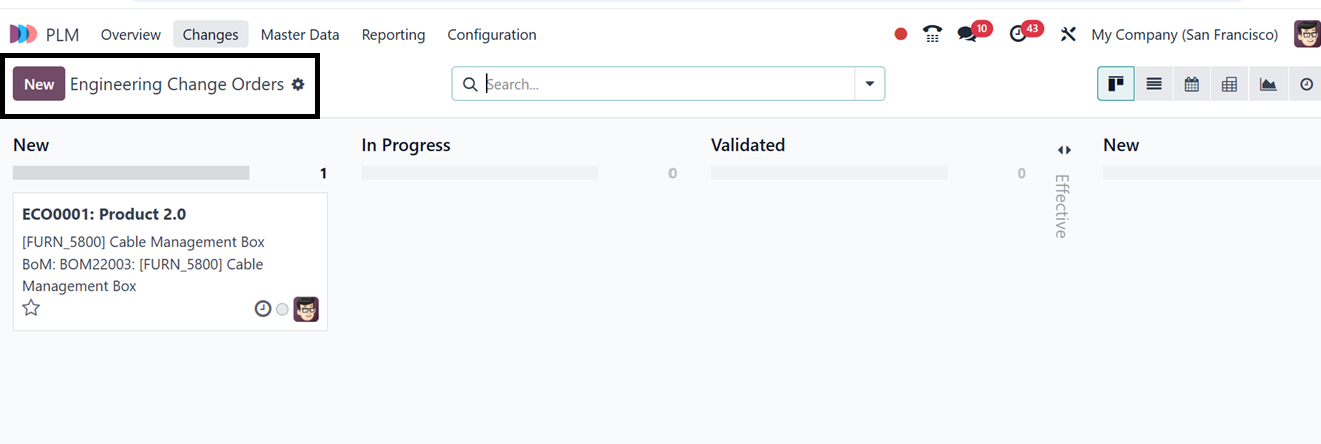

2. Changes Menu

An Engineering Change Order (ECO) outlines proposed modifications or

new designs for an existing product. The Odoo 18 PLM module

simplifies the creation and management of these orders. Users can

manage ECOs through the "Changes" menu, which provides a Kanban view

of existing orders arranged according to predefined stages, as

illustrated in the screenshot below.

There is also a platform for creating and controlling ECO phases in

the Configuration menu. So that you can create more ECO stages as

per the requirement. The list view of ECOs displays key details such

as Reference, Bill of Materials (BoM), Responsible Person, Stage,

Effective Date, and Company.

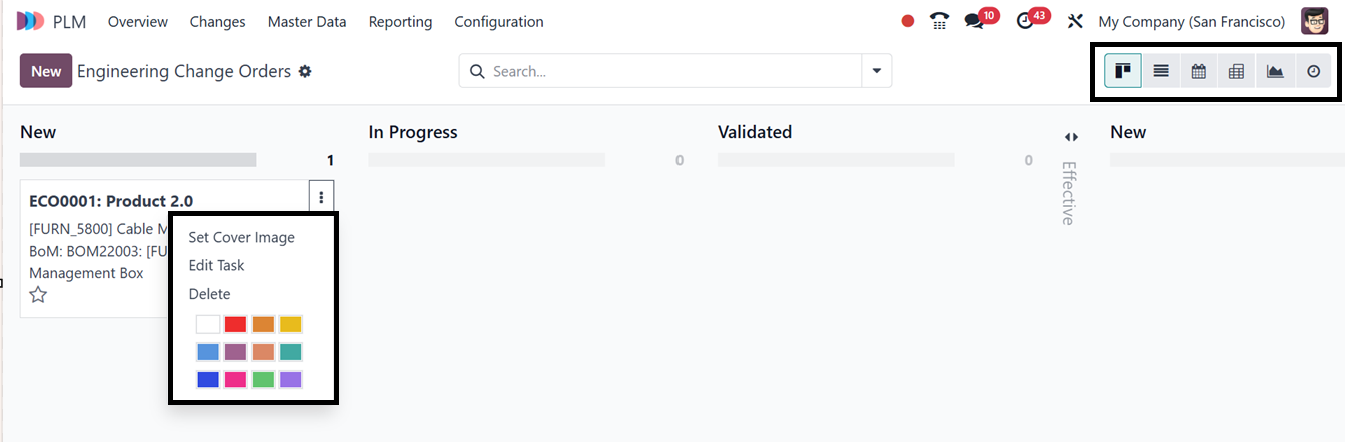

The three dotted vertical menu items placed on an ECO order card can

be used to set a cover image for the task, edit the task, and delete

it. Using the color icons, you can highlight the task according to

the priority. This Kanban view is also converted into List,

Calendar, Activity, Graphical as well as Pivot view using the

respective icons provided at the top right corner of the screen.

