2. Quality Control

2.1 Control Points

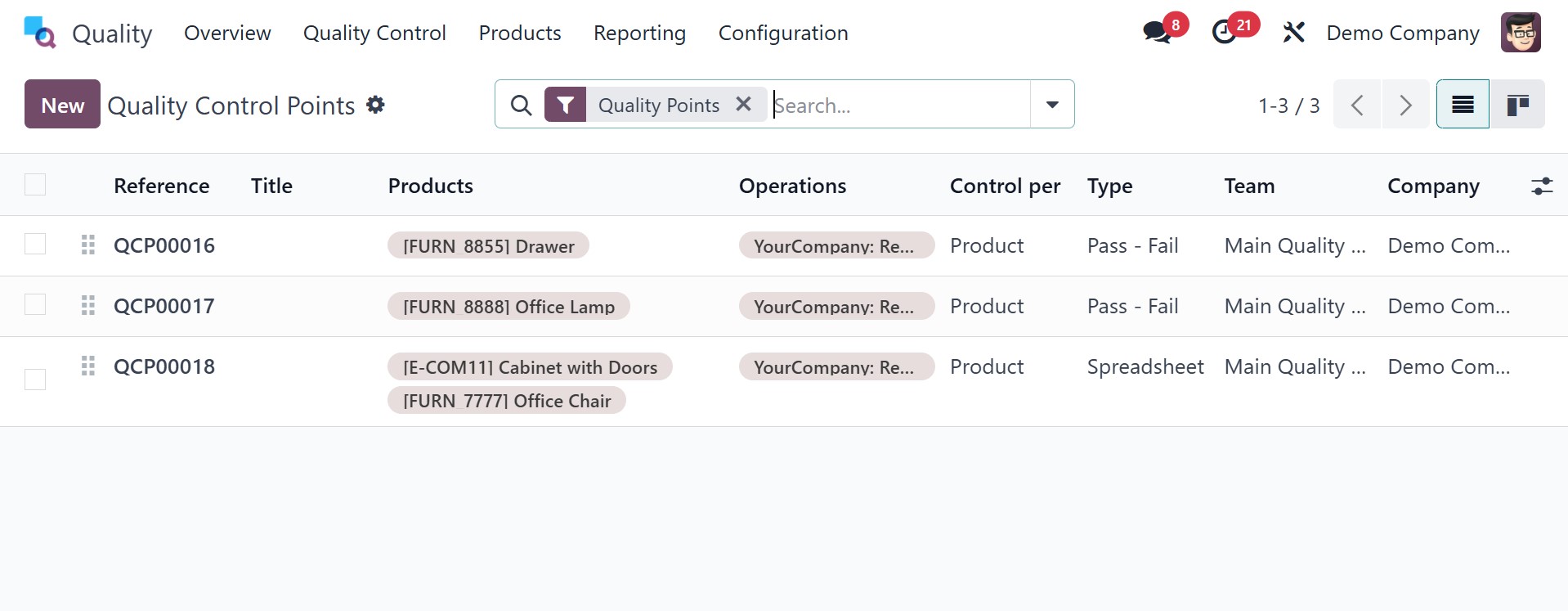

Quality control points assist in

reaching the phases where an

item must be inspected.

Identifying the methods for

assessing the quality of a

product is easy. Select the

Control Points menu from the

Quality Control tab to obtain

these standards. The details

of each quality control

point, such as Reference,

Products, Control Per, Team,

Title, Company, Type, etc.,

are defined in the List view

of the Quality Control Points

window. By choosing a Quality

Control point from the list,

you will be provided with

full details regarding that

specific point. To build

brand-new Quality Control

Points, click the New button

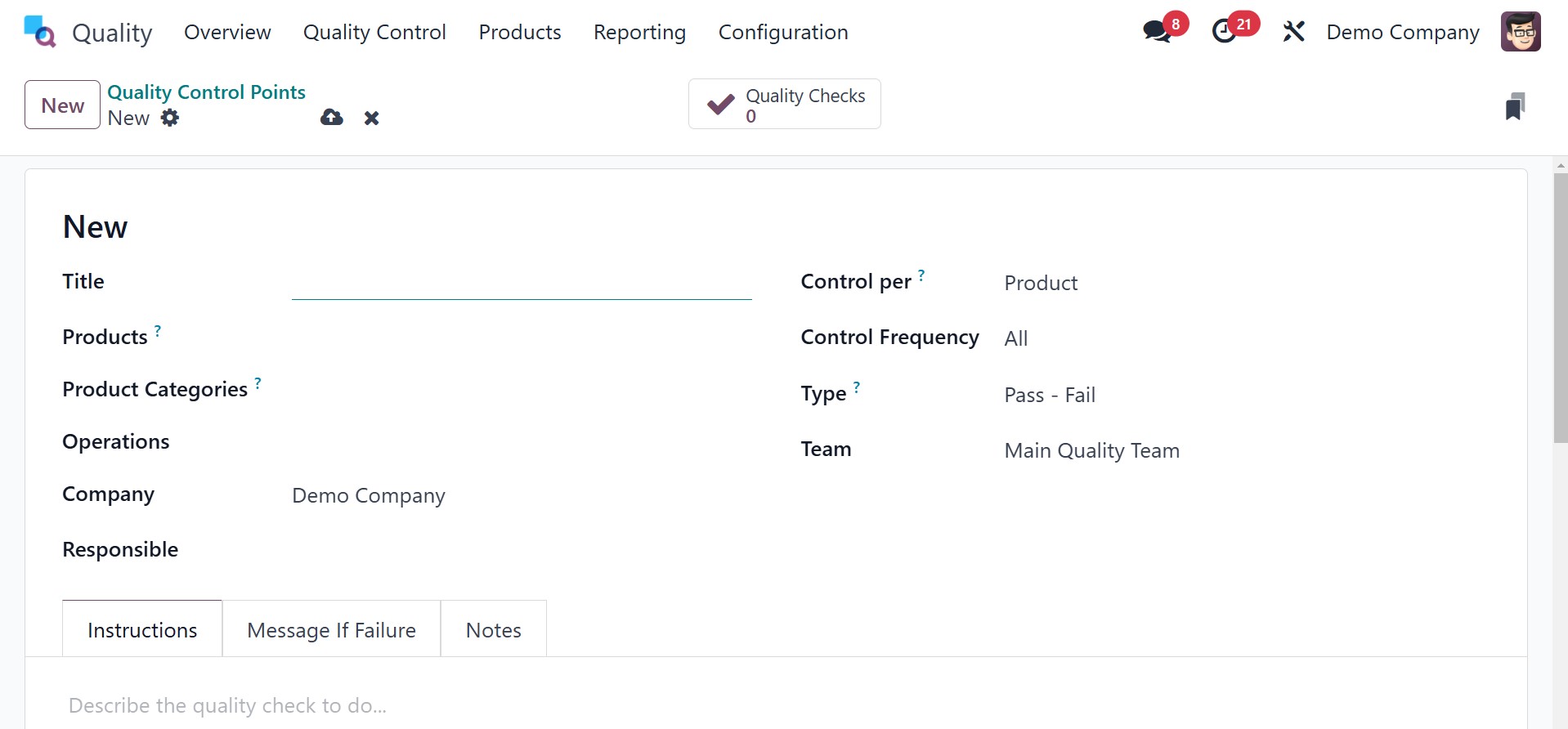

You can browse through a number

of options that have to do

with the open screen. In the

Title field, type in the name

that was selected for the

quality control point. The

products that are used on the

quality control point can

then be chosen in the

Products field. Other Quality

Control Points, items that

fall under the product

category of your choice,

trigger quality points. In

the Product Categories field,

users can cite the product

category that is applicable

to some products.

You can select the stage where

quality is to be checked in

the Operations field. Next,

in the Company field, choose

the company that is linked

with your generating quality

control point. Also, you can

define the quality check

request for every field in

the Control according to the

Product, Operation, and

Quantity.

If you choose the Operation

option under Control per

field, you can request a

quality check at the

operation level. If you

choose the Product option,

you can retrieve the quality

check based on the product.

Choose the Quantity option

under Control per field to

request a quality check on

the quantity of a recently

registered product.

The Control Frequency field

enables users to define

particular intervals for

quality inspections.

Intervals can be received

periodically, All, or

randomly.

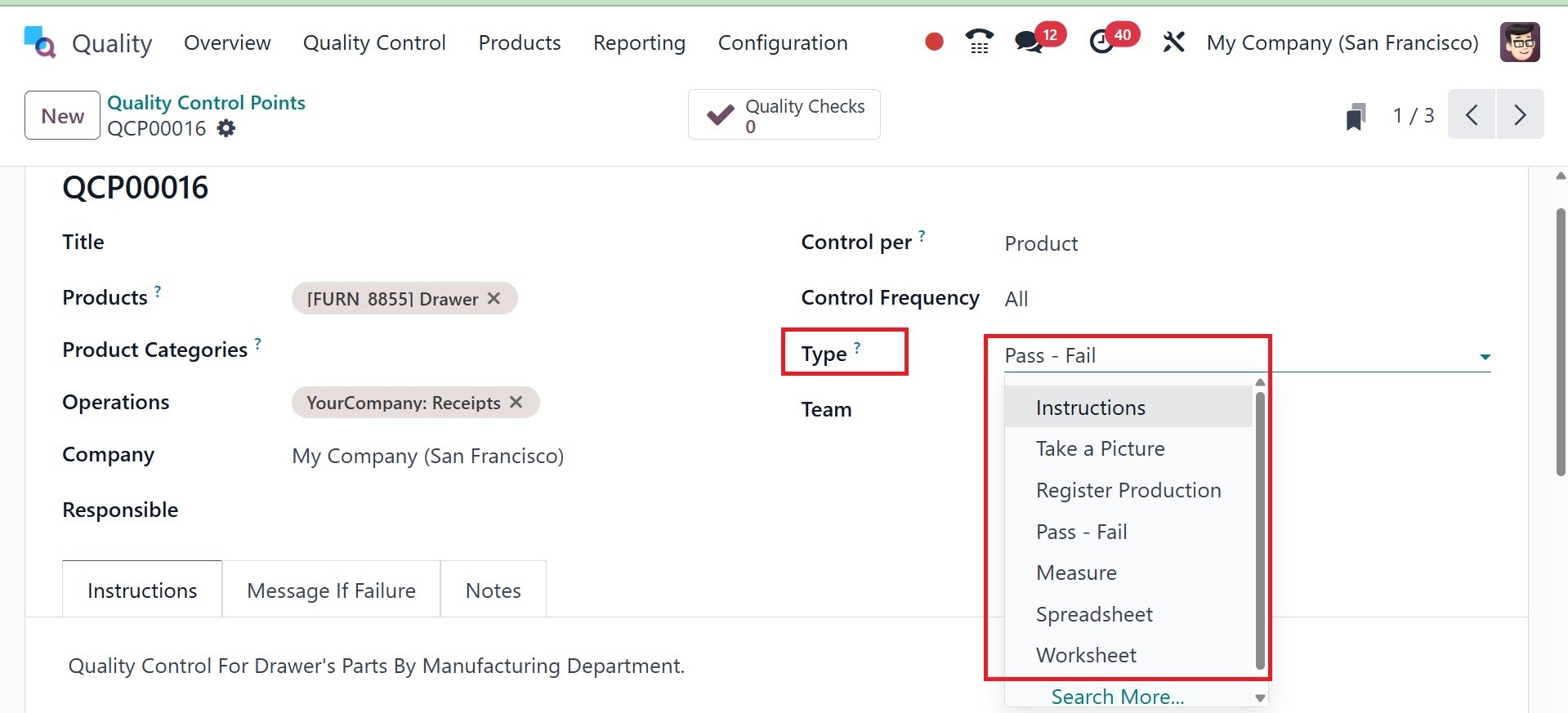

The Type option enables us to

define the category of the

quality control point. It is

classified as instructions,

take a picture, register

production, pass-fail,

measure, spreadsheet, and

worksheet. You can apply the

above types when performing a

quality check.

When doing quality checking, say,

you may check pass and fail

options when you put in

Pass-Fail in the Type field.

Through this, you can

identify if a product will be

a pass or a fail.

Let us look at each type in

detail.

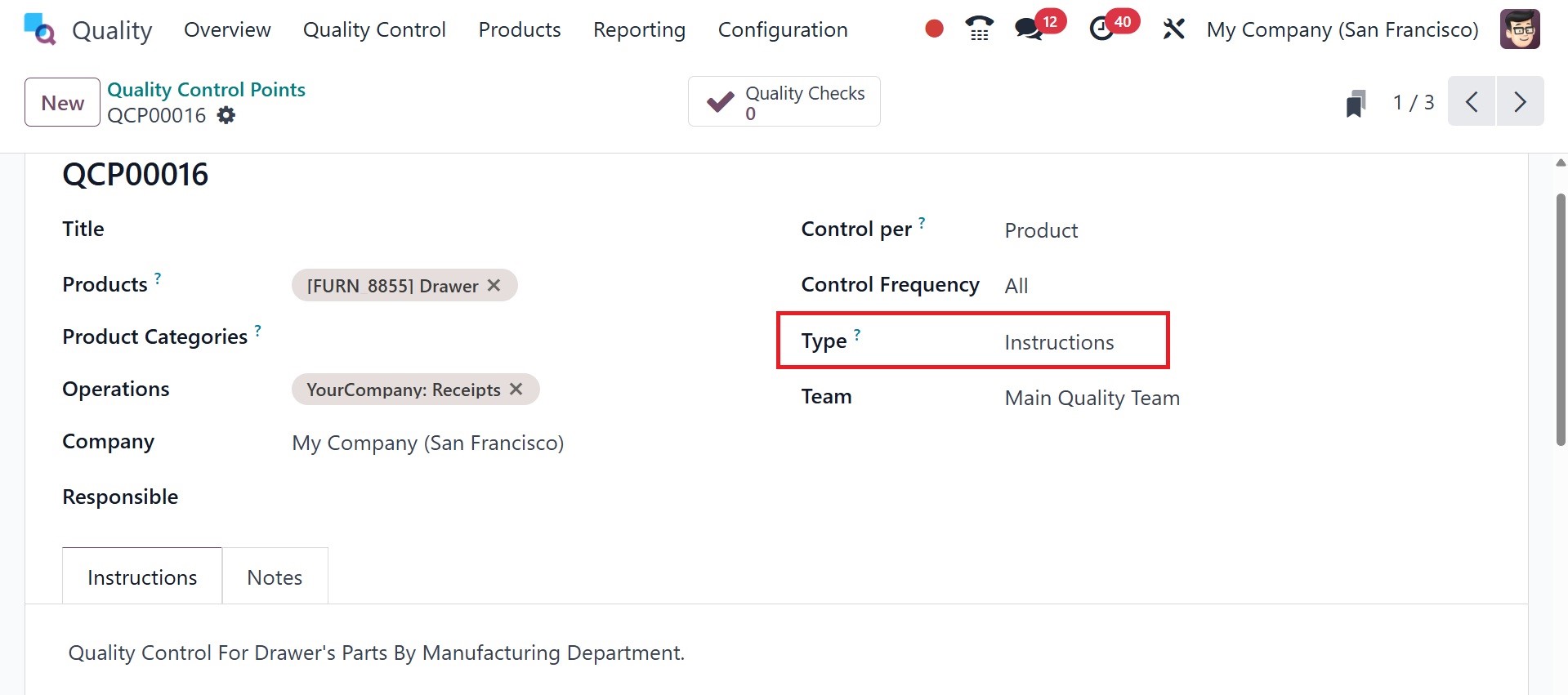

Instructions: During the

manufacturing process, Odoo

18's instructions quality

checks make sure that

operators follow established

instructions or guidelines.

