3. Master Data Menu

The Product Lifecycle Management (PLM) module of Odoo 18's Master

Data menu offers crucial capabilities for effectively managing

engineering modifications and product-related data. Important

settings that facilitate version control and product changes are

included in this menu including; Product, Bill of Materials (BoM),

and Work Center management options.

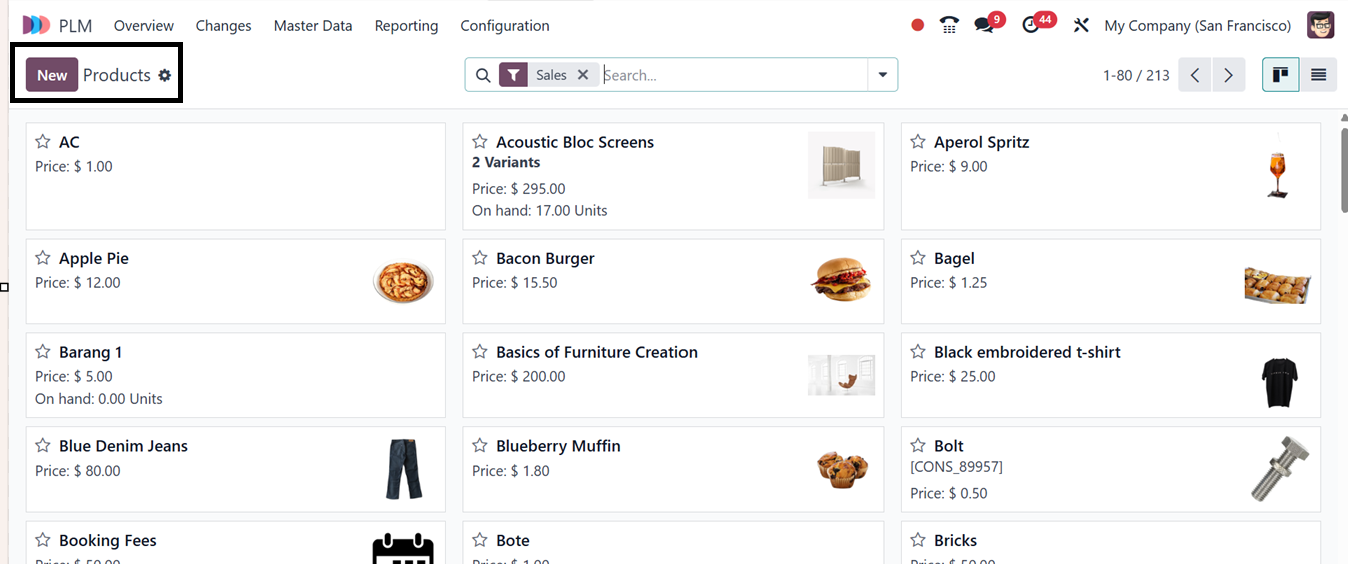

3.1 Products

The PLM module of Odoo 18 facilitates cross-departmental cooperation,

ECOs, and version control in product development. With a

consolidated view of all accessible products, the PLM module's

"Products" dashboard is the same as the product management dashboard

seen in other Odoo modules. It does not have a specific 'Products'

menu, but it interfaces with other modules for smooth

administration, allowing companies to effectively track BoMs and

product versions.