The search bar filter options allow you to Filter, Group, and mark

data as Favorites, making it easier to manage a large number of

tasks on the dashboard.

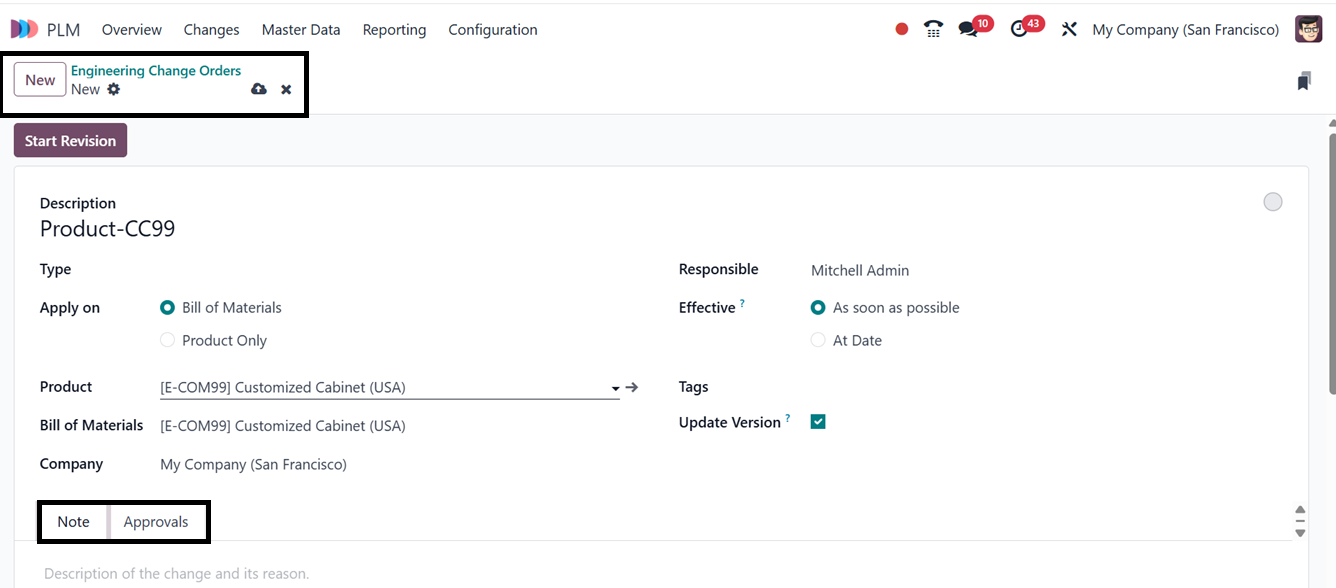

To create a new Engineering Change Order (ECO), begin by clicking the

New button. In the designated field, enter a detailed description of

the proposed modifications to clearly define the purpose of the ECO.

Next, select the appropriate ECO Type from the available dropdown

menu to categorize the change correctly. Determine whether the

changes apply to a specific Product Only or a Bill of Materials

(BoM) and fill in the relevant Product and BoM details accordingly.

Assign a Responsible person who will oversee the ECO process and

ensure proper execution. Set an Effective Date to schedule when the

modifications will be implemented. Then, add relevant Tags to

enhance organization and streamline tracking within the system.

Finally, disable the Update Versions option to keep the product/BOM

version unchanged after the ECO is applied.

