5. Settings

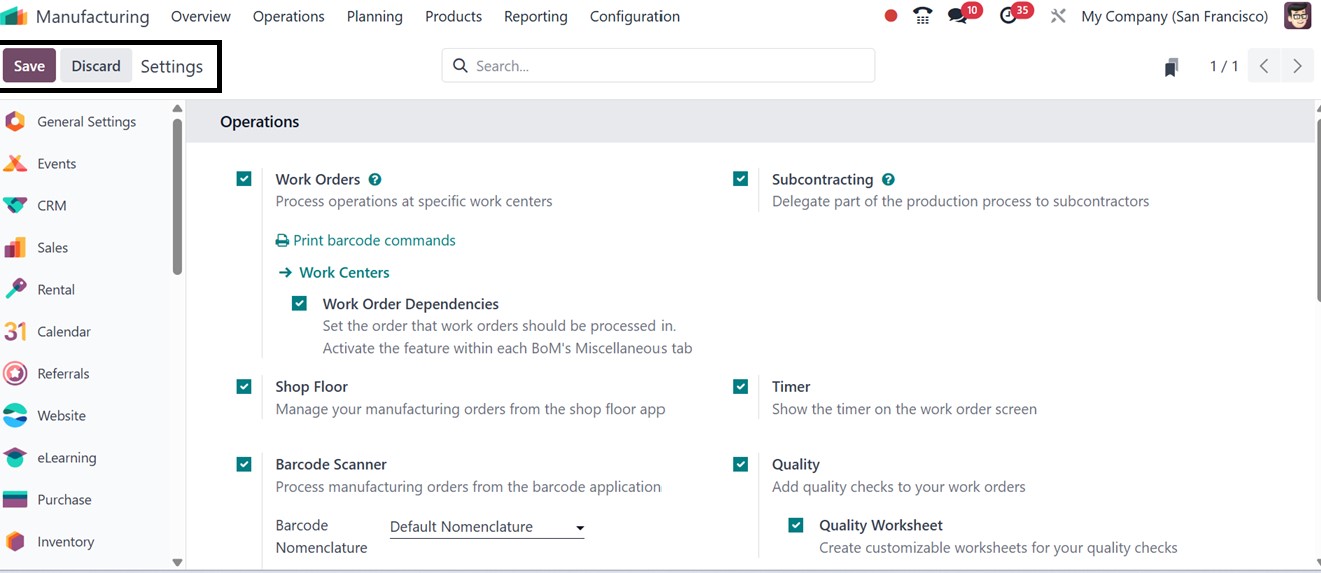

By going to the Manufacturing

module’s Configuration menu

then choosing the Settings

option, you may modify the

system to match your

manufacturing procedures.

Enabling Work Orders for

thorough task management,

using the Master Production

Schedule (MPS) for planning,

and keeping track of

By-Products in bills of

materials are important

choices. Work Centers may be

set up with efficiency

parameters, Subcontracting

can be configured, and

product variations can be

managed. To improve total

production efficiency,

further capabilities include

Quality Management,

Manufacturing Order

Management, Allocation

Reports as well as Security

Lead Time options can be

configured as per the

requirement.

Work Orders: Enabling Work Orders

allows you to break down the

manufacturing process into

detailed, manageable tasks

assigned to specific work

centers. This feature

supports better scheduling,

tracking, and execution of

operations on the shop floor.

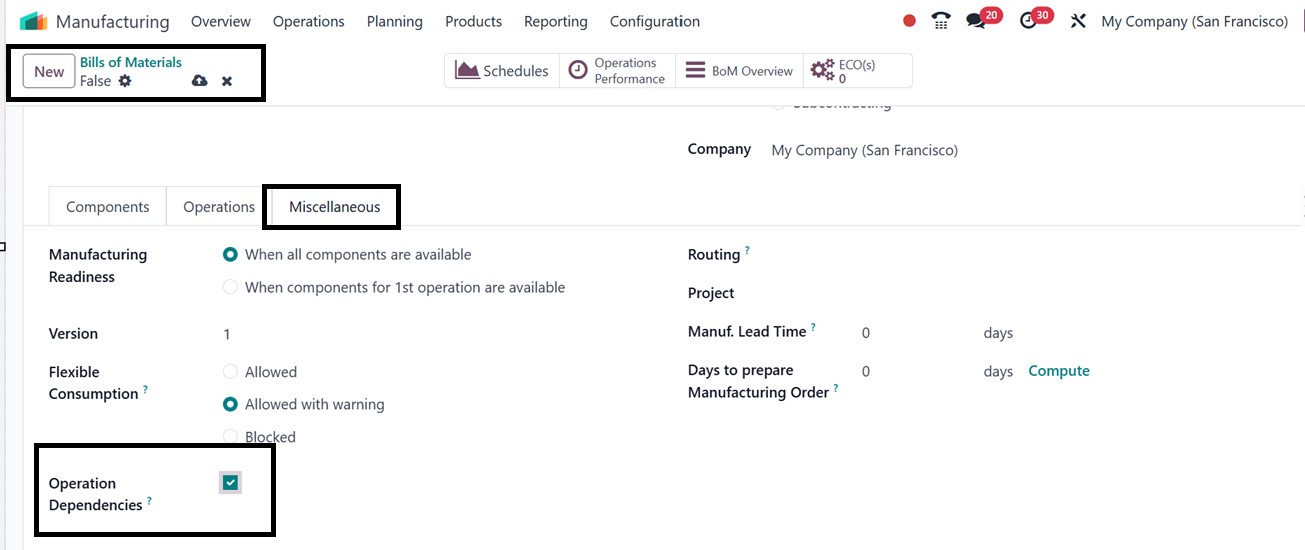

Work Order Dependencies: This

feature allows you to define

the sequence in which work

orders should be executed

within a manufacturing

process. To enable it,

activate the ‘Operation

Dependencies’ option in the

Miscellaneous tab of each

Bill of Materials (BoM), as

illustrated in the screenshot

below.

Shop Floor: The Shop Floor

feature enables you to manage

and execute manufacturing

orders directly from the

dedicated Shop Floor app. It

offers a user-friendly

interface optimized for

tablets and touchscreens,

allowing operators to view

assigned tasks, track

progress, and complete work

orders in real time,

improving on-the-floor

visibility and efficiency.

You can open the shop floor by

clicking on the ‘Open Shop

Floor’ button from a Work

Order configuration form or

using a ‘Shop Floor’ smart

button of a manufacturing

order configuration form.