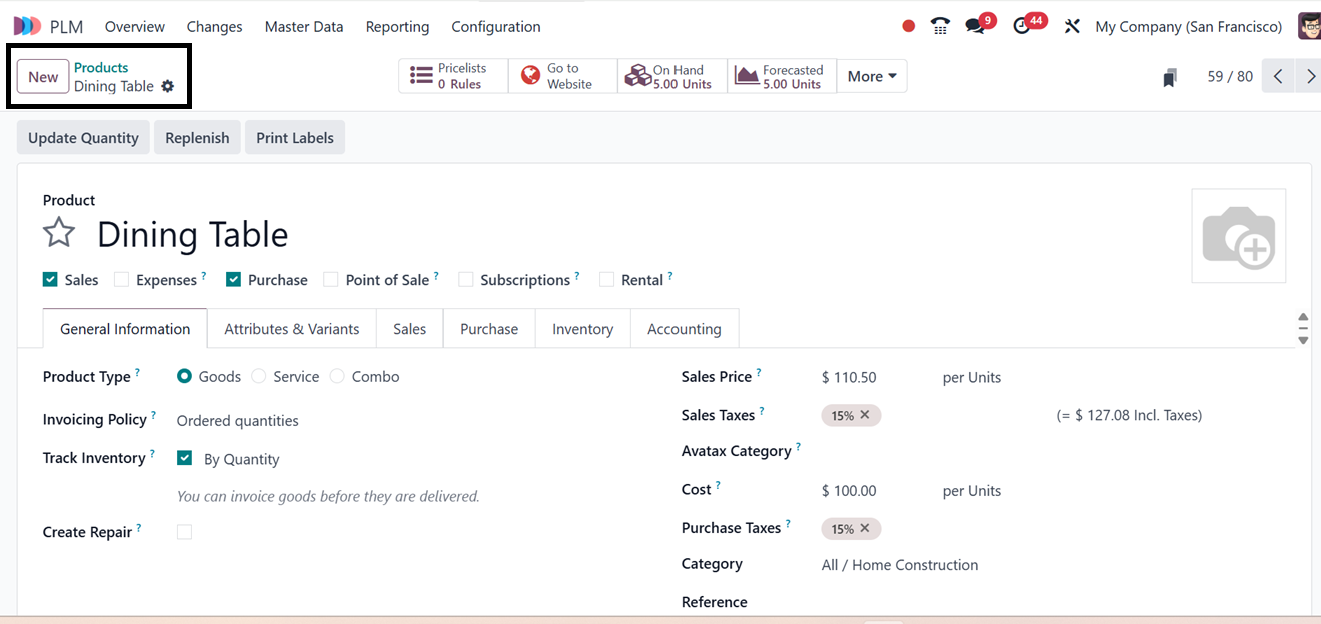

Similar to the previous versions of the Odoo modules, clicking the

"New" button enables you to quickly create a product by completing

the necessary information, as seen in the screenshot below.

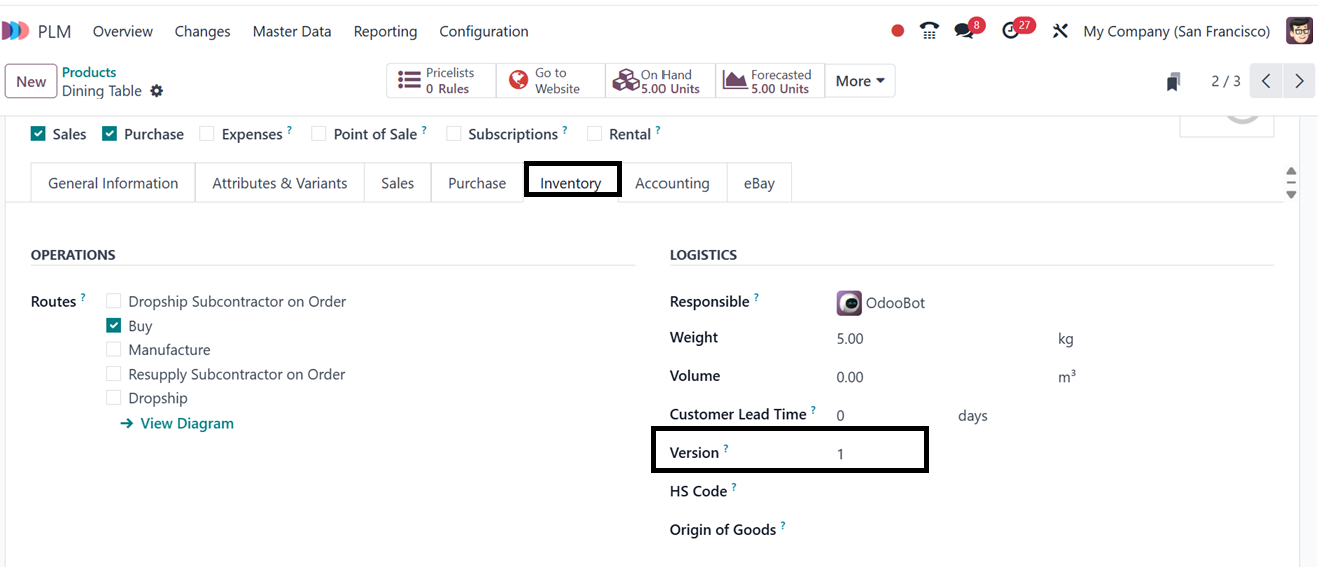

In the ‘Inventory’ tab, you can see the product version of this

particular product. Because each time you create a new Engineering

Change Order (ECO) with this product, Odoo will automatically change

the product versions. Here, we have not created any ECO products for

this particular one, so you can see ‘1’ in the 'Version’ field, as

illustrated in the screenshot below.