The ‘Note’ tab can be used to edit any notes regarding the order,

and the ‘Approval’ tab contains the record of approvals from the

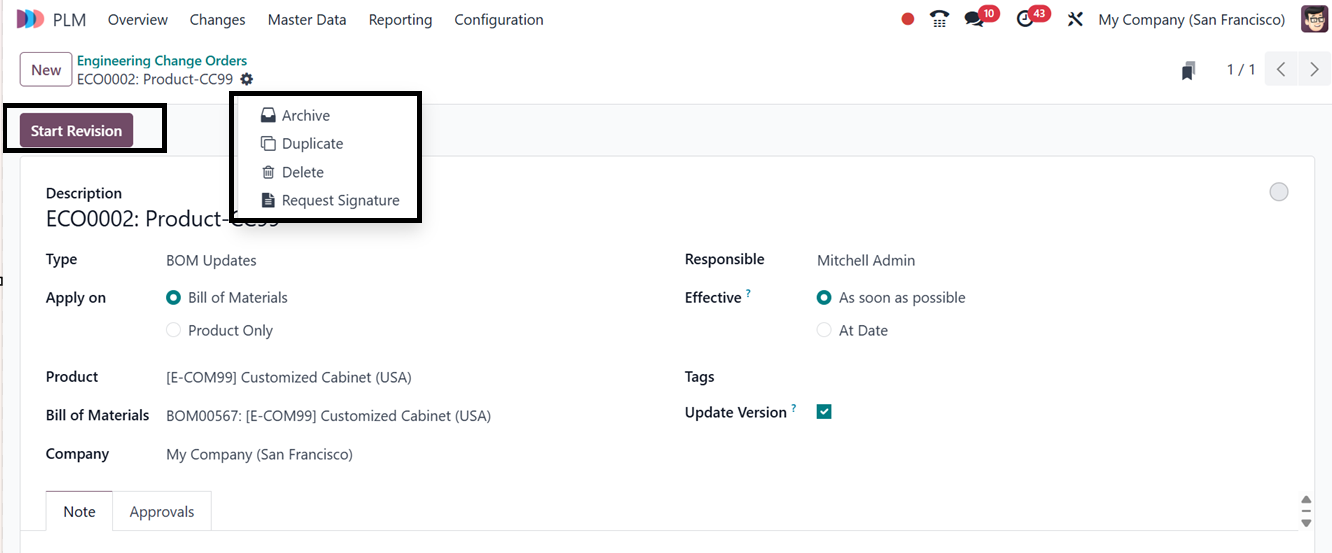

responsible users or the team. After saving the data, you can

utilize the ‘Action’ menu placed on the form to Archive, Duplicate,

Delete, and Request Signature from the responsible person.

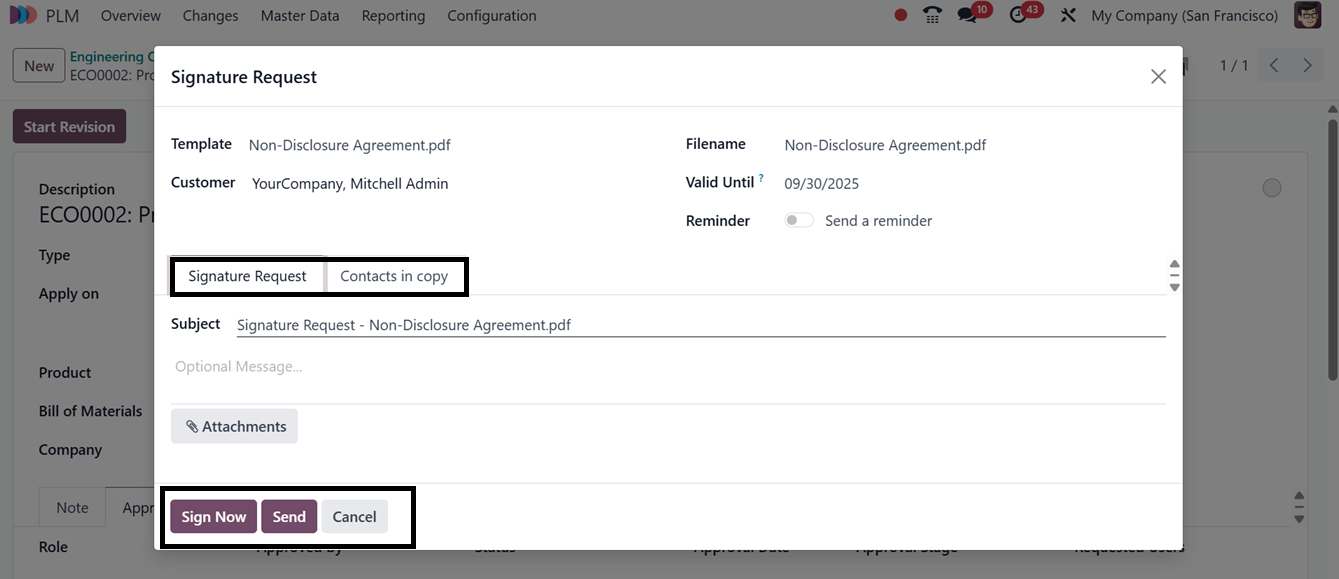

Clicking on the ‘Request Signature’ button will open a pop-up window

that can be used to send a signature request to the authorized user.

So, you have to choose the request Template, Customer, Validity, and

a Reminder, as illustrated in the screenshot below.

