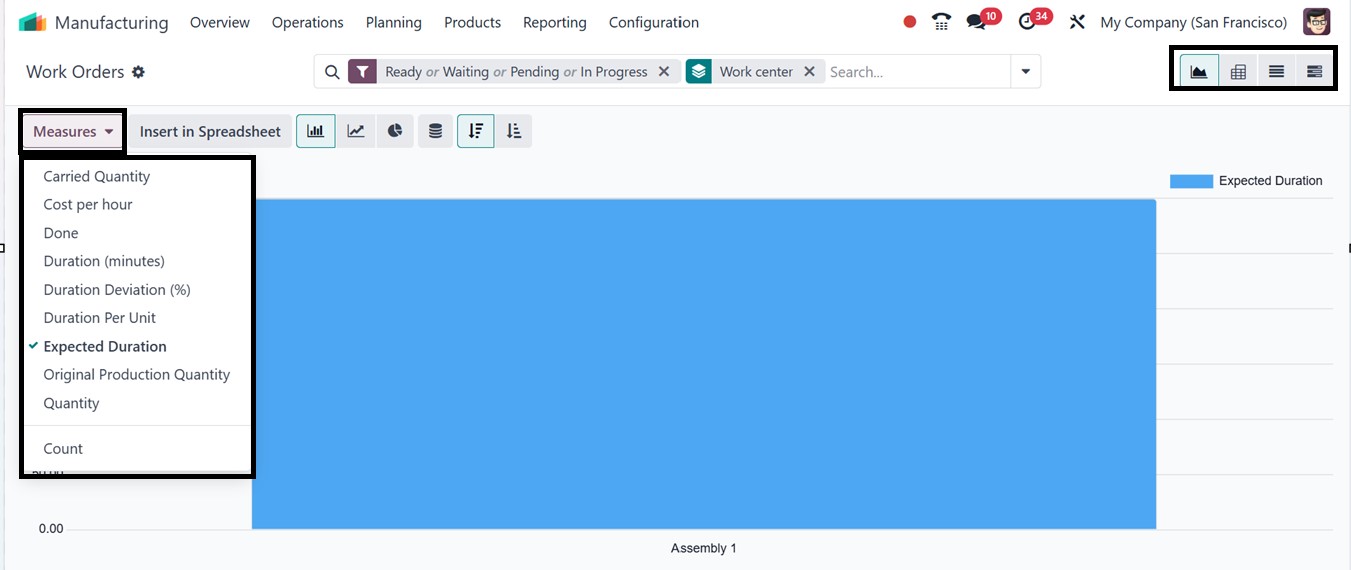

In this Work Orders window, the

report specifics can be

switched with various metrics

that can be used to analyze

the report data based on

multiple parameters such as

the Carried Quantity, Cost

per hour, Done, Duration

(Minutes), Duration

Deviation, Duration Per Unit,

Expected Duration and other

options from the ‘Measures’

button, as illustrated in the

screenshot below.