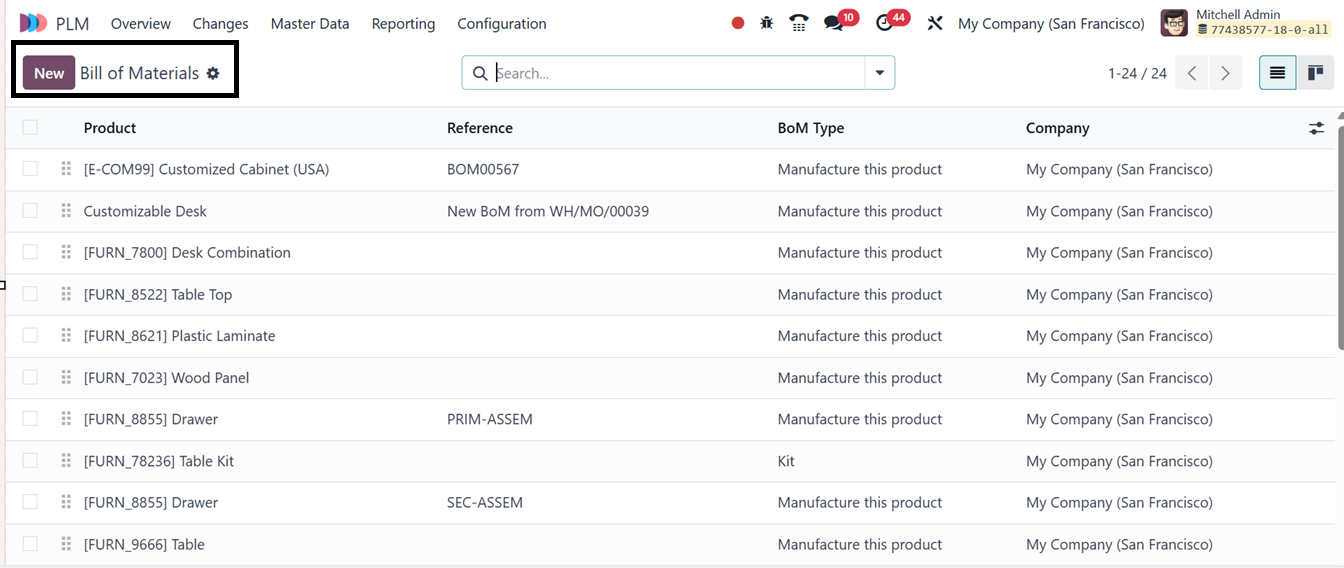

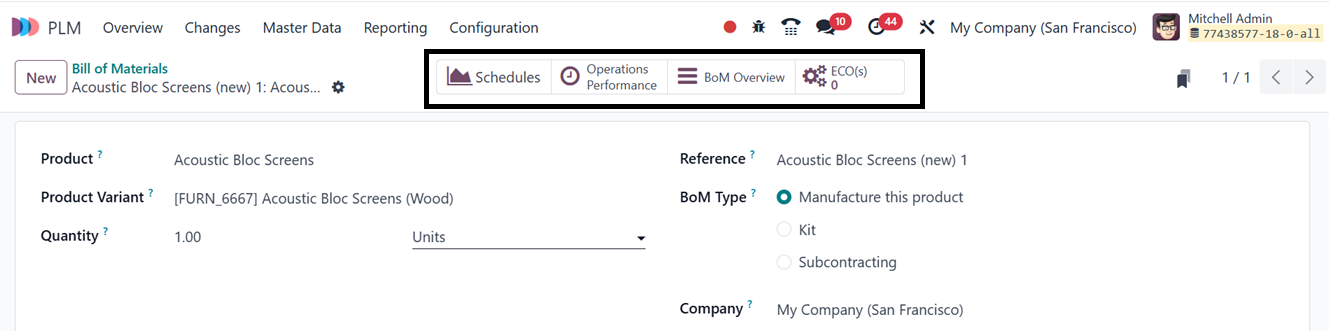

3.2 Bill of Materials

The Odoo 18 PLM (Product Lifecycle Management) module's Bill of

Materials (BoM) menu enables users to effectively manage engineering

modifications, version control, and product architectures. This

menu, which includes the dashboard for each BoM Product, Reference,

BOM Type, and Company information, is essential for monitoring and

changing BoMs throughout the product lifetime, as illustrated in the

screenshot below.