In the ‘Signature Request’ tab, you can edit the Subject as well as

an optional message about the request or document. You can also

attach any supporting documents or files in this tab area using the

‘Attachments’ link.

The ‘Contacts in Copy’ tab lets you include additional contacts or

users responsible for a task, ensuring better transparency and

accountability in each operation. Finally, send the request.

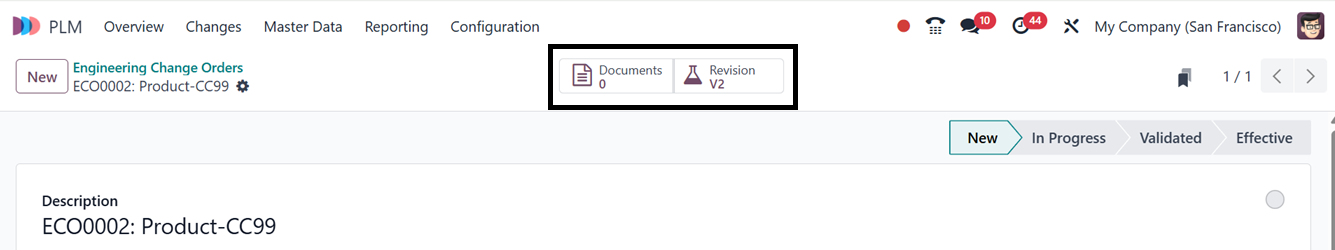

Clicking the Start Revision button initiates the revision process.

Once the required approvals are obtained, users can update the ECO’s

stage. The Document smart button displays associated files, while

the Revision option contains all the details about the ECO

modifications, Operation Performance, Schedules and BoM Overview,

Components, By-products, etc.

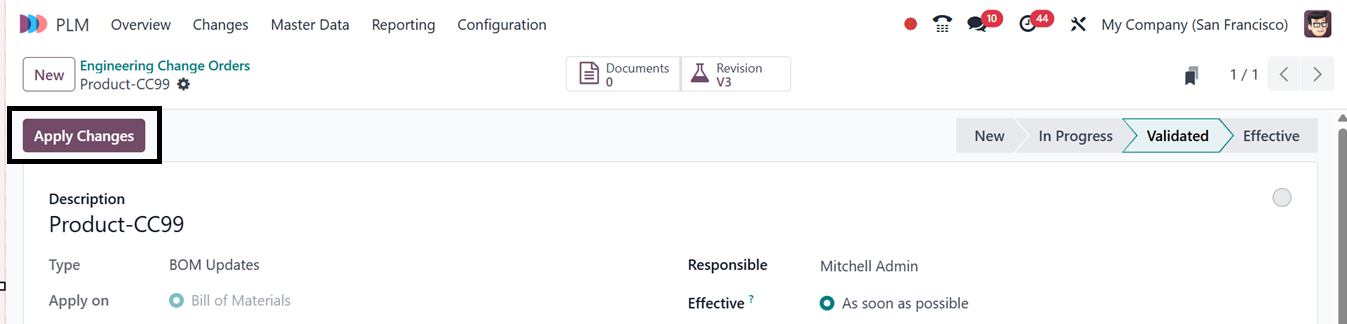

Once the relevant official has given their clearance, you can modify

the phases in accordance with the ECO's development. The Document

smart button will provide access to files pertaining to ECO. The

‘Apply Changes’ option will show up after the ECO has reached the

Validated stage, enabling you to make the recommended changes to the

product.