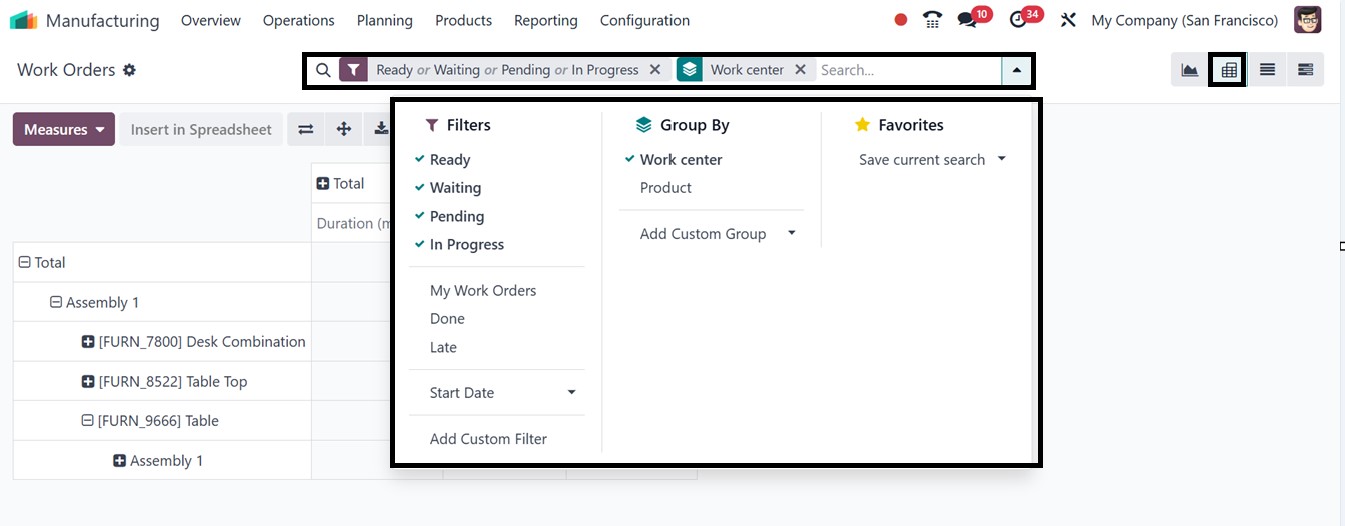

You can also view the reporting

data in Graphical, Pivotal,

List and Gantt formats by

choosing the relevant icon

provided at the top right

corner of the window, with

the pivot view providing a

more analytical approach. The

reporting tools help

facilitate effective and

insightful report creation

with the Filters, Group By

and Favorites sorting options

provided in the advanced

search bar area. To get

customized reports as per

your company specifics, you

can utilize the ‘Add Custom

Filter,’ and ‘Add Custom

Group’ options provided under

the Filters and Group By

sections respectively.

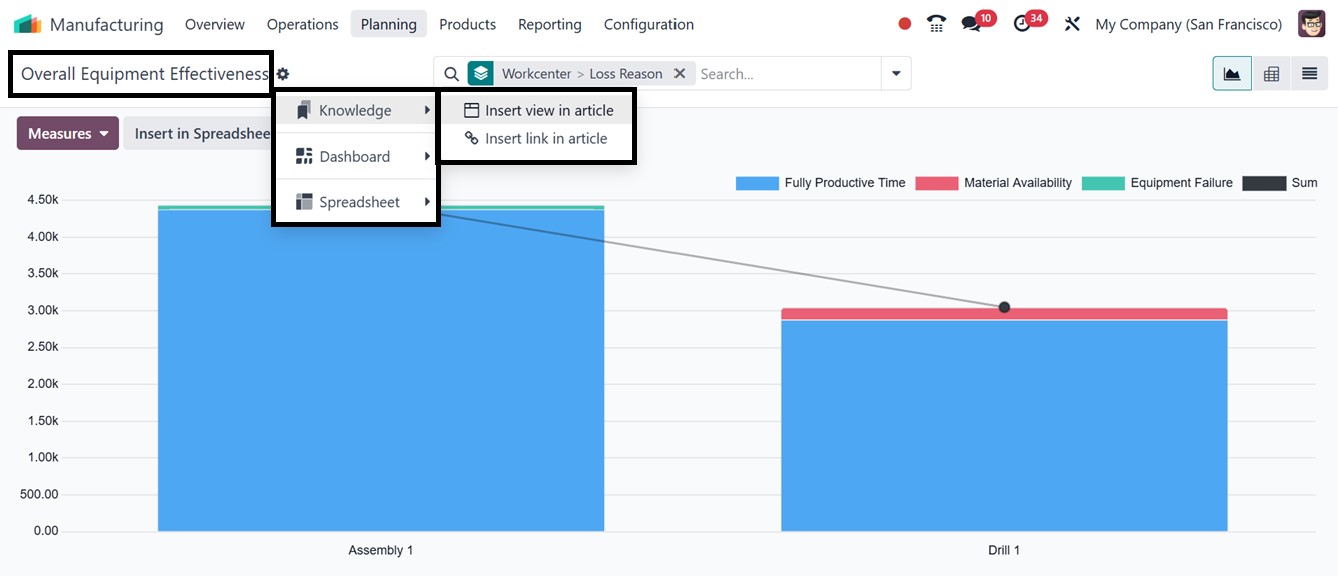

7.2 Overall Equipment

Effectiveness

The Overall Equipment

Effectiveness (OEE) of the

company's work centers can be

assessed using the OEE

reporting platform.

