Master Production Schedule

While planning over the work orders, it is also equally important to plan future actions based on the demands. The master production schedule feature of Odoo helps in reporting the activities through forecasting. By doing so you can adjust the manufacturing processes and orders by knowing the market demands. It helps us in calculating the quantity of the products that need to be manufactured in a particular period, in order to meet the demands of the market at the particular time. By using a master production schedule report, it will help to schedule your reordering and manufacturing operations. It is useful if you have a long lead time and if you produce based on sales forecasts.

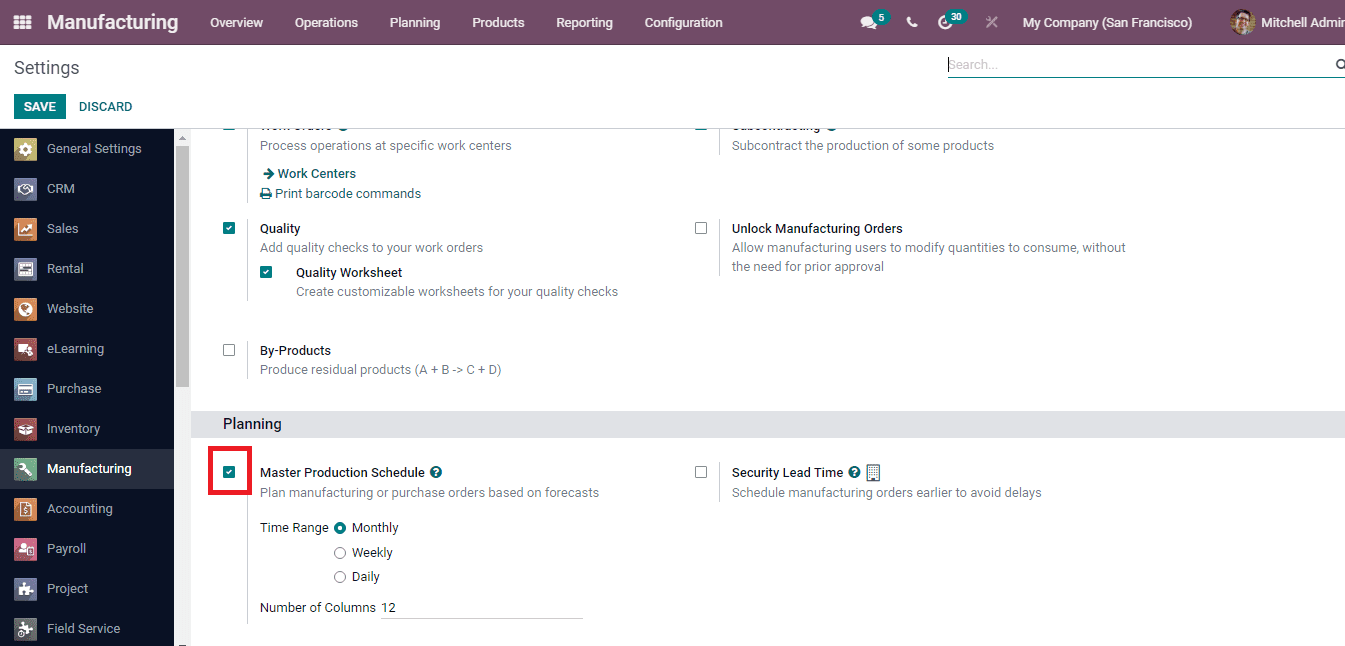

The Master Production Schedule tool of the Odoo 15 Manufacturing module is very systematic and helps in planning as well as organising the orders. In order to view the Master Production Schedule, you can enable the schedule from the configuration tab. From the Settings, enable the Master Production Schedule to help your company in planning manufacture or purchase orders based on the forecasts.

You can select the time range as Monthly, Weekly or as Daily, for forecasting the orders. The number of required columns can also be configured from the Settings. To check the schedule, select the Master Production Schedule option from the Planning tab.