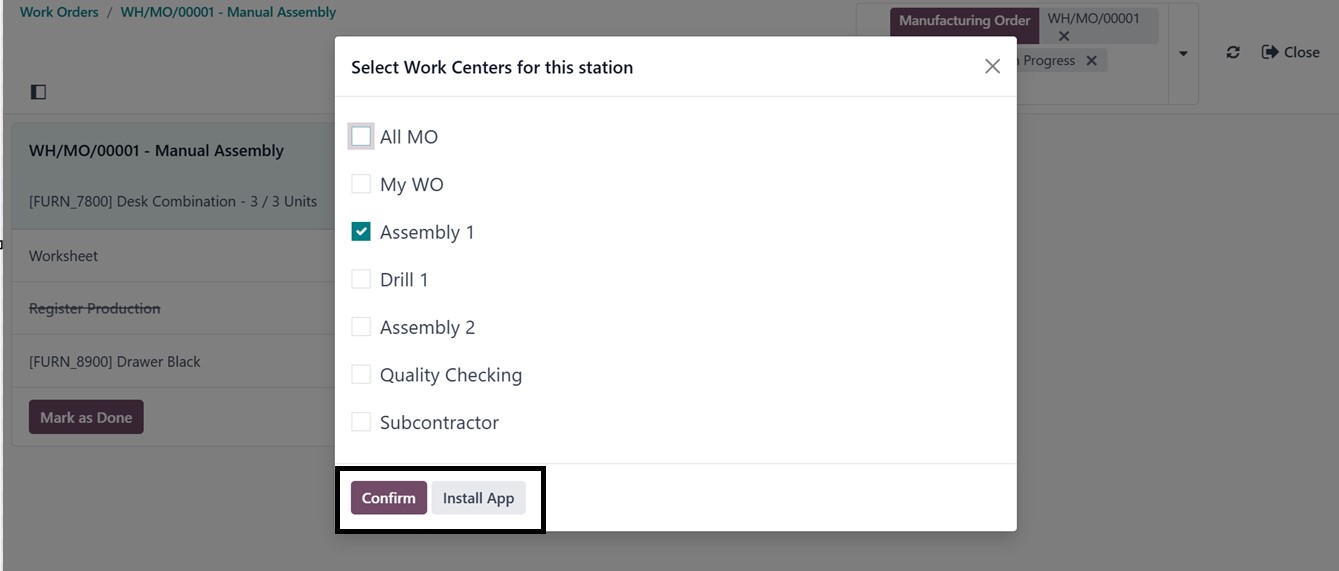

While choosing a work center

for the station, you can

install the shop floor app

using the ‘Install App’

button, as depicted in the

screenshot below.

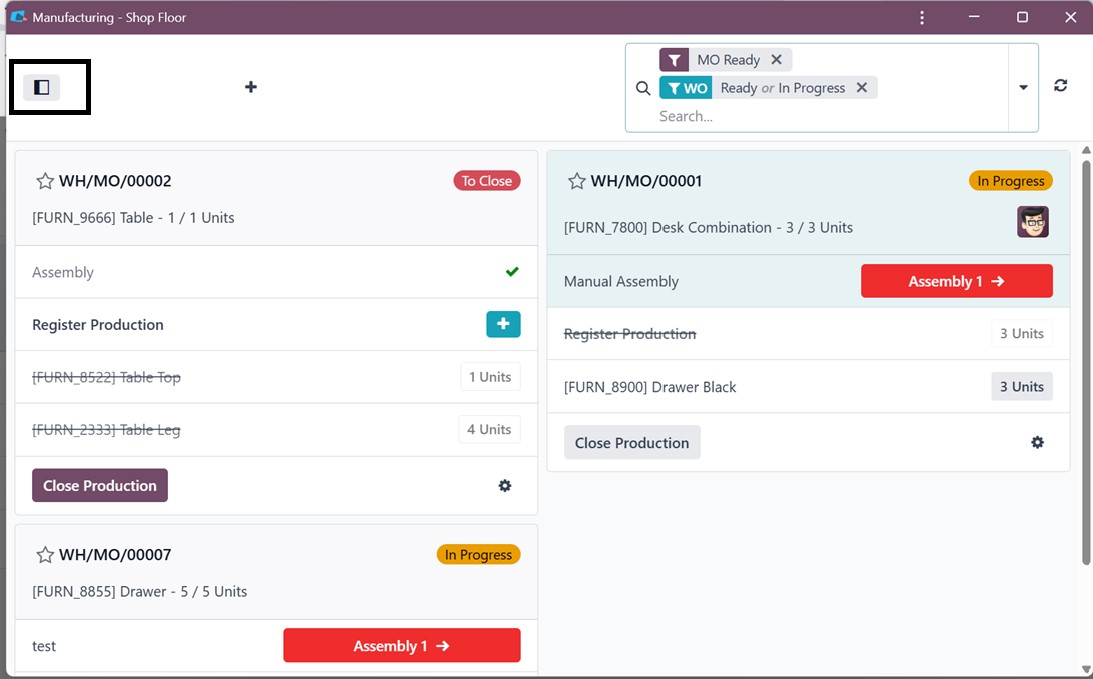

After proceeding with the

installation, choose a work

center, and you can manage

the work orders and other

operations in the Shop Floor

interface, as depicted in the

screenshot below

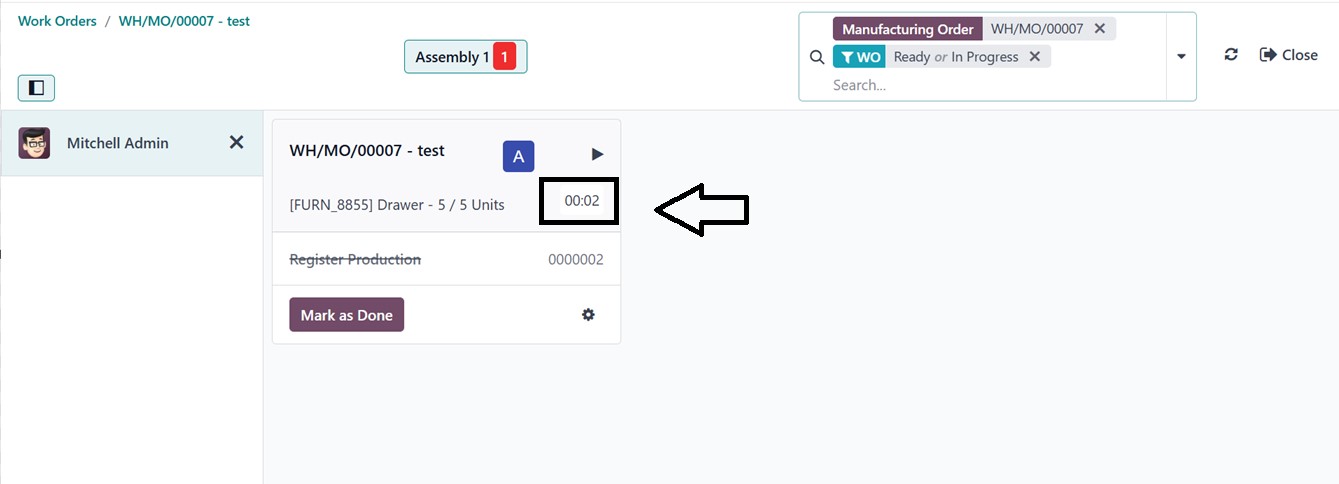

Timer: When enabled, the Timer

displays a stopwatch on the

work order screen. This helps

operators track the time

spent on each task, providing

more accurate production time

logging and supporting

performance monitoring and

time-based analysis.

To check the feature, click on

the ‘Open Shop Floor’ button

from a work order form. You

can see the timer running

under a work order, as

illustrated in the screenshot

below.