By integrating availability,

performance, and quality into

a single KPI, the

Manufacturing module of Odoo

18's Overall Equipment

Effectiveness (OEE) reporting

assists manufacturers in

increasing the efficiency of

their equipment. It has cycle

time analysis, quality

monitoring, downtime

tracking, and real-time

dashboards. You can also

export data for compliance

and sharing using the

‘Dashboard,’ and

‘Spreadsheet’ options

available in the ‘Actions’

menu of the window.

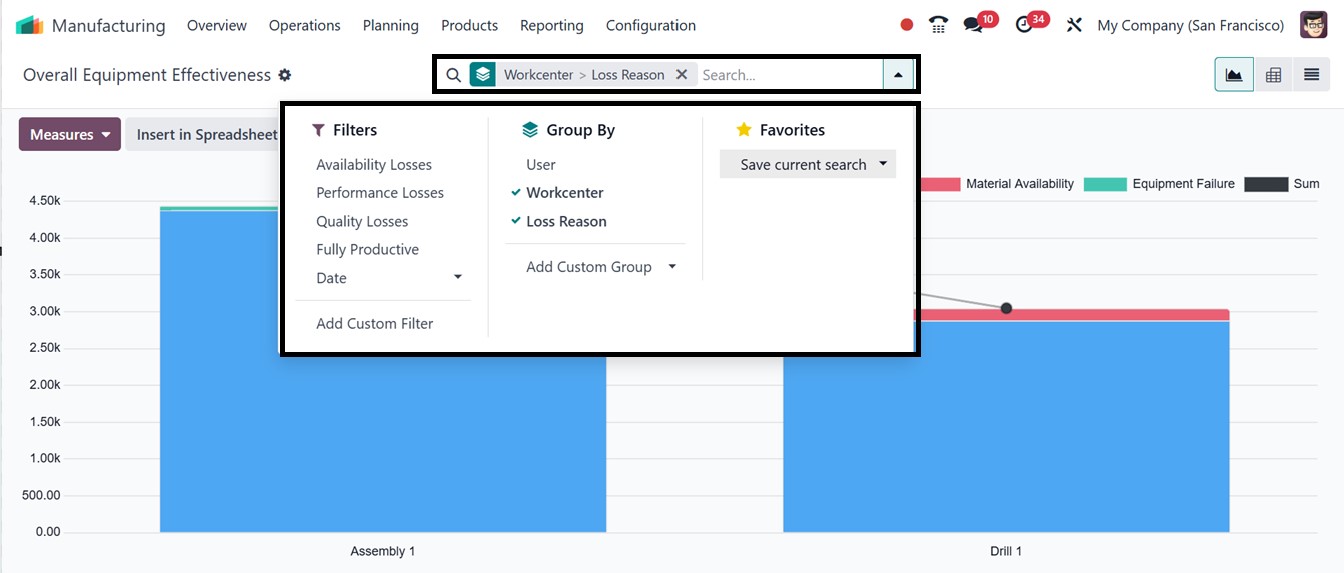

Then, examine time-based reports,

interact with maintenance

logs, and classify the causes

for losses using the

‘Measures’ options including;

Duration, Employee-cost and

Count. To refine the reports

to get specified reporting

you can use the ‘Filters’

option from the advanced

search bar area such as

Availability Losses,

Performance Losses, Quality

Losses, Fully Productive

Time, and Date. You can also

create customized filters

using the ‘Add Custom Filter’

button, as depicted in the

screenshot below.

The ‘Group By’ filters can be

used to create certain data

groups according to User,

Workcenter and Loss Reason.

You can also customize a new

group by filter using the

‘Add Custom Group’ option.

Finally, the ‘Favorites’

option can be used to mark

important data or save recent

searches.