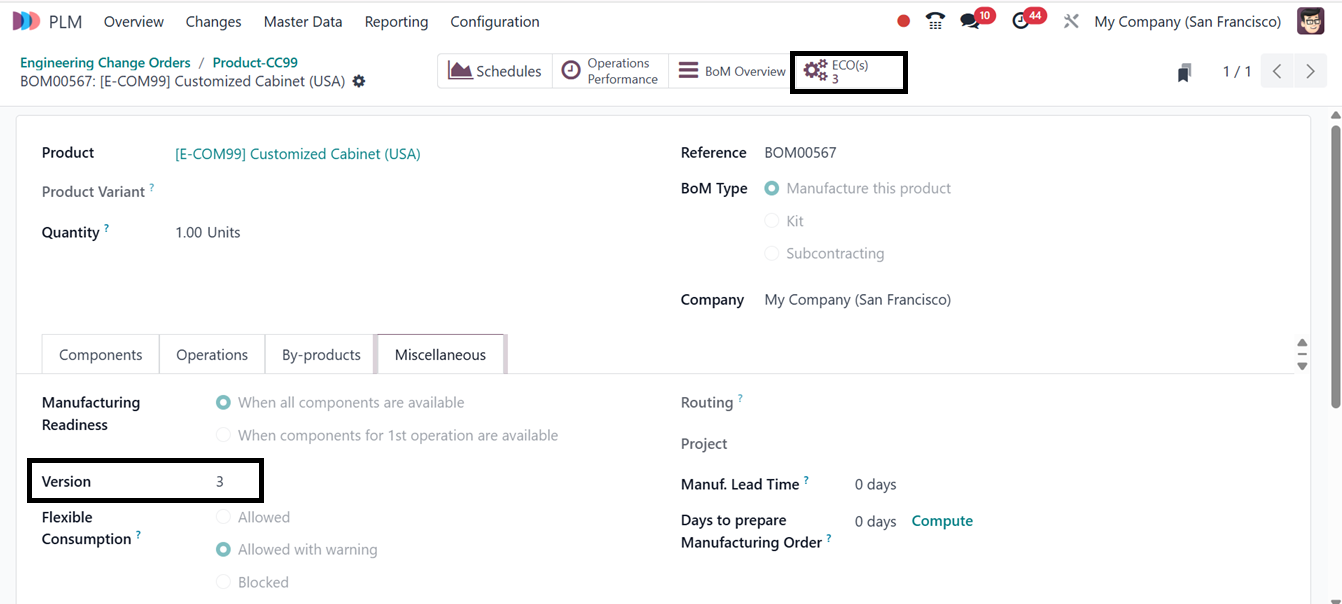

Once created, apply the necessary adjustments and modifications to

align with the required changes. After implementing the updates,

navigate to the Miscellaneous tab, where the revised Bill of

Materials (BoM) version will be displayed, reflecting the latest

modifications made to the product structure.

2.1 Creating ECO Orders for an

Existing BOM

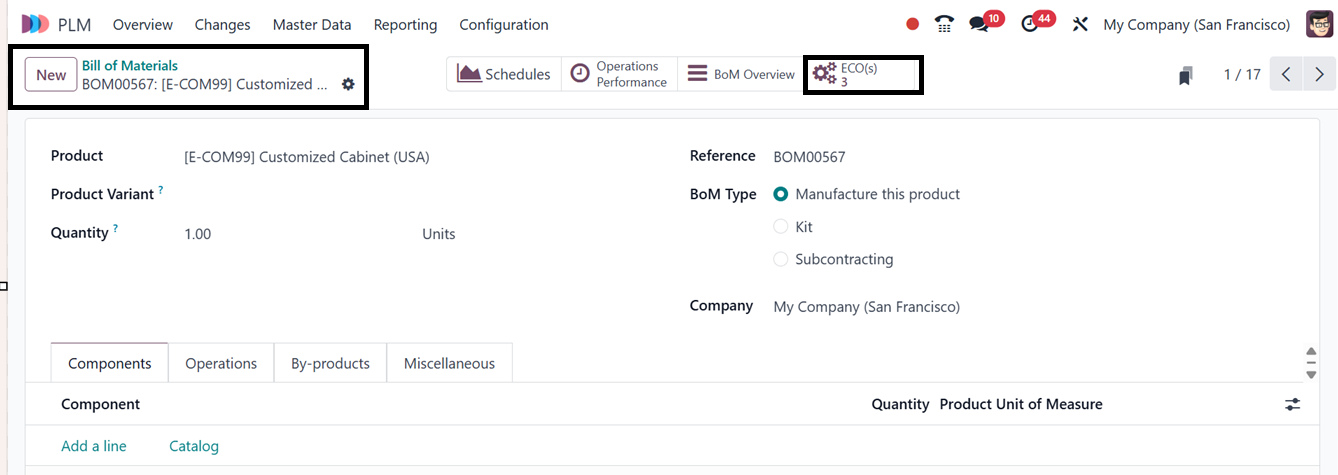

You can create Engineering Change Orders (ECOs) for an existing Bill

of Materials (BoM) from the ‘Bill of Materials’ window of the

‘Master Data’ menu of the PLM Module.

Then, choose the required product and use the ECO smart button

located in the BoM form view of a product to initiate an ECO for the

selected BoM, as illustrated in the screenshot below.