Barcode Nomenclature: This

setting defines how barcodes

are interpreted by the

system. It determines the

format (nomenclature) of

scanned barcodes for

different documents like

manufacturing orders,

operations, and products.

Custom barcode rules can be

configured to ensure

compatibility with your

workflows.

The Default Nomenclature offers a

pre-configured set of barcode

rules to identify standard

document types and

operations, which can be

customized as needed. With

the Print Barcode Commands

and Operation Types feature,

you can generate barcodes for

actions like start or pause

and place them on

workstations for quick

scanning. Additionally, the

Print Barcode Demo Sheet

provides sample barcodes for

training, testing, or

configuring barcode scanners

in your manufacturing setup.

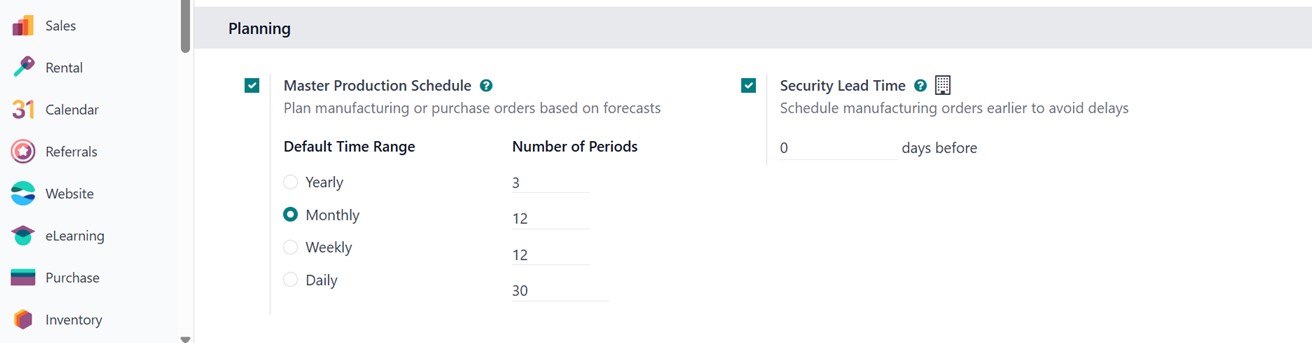

Master Production Schedule (MPS):

The MPS helps with production

planning by allowing you to

forecast demand and plan

manufacturing quantities over

a specific time horizon. This

tool provides a visual,

time-based grid to anticipate

production needs and align

them with resource

availability.

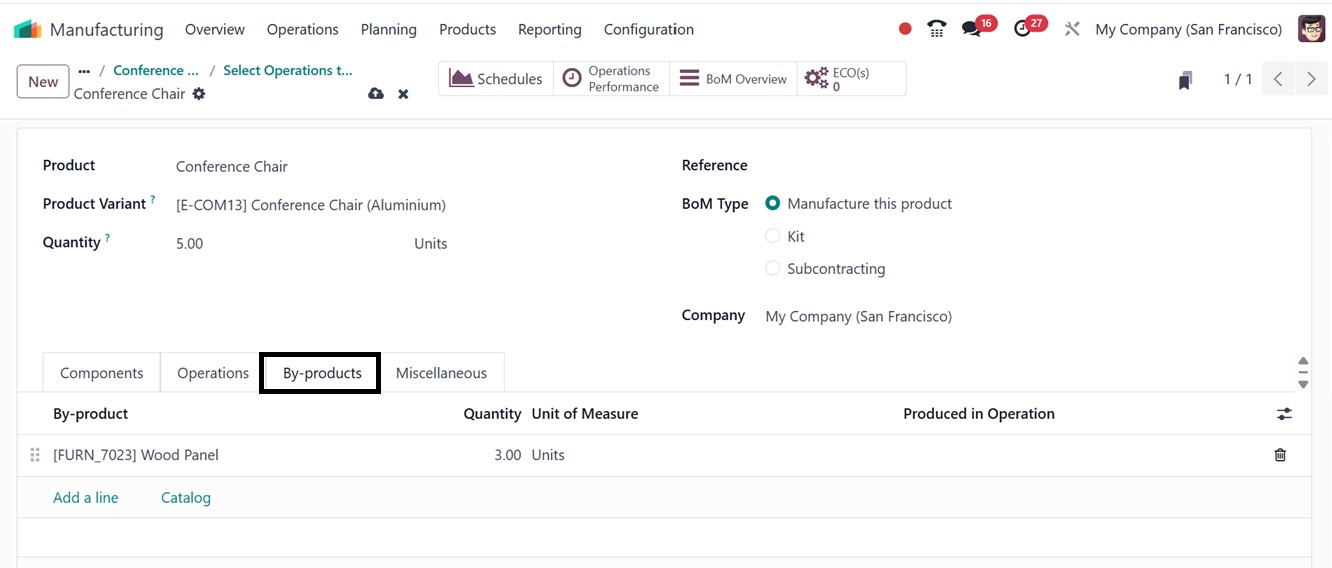

By-Products: Activating

By-Products allows you to

define secondary products

that are generated during a

manufacturing process in the

Bill of Materials (BoM). This

is useful for industries

where waste or reusable

materials are created as part

of the main production, as

depicted in the screenshot

below.

Work Centers With the Work

Centers link, you can

configure the physical or

logical locations where

operations take place. You

can also define parameters

such as capacity, efficiency,

and time tracking to ensure

optimal resource utilization.

From this window, you can

manage and create new Work

Centers.

Subcontracting: The

Subcontracting option enables

you to outsource specific

manufacturing operations to

third-party vendors. You can

track subcontracted work,

manage incoming components,

and monitor delivery of

finished goods.

Quality: Enabling the Quality

option allows integration

with the Quality module,

helping you define quality

control points, inspection

steps, and alert systems.

This ensures compliance and

consistency throughout the

production process.