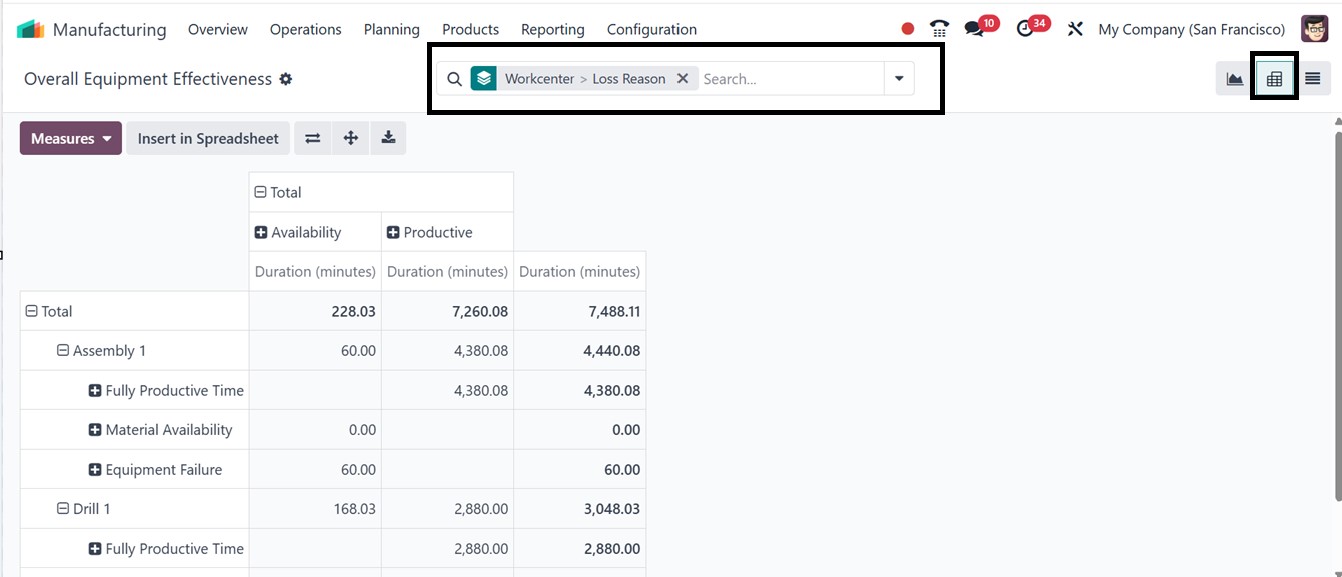

Like all reporting windows in

Odoo, you can switch the bar

chart to other graphical

views, as well as Pivot or

List views, using the icons

located at the top right

corner of the screen, based

on your analytical

requirements and

preferences.For instance, you

can see how the Pivot view

appears in the reporting

window, as shown in the

screenshot below.