Businesses can preserve

precision and consistency in

manufacturing operations by

implementing standardized

procedures. Errors are

avoided, variability is

decreased, and items are made

in compliance with standards

thanks to these inspections.

There are several approaches to

handling quality checks for

instructions. A quality check

can be done immediately

within a work order,

inventory, or manufacturing

order if it is associated

with that order. As an

alternative, the check can be

processed straight from its

own page.

Select a quality check and

complete the check by

following the given

instructions.

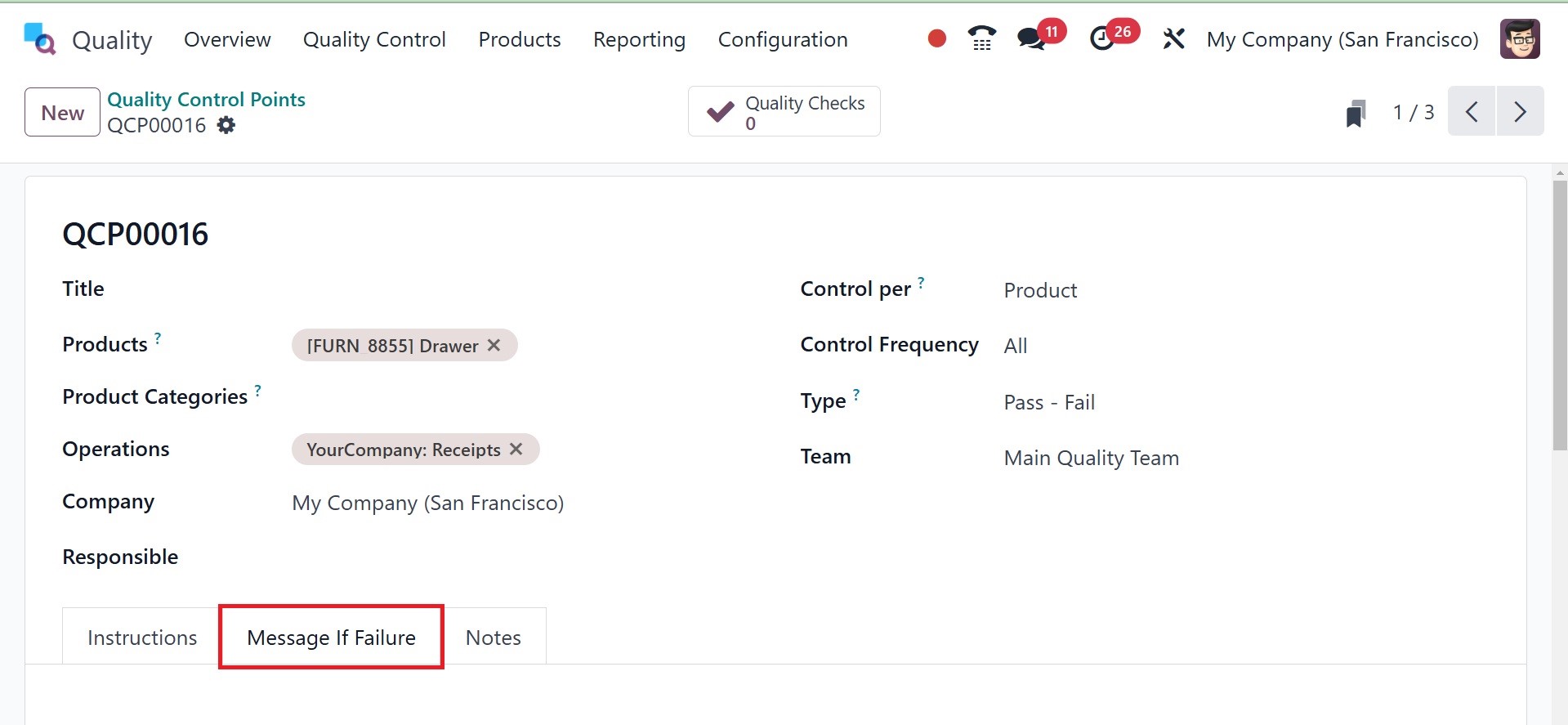

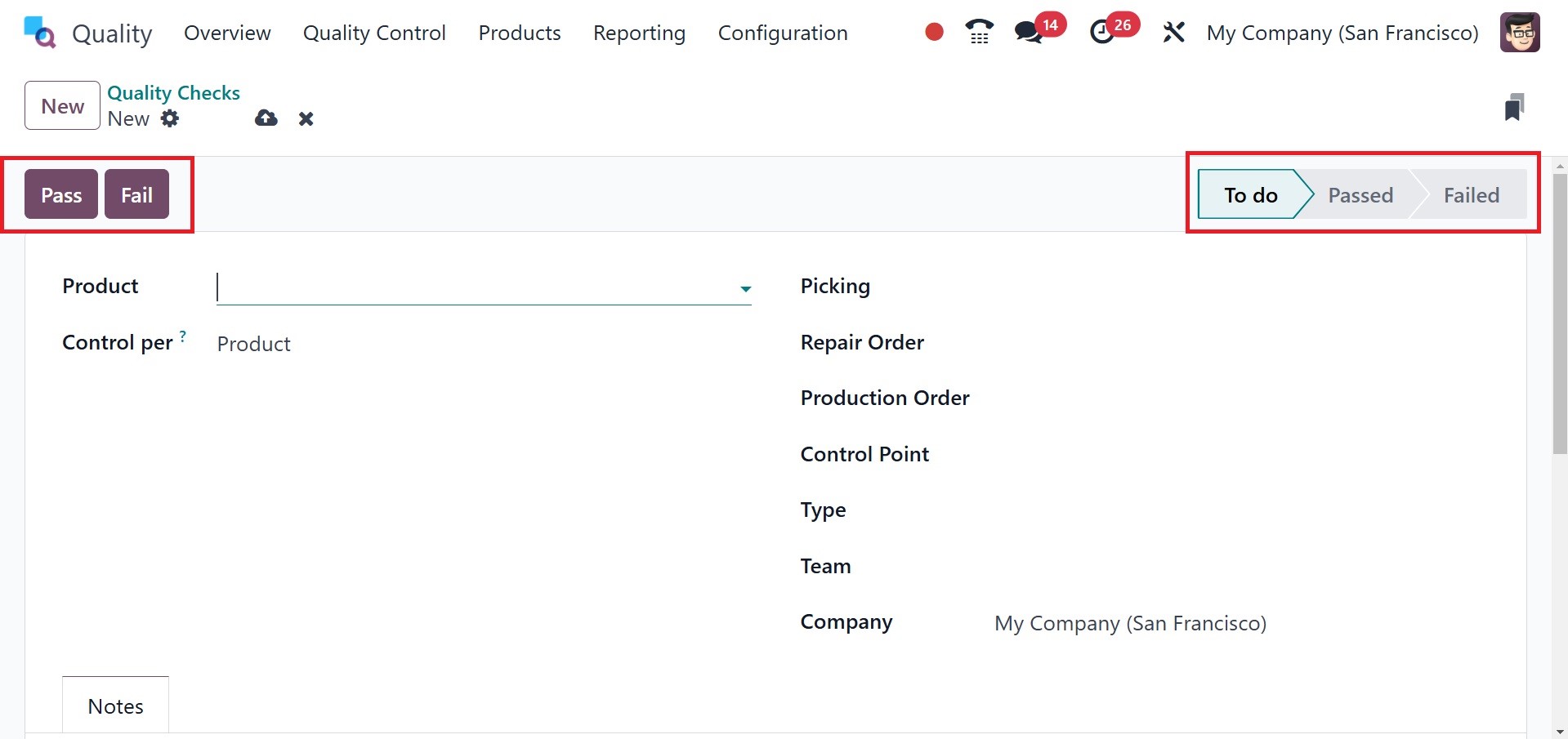

Pass-Fail: In Odoo 18, pass-fail

quality checks verify if a

product satisfies predefined

standards or requirements. A

product's success or failure

is determined by comparing it

to predetermined quality

standards. Businesses can

find non-conformities and

take immediate corrective

action by using pass-fail

tests, which offer a rapid

and simple method of

assessing product quality.

Pass-fail checks include a text

box that allows the developer

to specify particular

requirements necessary for a

product to pass the test.

There are two main ways to

create pass-fail quality

checks. The first option is

to manually build a single

check. Second, it is possible

to set up a Quality Control

Plan (QCP) to produce

inspections automatically at

predetermined intervals.

Use these procedures to start a

single Pass-Fail quality

check:

1. Click "New" after selecting

Quality > Quality Control >

Quality Checks.

2. Select the Pass-Fail quality

check type from the Type

drop-down menu.

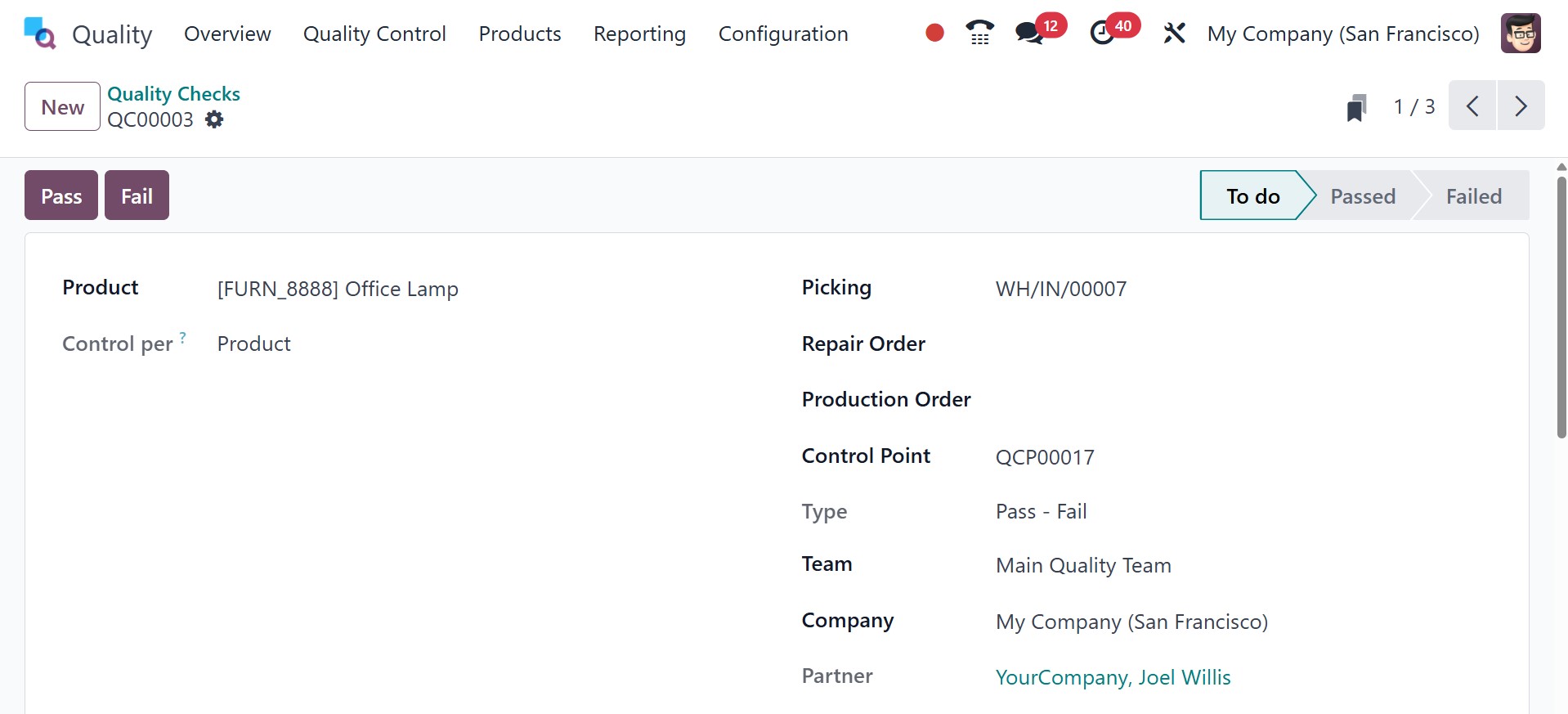

Then, you will get the pass and

fail options, as shown in the

image below.

3. From the Team drop-down menu,

choose the quality team

responsible for managing the

check.

4. Go to the Notes tab and

include instructions on how

to carry out the quality

check and list the

requirements that must be met

for the check to be

considered successful.

Click the "Pass" button in the

upper-left corner of the page

if the requirements are met.

On the other hand, select the

"Fail" button if the

requirements are not

fulfilled. Use these

procedures to create a

Quality Control Plan (QCP)

that creates Pass-Fail

quality tests automatically:

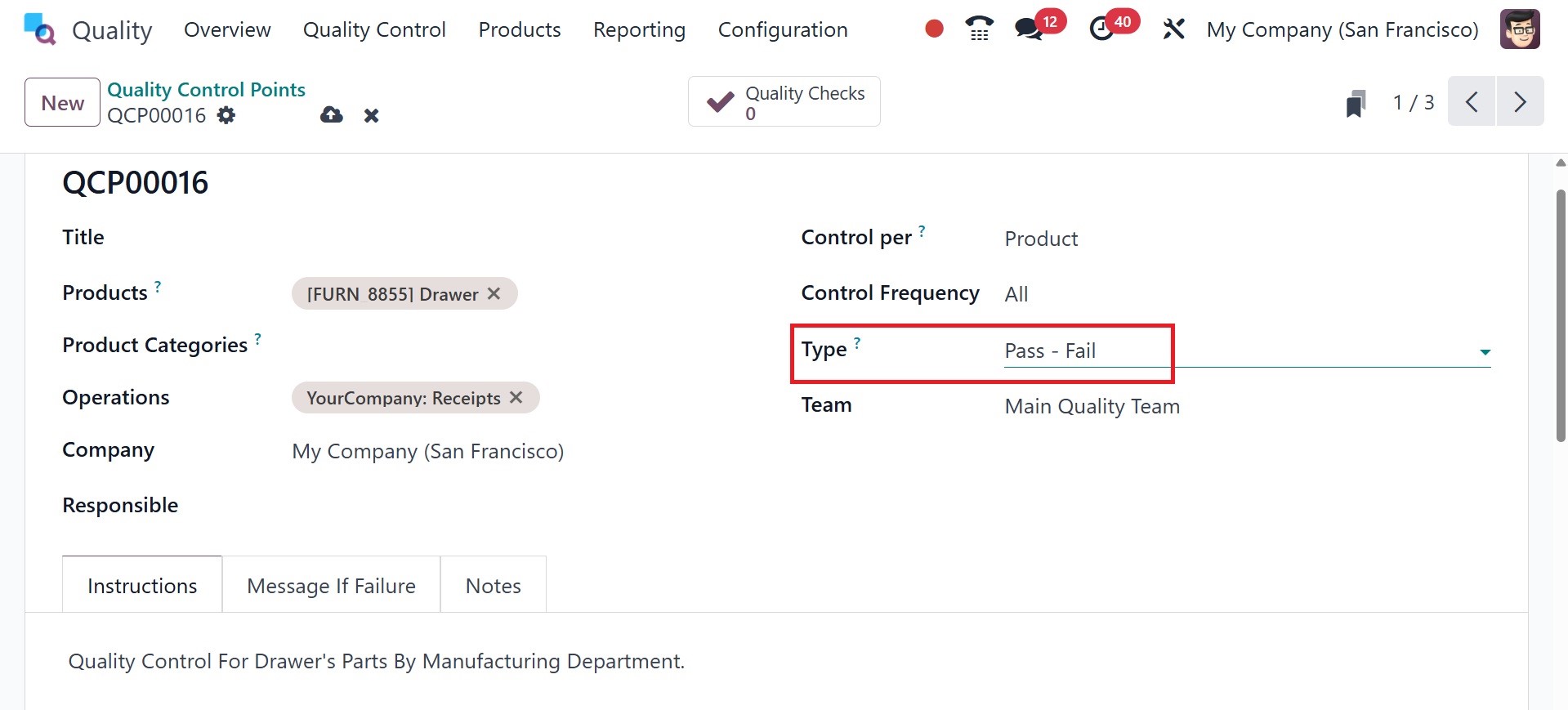

1. Click "New" after selecting

Quality > Quality Control >

Control Points.