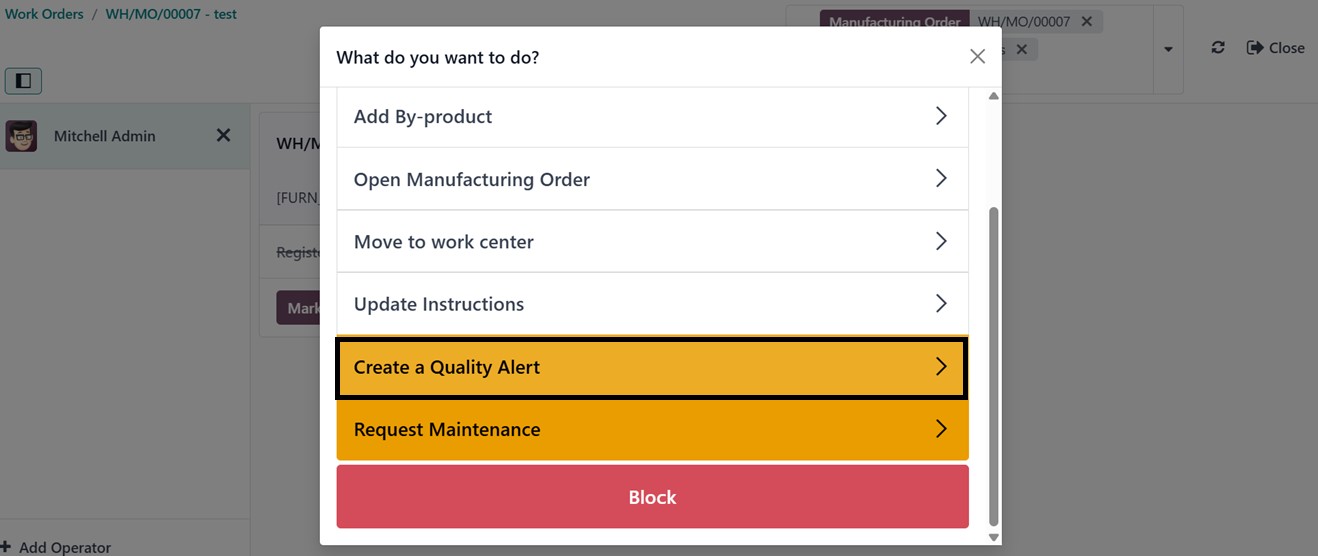

To check the feature, open a Shop

Floor and click on the small

settings icon from the

particular Work Order

station. This will open a

menu list where you can

choose the ‘Create a Quality

Alert’ option to create any

quality alerts when any

product quality issue

arrives.

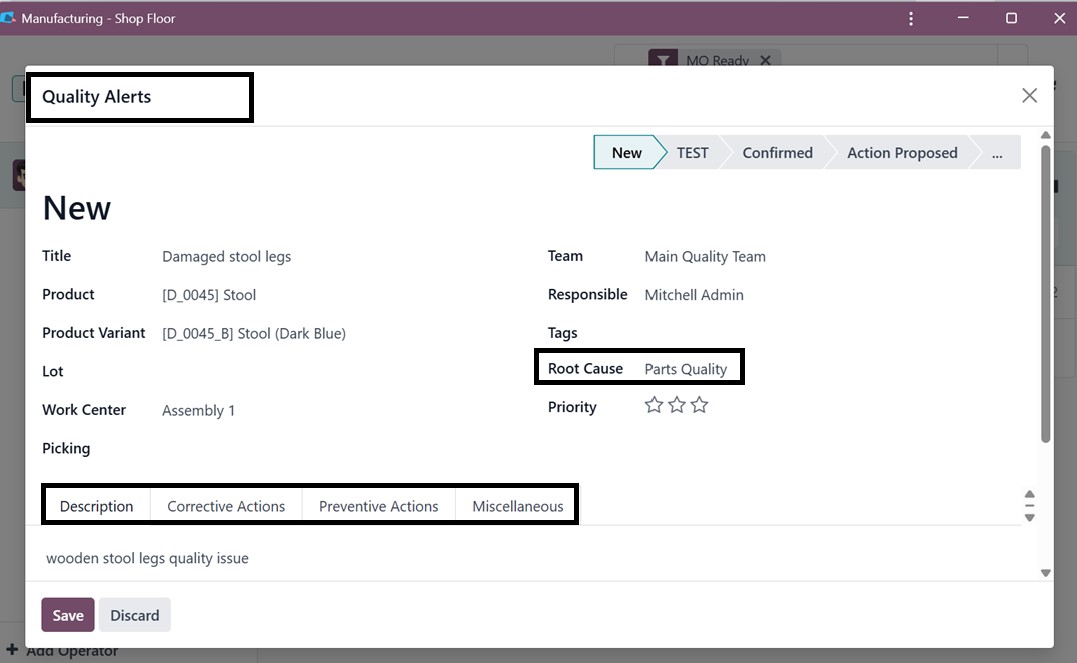

Then, you can provide the quality

alerts by providing a quality

issue Title, Product, Product

Variant, Lot, Work Center,

Picking, Team, Priority, Root

Cause etc, as illustrated

below.

Then, you can provide any

description regarding the

quality issue in the

‘Description’ tab, any

Corrective Actions,

Preventive Actions, and any

other Miscellaneous details

regarding the Vendor, Date

Assigned, etc, in the

relevant tab sections, as you

can see from the above

screenshot.

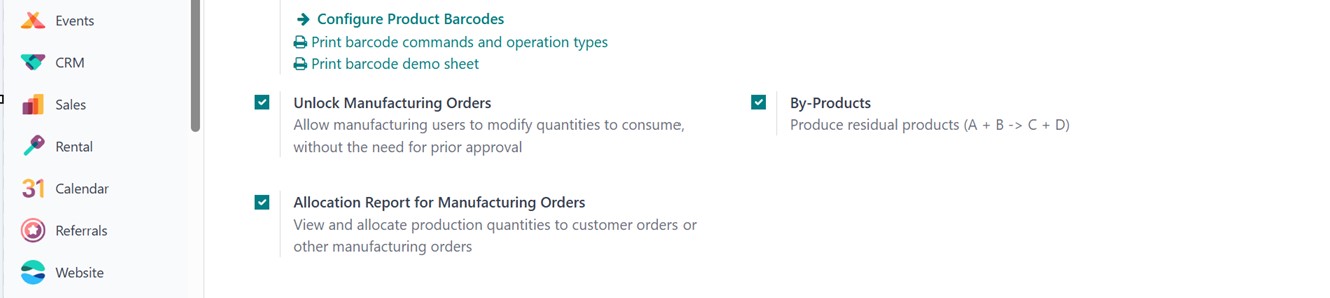

Manufacturing Order Management:

This function provides

options to automate and

streamline the creation,

tracking, and processing of

Manufacturing Orders (MOs),

ensuring visibility and

control across all stages of

production.

Allocation Reports for

Manufacturing Order provide

visibility into how materials

are allocated to different

manufacturing orders. This

helps in identifying

shortages or surpluses and

improves inventory planning.

Security Lead Time adds buffer

time to manufacturing

operations to account for

unexpected delays. This

ensures that production

deadlines are met even when

disruptions occur.

Each of these settings can be

enabled or configured

according to your specific

operational needs, allowing

Odoo to adapt seamlessly to

your manufacturing workflows.

6.1 Work Centers

Work Centers are the core of

production activities,

serving as dedicated spaces

or units where manufacturing

processes occur. The Odoo 18

Manufacturing module allows

users to create and manage

multiple work centers,

ensuring that every

production activity is

assigned a proper space. This

feature helps ensure quality

at each stage of production.

To set up a new work center,

navigate to the settings

window and activate the Work

Orders option. After

activation, the work center

setup link becomes

accessible, displaying

existing work centers and

their configurations.