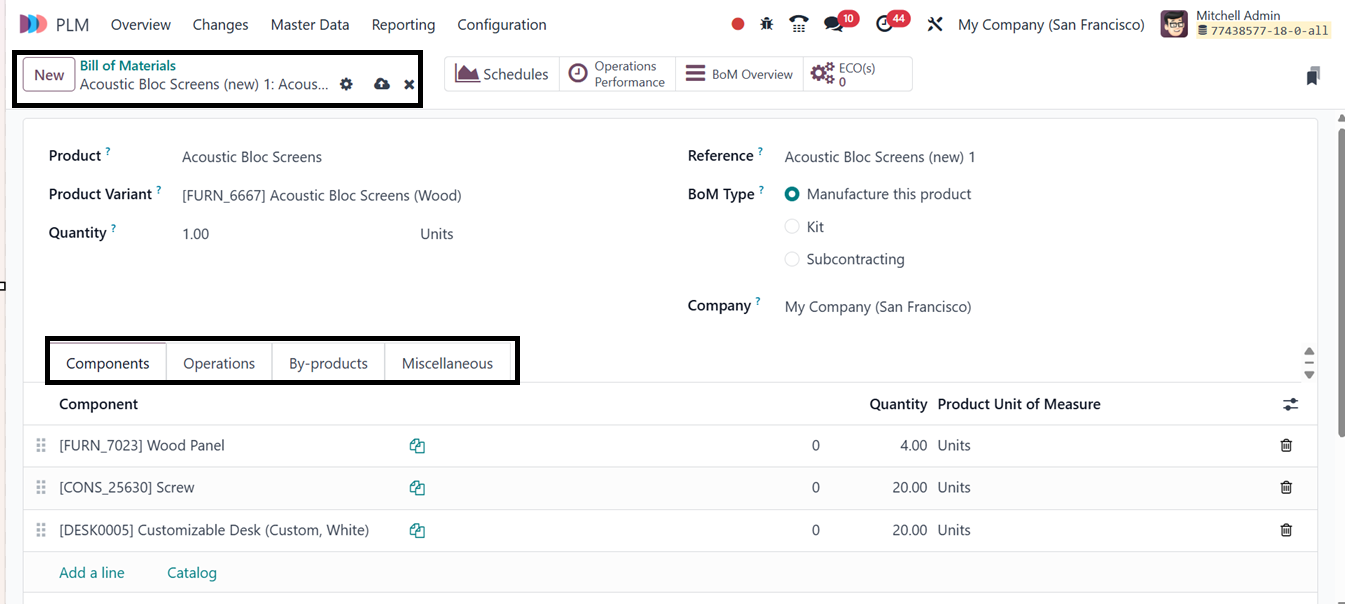

Click the New button to generate a new Bill of Materials (BoM) in

Odoo. Next, fill in the appropriate areas with the necessary

information, including Product, Product Variant, Reference, and

Quantity. You may establish three different kinds of BoMs using

Odoo: Subcontracting, Kit, and Manufacture This Product. Choosing a

Manufacturer The BoM for in-house production is indicated by this

product. By selecting Kit, the parts will not be created but will

instead be sold as a set. A designated subcontractor is instructed

to use this BoM for manufacturing using the Subcontracting option.

Every kind operates differently and is handled as such.

Click the ‘Add a line’ under the Components tab and enter the needed

quantities to establish a Bill of Materials for product manufacture.

Next, provide the work center procedures required to finish

production under the Operations tab.