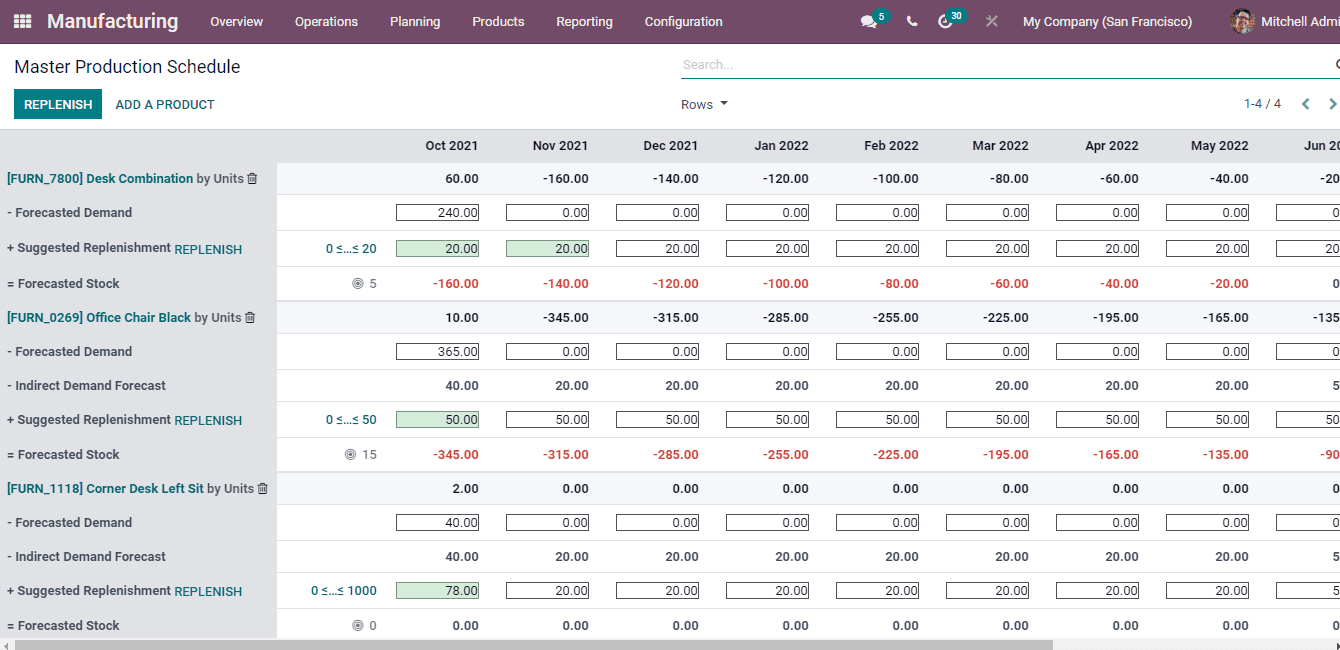

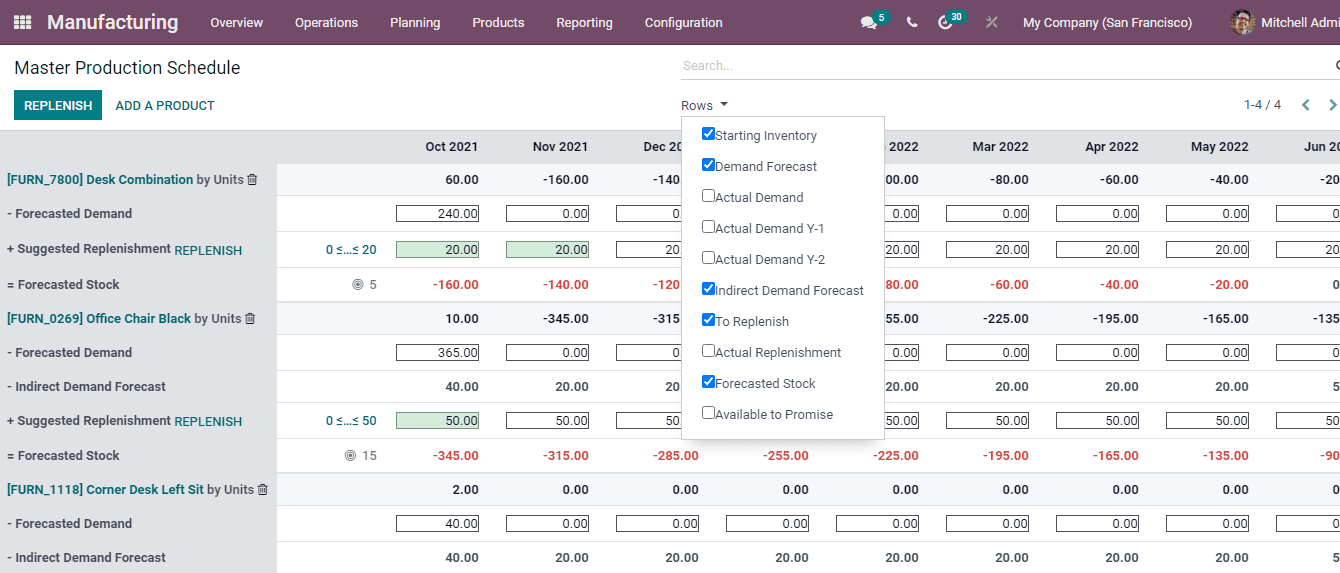

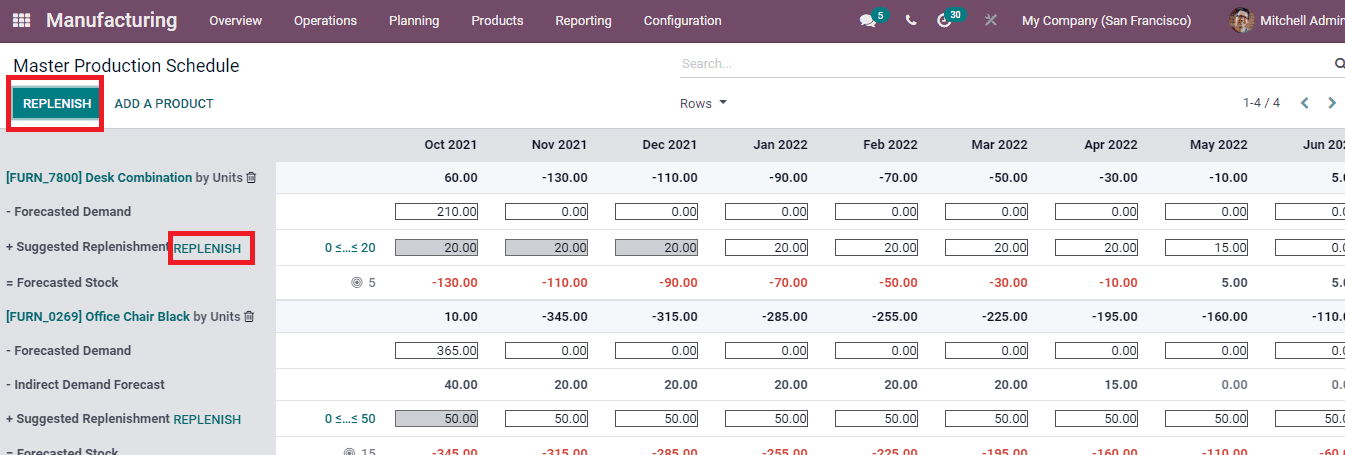

The above screenshot is what your master production schedule will look like. The details of the orders for every coming month (as you have selected Monthly as your Time Range) are displayed in the chart. By default you can view the details of the order’s Forecasted Demands, Suggested Replenishment, Indirect Demand Forecast and Forecasted Stock. You can add more rows such as the Actual Demand, Actual Demand Y-1, Actual Demand Y-2, Actual Replenishment and Available to Promise.

The Forecasted Demand value will have to be entered manually. The Suggested Replenishment shows the quantity to be replenished through purchase orders or manufacturing orders. The quantity in the stock that has been forecasted for the end of the period is displayed at the Forecasted Stock. Actual Demand indicates the confirmed sales of the product. The Indirect demand Forecast reveals the forecasted demand to fulfil the needs in components of the manufacturing orders.

By evaluating the chart you will get a clear picture of the required quantity of each order. You can select the products from the rows and view their in depth details.