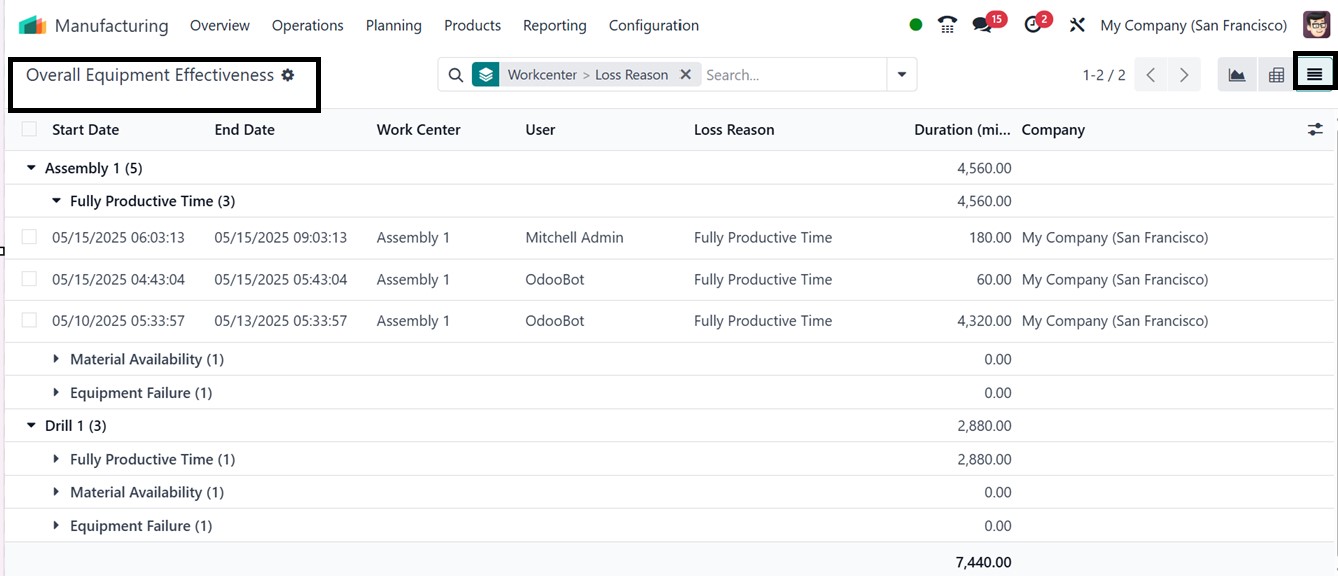

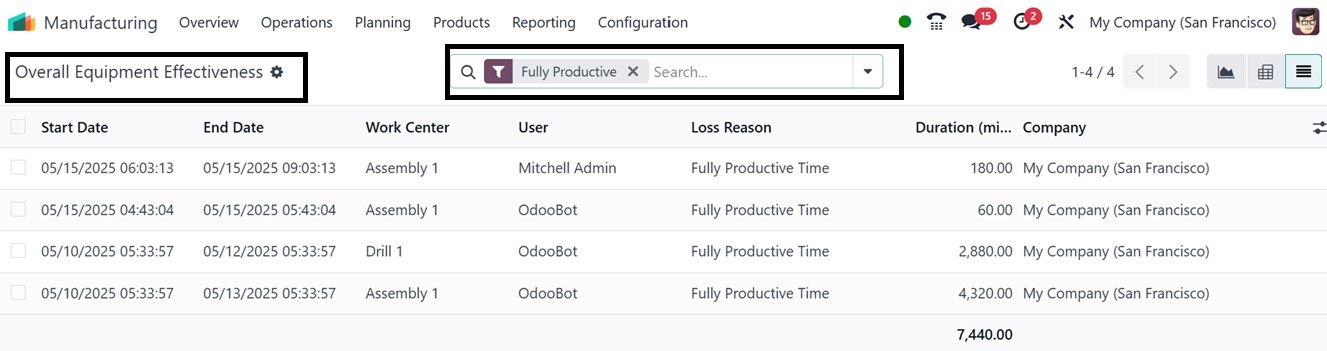

The list view shows critical

parameters like Start Date,

End Date, User, Duration in

Minutes and Loss Reason for

each work center or machine.

You can check the Fully

Productive Time, Material

Availability and Equipment

Availability of a work center

quickly from this dashboard

view. Also, you can sort and

filter out the required data

to identify trends using the

Filter, Group By and

Favorites filter options.

