1. Overview Menus

The “Overview” menu in the Repair module of Odoo 18 functions as a

central dashboard that provides a thorough overview of all repair

procedures, statuses, and activities. The ability to effectively

monitor current repair jobs and evaluate workloads in real time is

very helpful for managers and service teams.

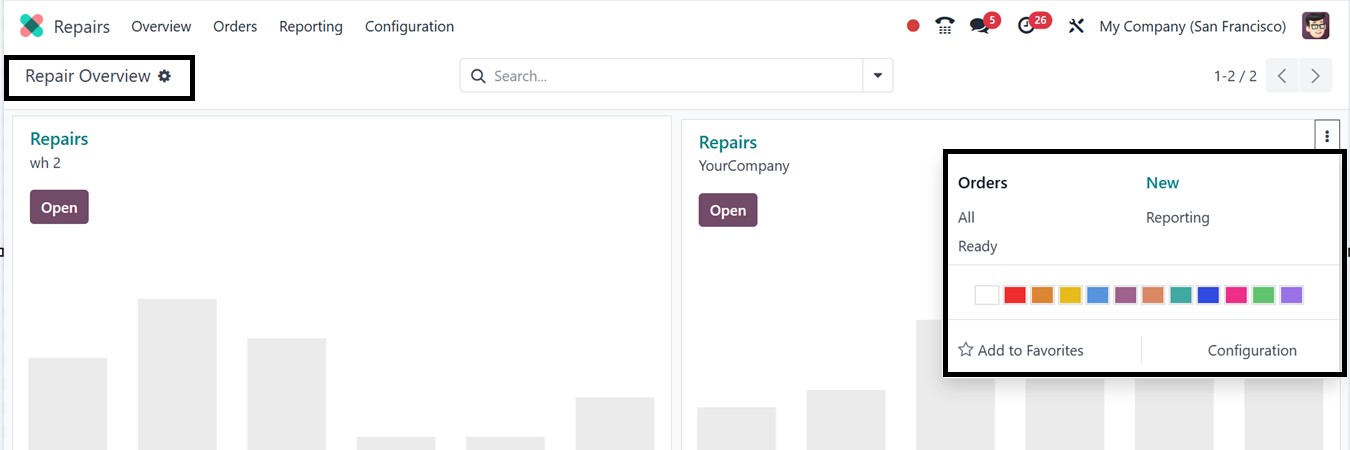

In the ‘Repair Overview’ window, you can see all the available repair

order categories in a Kaban tile view, as depicted in the screenshot

below.

From the kanban card, you can utilize the vertical menu to check and

manage the All Orders, Ready Orders, Reporting, and Configurations.

The ‘Add to Favorites’ button can be used to mark the important

repair orders

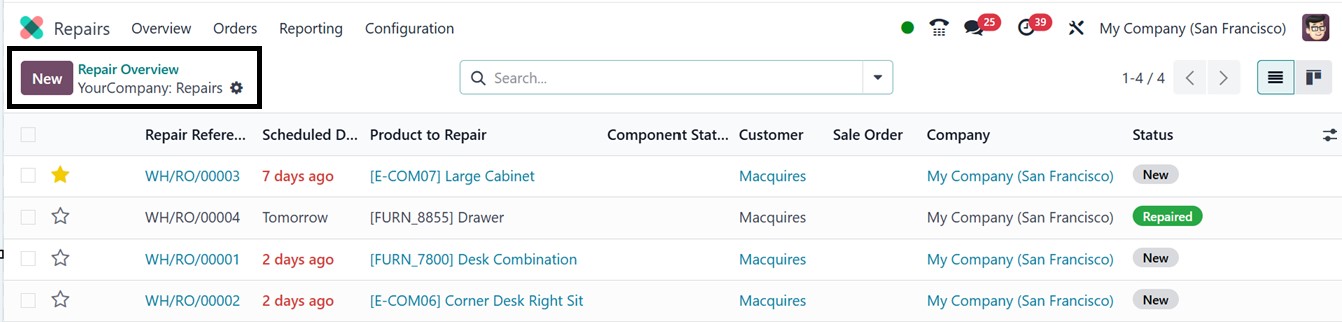

Opening any of the repair categories, the Repair orders are arranged

in a list view, you'll find details such as Repair Reference,

Scheduled Date, Product to Repair, Customer, Delivery Address,

Warranty Expiration, Sale Order, Company, and Status. The status of

each repair order is visually represented using various color codes.