2. Select the Pass-Fail quality

check type from the Type

drop-down menu.

3. From the Team drop-down field,

choose the quality team

assigned to manage the checks

produced by the QCP.

4. Type instructions on how to

perform the quality check and

what criteria must be met for

the check to be considered

successful in the

Instructions text area.

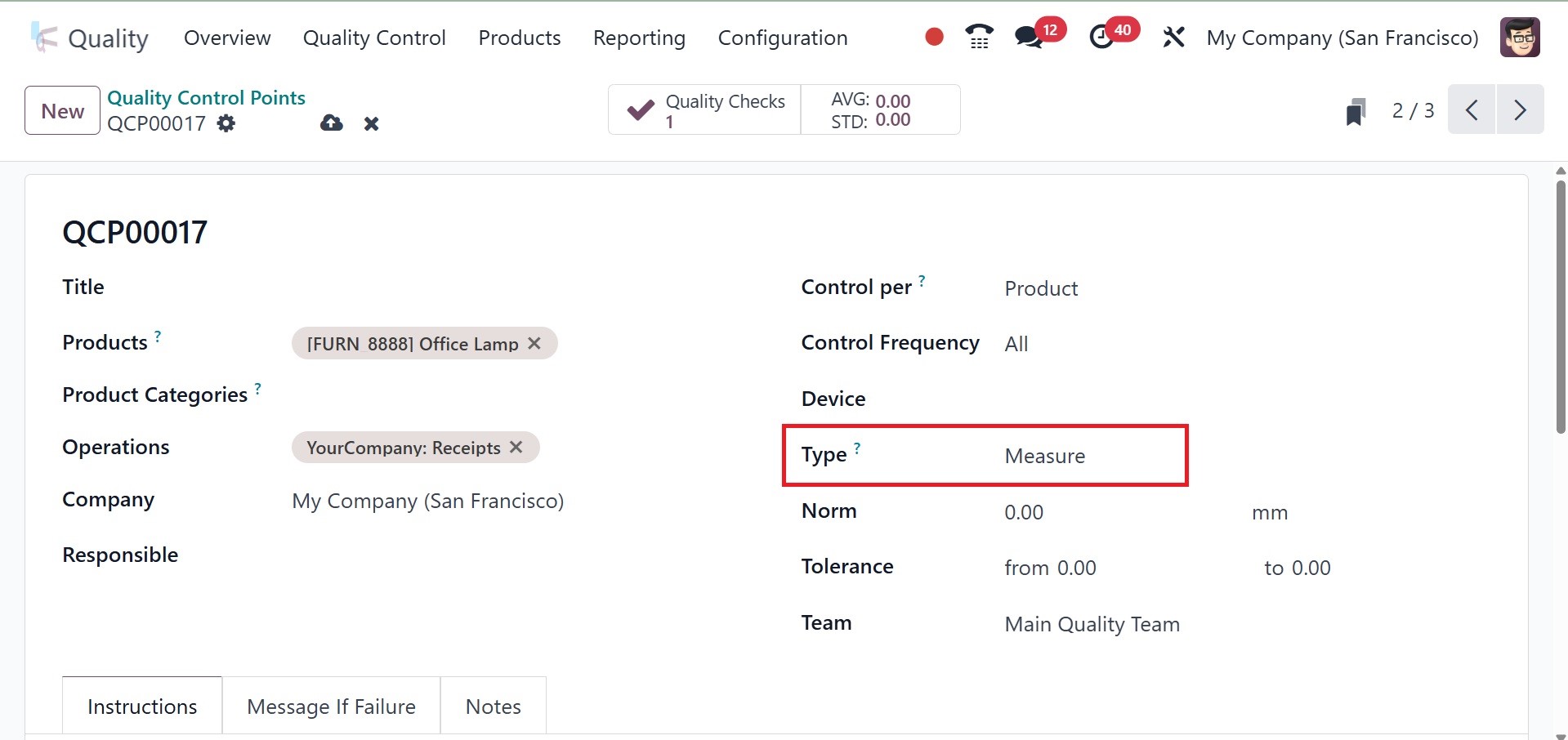

Measure: Measurable evaluations

of product characteristics

including weight, volume, and

dimensions are part of

measure quality checks.

Businesses may specify

precise measurement standards

and tolerances for any

product attribute in Odoo 18.

Products are evaluated in

relation to these standards

during production to make

sure they fulfill the

necessary requirements.

Measure quality checks give

firms reliable measures that

enable them to confirm the

quality of their products and

their compliance with

requirements.

The recorded measurement must be

within a given tolerance

range of a norm value in

order for the quality check

to be successful. Measure

quality checks can be created

in two primary ways. Making a

single check by hand is one

approach. As an alternative,

checks can be automatically

generated at predetermined

intervals using a Quality

Control Plan (QCP).

Use these procedures to produce a

single Measure quality check:

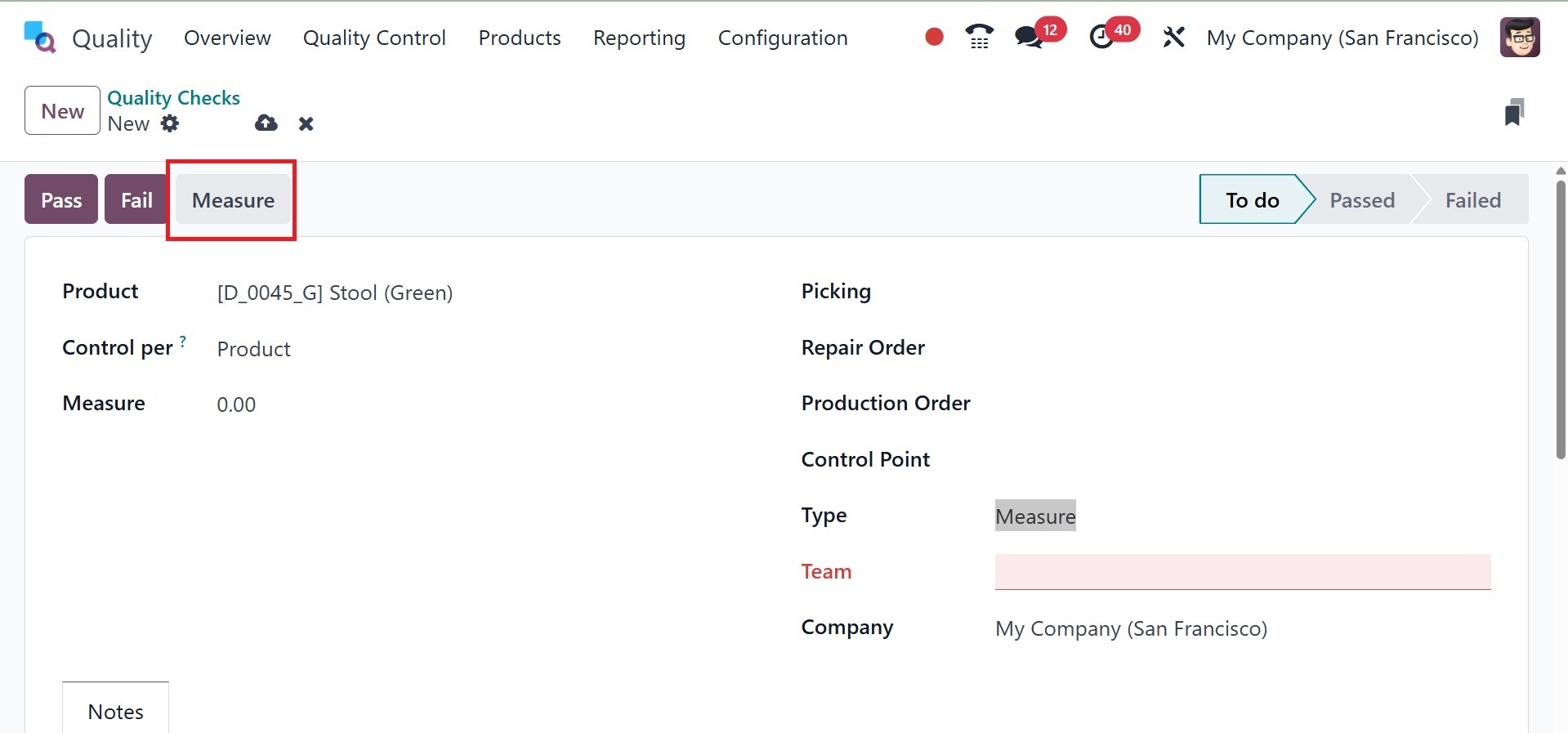

1. Click "New" after selecting

Quality > Quality Control >

Quality Checks.

2. Select the Measure quality

check type from the Type

drop-down menu.

For quality checks, Norm and

Tolerance are used to specify

acceptable measurement

ranges, particularly for

measure-type controls like

weight, temperature, and

dimensions.It is essential

for maintaining constant

product quality and

minimizing flaws in

manufacturing, receiving, or

delivery.

The ideal or target value

anticipated for a certain

quality metric is known as

the Norm. It specifies what

the ideal measurement is. The

permissible range of

deviations from the norm is

defined by tolerance.

Then, you will get the measure

option, as in the image

below.

3. From the Team drop-down menu,

choose the quality team

responsible for overseeing

the check.

4. Select the Notes tab and fill

in the Instructions text area

with instructions on how to

take the measurement.

After obtaining the measurement,

put the value in the quality

check form's Measure area.

Click "Pass" or "Fail" in the

upper-left corner of the

check to manually determine

if it passes or fails.

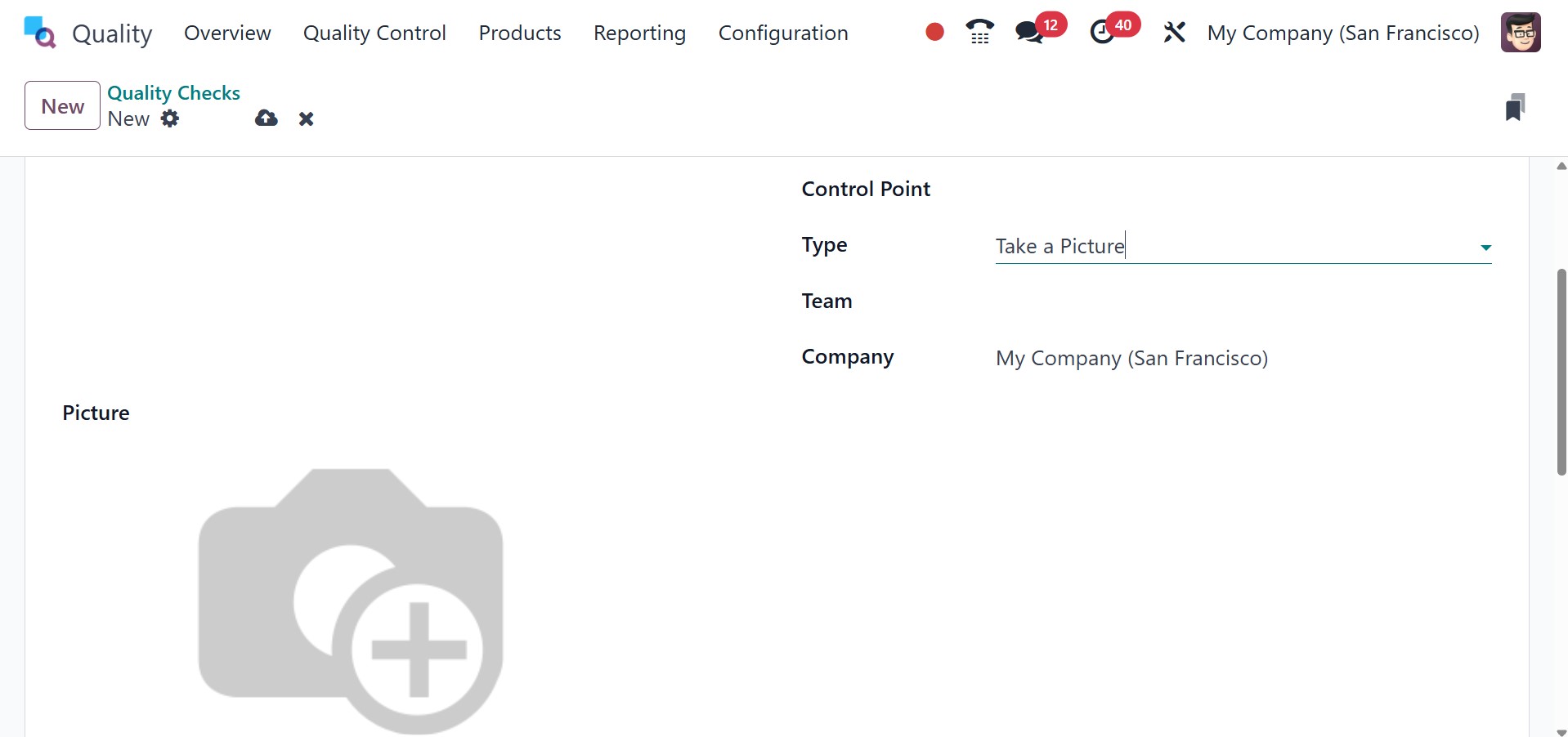

Take a Picture: In Odoo 18,

quality checks entail taking

pictures of goods or

manufacturing procedures for

visual examination.

Businesses can visually

evaluate product quality and

spot flaws or irregularities

by including picture capture

technology into quality

inspections. Problems like

surface flaws,

irregularities, or departures

from quality norms can be

found in images through

analysis. By offering visual

proof and enabling thorough

inspections, take-a-picture

quality checks improve

quality control initiatives.

In order for the quality team to

examine "Take a Picture"

checks, an image must be

attached to the check. There

are two ways to set up Take a

Picture quality checks:

either manually create each

check or set up a Quality

Control Plan (QCP) to

generate checks automatically

at predetermined intervals.

To produce a single Do a picture

quality check by doing the

following:

1. Click "New" after selecting

Quality > Quality Control >

Quality Checks.

2. Select the Take a Picture

quality check type from the

Type drop-down menu.

3. From the Team drop-down menu,

choose the quality team

responsible for overseeing

the check.

4. Give instructions on how to

snap the photo in the Notes

tab's Instructions text

field.