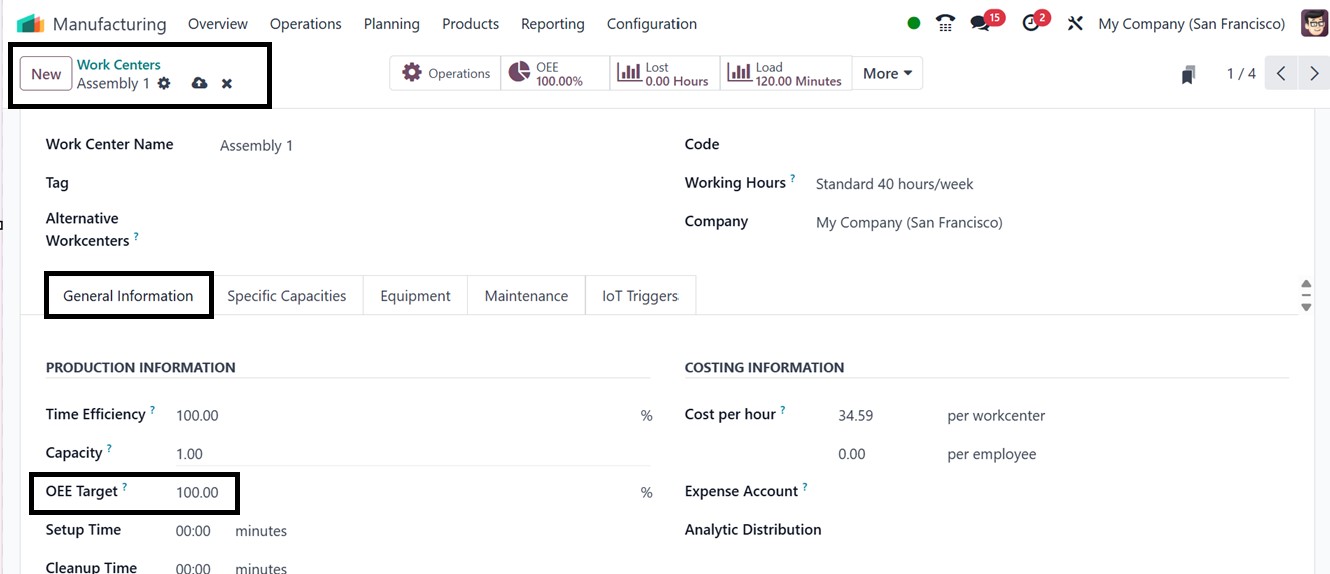

The OEE Target determines the

expected percentage of

totally productive time for a

work center and serves as a

benchmark for efficiency. You

can set your work center

efficiency OEE target to 100%

to monitor performance and

discover inefficiencies from

the ‘Work Centers’ option of

the ‘Configuration’ menu.

After choosing a work center,

input a value (up to 100.00)

in the ‘OEE Target’ field

under the ‘General

Information’ tab of the form

view, as illustrated in the

screenshot below.

In Odoo, the OEE is calculated as

a percentage from 0 to 100,

showing how much of the

planned time a work center

was fully productive. Values

below 100% indicate lost

efficiency due to issues like

reduced operation speed,

material shortages, or

equipment faults. In the

reporting window, use the

'Fully Productive' filter to

see which work centers

achieved or exceeded the

specified OEE target, as

illustrated in the screenshot

below.