Additionally, a star icon is available for each entry, allowing you

to mark the significance of the repair request

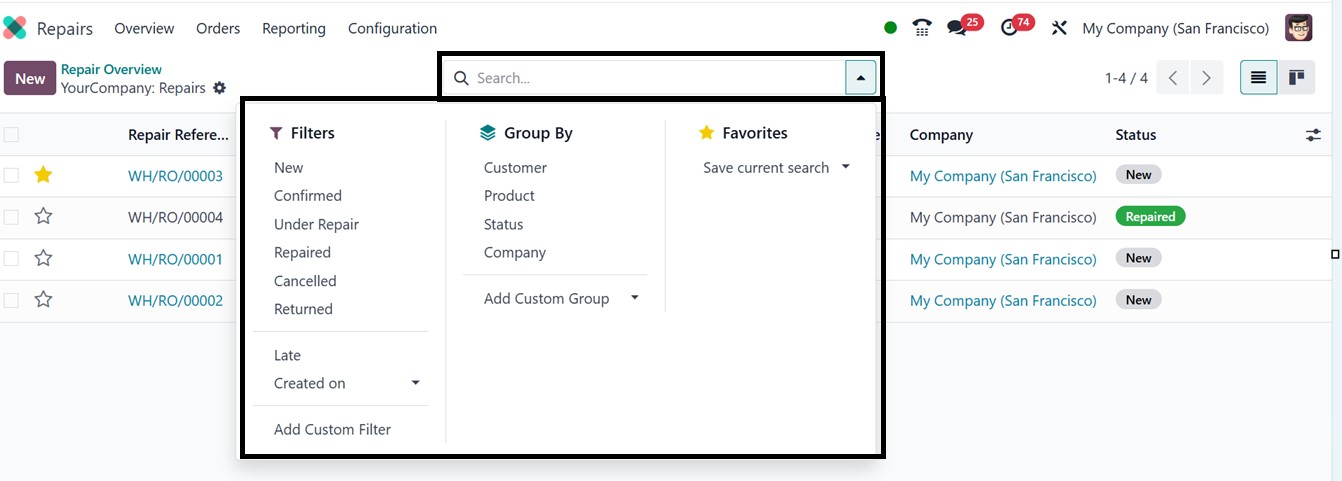

Users may refine repair orders by status, assigned technician,

warranty coverage, product, or client using a search bar filter.

Furthermore, clever indicators draw attention to crucial data,

including warranty tags, past-due chores, and maintenance

priorities. The dashboard is a useful tool for managing service

operations and balancing workloads since it allows real-time

tracking of the quantity of repair orders at each step.

By default, the system includes filters such as New, Confirmed, Under

Repair, Repaired, Cancelled, Returned, Late, Created on and Add

Custom Filter options. If these are not sufficient, custom filters

can be created using the Add Custom Filter tool. The Group By

function helps categorize repair orders based on Customer, Product,

Status, and Company. Any existing repair order can be accessed and

edited by simply clicking on it. You can also crete customized group

data using the ‘Add Custom Group’ option.