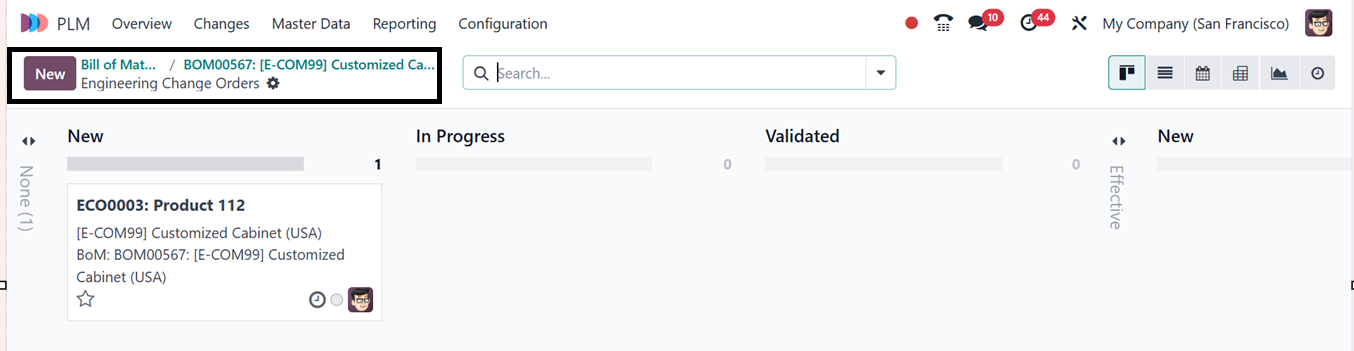

Inside the ECO(s) smart button, you can see the previous ECO orders

carried out for this particular product as a dashboard, as depicted

in the screenshot below.

Simply select the "New" option and follow the instructions we covered

in the last section to make a brand-new order.

2.2 Generating ECOs from the

Manufacturing Module

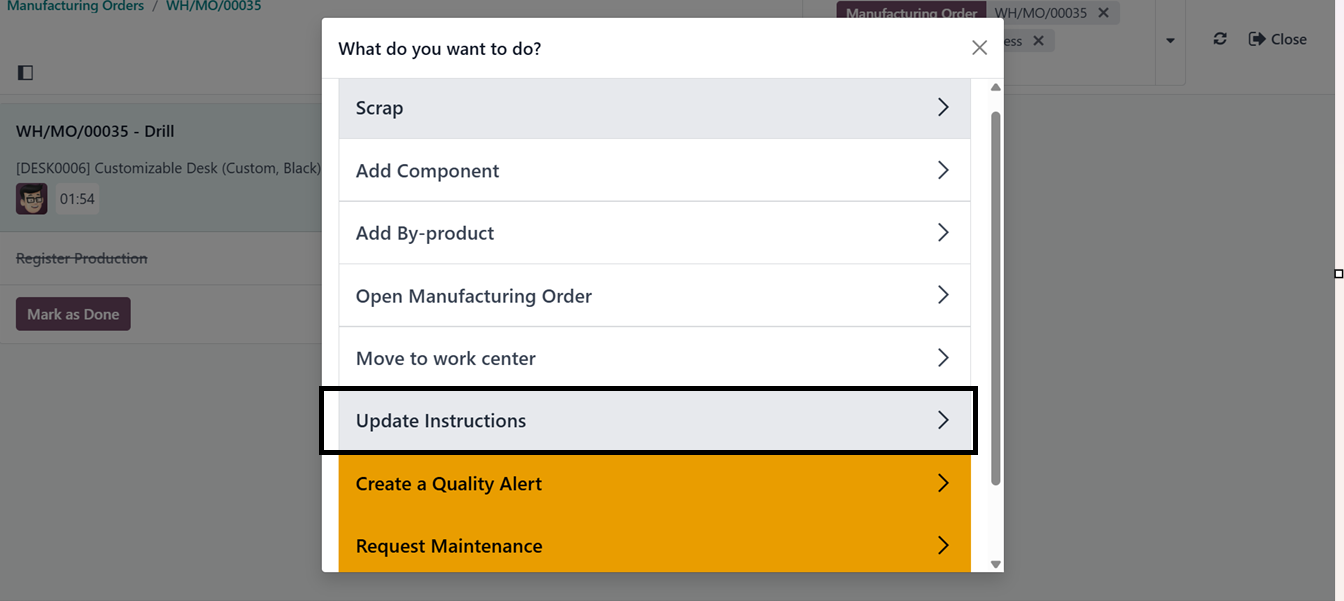

Users can also generate ECOs within the Manufacturing module. This is

facilitated by an advanced menu bar in the work order’s Shop floor

view.