7.3 Production Analysis

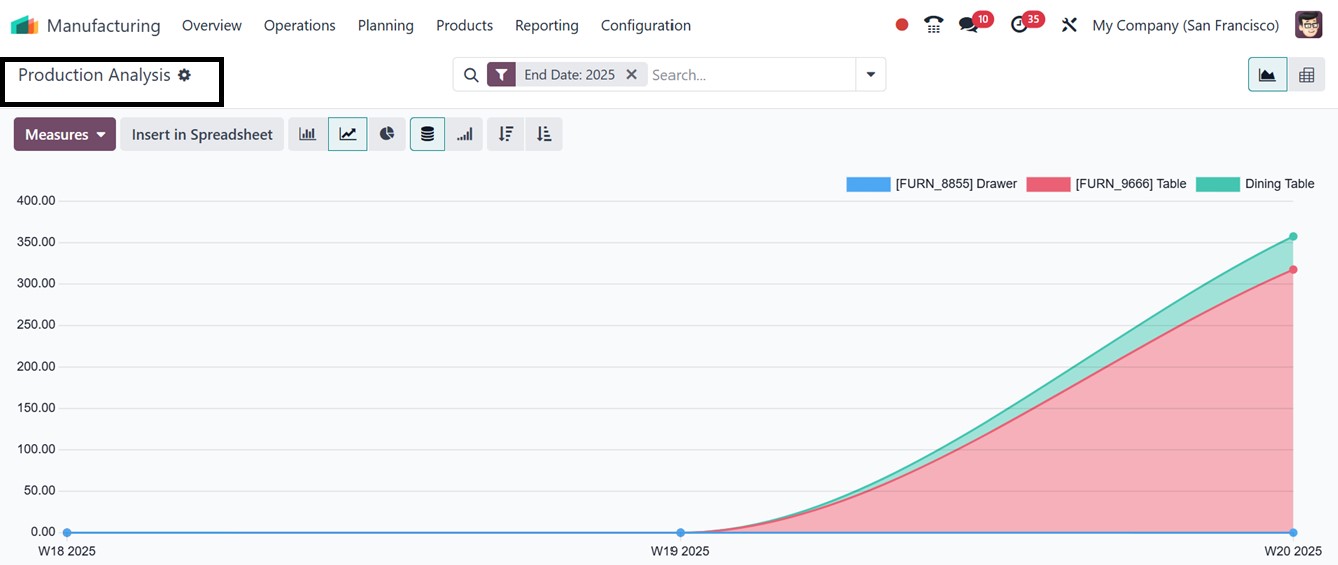

In Odoo 18's Manufacturing

module, the "Production

Analysis" reporting window

provides comprehensive

insights into manufacturing

activities, assisting

companies in monitoring

production orders, assessing

productivity, and pinpointing

inefficiencies. It enables

users to assess lead times

and delays, track product

output, and analyze work

center performance in a

default graphical view. On

the X-axis, you can see the

production orders are

displayed, while the Y-axis

shows the corresponding

production costs per unit, as

illustrated in the screenshot

below.

Reports can be exported for

specific time periods using

the ‘Insert in Spreadsheet’

button, helping with trend

analysis and informed

decision-making.

Additionally, the ‘Action’

menu allows you to generate

reports or articles and add

views or data to dashboards

and spreadsheets using the

Knowledge, Dashboard, and

Spreadsheet options.

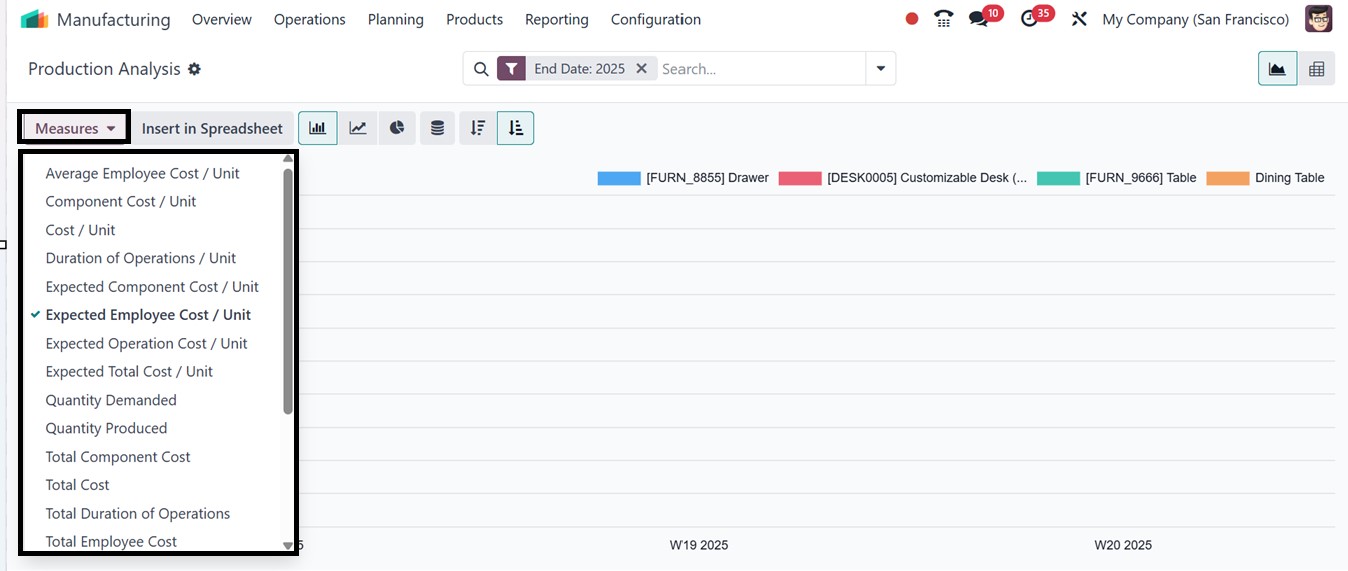

To change the y-axis perspectives

or analytical parameters, you

can utilize the ‘Measures’