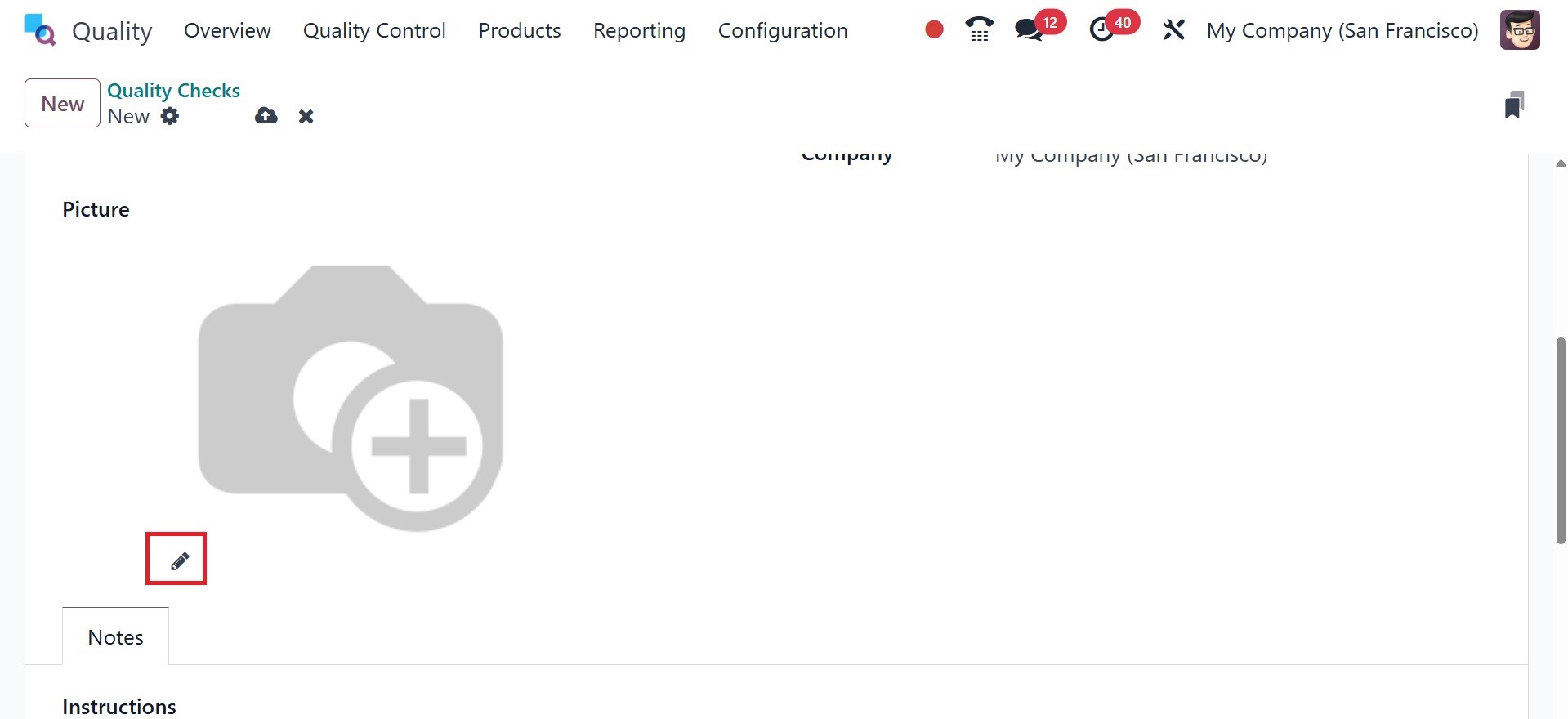

A "Take a Picture" quality check

can be completed on the

check's page by taking a

picture as directed. Make

sure the image is stored on

the computer, tablet, or

other device being used for

the quality check.

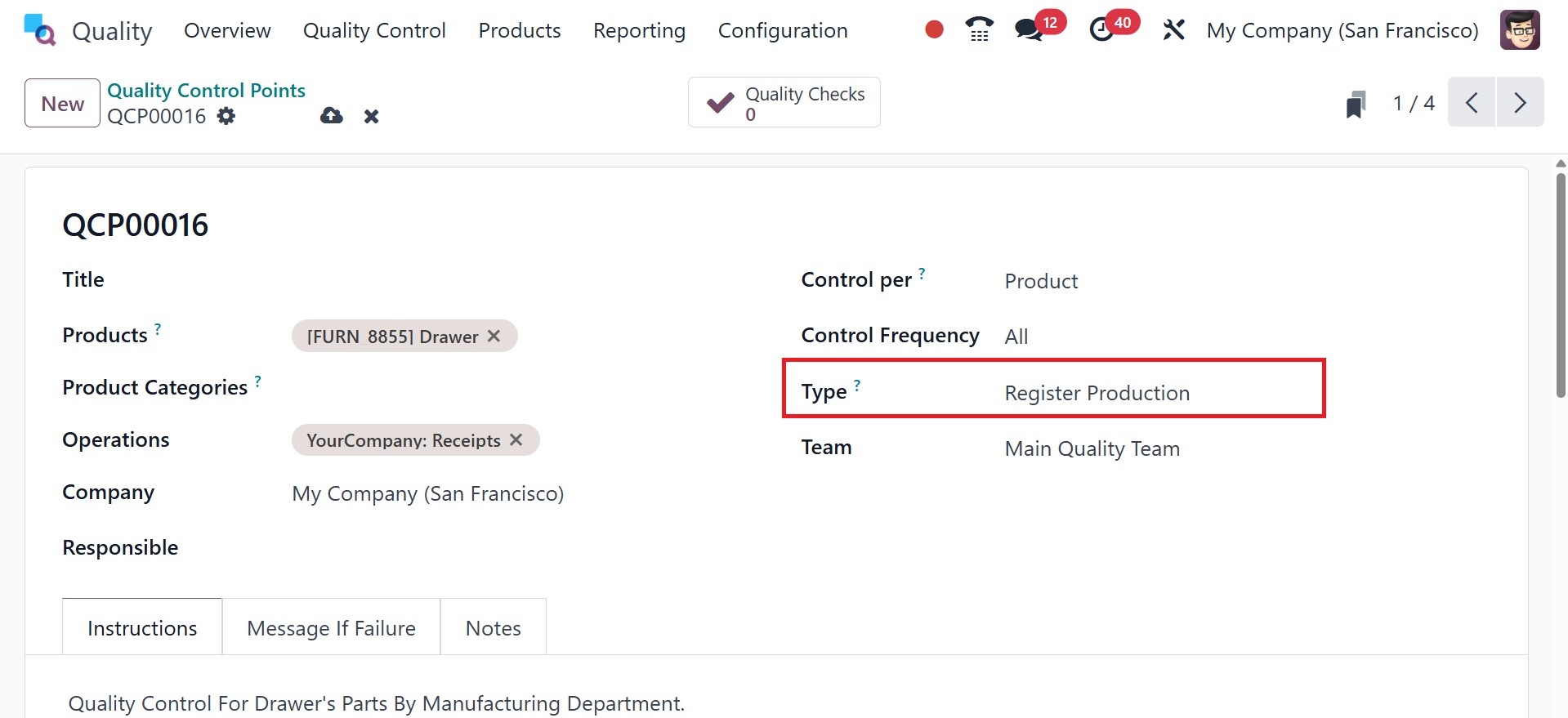

Register Production: Quality

checks that take place

throughout the production

process are referred to as

"Register Production" type

QCPs. These inspections

guarantee that goods fulfill

quality requirements

throughout the production

process.

Select the type as register

production fro the type, as

in the image below.

The type guarantees quality

throughout the whole

production process. Minimizes

flaws prior to final

assembly. Enhances adherence

to quality requirements.

Improves the traceability of

defective goods.

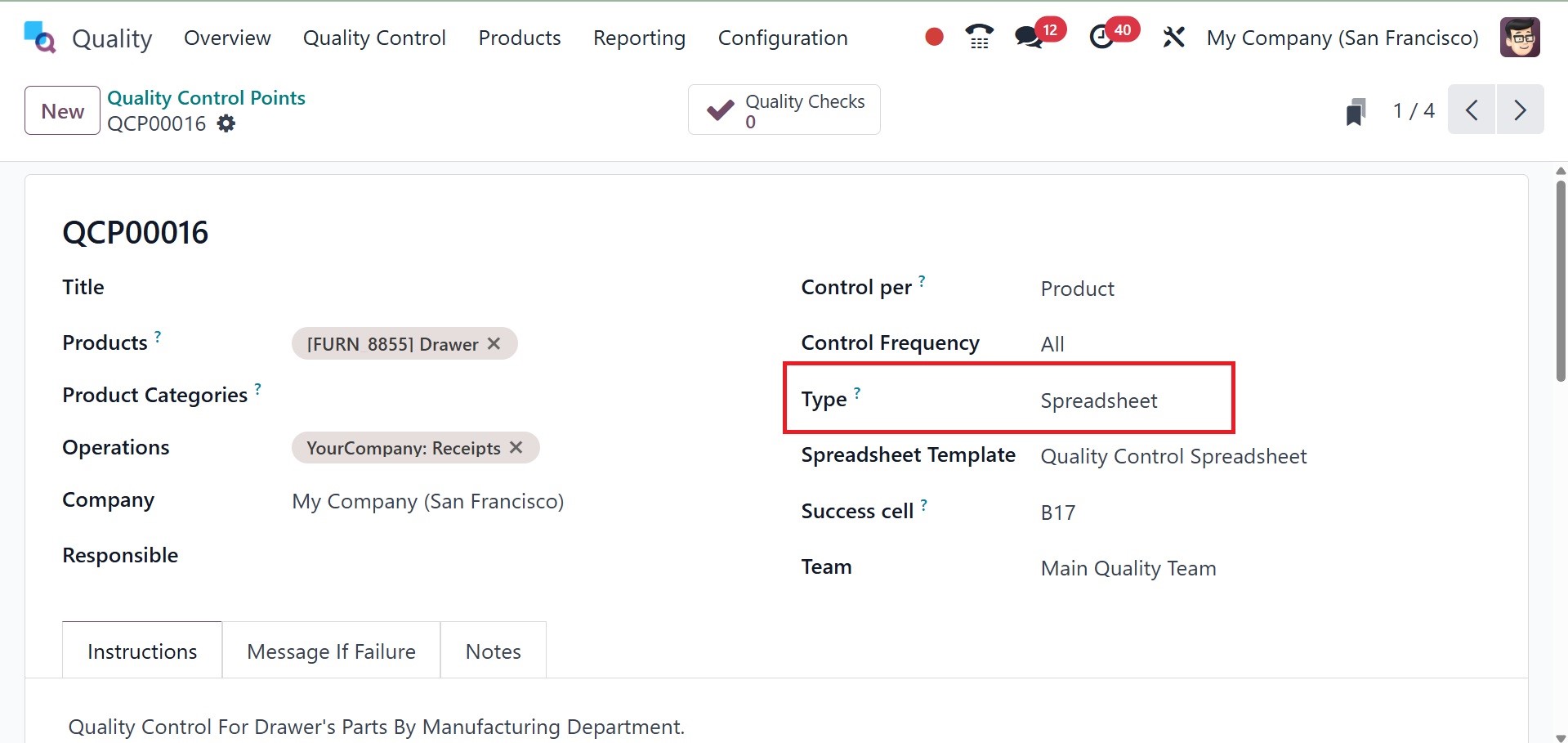

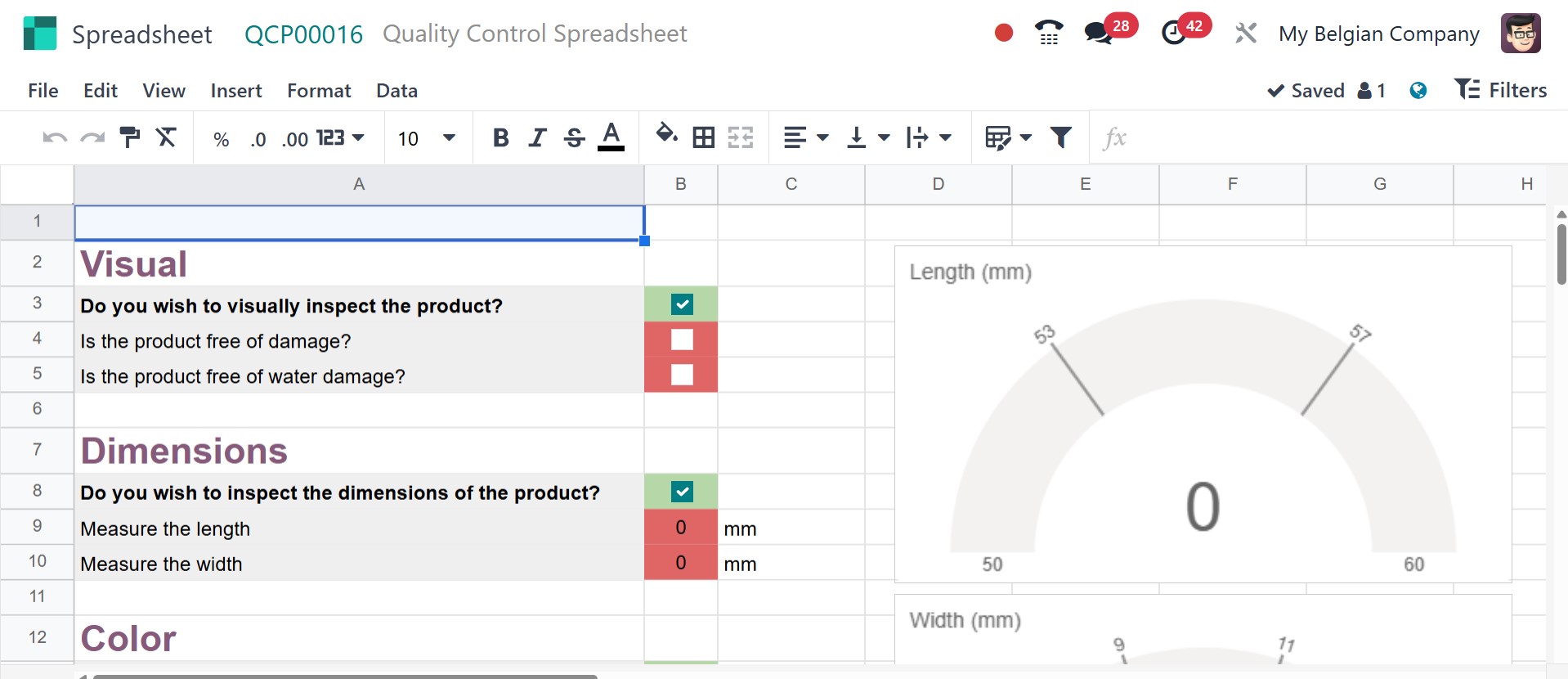

Spreadsheet: Users are able to

record several measurements

in a tabular (spreadsheet)

manner using the

"Spreadsheet" kind of Quality

Control Points. This is

helpful for intricate quality

checks that ask for the

systematic collection and

analysis of numerous data

points. Spreadsheet templates

allow you to quickly create

spreadsheets without starting

from scratch.

The layout, calculations, and

logic of a quality check are

specified in a bespoke

Excel-like document called a

spreadsheet template, which

is made with Odoo's

integrated spreadsheet

editor.

It is employed when a more

intricate quality control

procedure is required, one

that goes beyond simple

measurement checks or yes/no

or pass/fail assessments.

And the success cell option is a

specific cell reference in

the spreadsheet that tells

Odoo where to look for the

pass/fail result.

On selecting the type as

spreadsheet, you will get the

spreadsheet template option

and a success cell. On

providing the spreadsheet,

you can move to the quality

control spreadsheet using the

internal link, and the page

will be, as in the image

below.