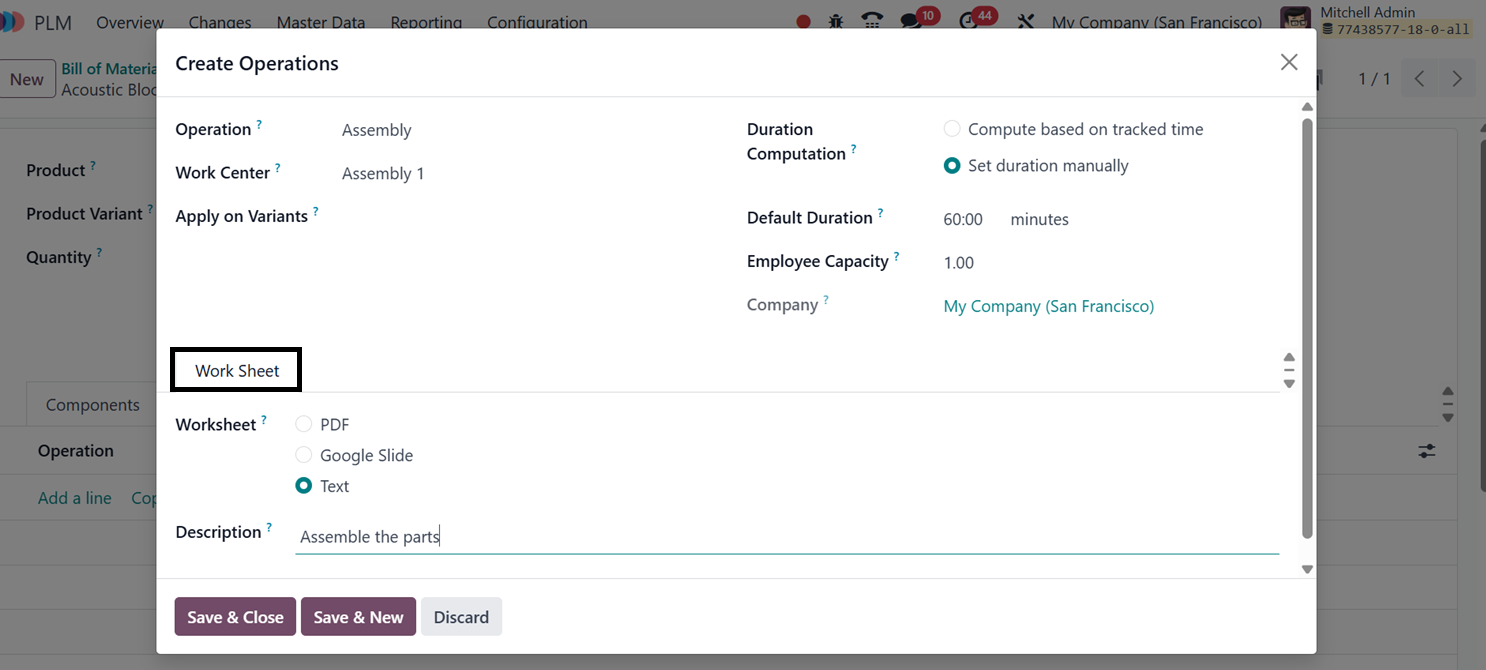

You can name the Operation and choose the right Work Center and

define the operation to be carried out in the pop-up box that

appears when you add an operation in Odoo. If product variations are

affected by the operation, you may add them in the Apply on

Variations area to ensure consistency across different variants.

Next, set up the Duration Computation by either manually determining

the duration of the process or allowing Odoo to calculate it using

the time that has been monitored, with the Default Duration being

shown automatically. The number of personnel required for the

operation can be specified in the Employee Capacity column.