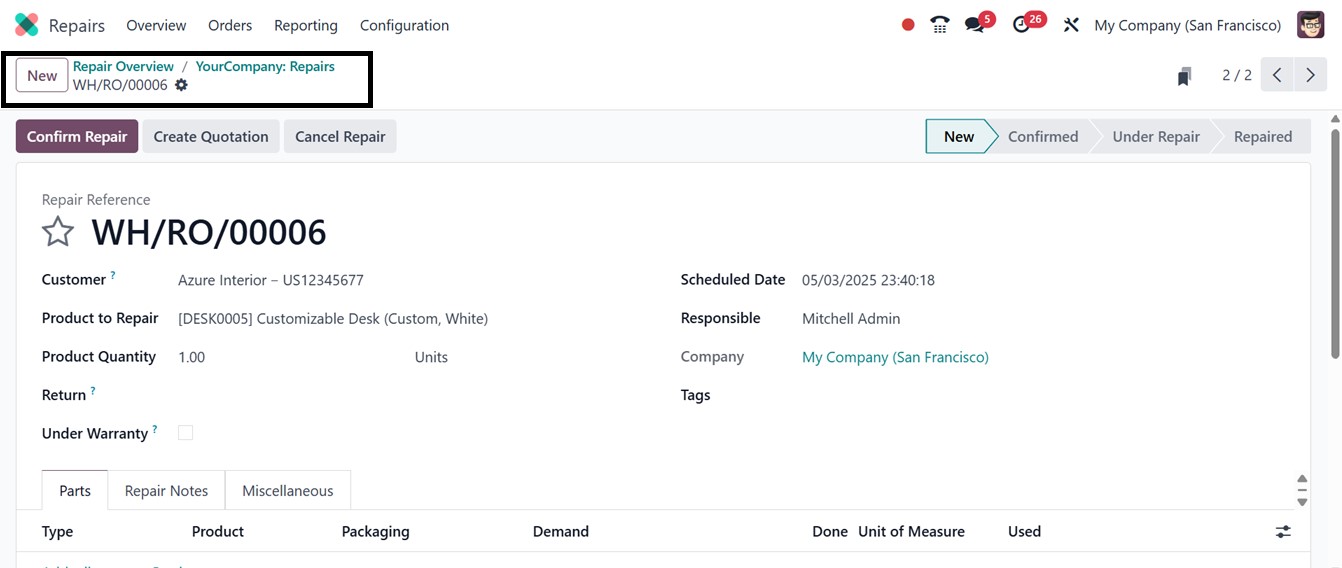

To initiate a new repair request, click the New button, which opens a

form view, as depicted in the screenshot below.

In the form, the Customer section is where the client's name is

entered. The Product to Repair field lets you specify the item that

needs fixing, and the Product Quantity field is used to indicate the

number of items. The customer’s contact details and delivery address

can be provided in their respective fields. The Return Order

checkbox can be used if the repair is for a returned product. The

Scheduled Date field allows you to plan when the repair should

occur. Assign a technician in the Responsible field to handle the

repair process. If the Under Warranty option is checked, the items

from this repair order will be treated as invoiced at zero cost. You

can also enter Tags and select the Company name. The star icon next

to the Repair Reference can be used to prioritize the task.

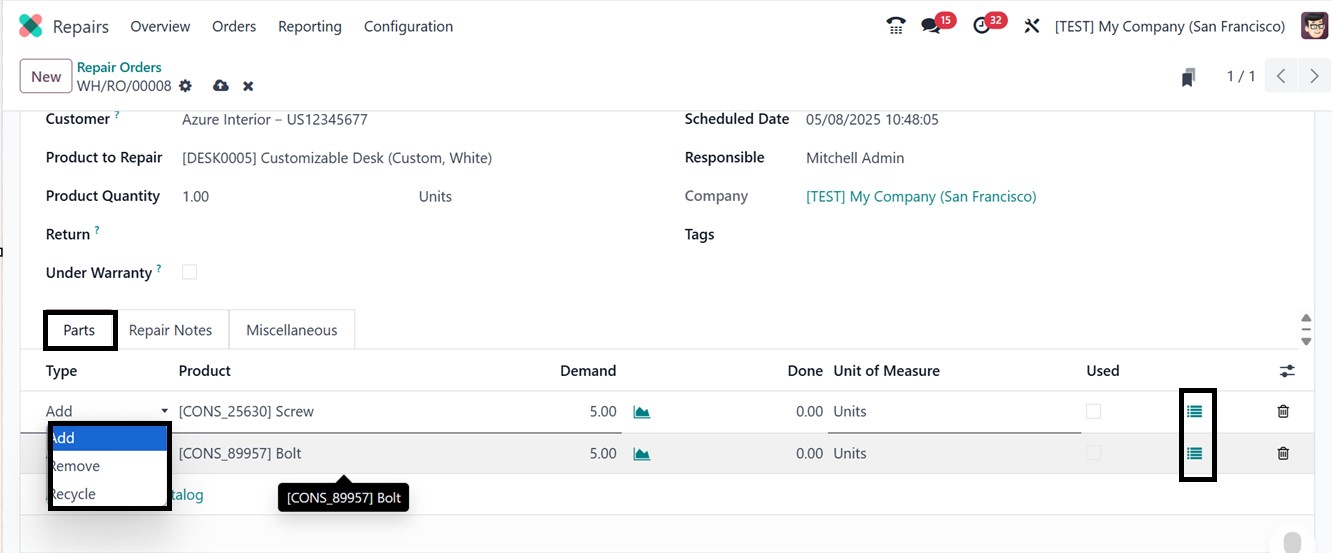

The Parts tab is used to define the specific components involved in

the repair. You can list the items that were either added or

replaced to fix the product. Use the Add a Line button to input part

details. The Type can be set to Add, Remove, or the newly available

Recycle option.