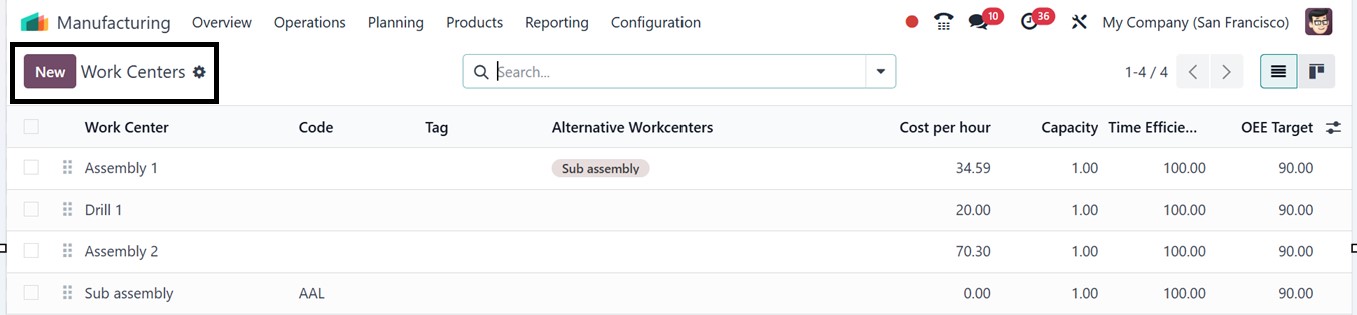

In the ‘Work Centers’ window of

the ‘Configuration’, you can

see the dashboard of all the

available work centers with

their Name, Code, Tag,

Alternative Work Centers,

Cost per hour, Capacity, and

other details, as depicted in

the screenshot below.

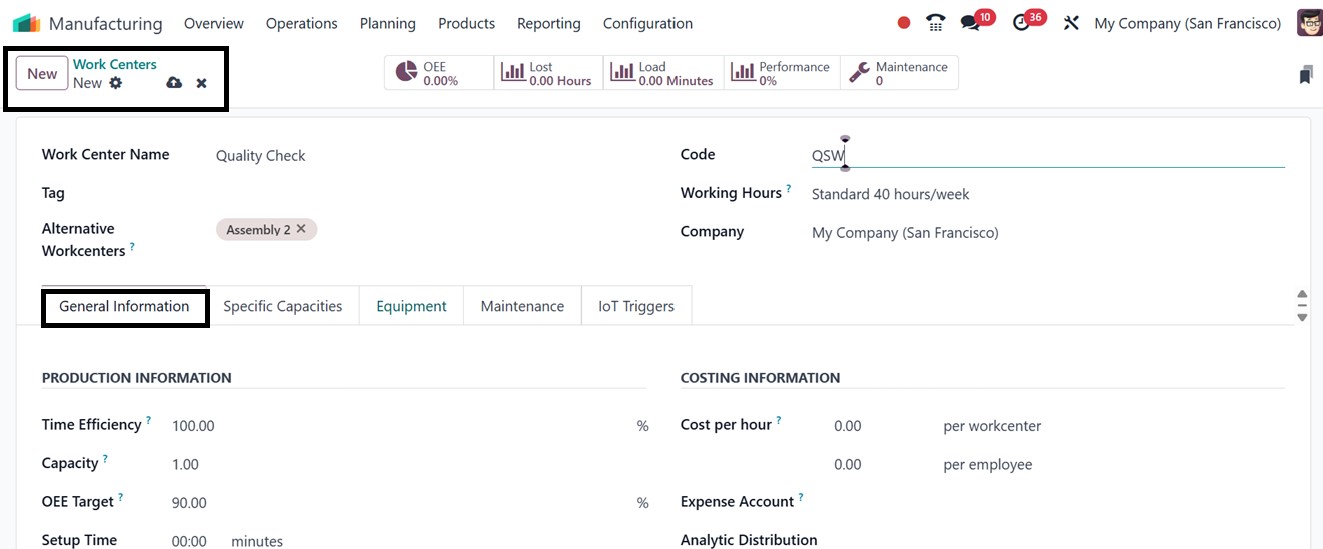

To create a new work center for

your company, click on the

‘New’ button and proceed by

filling in the required

fields, including the unique

‘Work Center Name.’ The

‘Tags’ aid in classifying and

arranging work centers for

simpler filtering. You can

choose a backup center in the

‘Alternative Work Center’

field to maintain operations

in the event that the primary

center is unavailable.

For the purpose of indicating its

availability, every work

center also has a distinct

‘Code’ and set ‘Working

Hours’. You can also input

Cost per Hour, Setup Time,

and Cleanup Time; all crucial

for precisely estimating

production costs as well as

establishing ‘OEE Targets’

(Overall Equipment

Effectiveness targets) to

monitor efficiency and select

the ‘Capacity’ (number of

things it can manufacture

concurrently).

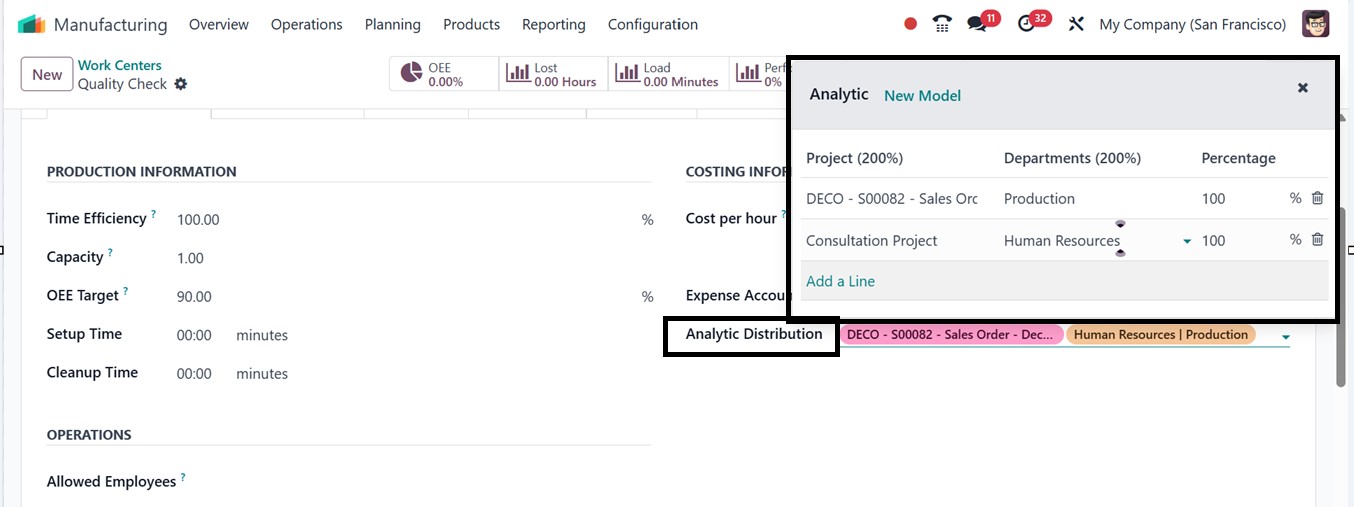

Odoo 18's Manufacturing module

allows for the assignment of

an ‘Expense Account’ to each

work center, ensuring

accurate tracking of costs

like labor, machine usage,

setup, and maintenance. The

'Analytic Distribution'

button allows for precise

allocation of expenses across

departments, projects, or

cost centers, enhancing cost

control and profitability

analysis. Using the ‘Add a

Line’ button from the pop-up

window, you can mention the

Projects, Departments, and

the analytic Distribution

Percentages, as depicted in

the screenshot below.

You can specify the employees

responsible for or permitted

to access a particular work

center in the ‘Allowed

Employees’ field.

Additionally, any relevant

information or notes about

the work center can be added

in the ‘Description’ section.