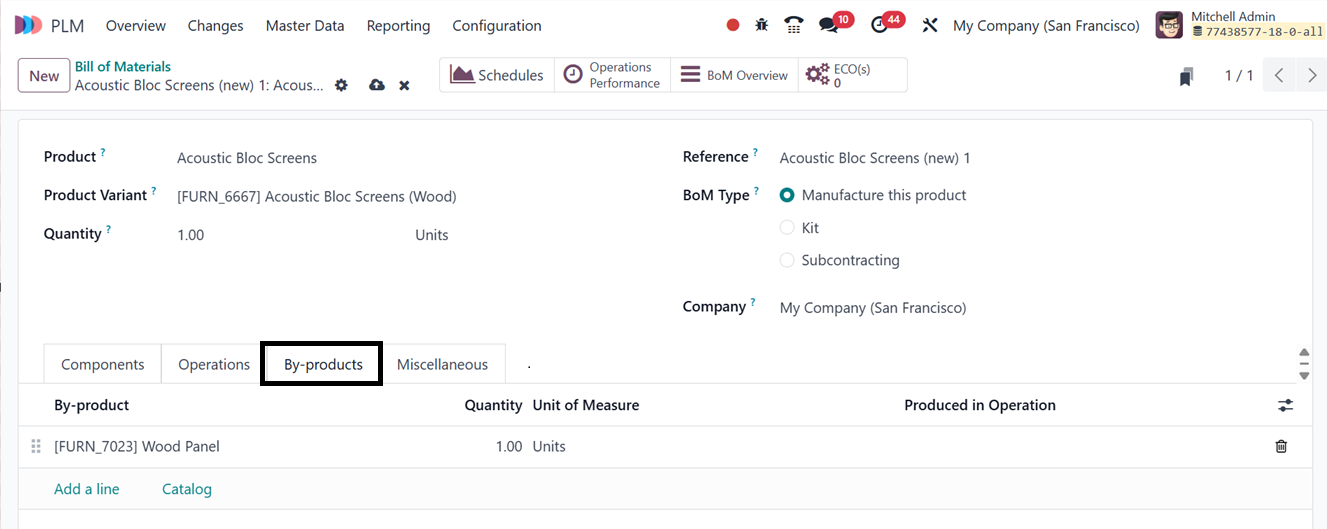

In the ‘By-products’ tab, the related by-products of the primary

product can be added using the ‘Add a line’ button.

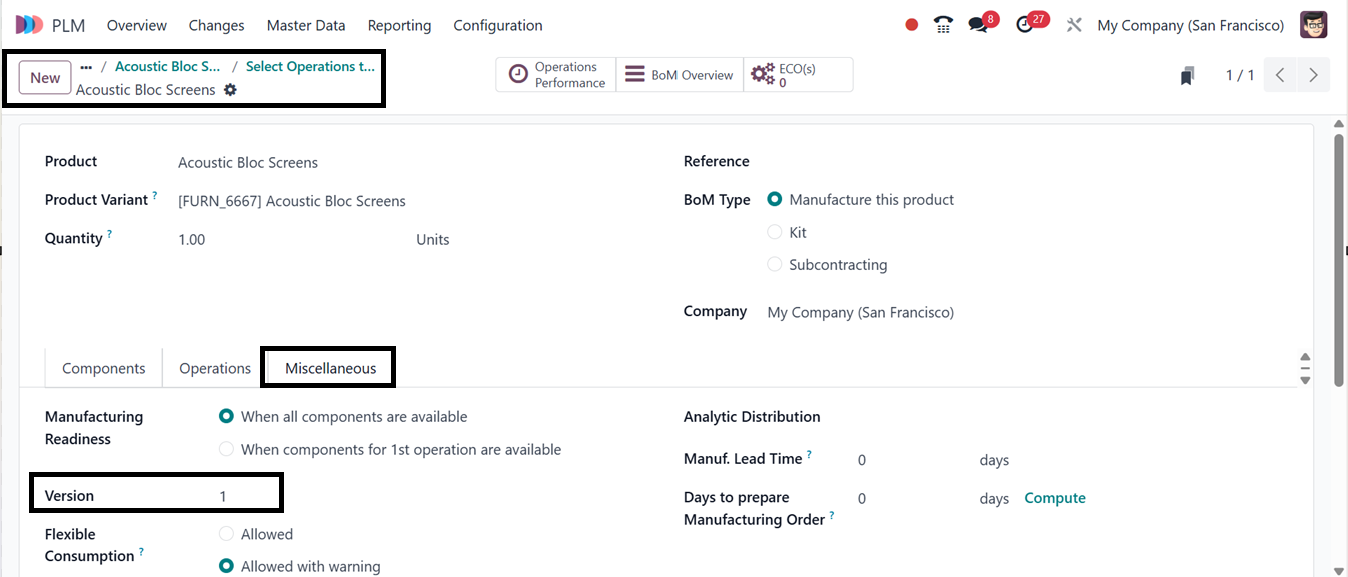

You may modify the sequence of operations in the BoM by turning on

the Operation Dependencies button located under the Miscellaneous

tab. You may choose the order in which work orders are finished by

turning on the Work Order Dependencies option from the Settings

menu. When enabled, a Blocked By field will appear in the Operation

window, allowing you to define dependencies for additional

activities. Furthermore, Manufacturing Lead Time is the average

amount of time needed to manufacture a product, taking component

lead times into account in multi-BoM scenarios. This aids in

deciding when to send component parts for items that are

subcontracted. The Days Needed to Prepare Manufacturing Orders

setting ensures that orders are made ahead of time, giving

sufficient time for the replenishment of components or semi-finished

goods.