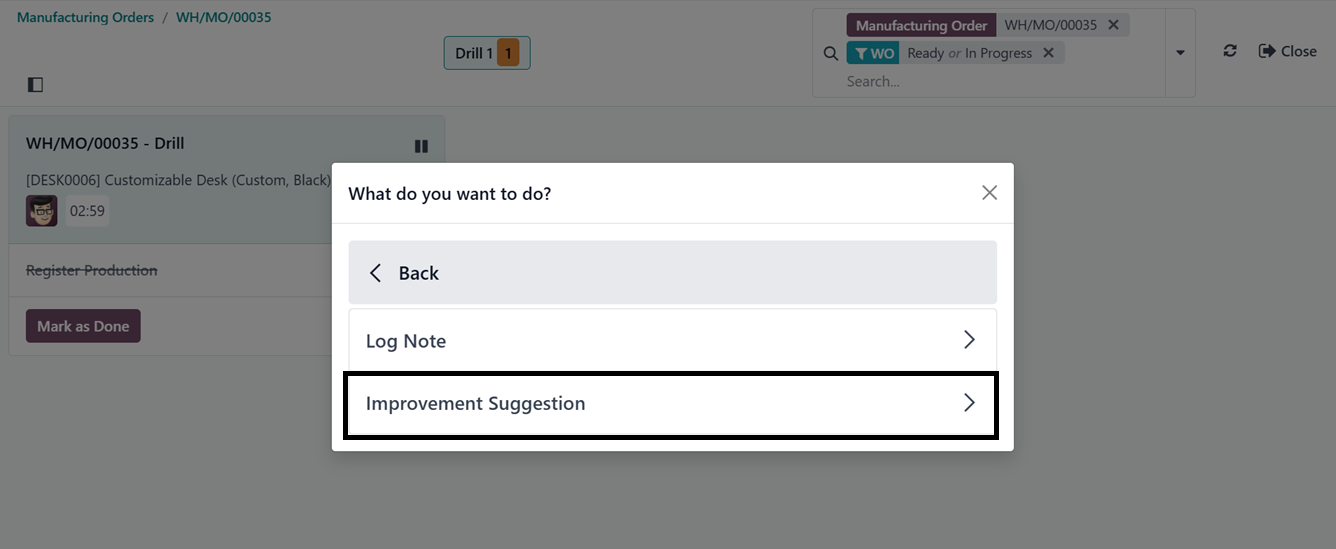

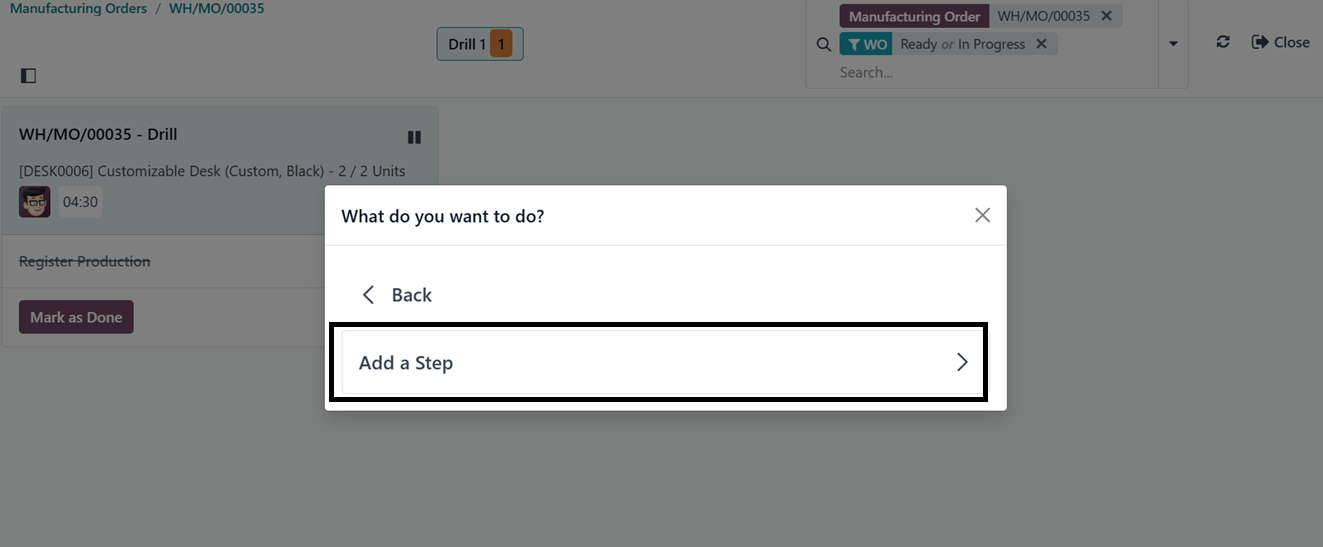

By selecting the ‘Update Instructions’ option, you will get a pop-up

window asking what to do next. Here, you can log messages to the

work order team using the Log Note feature or go with the

Improvement Suggestion button to proceed.