Perfect for businesses that

depend on precision, such as

food production and

medicines. It facilitates

monitoring changes in

production parameters and

helps with compliance audits

by keeping thorough

documentation.

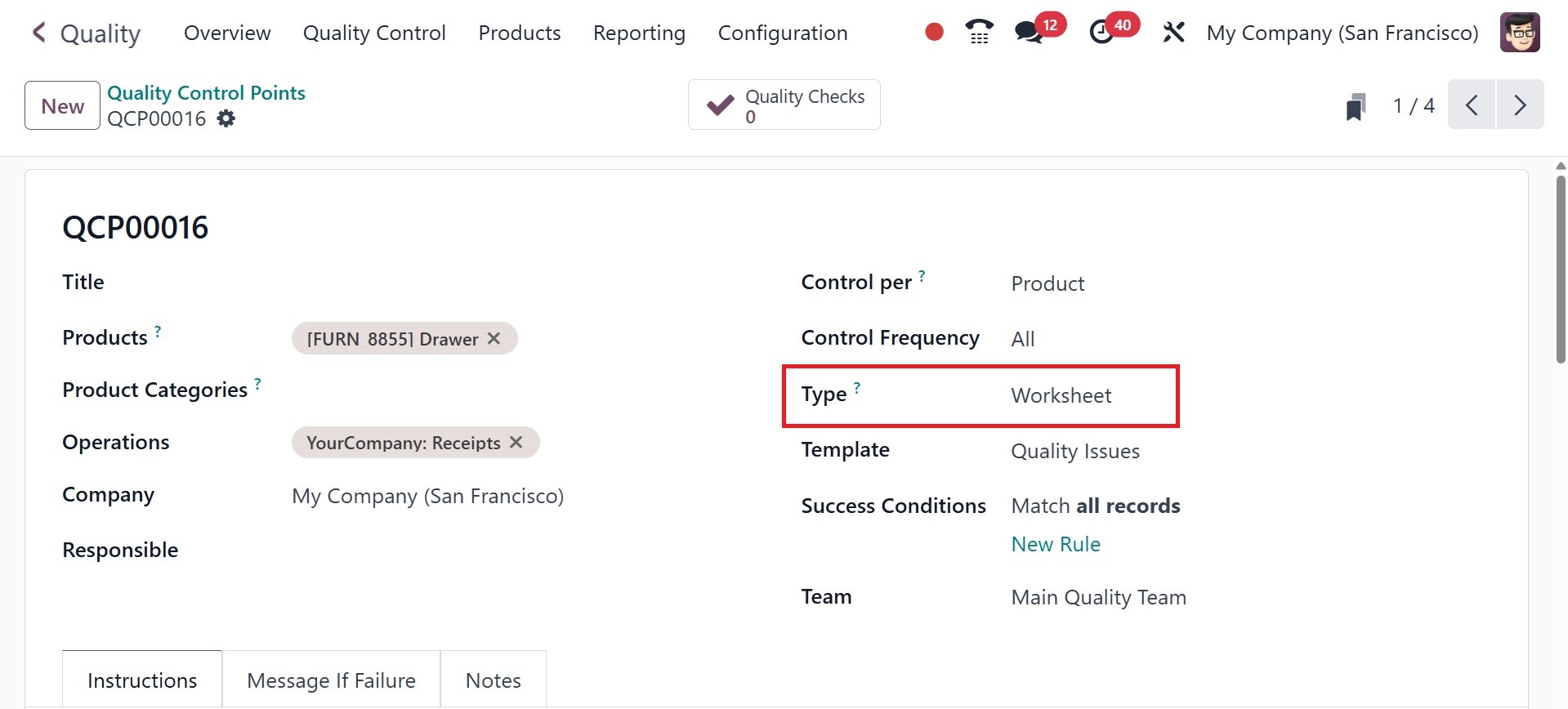

Worksheet: You can attach a

comprehensive worksheet (in

PDF or Google Sheet format)

for operators to follow while

doing quality checks when

using the "Worksheet" kind of

Quality Control Points. When

thorough instructions,

checklists, or compliance

documents are needed for

quality inspections, this

kind is helpful.

These are the types of quality

control points in odoo 18

Quality. Now, choose your

team in the Team field to

evaluate the quality control

point. Also, enter the name

of the person who manages

your quality control point in

the Responsible field. You

can select the Custom or

Specific page of the

operation sheet as the source

document in the Step Document

option.

In the Instructions tab, we can

include additional

information regarding the

quality control points. Most

instructions will specify the

product quality checks

required.

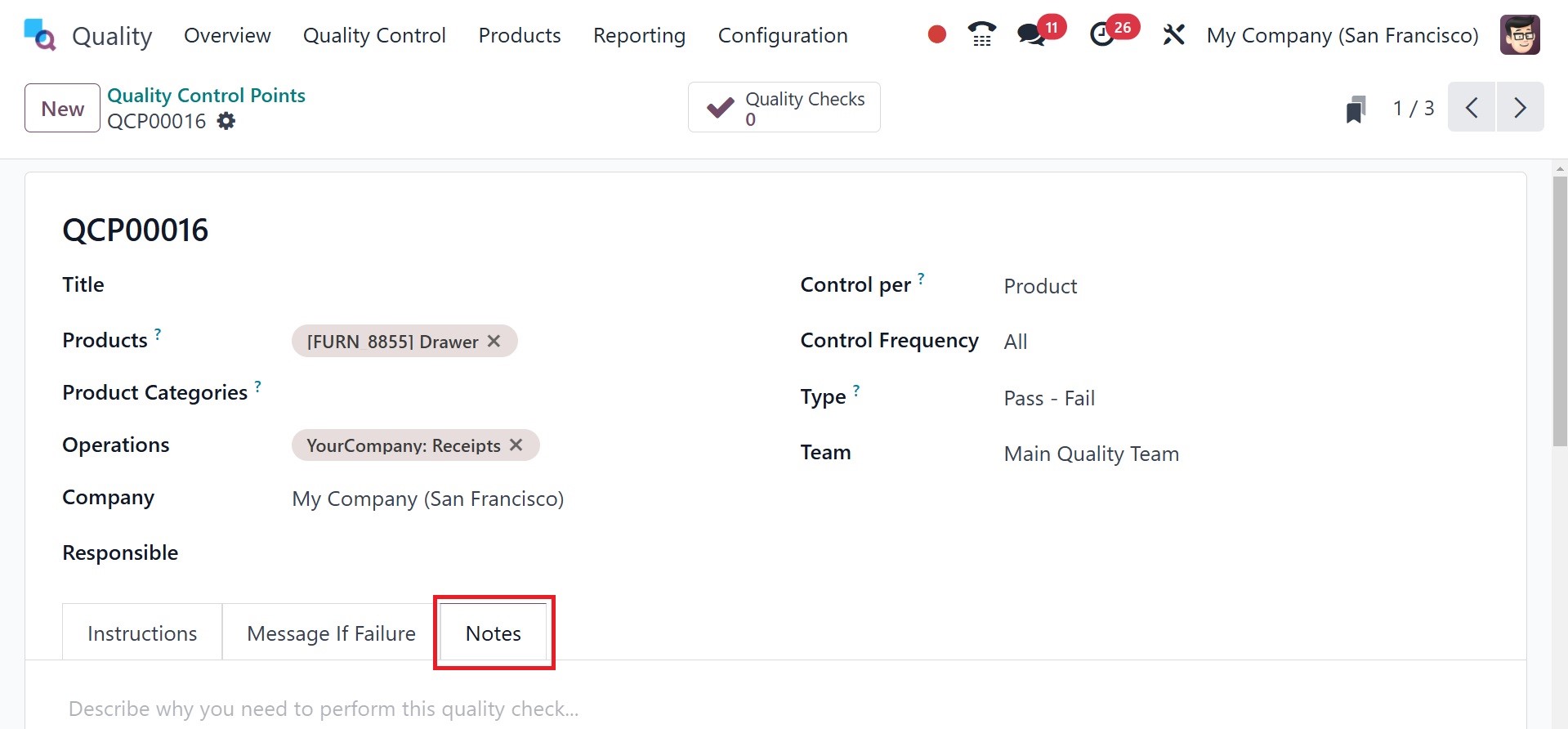

You can also enter any product

failure message in the

Message If Failure tab.

Include the information

needed to complete the

quality check in the Notes

tab.

All applied data is instantly

saved in Odoo 18 Quality.

Users can access the

generated sample in the

Quality Control Points

window.

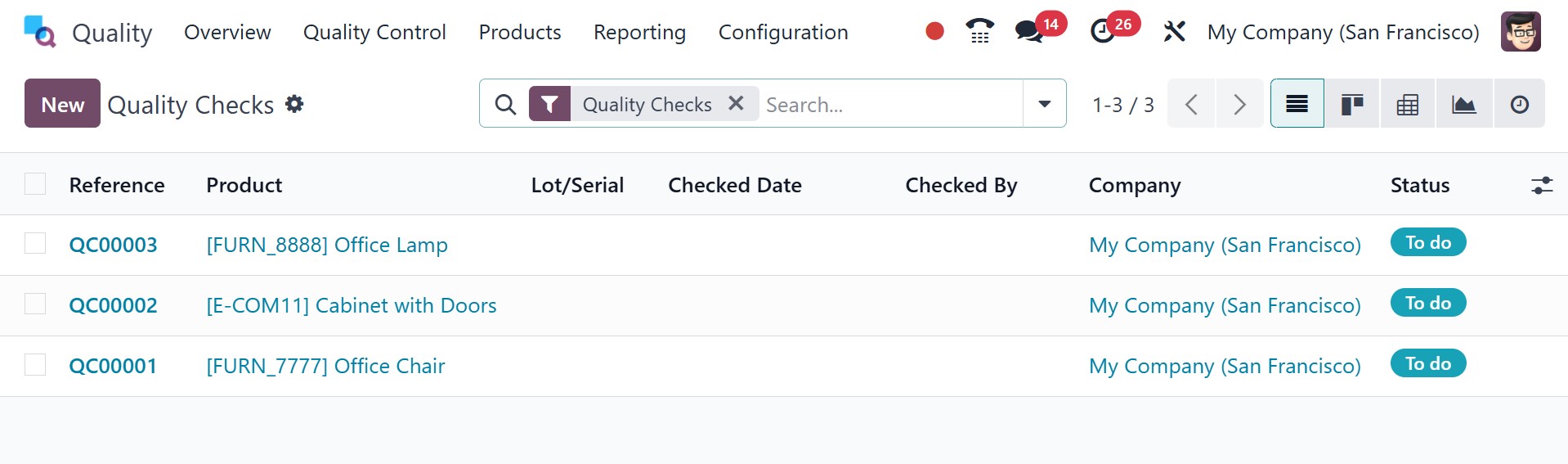

2.2 Quality Check

Quality checks are applied to

find needed defects in a

specific product or service.

It gets automatically

generated upon manufacturing

transfers and orders. When

you select the Quality Checks

menu from the Quality Control

tab, you might find details

about all the things that

need to be checked in your

organization. We can notice

in the List view that data of

each product, such as

Reference, Product, Team,

Lot/Serial, Status, etc., has

to be checked. By clicking on

the New button in the Quality

Checks window, a new quality

check can be easily created.

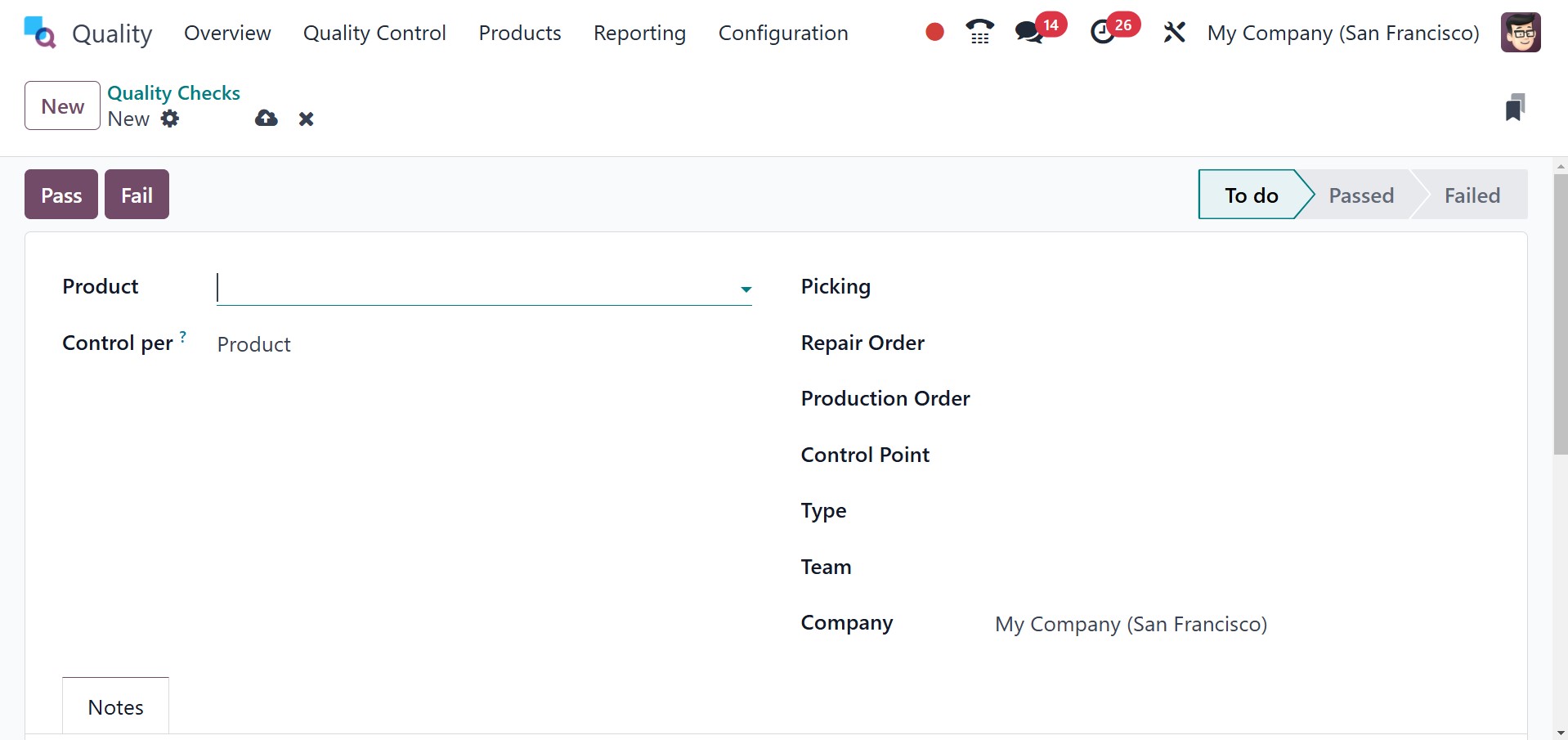

You can choose the commodity to

be verified under the Product

field on the open screen.

Determine the steps for each

field's quality checks to

follow. Executing quality

checks at the level of

quantity, product, or

operation is easy. Indicate

the principal warehouse on

the picking field

subsequently, where

manufacturing items are

processed.

In the Production Order field,

you can choose the order

number of the item. In the

Control Point field, you can

also select the point id of

the product. Then, choose

your group in the Type field

for quality checking.

Worksheets, Print Labels,

Instructions, Measure,

Pass-Fail, and others can be

chosen as the type. In the

Team field, choose the team

to check the quality of the

product. After the team has

been selected, choose the

company name from the Company

field.

In the Notes tab, users can

obtain additional information

on product quality checks.