You can specify the start date of production in the Manufacturing

Readiness box located under the Miscellaneous tab. Select "When

components for the 1st operation are available" to start with enough

materials for the first step, or "When all components are available"

to start only when all parts are ready.

The "Version" field in the ‘Miscellaneous’ tab represents the

engineering version or revision level of a product, tracking changes

in design or specifications over time. It distinguishes between

different iterations of the same item, ensuring correct version

usage across manufacturing, purchasing, and inventory operations.

The versioning system supports engineering change orders (ECOs) and

version-controlled updates, allowing for easier tracking of current

stock or use of a product's version due to design improvements or

material changes.

When an Engineering Change Order (ECO) is applied in the PLM module

of Odoo 18, the Bill of Materials (BoM) version will be updated.

Users can change components or routings in a BoM using the ECO, and

Odoo will either update the current BoM or generate a new one based

on the configuration. This updated version may be seen in the

product's inventory data as well as on the BoM form in its ‘ECO(s)’

smart button. By preserving prior versions for reference, versioning

guarantees the traceability of changes. The revised BoM may

optionally go into effect on a given future date.

With the choices of Blocked, Allowed, or Allowed with Warning,

Flexible Consumption establishes whether you are permitted to

utilize more or less components than those listed in the BoM. To

specify the sequence of BoM actions, you may also activate Operation

Dependencies.

You may define the manufacturing process for the product and the

project that it is linked to using the Routing and Project options.

The Version in a Bill of Materials (BoM) is a revision control

system that tracks changes, ensures accuracy, and manages updates

through Engineering Change Orders (ECOs) for approval, effective

dates, and seamless transitions in manufacturing.

After the Bill of Materials (BoM) has been configured up, a

Manufacturing Order for the relevant product may be made using it.

Routing-related work order duration statistics are provided by the

Operations Performance Smart button feature. Use the BoM Overview

smart button to examine all of the BoM's important information,

including Product, Operations, Quantity, Free to Use/On Hand,

Availability, Lead Time, Route, BoM Cost, and Product Cost.

The Schedules smart button will provide the details of all the

schedules related with this product and the ECO(s) smart button will

show the details of all Engineering changed orders.

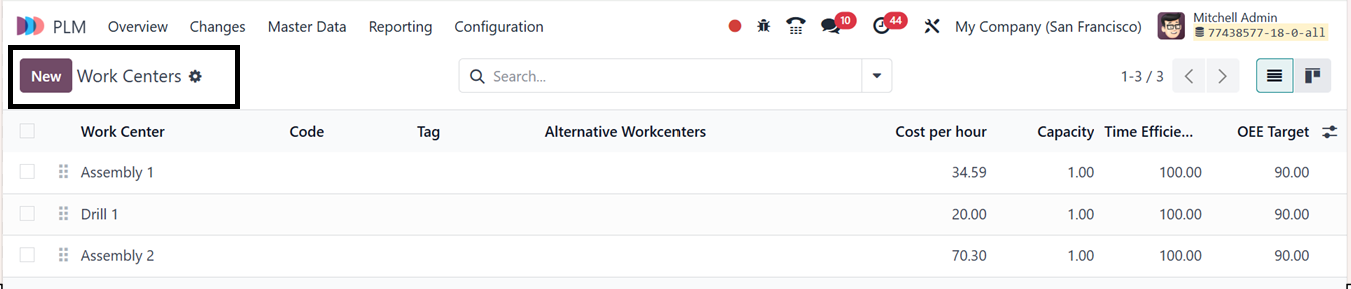

3.3 Work Centers

Work Centers in Odoo 18's PLM (Product Lifecycle Management) module

stand in for the actual buildings or equipment used for

manufacturing processes. These facilities provide resource

management, workflow optimization, and production efficiency

tracking. The dashboard provides the details of Work Center, Code,

Tag, Alternative Workcenters, Cost per hour, Capacity, Time

efficiency and OEE Target as illustrated in the screenshot below.