Then, you will get an ‘Add a Step option, users can introduce new

workflow steps using this feature.

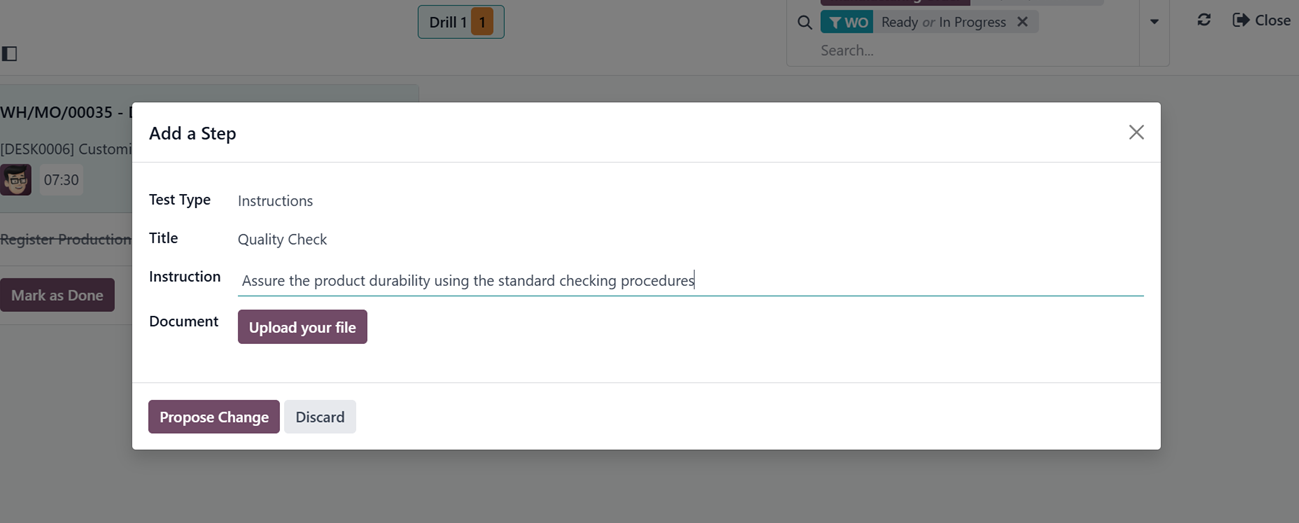

The ‘Add a Step’ button will open another pop-up with the options to

mention the Test Type, Title, Instruction along with the Upload file

facility.

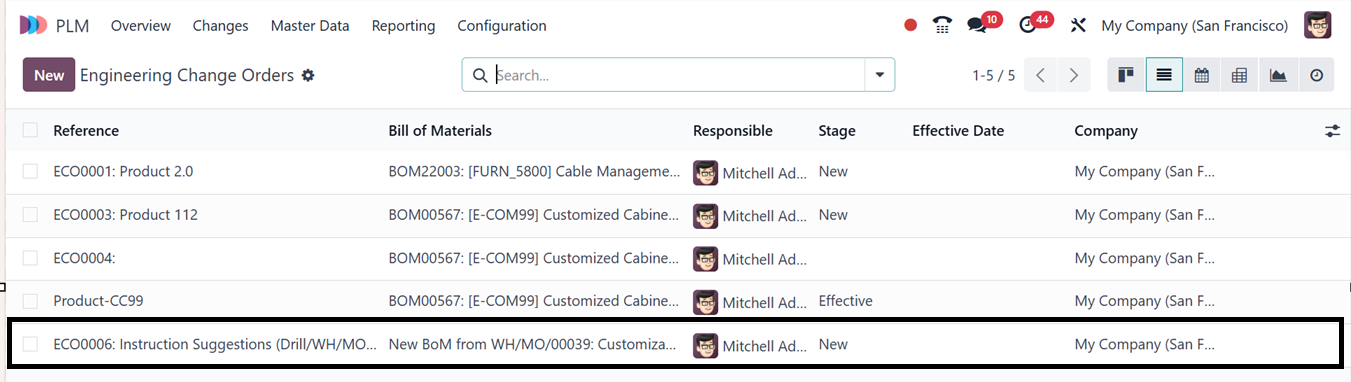

Clicking the Proposed Change button automatically creates a new ECO

in the PLM module.

Once the order is approved, the responsible employee can review and

implement the necessary adjustments.