Additional comments on your

quality check can be

conveniently inserted in the

Notes and Instructions fields

located in the Notes tab.

The Pass and Fail buttons in the

Quality Checks window inform

you if the product has passed

or failed a test. Users can

select the product's quality

check status using these

buttons. The stage is marked

as Passed when you press the

Pass button. On the other

hand, the stage can be seen

as failed, and the Fail

button defines the product

failure.

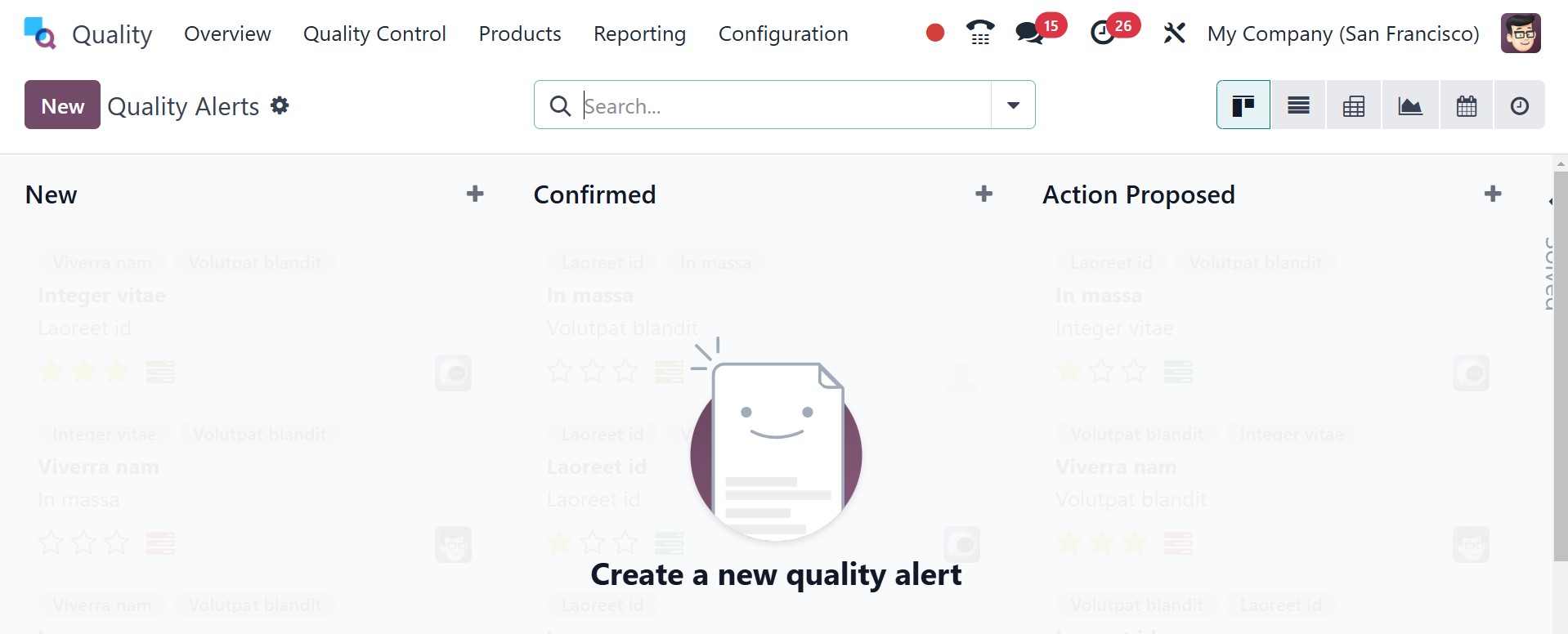

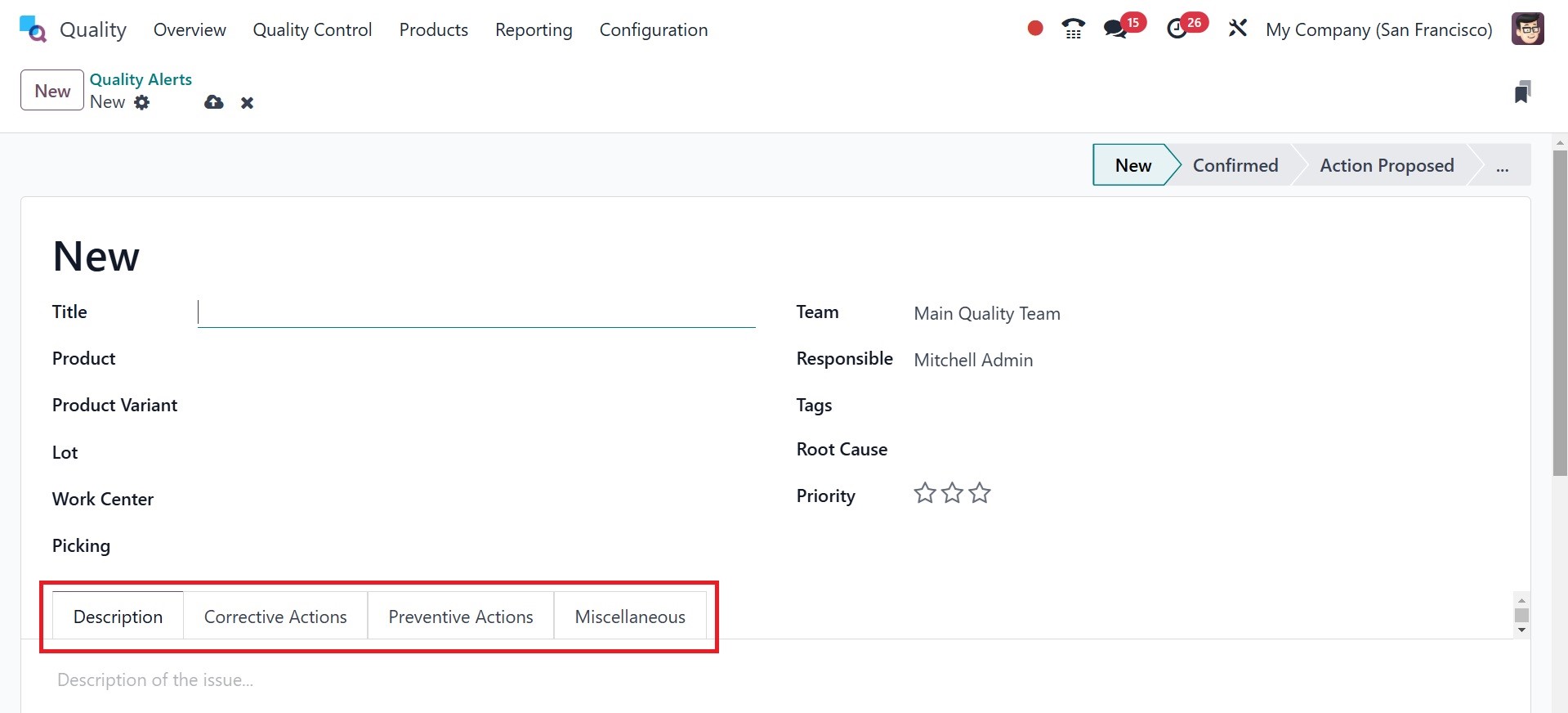

2.3 Quality Alerts

Rather than making production

orders, we are able to make

quality alerts for deliveries

and services in Odoo 18.

After enabling quality

alerts, reminding the

responsible party to check

the product/service quality

is easy. When you choose the

Quality Alerts option from

the Quality Control tab, data

for quality alerts will be

accessible.

Each alert's unique details,

including Name, Work Center,

Responsible, Date Assigned,

Team, etc., are shown

separately in the List view.

To create a new alarm, click

the New icon on the Quality

Alerts panel.

On the given page, we can fill in

various details. Let us

consider each option's

details in the Quality check

window separately below:

Title: On the Title line, you can

add the quality alert's name.

Product: The Product line shows a

list of all the items of your

company. Under the Product

option, choose the exact

product for which you need a

quality alert.

Product variant: "Variant" is a

product type with various

sizes and colors. In the

Product variant field, select

the variant that corresponds

to the chosen commodity.

Lot: A lot number is a

distinctive number for a

specific item or quantity of

an item produced by one

manufacturer. The user can

input the product's lot id in

the Lot box.

Work Centre: A work centre is

where all production

activities are carried out.

Choose the work centre field

that best represents the

central hub of your product

or piece of equipment.

Picking: Picking is the transfer

number where the quality

needs to be guaranteed. To

trigger the quality alerts,

you can enter the picking id

of your products.

Team: Designate a team to verify

the items' quality alerts.

The Team field enables users

to mention the team name.

Responsible: Choose the user in

the Responsible field who

confirms the quality checks

of the goods/services.

Tags: A tag which is attached to

specific products with the

intention of identifying the

products. In the Tag option,

you can select the necessary

tags for quality alert

generation.

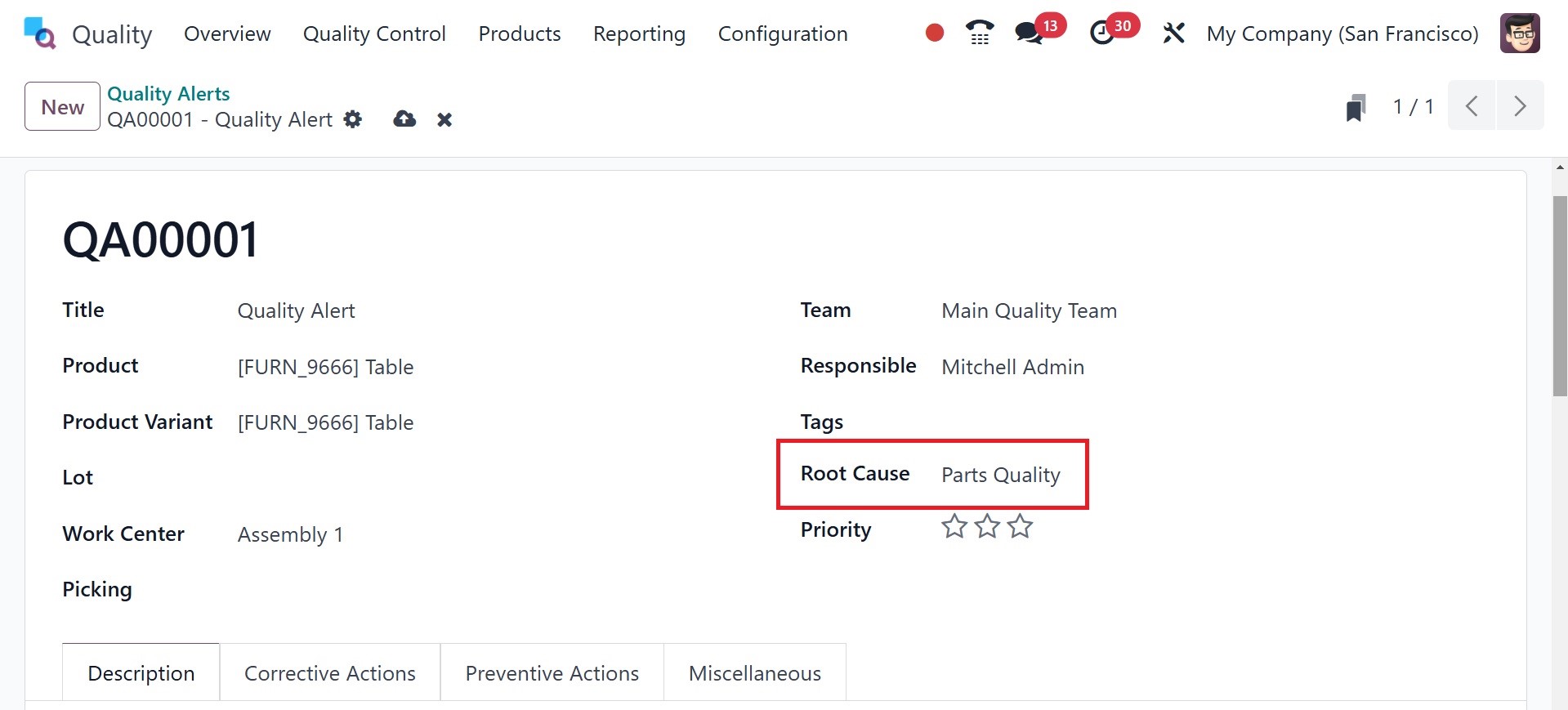

Root Cause: We can add the reason

for generating the quality

alerts to the Root Cause. You

can select different types of

reasons for the cause such as

work center failure, work

operation failure, parts

quality failure, etc.

Priority: It is possible to

change the priority of

quality alerts using the star

icon under Priority. The

initial issue will be soon

resolved by the primary

backend team.

Description: On the Description

tab, the root of the issue

can be easily identified.

Corrective Actions: On the

Corrective Actions page, you

can detail the actions taken

to rectify product-related

problems.

Preventive Actions: The actions

you need to take to avoid

quality failure of your

commodity are outlined below

in the Precautionary Measures

tab.

Miscellaneous: The Miscellaneous

tab enables you to view

information regarding a firm,

an assigned date, a vendor,

and an email address.