By choosing the ‘Add’ option from the ‘Parts’ tab, the part is listed

as a component meant to be used during the repair and is included in

the Repair Order (RO). Unused parts can be saved for later use, as

the user can verify whether the part was utilized or not while

performing the repair.

When you select the ‘Remove’ option, the part is shown as one that

has to be removed from the product in order to be repaired. After

that, the technician can say if the part was indeed taken out.

By choosing the ‘Recycle’ option, the part is designated as recycled

and will be stored for future use or repurposed at the warehouse.

You can also fill in fields such as Product, Demand Quantity, and

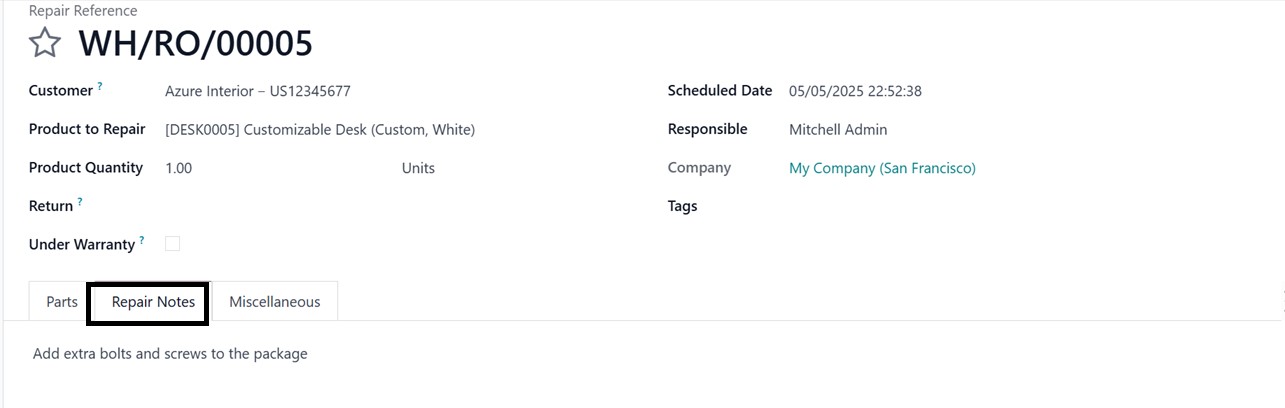

others. Any notes or descriptions regarding the repair order or the

product can be edited under the Repair Notes tab, as illustrated in

the screenshot below.