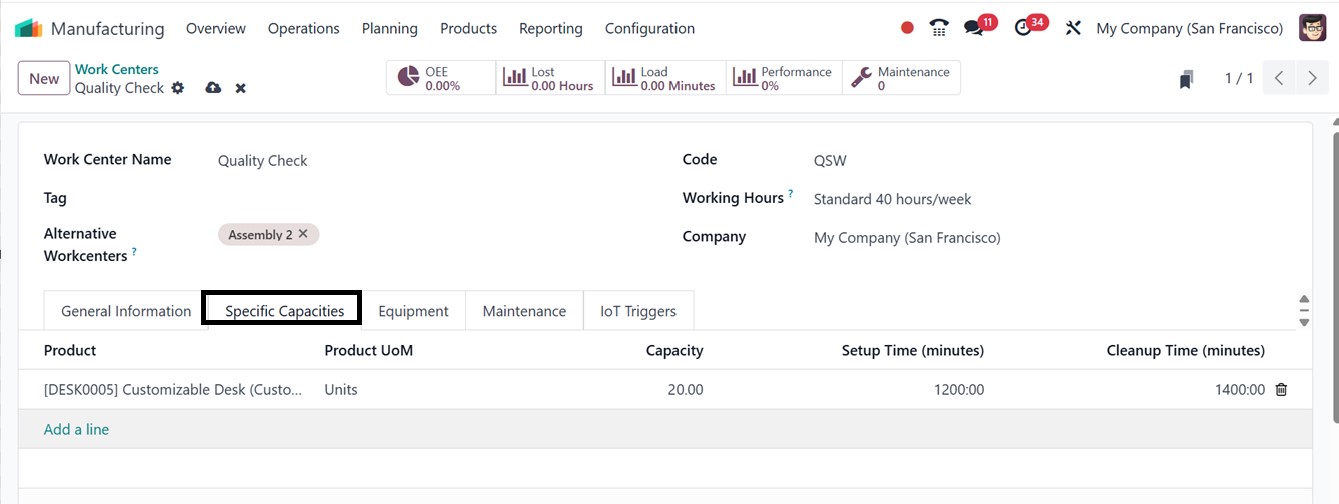

The Specific Capacity setting in

a work center defines the

default number of units that

can be produced

simultaneously during a

single production cycle. This

value serves as a general

benchmark for the work

center’s output capability.

However, if a work center is

capable of handling different

production capacities

depending on the product, you

can configure this by

navigating to the Specific

Capacities tab.

Here, you can set customized

capacity values for

individual products, allowing

for more accurate planning

and resource allocation based

on the unique production

requirements of each item by

clicking on the ‘Add a line’

button, as depicted in the

screenshot below.

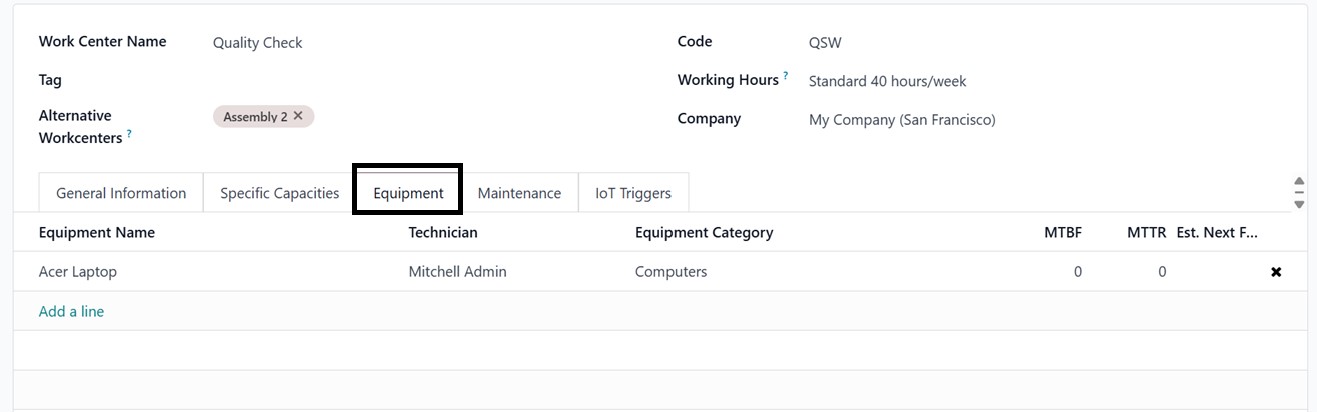

The ‘Equipment’ tab allows users

to assign specific equipment

to a work center and track

each item's costs and

productivity individually.

When you click on the ‘Add a

line’ button inside the tab,

you can add any equipment

from the list of all

available equipment.

Within the Equipment tab, you can

view detailed information

about each item, including

the Equipment Name, the

Technician responsible for

its upkeep, its Category, and

key performance indicators

such as MTBF (Mean Time

Between Failures), MTTR (Mean

Time to Recovery), and the

Estimated Next Failure date,

as shown in the screenshot

below.

This functionality supports

better maintenance planning,

minimizes downtime, and

improves equipment

reliability.

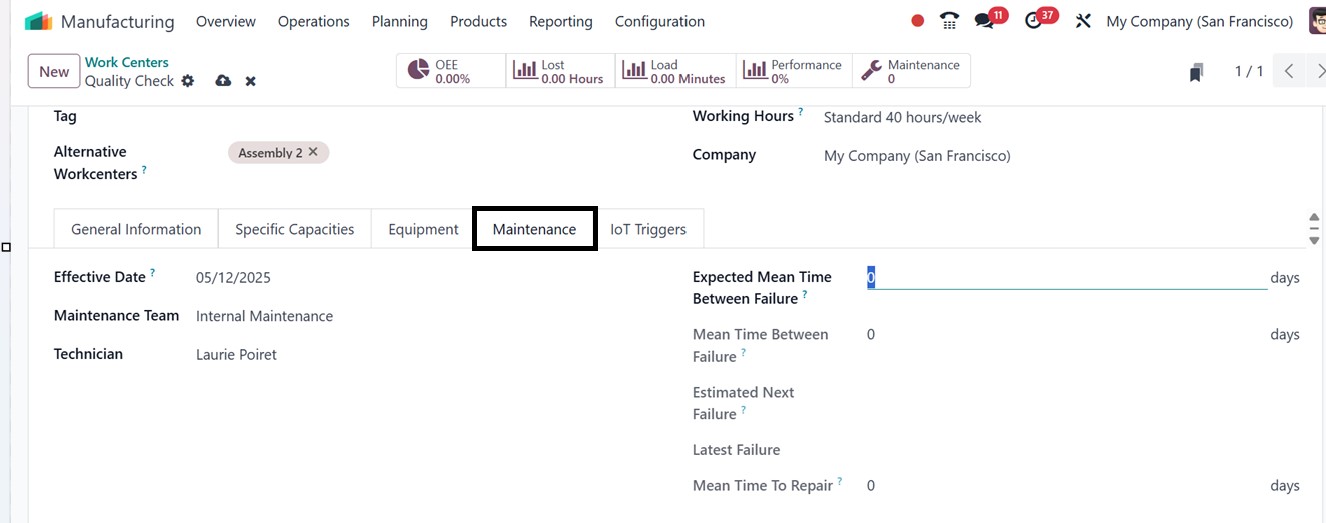

The Maintenance tab allows you to

define key maintenance

details for a work center. In

the Effective Date field, you

can set the start date of the

work center’s operation. You

can then specify the

Maintenance Team and the

responsible Technician

assigned to handle

maintenance tasks.