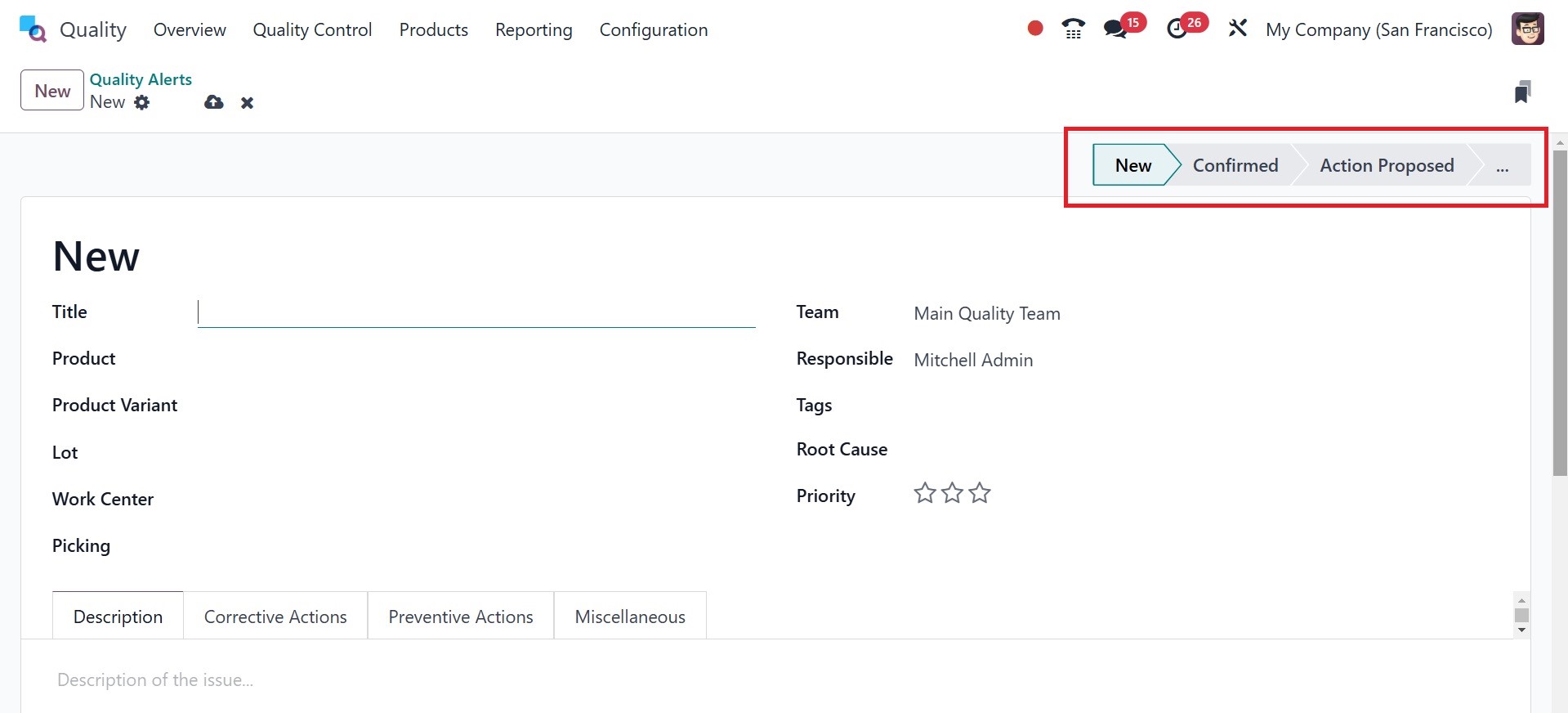

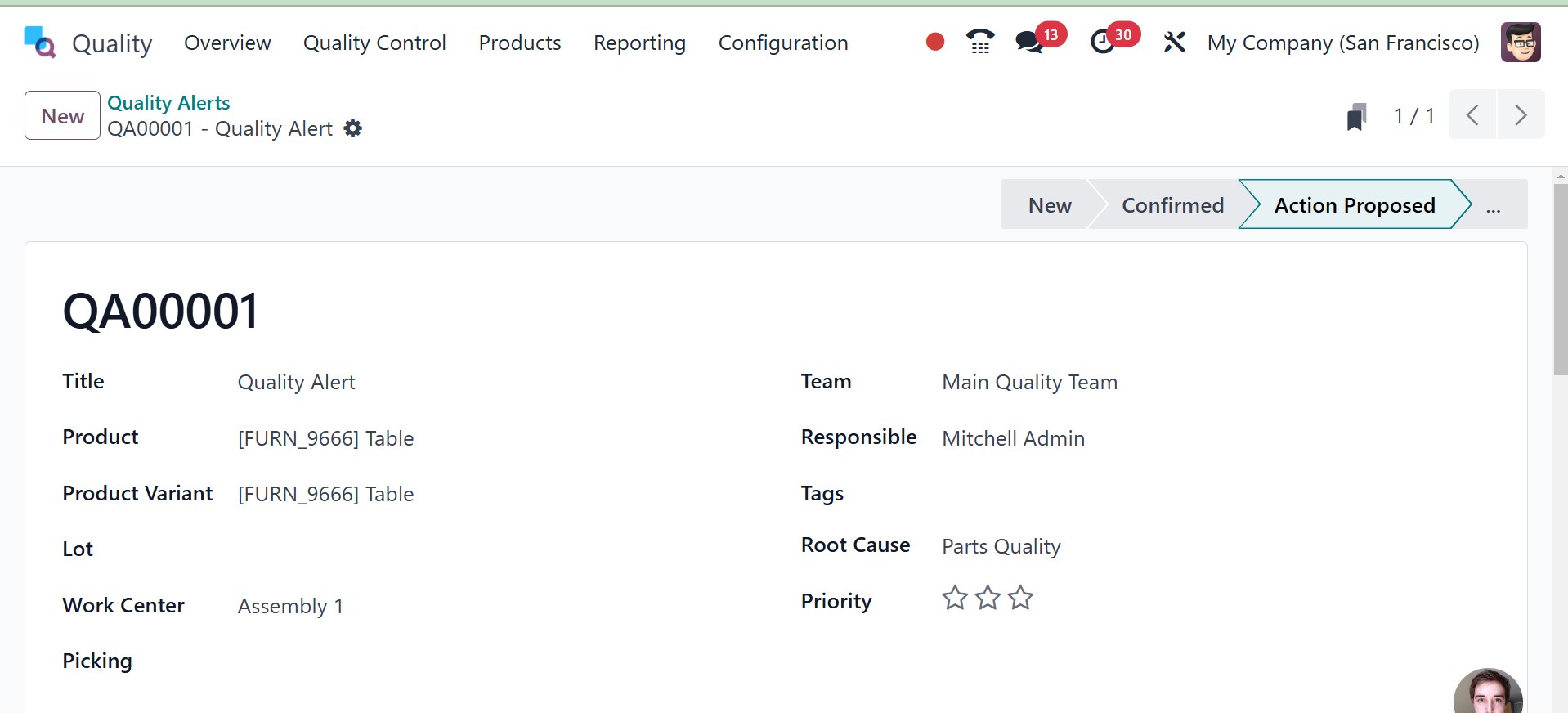

Every entered value is manually

entered into the Quality

module of Odoo 18. The

Quality Alert stages are NEW,

CONFIRMED, ACTION PROPOSED

and so on, and are different

for every operation.

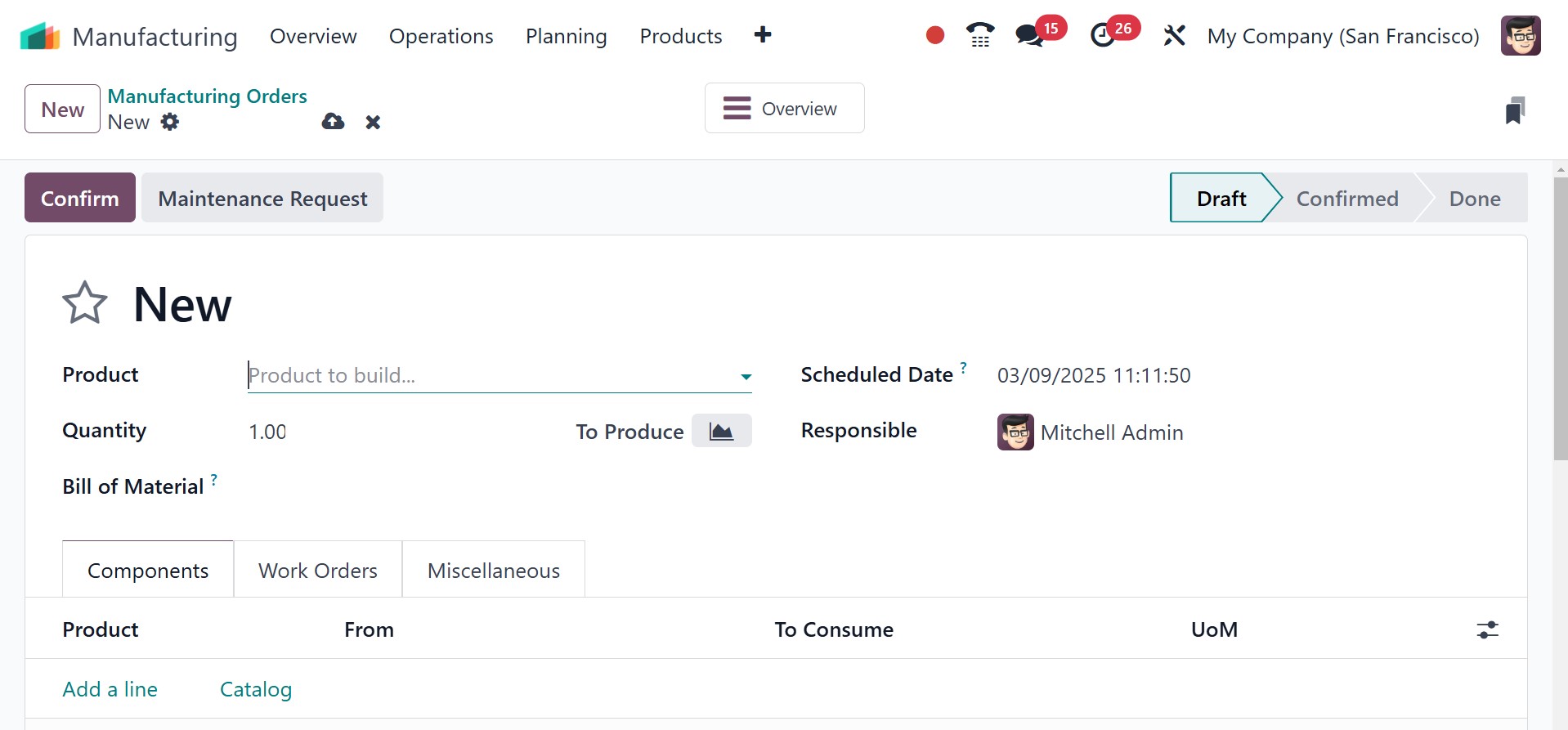

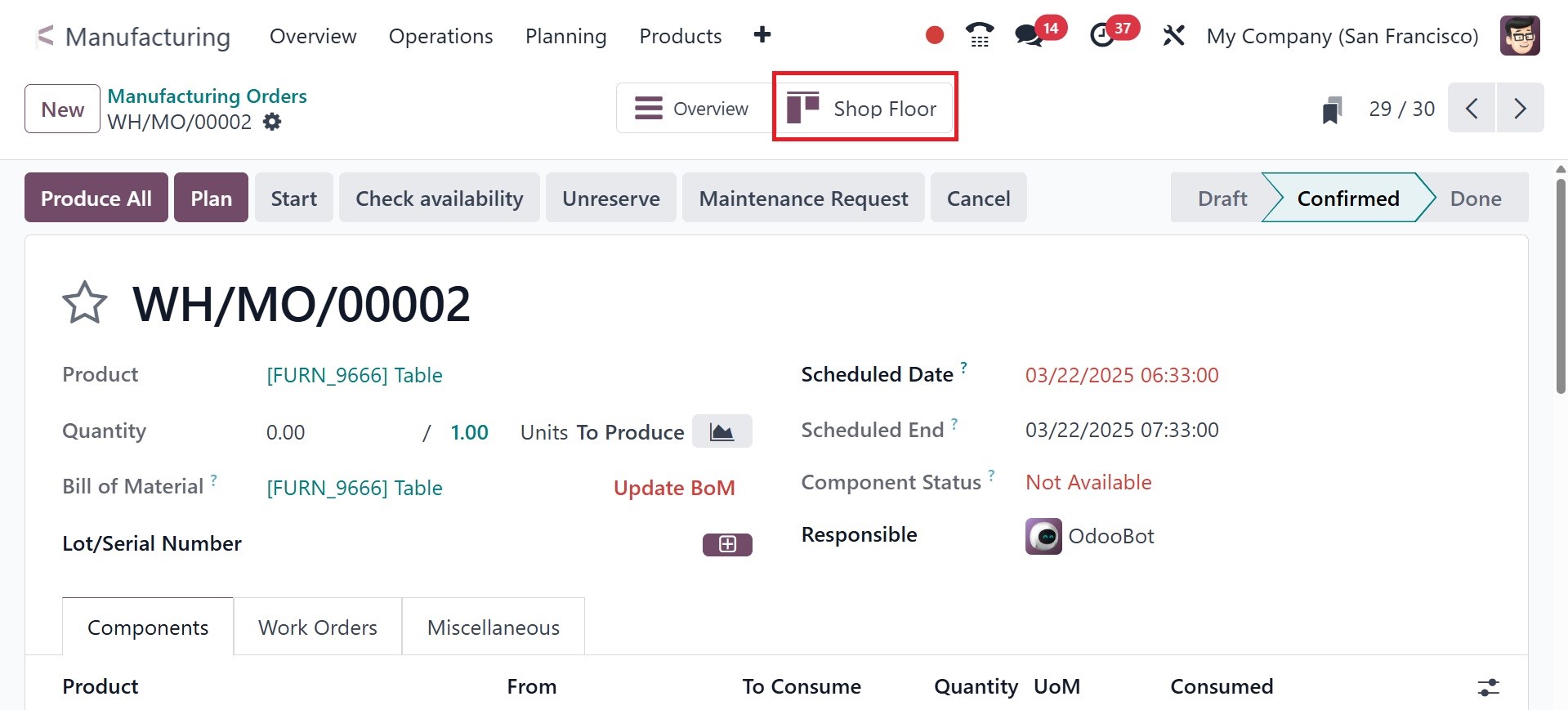

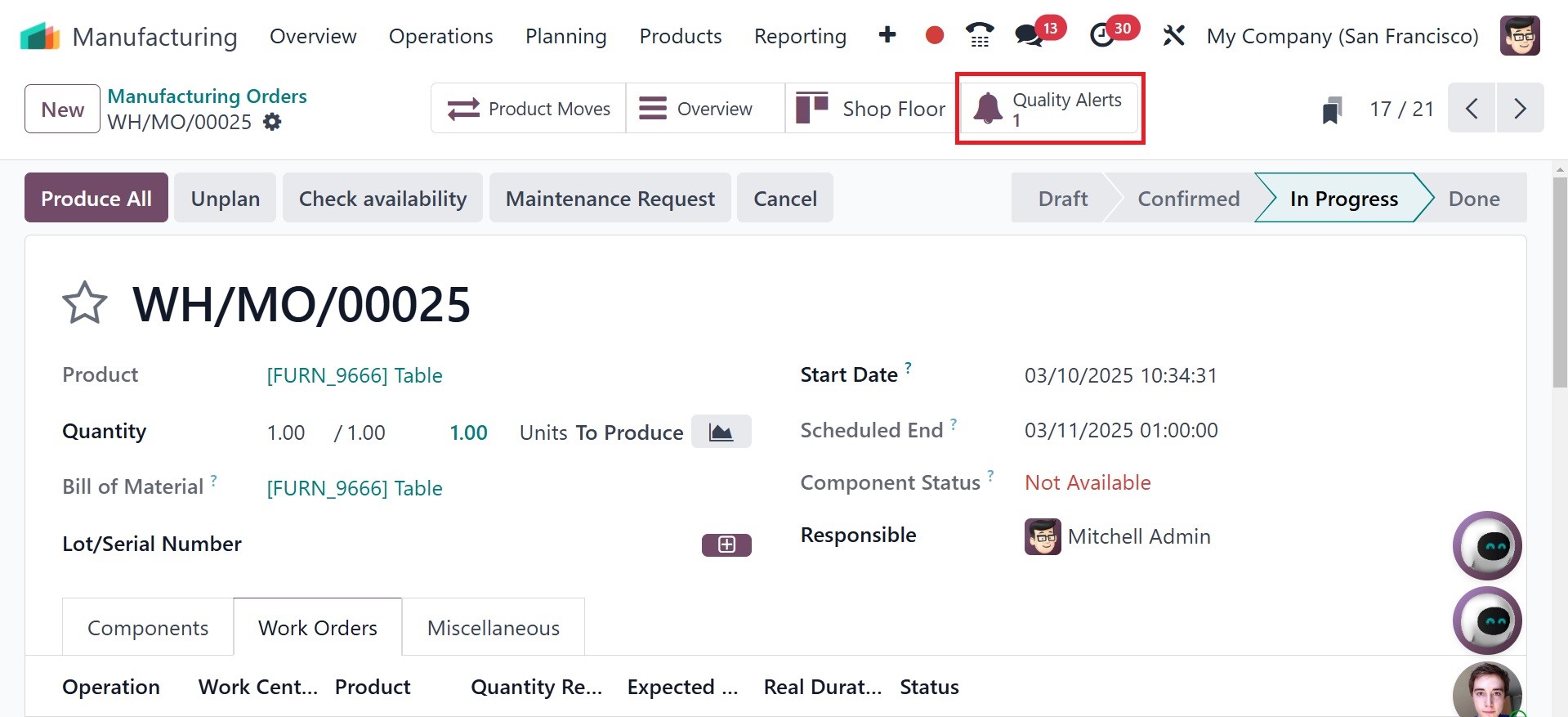

The following is an example of a

quality alert set using an

Odoo 18 manufacturing order.