For internal documentation, a designated section is available to add

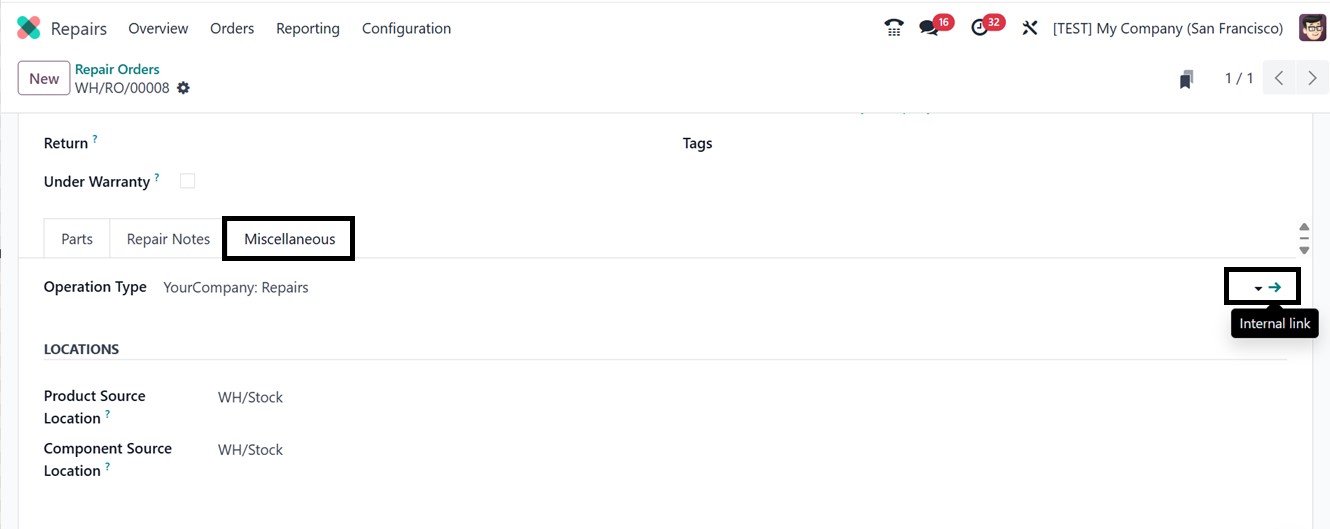

repair notes. The Miscellaneous tab allows you to define the

Operation Type. This Operation Type determines the stock operation

type associated with the repair process. This controls how the

system manages inventory movements associated with the repair,

including returning the repaired goods to the client or bringing in

and taking out components.

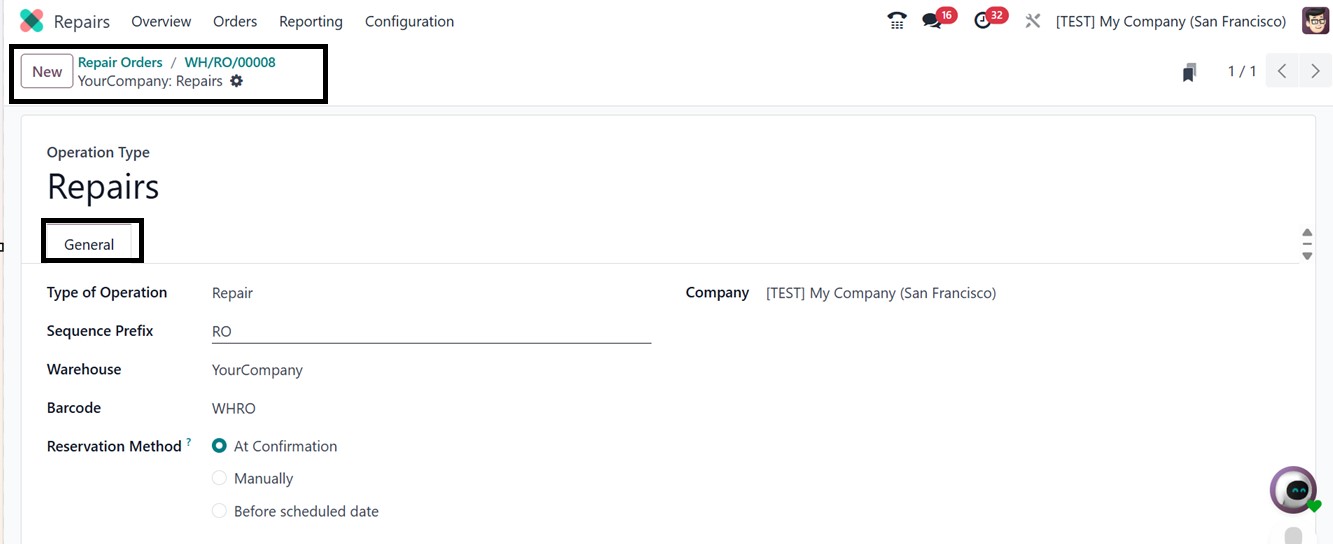

Selecting the right operation type guarantees that the repair process

accurately reflects stock adjustments and connects with your

warehousing operations. So, click on the interlink provided in the

Operation Type field to check the Type of Operation, Sequence,

Warehouse, Barcode, Reservation Methods, and Locations of this

operation type as depicted in the screenshot below.