Additionally, you can enter

the Expected Mean Time

Between Failure (MTBF), a

manually defined metric that

estimates the average time

the equipment is expected to

function before failing. This

helps in planning maintenance

schedules and improving

overall equipment reliability

and performance.

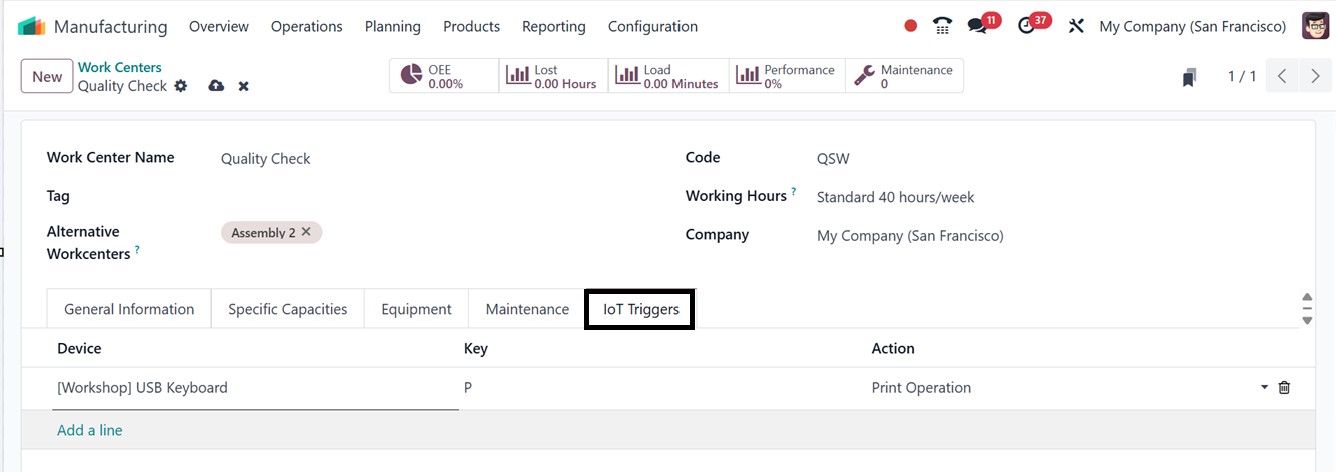

You can automate particular tasks

by integrating IoT devices

with a work center using the

‘IoT Triggers’ tab. This tab

allows you to specify the

action that the device should

do when activated, define the

device to be triggered, and

input the appropriate key for

device authentication. For

increased efficiency, this

permits smooth communication

between linked hardware and

production processes.

After entering all the necessary

information, users can save

the new work center, adding

it to the list of available

centers.

Then the work center form’s smart

buttons provide easy access

to key operational insights,

including scheduled

operations, Overall Equipment

Effectiveness (OEE),

productivity losses, work

center load, and work order

performance. By clicking the

Overall Equipment

Effectiveness button, you can

generate a performance

analysis report that

evaluates employee costs,

task duration, user

performance, and loss

reasons.

The Productivity Loss button

displays reports on

productivity impacts caused

by factors like equipment

failure or reduced speed. The

Loads button compares actual

work order completion times

with planned timelines,

giving insights into work

center capacity. Lastly, the

Performance button lets you

access the performance

analysis report for work

orders assigned to the

specific work center.

Finally, the ‘Maintenance’

smart button will show the

maintenance operations

related to this particular

work center.

6.2 Operations

The ‘Operations’ are the

production procedures

established by the Odoo

software. Effective

coordination of these

operations across different

work centers ensures that

high-quality products are

efficiently produced for

clients. Setting up and

managing operations in the

manufacturing module can be

done through the

Configuration menu or by

enabling it in the settings

menu.

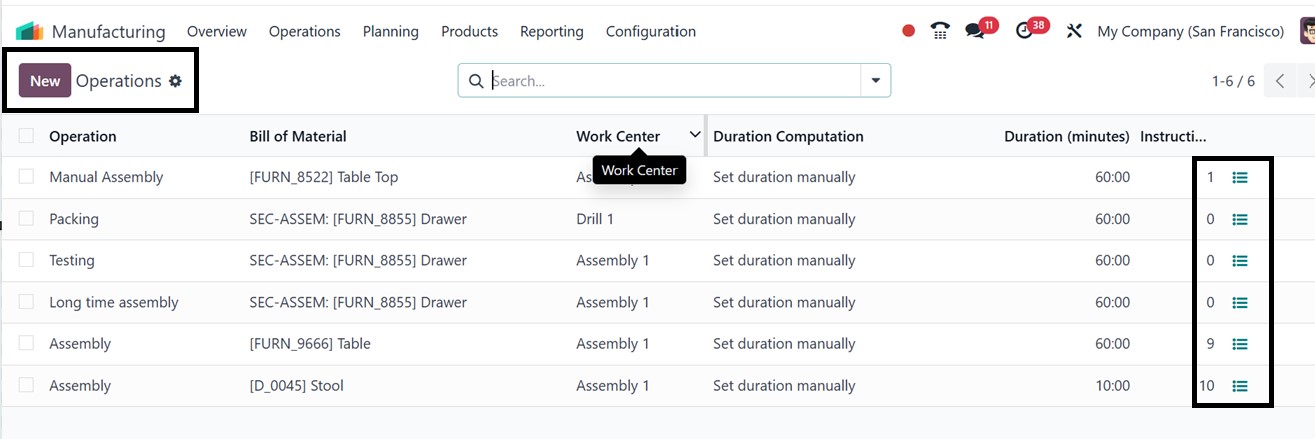

After opening the ‘Operations’

menu, you can see the

dashboard of all the

available operations with

their respective Name, Bill

of Material, Work Center,

Duration Computation,

Duration in Minutes, and

Instructions.

To quickly check the instructions

of any operation, simply

click on the ‘Show

Instructions’ (three lines)

icon, as depicted in the

screenshot below.

You can open an entry by clicking

on an operation column to get

a detailed view of the

operations in a form view.