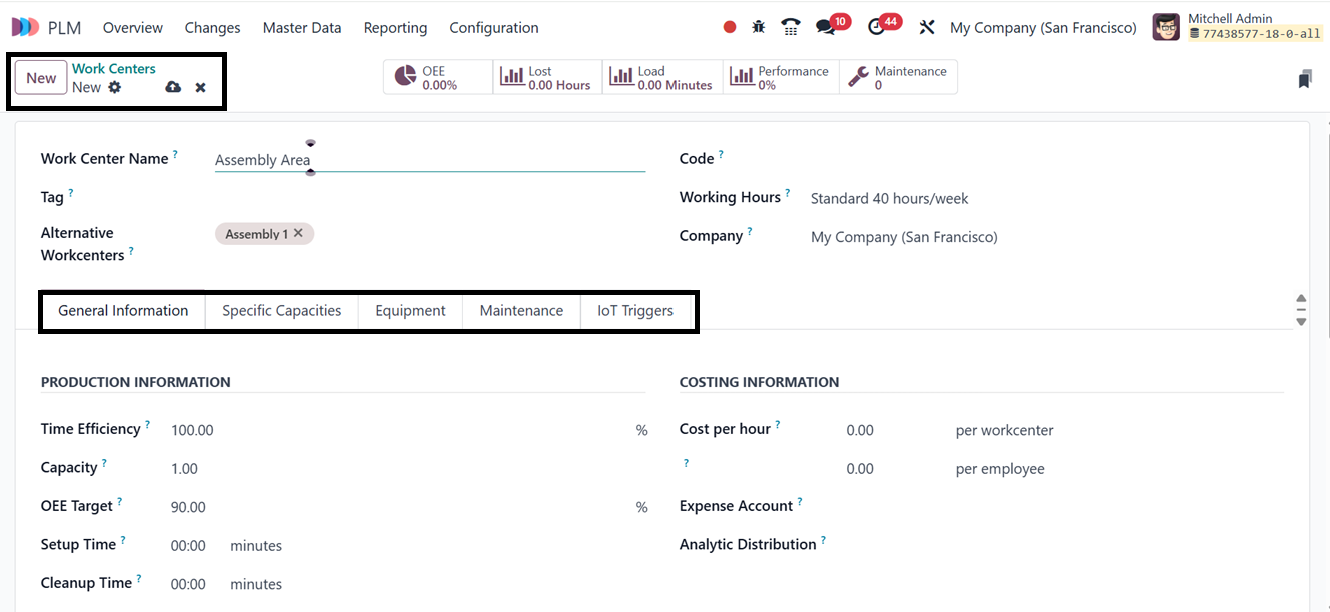

Click the "New" button to bring up the configuration form for a new

Work Center in Odoo. Provide an alternative work center, code,

working hours, and company in the "Workcenter Name" section. You can

also include pertinent tags. For a thorough configuration, the form

has sections for General Information, Specific Capacities,

Equipment, and IoT Triggers.

- Production Information, Operations, and Costing, including OEE

Target, Capacity, and Time Efficiency, may be defined under the

General Information tab. While the Costing Information part

allows you to link an Analytic Account and define Cost per Hour,

the Operations portion allows you to limit access to select

staff.

- While the Equipment tab includes allocated equipment and permits

maintenance tracking.

- The Specific Capacities tab allows determining work center

capacity per product. The "Add a line" button can be used to add

new equipment.

- Automation is made possible by connecting external devices to

the work center via the IoT Triggers tab. In a specific form,

users may change IoT settings and specify device ID, Key, and

Action.

- The Maintenance Tab allows you to determine the maintenance team

and technician details.

After saving the details, the Work center efficiency is revealed via

smart buttons such as OEE, Lost, Loads, Performance and Maintenance.

Performance is monitored by the OEE Smart Tab according to cost,

duration, and loss factors. Productivity losses brought on by things

like equipment breakdown and inefficiencies are recorded by the Lost

Smart Tab.

The "Performance" smart tab analyzes Work Center Performance based on

Work Orders. The Work Center Loads display real-time work order

status compared to the estimated time. The Maintenance tab provides

details of all maintenance activities within the Work Center.

After saving all the work center details, you can utilize them for

the future PLM as well as manufacturing operations.