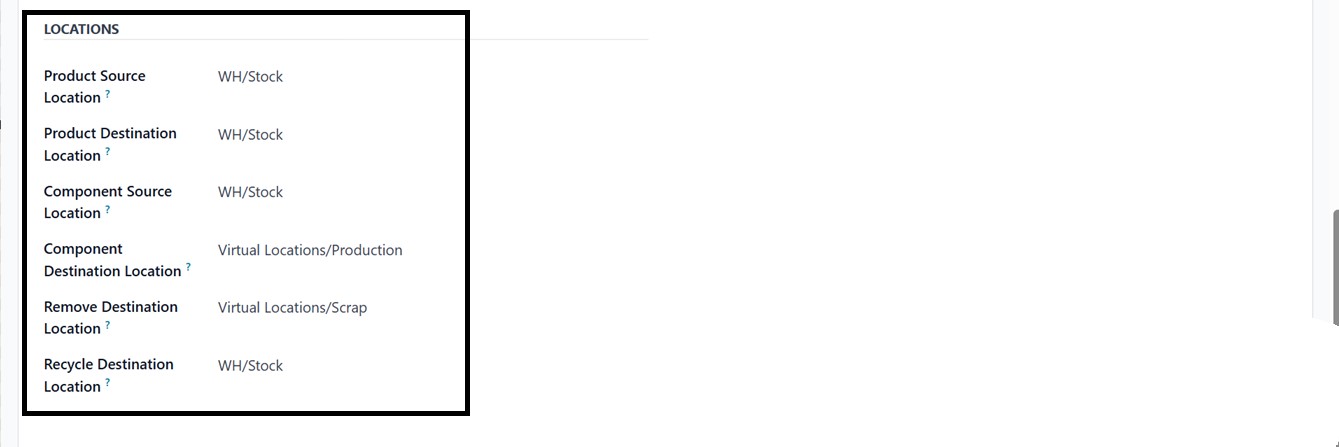

The ‘Reservation Method’ option defines how the product is

transferred. When adding, deleting, or recycling parts during the

repair process, you can see where the product and its components are

relocated from the Component Destination Location, Remove

Destination Location, and Recycle Destination Location fields of the

"LOCATIONS" area. According to the chosen Operation Type parameters,

this also contains information like the Product Source Location,

Product Destination Location, and Component Source Location.

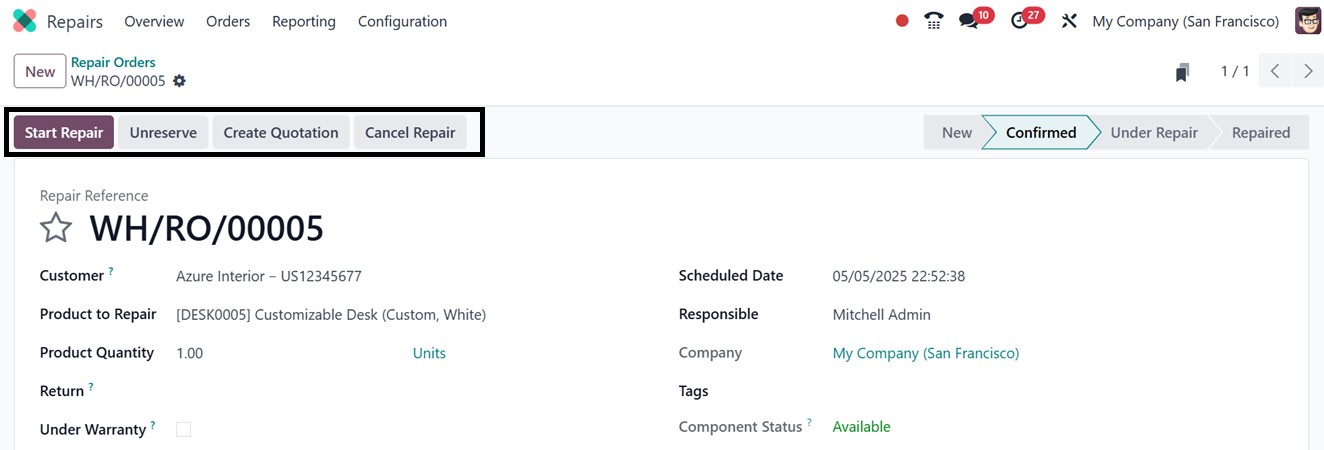

Once all the required fields have been completed, the repair order

form will be ready for further actions. To start and validate the

repair, click the Start Repair button. If you wish to prepare a

quotation based on this repair, use the Create Quotation button. If

you want to unreserve the order, click on the Unreserve button.

Finally, to cancel the repair order process, select the Cancel

Repair option. At this stage, we proceed by confirming the order.