In Odoo 15 you can replenish the product if after comparison replenishment is suggested. By selecting the REPLENISH button situated under the product the replenishment will be recorded. Also you can select the REPLENISH button situated at the top of the page for replenishing all the listed products. The replenishment quantity can be edited and changed also. If you want the system generated replenishment quantity back, then select the X option placed next to it. The grey colour of the replenishment column depicts that the particular item has been replenished. By selecting the replenish button, Odoo automatically creates a request for quotation (RFQ) or manufacturing order in order to meet the demand.

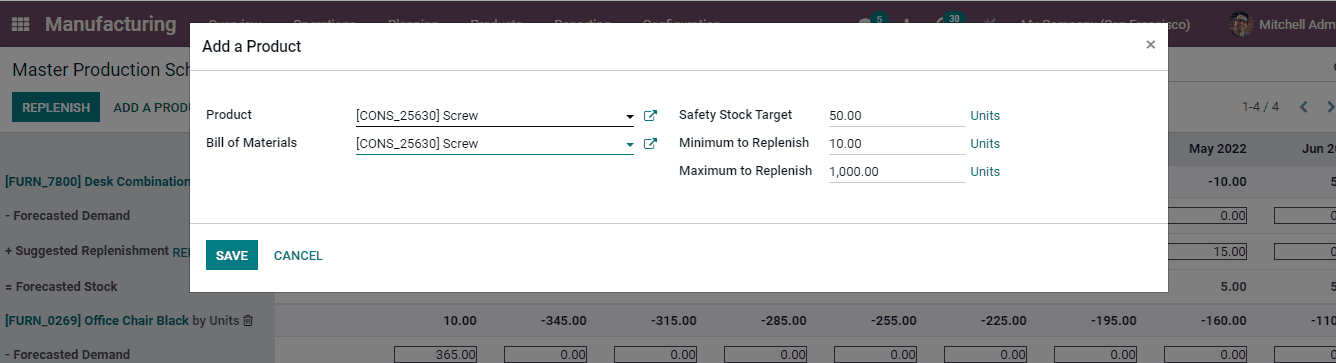

New products can be added to the chart by selecting the ADD A PRODUCT button. At the Add a Product pop up window, enter the details of the product that you are adding. These details include, name of the Product from the drop down menu, the product’s Bill of Material, Safety Stock Target, Minimum to Replenish and Maximum to Replenish quantities. The Safety Stock Target indicates the quantity of the extra products that will be kept in the inventory for the purpose of not running out of stock. After entering the details you can select the SAVE button. The added product will be shown in the master production schedule chart and you can directly replenish as well as evaluate the forecast report.

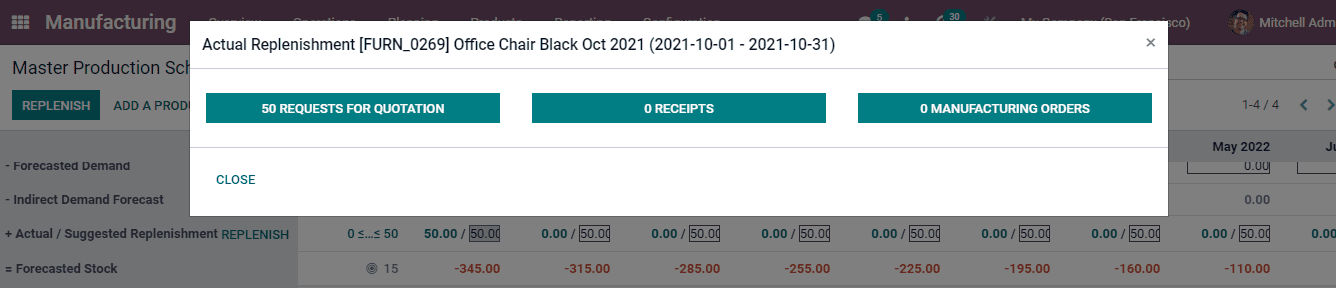

After making replenishment, you can enable Actual Replenishment from the Rows. In the chart, by selecting the actual replenishment quantity you can view the number of requests for quotation, number of receipts and number of manufacturing orders of the specific product.