Filters, Group By, and

Favorites features are

available to help you

navigate and customize the

display according to your

needs. Let’s now discuss how

to create a similar function

in the Odoo ERP's

manufacturing module,

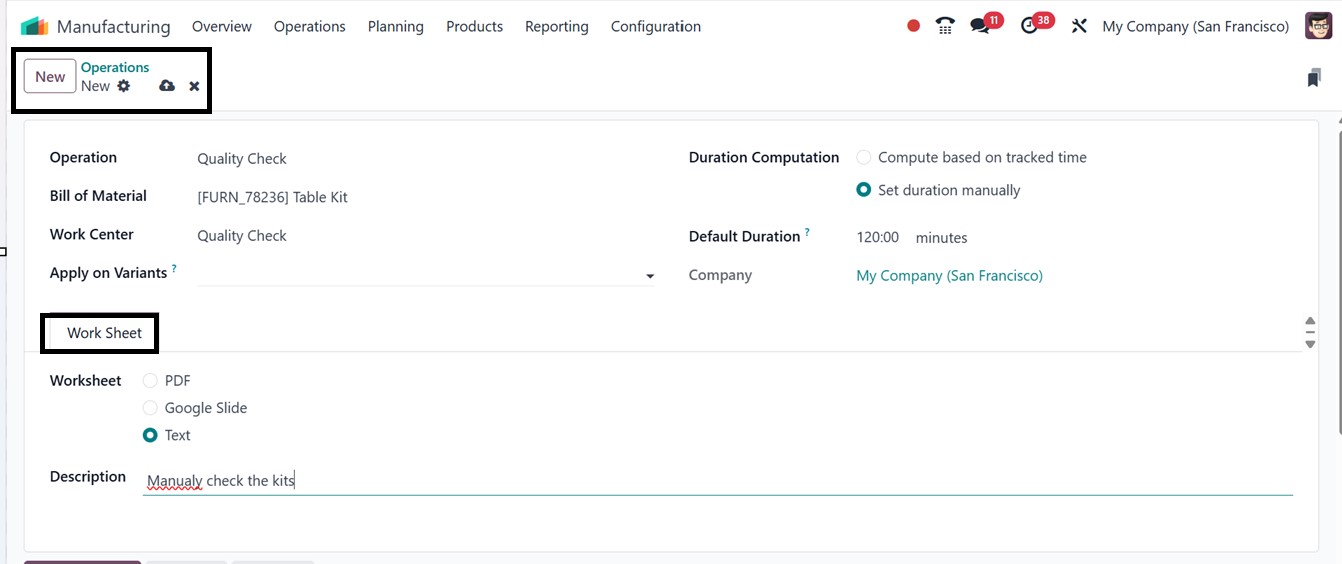

After opening a new Operation

creation form, you will need

to add key information such

as the Operation Name, Bill

of Materials, and Work

Center. These details are

then linked to different

Duration Computations, which

can either be manually

defined or automatically

calculated based on tracked

time.

Then, you can set the Default

Duration for the operation in

the designated field and

specify any Product Variants

that should automatically

undergo this operation by

entering them in the Apply on

Variants field, as shown in

the screenshot below.

Finally, you can refer to the

worksheet under the Worksheet

tab, which could be a Text

document, Google Slide, or

PDF. This section also allows

for a brief explanation of

the procedure in a

Description field. Once

completed, click the save

button to include the newly

created operation in the list

of existing operations. This

is the standard method of

creating operations in the

manufacturing module.

Then, you can add any

instructions to the

operations as per your

company policies by clicking

on the ‘Show Instructions’

icon provided inside the

operation’s column from the

dashboard.

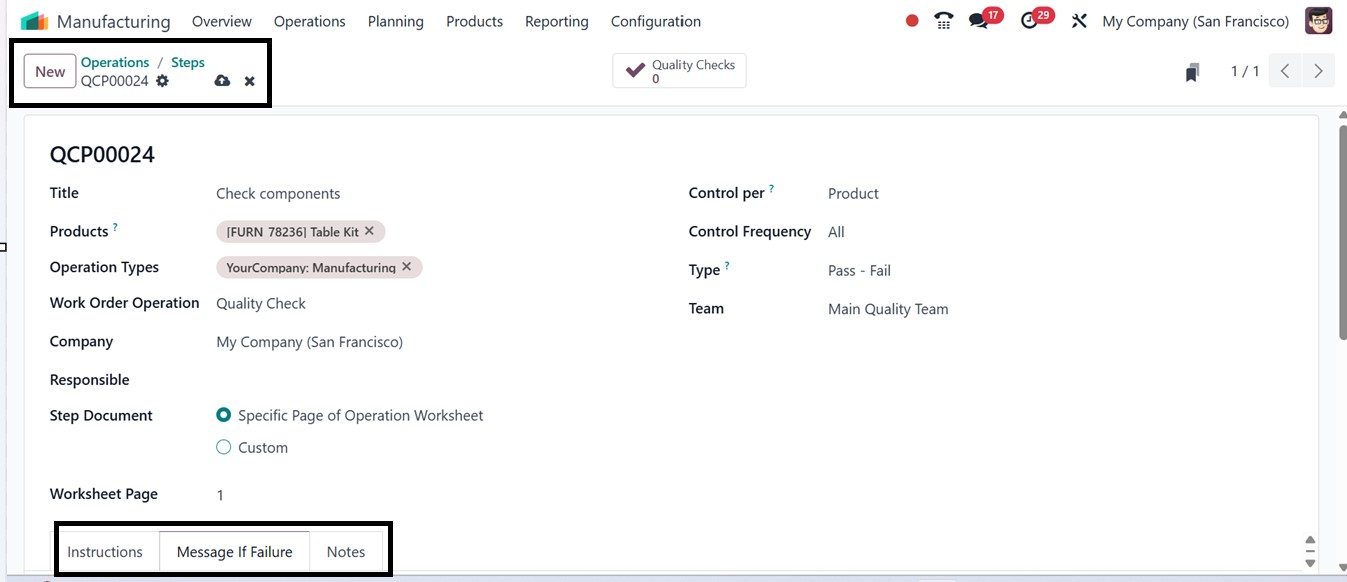

The Title field is used to enter

clear, detailed instructions

that guide the operator

through the task. Eg: "Check

components of the product."

The Products field specifies

which product(s) the step

relates to, helping identify

involved components or

finished goods. The Operation

Types field links the step to

a particular type of

operation such as

Manufacturing or

Subcontracting. The Work

Order Operation field

connects the step to a

specific operation within a

routing, like Welding or

Assembly. The Company field

indicates which company the

step is configured for,

especially useful in

multi-company environments.

The Responsible field assigns

accountability to a specific

individual who will perform

or oversee the step. The

‘Step Document’ field allows

you to customize or choose a

specific page of the

operation worksheet to

explain the instruction steps

for this particular

operation. For quality

control, the Control per

field sets the basis (Unit,

Batch, or Time), while the

Control Frequency field

determines how often this

control occurs; for example,

checking every 10 units. The

Type field classifies the

step’s nature, such as

Instruction for guidelines,

Check for validations,

Picture for image-based

tasks, or Measure for

recording metrics like

temperature or pressure.

Lastly, the Team field

assigns a responsible work

center or quality team to

handle the step, ensuring

accountability and structured

execution.

Next, you can add detailed notes

or instructions for complex

operation steps in the

Instructions tab. Use the

Message If Failure tab to

specify contact information,

such as responsible users or

email addresses, to be

notified in case of an

operation failure or a

product-related issue.

Additionally, the Notes tab

can be used to include any

extra information or remarks

related to the steps or the

overall operation.

After saving all the details, you

can access the dashboard of

completed operations or steps

linked to this specific step

through a smart button, based

on the associated work order

operation's name. In this

example, a Quality Checks

smart button is displayed

because the work order

operation is set to Quality

Checking.