After confirmation, the order status will change to Confirmed, as

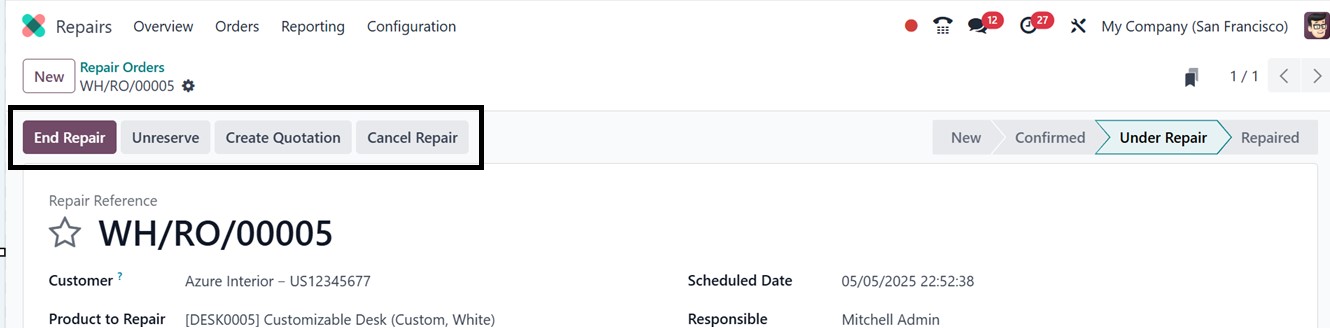

shown in the interface. Clicking Start Repair begins the repair

operation. While the repair is ongoing, the status will reflect as

Under Repair in the pipeline stages area. Once the process is

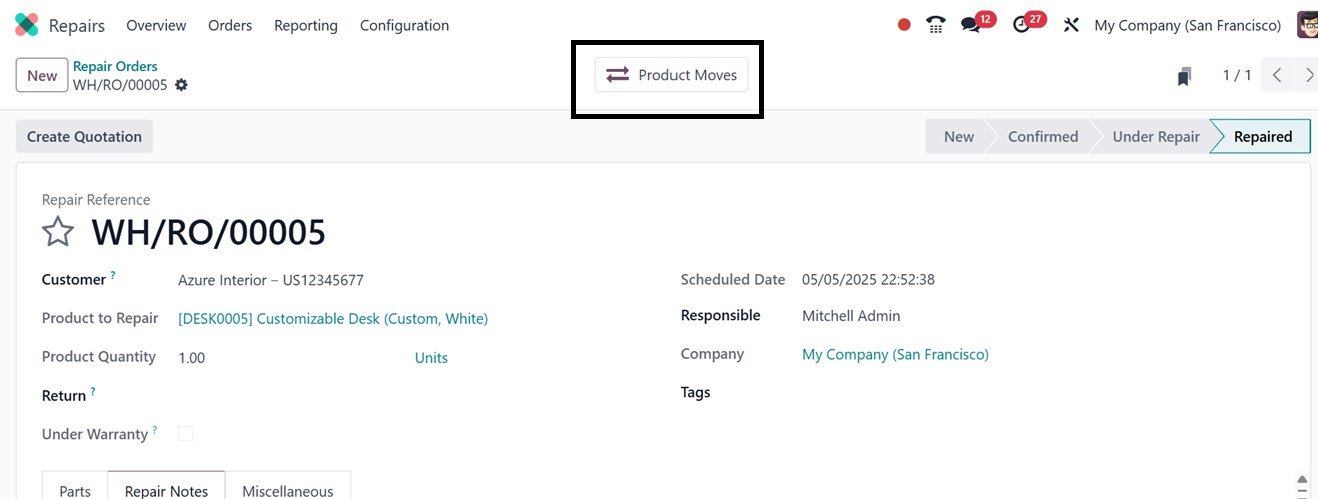

finished, click on the End Repair button to complete the procedure.