Click the Operations tab's

Manufacturing Orders menu.

The user is able to get all

the created manufacturing

orders along with details

like Reference, Product,

Component Status, Quantity,

etc. In order to create a new

order, click on the New icon

in the Manufacturing Orders

page.

A new screen appears, and you

should choose your product

from the Product option. The

list of required components

will then show up under the

Components tab after you

select your freshly created

BoM Table.

Enter the quantity you want in

the Quantity field. The

Scheduled Date column also

provides you with the

manufacturing order's planned

date. The Responsible option

should then be assigned to

the user who is responsible

for the manufacturing order.

The information is saved

manually in Odoo 18 after

handling each piece of

information. Once you have

stored your information,

click on the Confirm icon.

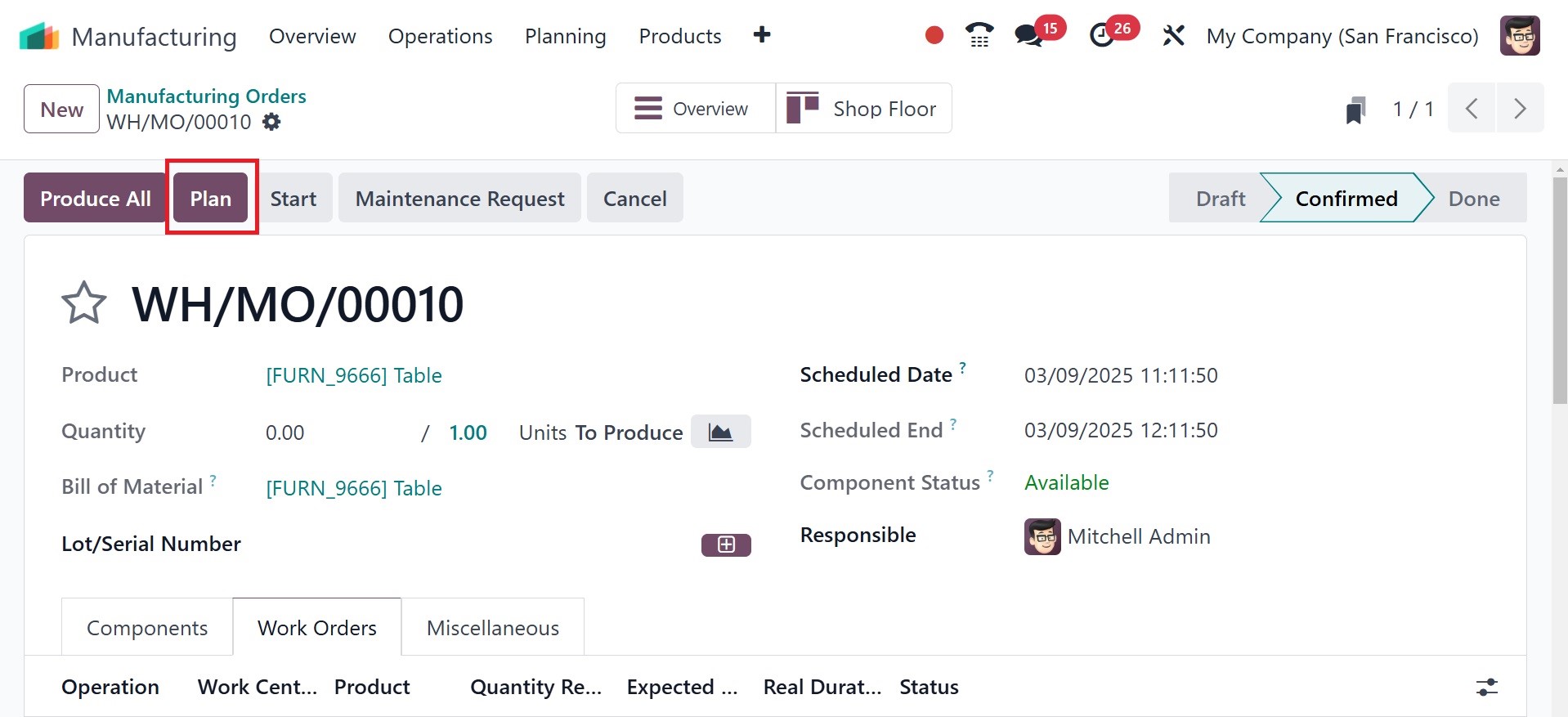

The shop floor smart tab can be

seen in the page, which

improves manufacturing order

management efficiency,

particularly with regard to

quality checks. The Shop

Floor Smart Tab facilitates

quality control procedures on

the shop floor by integrating

with the production order

workflow.

In the Work Orders tab, you can

view information regarding

the work center.

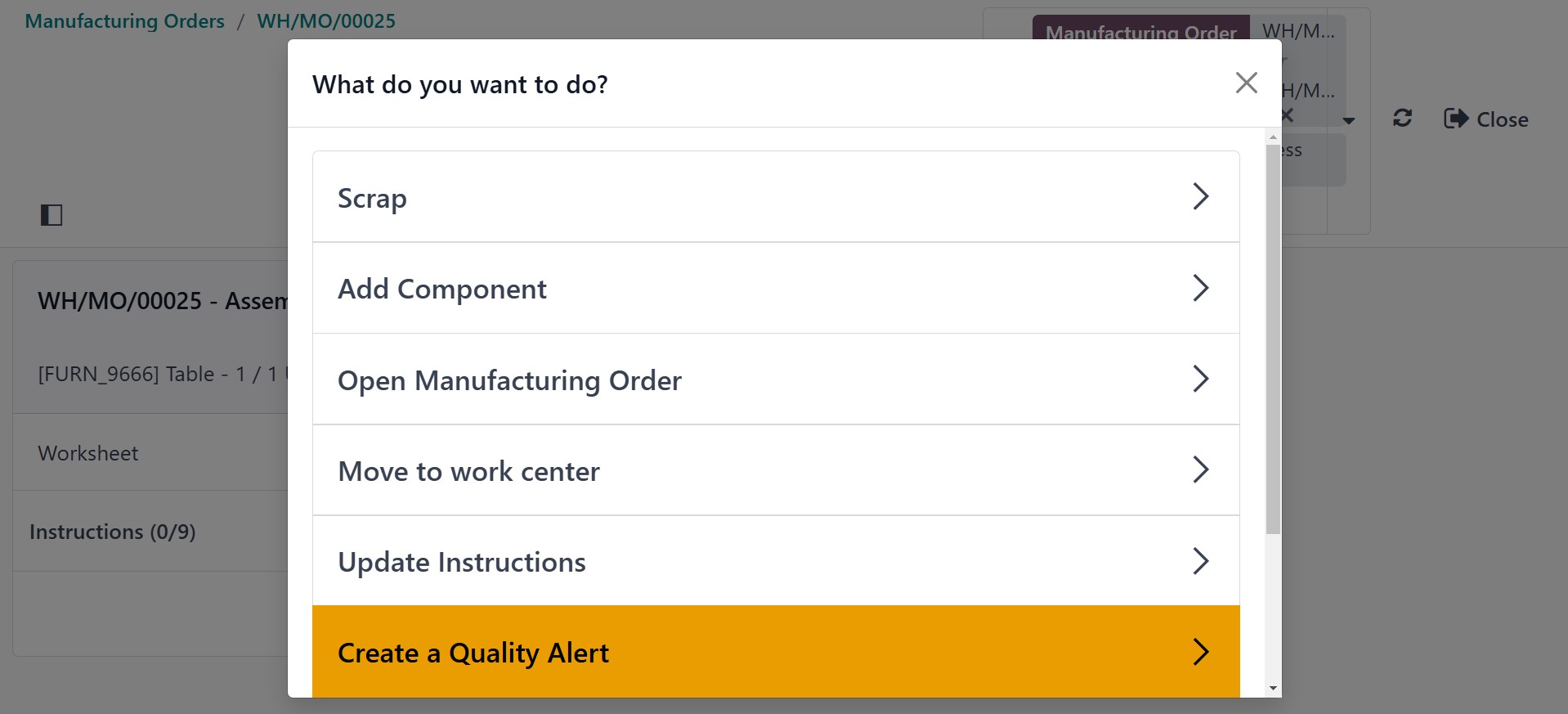

The new window holds the product

details. In case an employee

encounters an issue, they can

create a quality alert. The

user can get access to

features such as Scrap, Add

Component, BLOCK, and others

by choosing the Top Left menu

in the window. Choose Quality

Alert from the user-visible

menu.

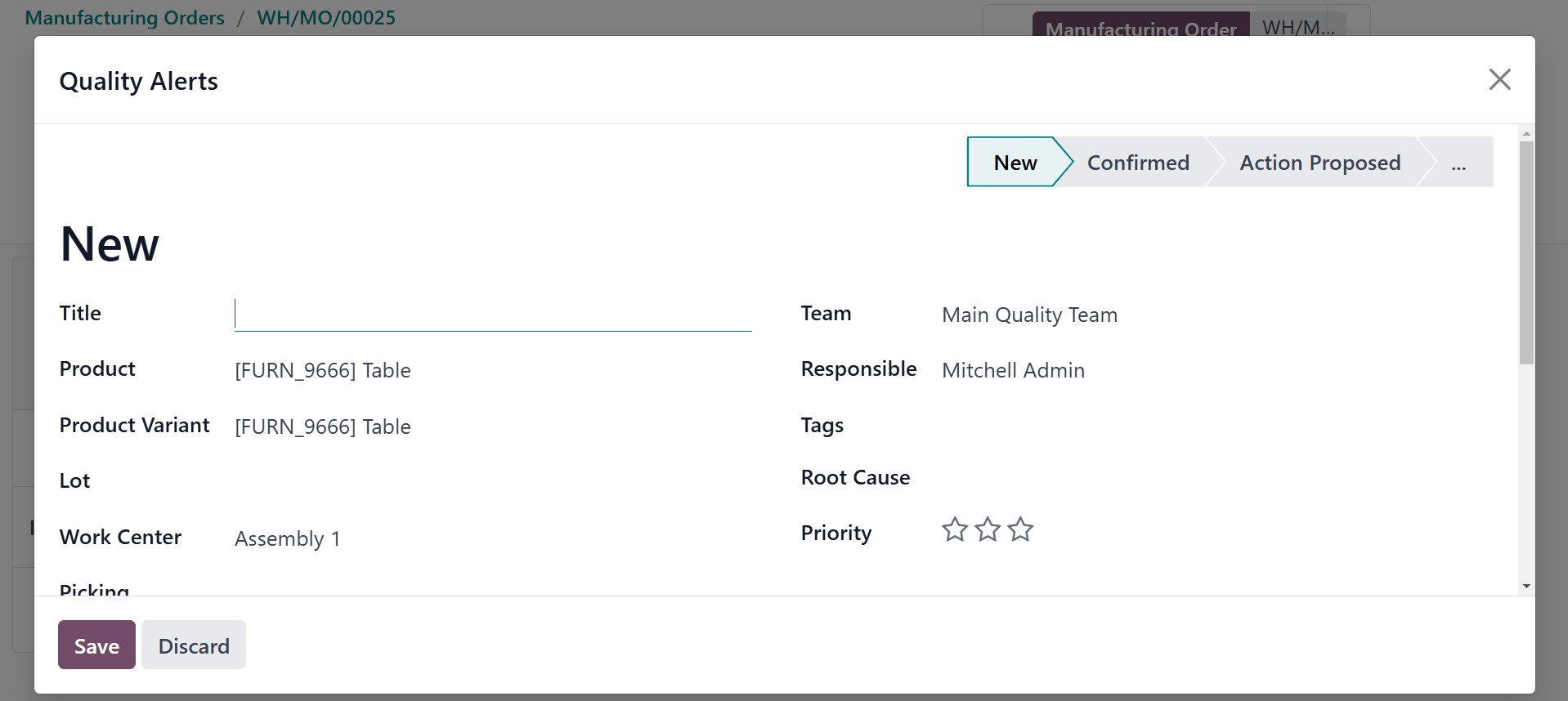

Entering the name of the quality

alert in the Title field

automatically updates the

user's other information.

Click the SAVE icon after

providing an explanation of

the product quality alert's

trigger under the Description

tab.

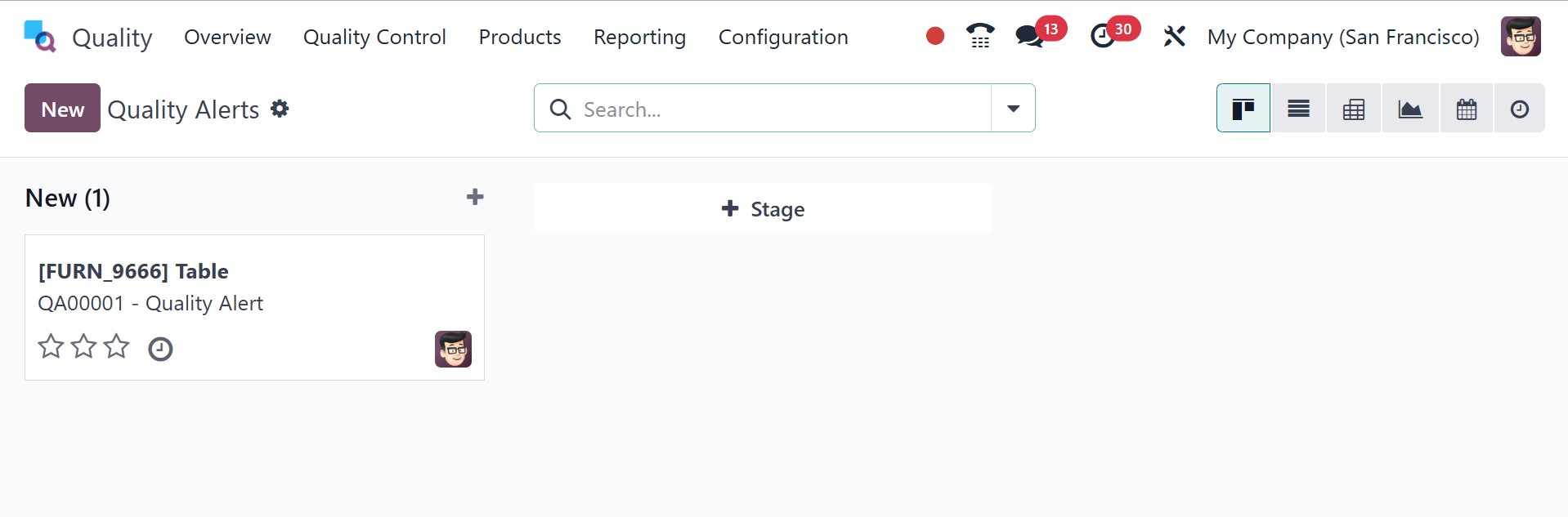

Now let's check the Odoo 18

Quality module for the

Quality Alerts pane. The

created quality alert for the

Table is visible inside the

New stage.

Next, explain the reason for the

product quality warning in

the Root Cause area.

After managing the data, change

the stage to Action Proposed.

The next step is to choose your

Manufacturing Order in the

Odoo 18 Manufacturing module.

As we can see, there was only

one quality alert generated

for the order.

Consequently, passing the quality

alert within a production

order is easy.