button that contains various

options including, Component

Cost/Unit, Average Employee

Cost/Unit, Cost/Unit,

Duration of Operation,

Expected Component Cost/Unit,

Expected Employee Cost/Unit,

Expected Operation Cost/Unit

etc, as depicted in the

The icons in the upper right

corner of the reporting

window provide access to a

number of visualization

options including a detailed

Pivot view and different

graphical chart views (such

as bar, line, and pie charts)

for adaptable data analysis.

These tools will allow you to

examine data from various

angles based on your own

requirements.

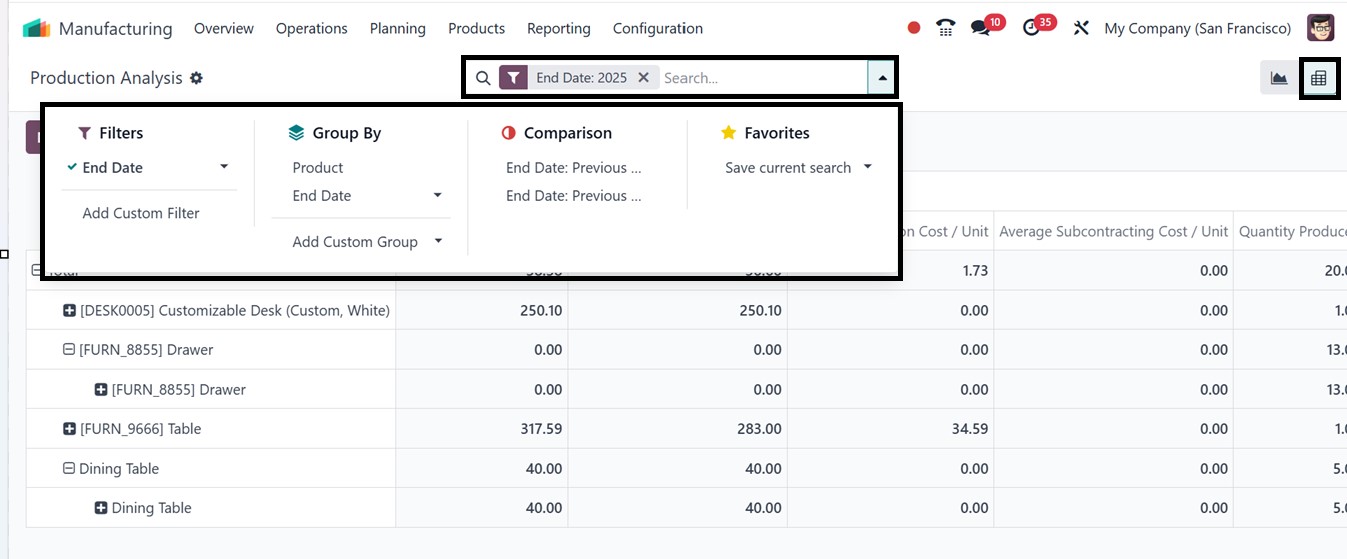

Then, you can utilize the Filters

and Group By options in the

search bar area to apply

filters and group data by

product, work center, date,

or other criteria in order to

further narrow the study.

This facilitates the process

of separating important data

and spotting trends or

inefficiencies. You can also

store frequently used search

criteria in the Favorites

area, giving instant access

to personalized views for

later usage. Additionally,

you can compare production

data from various time

periods using the Comparison

filter, which facilitates

trend research and

performance benchmarking. As

seen in the picture below,

these features are

particularly helpful while

working in the Pivot view.

Overall, the reporting menu of

the Manufacturing Module

facilitates cost analysis,

which enables companies to

use workforce, material, and

overhead costs to evaluate

manufacturing profitability.

In conclusion, the Odoo 18

Manufacturing module provides

robust tools to manage the

full production cycle,

improving efficiency through

features like order

management, by-product

tracking, inventory

automation, and quality

control.