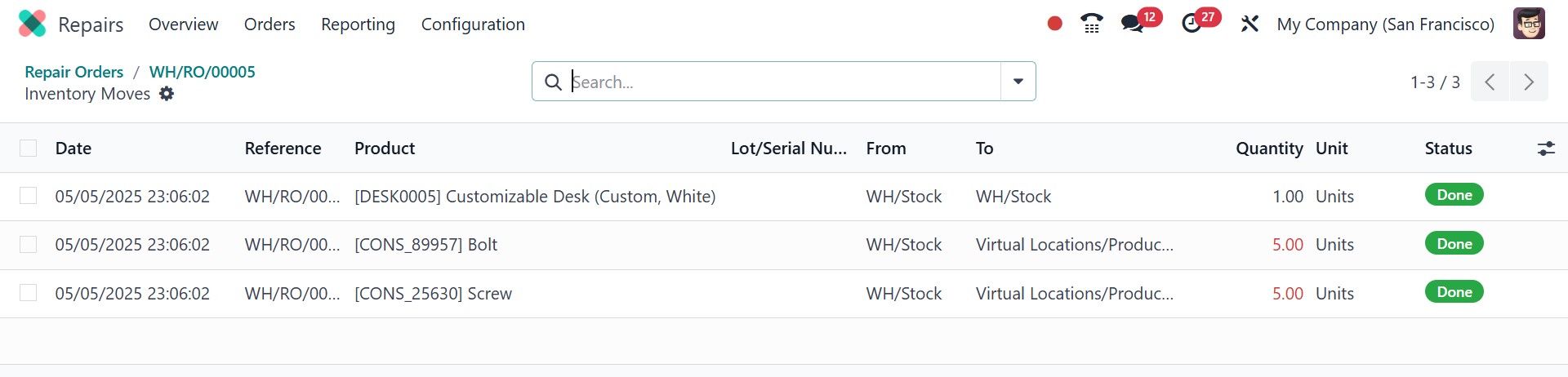

A smart tab labeled Product Moves displays the movements of the

product following the repair.

The Product Moves dashboard will show detailed information such as

Date, Reference, Product, Lot/Serial Number, From, To, Quantity,

Unit, and Status. This provides a full record of the product’s

logistics after servicing.

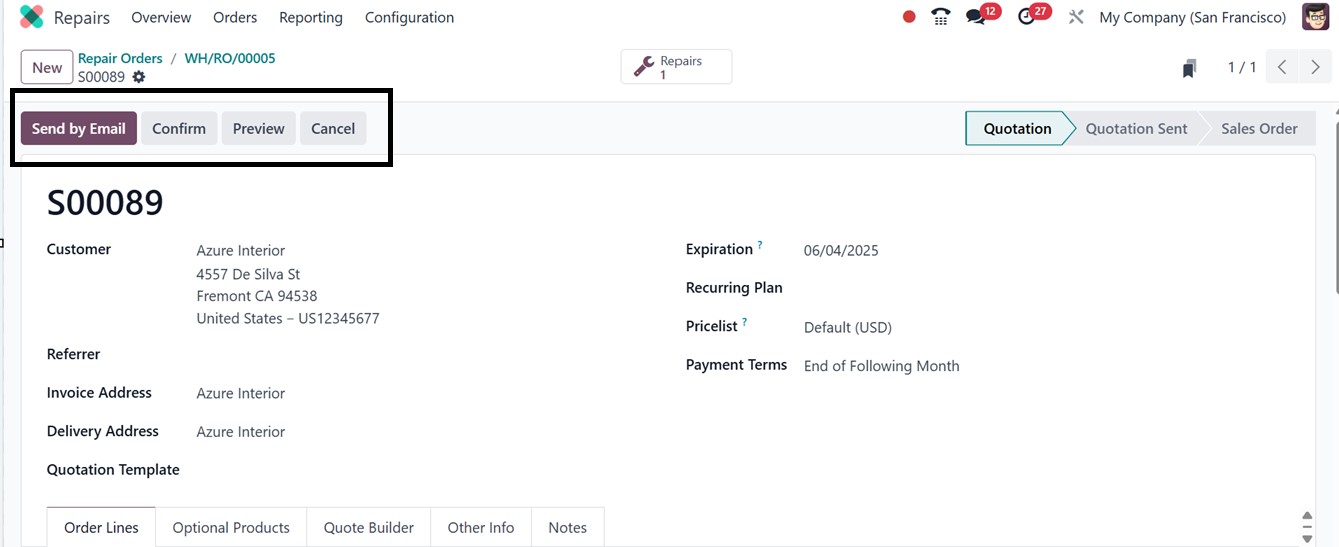

After completing the repair, you can create a new quotation by

selecting the Create Quotation option. This action will immediately

convert the order into a new quotation, and you can see the

quotation form with all the details, as depicted in the screenshot

below.

Following the creation and confirmation of the quotation, users can

proceed to generate an invoice by clicking on the Create Invoice

button from the menu. After the creation of the invoice, a Sales

Orders smart button will appear on-screen, giving access to all the

related Sales Orders for the repair.